Professional Documents

Culture Documents

Protocolo Mpreventivo Luminos Fusion - 20211126-150651651 - 00573124579179 - 480200094365

Protocolo Mpreventivo Luminos Fusion - 20211126-150651651 - 00573124579179 - 480200094365

Uploaded by

Stephanie CruzCopyright:

Available Formats

You might also like

- Quality Control (QC) Manual: Planmed Nuance & Nuance Excel FFDM SystemsDocument132 pagesQuality Control (QC) Manual: Planmed Nuance & Nuance Excel FFDM SystemsRoshi_11No ratings yet

- MW512 GW512 MW612 GW612 GW712 MWC12 GWC12 GWM12 GWL12 Service Manual PDFDocument62 pagesMW512 GW512 MW612 GW612 GW712 MWC12 GWC12 GWM12 GWL12 Service Manual PDFpowersonicNo ratings yet

- Spek HelianthusDocument12 pagesSpek HelianthusMeachel MartiosoNo ratings yet

- CANIS5A Operation ManualDocument14 pagesCANIS5A Operation Manualdaniel muñozNo ratings yet

- GE Healthcare Aespire 7900 SmartVent BrochureDocument6 pagesGE Healthcare Aespire 7900 SmartVent BrochureVladimir OsunaNo ratings yet

- CG Data Management SystemDocument2 pagesCG Data Management SystemKhwaja MaqsoodNo ratings yet

- Document Information For:: 5339157TST 5339157TSTDocument19 pagesDocument Information For:: 5339157TST 5339157TSTMkrtich AltunyanNo ratings yet

- Opti Vantage Dual-Head Contrast Delivery System V-5 and AboveDocument2 pagesOpti Vantage Dual-Head Contrast Delivery System V-5 and AboveMuratOguz UcakNo ratings yet

- Proven Track Record and Advanced Image Resolution: X-Ray Tubes For CT SystemsDocument2 pagesProven Track Record and Advanced Image Resolution: X-Ray Tubes For CT SystemsIan Bruno Rodriguez CenturionNo ratings yet

- L23 Interaction Between AC-DC SystemsDocument55 pagesL23 Interaction Between AC-DC Systemssin_laugh100% (9)

- Assembly, Installation, Adjustment & Testing (AIAT) PrerequisitesDocument4 pagesAssembly, Installation, Adjustment & Testing (AIAT) PrerequisitesJames Giancola100% (1)

- GEHC DICOM Conformance - BrivoOEC715 785 865 VWKS1 XX - DOC1188156 - Rev3Document123 pagesGEHC DICOM Conformance - BrivoOEC715 785 865 VWKS1 XX - DOC1188156 - Rev3sec.ivbNo ratings yet

- Monoblock E-40R-XR05Document9 pagesMonoblock E-40R-XR05wellsuNo ratings yet

- 03-V1-ECLOS 16 Daily Check ROI Instruction Manual (US)Document26 pages03-V1-ECLOS 16 Daily Check ROI Instruction Manual (US)José Manuel Valdez RevillaNo ratings yet

- Installation Procedure - CR 30-X 2nd CR30-XmDocument101 pagesInstallation Procedure - CR 30-X 2nd CR30-XmIranildo BarbosaNo ratings yet

- System Manual BV Family R1.2 General IntroductionDocument31 pagesSystem Manual BV Family R1.2 General IntroductionRSX SNo ratings yet

- RefrigeranteDocument7 pagesRefrigeranteDiasarmaNo ratings yet

- TH EN VisionVario 28299 28263 01 08 2015Document198 pagesTH EN VisionVario 28299 28263 01 08 2015mukaNo ratings yet

- MedRad Service Manual Mark V PDFDocument242 pagesMedRad Service Manual Mark V PDFAnthony T. BennaNo ratings yet

- MAN-01057 Rev 001 PanelCert User ManualDocument14 pagesMAN-01057 Rev 001 PanelCert User Manualwilton alves da silvaNo ratings yet

- Texas Microsystems P5200HX 512 Datasheet 201526125556Document4 pagesTexas Microsystems P5200HX 512 Datasheet 201526125556uzairNo ratings yet

- PLX5100 - 2020Document1 pagePLX5100 - 2020Jorge GranadosNo ratings yet

- Omega Air-Rdp - en - 950376 - 06-2020 - A4Document8 pagesOmega Air-Rdp - en - 950376 - 06-2020 - A4Taufan JustvandsNo ratings yet

- Elara MaxDocument11 pagesElara MaxErhan DersNo ratings yet

- CT BR Aquilion One PrismDocument26 pagesCT BR Aquilion One PrismXi WangNo ratings yet

- Planning GuideDocument47 pagesPlanning GuideGon LizaNo ratings yet

- Artromot K3 Knee CPM Service Manual SN Over 10000 PDFDocument17 pagesArtromot K3 Knee CPM Service Manual SN Over 10000 PDFمركز ريلاكس للعلاج الطبيعيNo ratings yet

- Aquilion PC Parts ListDocument348 pagesAquilion PC Parts ListvitapabloNo ratings yet

- Parker-Hannifin Spindleblok Troubleshooting Guide: Philips P/N Parker P/N Motor HP Stator Application Parker FirmwareDocument1 pageParker-Hannifin Spindleblok Troubleshooting Guide: Philips P/N Parker P/N Motor HP Stator Application Parker FirmwareAndreyNo ratings yet

- ISERV For Revolution ACT SM DOC2056202 2Document25 pagesISERV For Revolution ACT SM DOC2056202 2gyannkNo ratings yet

- Senographe 2000 DDocument174 pagesSenographe 2000 DReneNo ratings yet

- O-D4000dr C Ser en V4.1Document152 pagesO-D4000dr C Ser en V4.1Petko EnchevNo ratings yet

- Spesifikasi Mammomat RevelationDocument2 pagesSpesifikasi Mammomat RevelationMfkNo ratings yet

- Polimobil PlusDocument8 pagesPolimobil Plusrossi100% (1)

- Manual S50 Elite Basic User ManualDocument178 pagesManual S50 Elite Basic User ManualSoporte Centro Radiologico Plaza Baquedano S.p.ANo ratings yet

- PR Shimadzu Opescope Acteno PDFDocument3 pagesPR Shimadzu Opescope Acteno PDFYouness Ben TibariNo ratings yet

- Operating Manual Ergometrics ER 900 (English) PDFDocument84 pagesOperating Manual Ergometrics ER 900 (English) PDFmiryangelNo ratings yet

- Philips 190s8 - 190v8Document71 pagesPhilips 190s8 - 190v8Marek ZettíkNo ratings yet

- No. 2D621-230E D: 0 Toshiba Medical Manufacturing CO., LTD. 2003-2008 All Rights ReservedDocument88 pagesNo. 2D621-230E D: 0 Toshiba Medical Manufacturing CO., LTD. 2003-2008 All Rights ReservedAriangel Maso100% (1)

- API User Manual-V4.8.0Document120 pagesAPI User Manual-V4.8.0Girish SNo ratings yet

- Gehc SP - Brivo XR385 - 1 146FDocument9 pagesGehc SP - Brivo XR385 - 1 146FRodrigo Botelho de LimaNo ratings yet

- CT 2014aDocument352 pagesCT 2014aCristiGabrielFocsaNo ratings yet

- MTHELI-U01-CB Cap1Document21 pagesMTHELI-U01-CB Cap1blaisejeanNo ratings yet

- Rws Service PDFDocument288 pagesRws Service PDFbruce huNo ratings yet

- 1.1. Firecr Calibration: ArningDocument11 pages1.1. Firecr Calibration: ArningAndresNo ratings yet

- Prospeed Error 117 XG FailDocument12 pagesProspeed Error 117 XG FailvitapabloNo ratings yet

- Ealth ARE: Service Manual SE Suite 2.0Document400 pagesEalth ARE: Service Manual SE Suite 2.0Svilen PopovNo ratings yet

- 02-1529 - U - Bucky ManualDocument39 pages02-1529 - U - Bucky ManualJosabeth galicia de jesusNo ratings yet

- Brochure Mammomat InspirationDocument8 pagesBrochure Mammomat InspirationJenny LayunwiraNo ratings yet

- Cifrovaya Mobiljnaya Sduga GE OEC Fluorostar GE HealthcareDocument6 pagesCifrovaya Mobiljnaya Sduga GE OEC Fluorostar GE HealthcareНиколай ШереметьевNo ratings yet

- Operation Manual APO100M A1-2018.3.27Document36 pagesOperation Manual APO100M A1-2018.3.27Gabriela GheorgheNo ratings yet

- Siremobil Compact L Troubleshooting GuideDocument273 pagesSiremobil Compact L Troubleshooting GuideRuben Dario Vazquez VeraNo ratings yet

- Italray Digital-MammographDocument17 pagesItalray Digital-MammographBrahim lahmaid100% (1)

- Siemens ManualDocument10 pagesSiemens ManualFrancisco AvilaNo ratings yet

- Tda Optima 01Document12 pagesTda Optima 01vincenzoNo ratings yet

- ENG - 6984924503 - Rev2 (Service Manual)Document440 pagesENG - 6984924503 - Rev2 (Service Manual)l.n.a.92100% (1)

- Function Description SoftwareDocument96 pagesFunction Description Softwareaytek ertuncNo ratings yet

- S9 Series Service ManualDocument122 pagesS9 Series Service ManualRadovan JakovljevicNo ratings yet

- 04-V1 (Q1E-BW1311) - ECLOS Daily QC Phantom Instruction Manual (Japan)Document31 pages04-V1 (Q1E-BW1311) - ECLOS Daily QC Phantom Instruction Manual (Japan)José Manuel Valdez RevillaNo ratings yet

- 00-441128-02 - IPC1000 BIOS Setup - IBT - MB885 - 091203Document29 pages00-441128-02 - IPC1000 BIOS Setup - IBT - MB885 - 091203Badr QubatiNo ratings yet

- Maintenance Protocol Siemens Iconos R200Document21 pagesMaintenance Protocol Siemens Iconos R200cankutayhotmail.comNo ratings yet

- Dcim-B02 832 01 07 02Document12 pagesDcim-B02 832 01 07 02ОлександрNo ratings yet

- RT - SCADA - FY2019 - v5Document18 pagesRT - SCADA - FY2019 - v5Mas Ahmad Safwan Masbah100% (1)

- Phy HHW Xii BDocument6 pagesPhy HHW Xii BSubhendu KumarNo ratings yet

- Application Note CORR-4 PDFDocument15 pagesApplication Note CORR-4 PDFaneesh19inNo ratings yet

- Verifiarea - Motoarelor - Electrice - IP-11 - v25Document6 pagesVerifiarea - Motoarelor - Electrice - IP-11 - v25AlinaIordacheNo ratings yet

- FlowCAD App NoteDocument10 pagesFlowCAD App NotePavan KumarNo ratings yet

- Lecture #1 Resistance - The Property of A Material Tending To Prevent The Flow of ElectronsDocument3 pagesLecture #1 Resistance - The Property of A Material Tending To Prevent The Flow of ElectronsBolocon, Harvey Jon DelfinNo ratings yet

- 100-Watt + 100-Watt Dual BTL Class-D Audio Amplifier: FeaturesDocument22 pages100-Watt + 100-Watt Dual BTL Class-D Audio Amplifier: FeaturesAli NaderolasliNo ratings yet

- ASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignDocument38 pagesASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignNguyễn Hữu TàiNo ratings yet

- Substation Name Location Relay Model Number Relay Serial NumberDocument8 pagesSubstation Name Location Relay Model Number Relay Serial NumberAssistant executive engineerNo ratings yet

- Guidelines For PCB Layout DesignDocument5 pagesGuidelines For PCB Layout DesigncooksandNo ratings yet

- TKR 720 NDocument116 pagesTKR 720 NJose Gregorio GomezNo ratings yet

- AME Lab ManualDocument68 pagesAME Lab ManualNagaraju DevajjiNo ratings yet

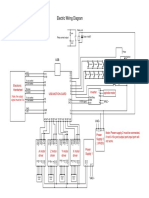

- Electric Wiring DiagramDocument1 pageElectric Wiring DiagramaliNo ratings yet

- LG 43UJ6200 Chassis UA71PDocument62 pagesLG 43UJ6200 Chassis UA71PMIGUEL FRANCONo ratings yet

- Interpret Drawing and Symbols FactsheetDocument7 pagesInterpret Drawing and Symbols FactsheetnoyNo ratings yet

- Data SheetDocument4 pagesData SheetLeonardoNo ratings yet

- Technical Program Schedule PDFDocument39 pagesTechnical Program Schedule PDFSoumitra MehrotraNo ratings yet

- Homework Solutions 4Document4 pagesHomework Solutions 4Minh HoangNo ratings yet

- 577-Leakage Current and Flashover Onset With Various Conductivities-577 Paper 1Document7 pages577-Leakage Current and Flashover Onset With Various Conductivities-577 Paper 1chandraippa2No ratings yet

- Usb 3100Document2 pagesUsb 3100terenceNo ratings yet

- Instruction - Resistance Heating Element ProjectDocument6 pagesInstruction - Resistance Heating Element Projectarg0nautNo ratings yet

- 34-Samss-718 (12-02-2015)Document14 pages34-Samss-718 (12-02-2015)Mubin100% (1)

- Plasma DrillingDocument31 pagesPlasma DrillingSaurav SenguptaNo ratings yet

- Different Types of Transducers - Characteristics, Classification, Applications PDFDocument18 pagesDifferent Types of Transducers - Characteristics, Classification, Applications PDFAAKASHNo ratings yet

- The 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsDocument45 pagesThe 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsFrancisco EstrellaNo ratings yet

- Power Distribution System Master Plan Study For GhanaDocument82 pagesPower Distribution System Master Plan Study For Ghanabudi hermawanNo ratings yet

- 2020 Full Exam SolutionDocument6 pages2020 Full Exam SolutionAhmed AliNo ratings yet

- Gamatronic - Modular UPS SystemsDocument5 pagesGamatronic - Modular UPS SystemsFELIXDEJNo ratings yet

Protocolo Mpreventivo Luminos Fusion - 20211126-150651651 - 00573124579179 - 480200094365

Protocolo Mpreventivo Luminos Fusion - 20211126-150651651 - 00573124579179 - 480200094365

Uploaded by

Stephanie CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protocolo Mpreventivo Luminos Fusion - 20211126-150651651 - 00573124579179 - 480200094365

Protocolo Mpreventivo Luminos Fusion - 20211126-150651651 - 00573124579179 - 480200094365

Uploaded by

Stephanie CruzCopyright:

Available Formats

Luminos Fusion

Maintenance Protocol

System

For Luminos Fusion

Customer: IMEX - SANTA MARIA DEL LAGO

Clínica infantil Colsanitas

Address: IMAGING EXPERTS AND HEALTHCARE

Fax / E-Mail:

Fax / E-Mail:

Department: Radiología Room:

Material-No.: Serial-No.: 31274

Contract-No.: Expire date:

Order-No.: 480200094365 System - ID:

The instructions XPD3-380.831.20.06.XX are required for this protocol

2 Protocol Date: 26/11/2021 Serial-No.: 31274

Evaluating the Condition of the System

The system has no deficiencies. * ✔

The system has slight deficiencies that have no effect on contin‐

ued operation of the system. The deficiencies should be corrected

preventively. *

The system has serious deficiencies. For safety reasons, continued

operation of the system is permitted only after successfully cor‐

recting the deficiencies.

*) For imaging systems: The result of the image quality check shows no deviation from

the reference values.

The evaluation was performed after completing all work steps.

Signature:

Date: 26/11/2021 Name: Julio Camacho

If required by country-specific regulations:

The customer or a representative has taken note of the result of the evaluation of the

system condition.

Signature:

Date: Name:

Remarks:

Número disparos tubo 1: S: 43207 L: 16298

Número disparos tubo 2: S: 240 L: 1

Pendiente cambio de potenciómetros referente a la mesa,

ya que se bloquea intermitentemente.

Luminos Fusion XPD3-380.832.20.06.02 Page 2 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 3

Remarks Regarding the Protocol

The chapter numbers refer to the chapters in the instruction, which is referenced on the

cover page.

All pages have to have the serial number of the system and the date of maintenance in

the page header.

The abbreviation n.a. (not applicable) indicates that the test item or measured value does

not apply to this system.

On page 2 the completeness and the results of the maintenance work is confirmed.

Explanation of Abbreviations in the Protocol

Abbrev. Explanation Abbrev. Explanation

SI Safety Inspection PMF Preventive Maintenance, Operating

Value Check, Function Check

SIE Electrical Safety Inspection Q System Quality, Image Quality

SIM Mechanical Safety Inspec‐ QIQ Image Quality

tion

PM Preventive Maintenance QSQ System Quality Check

PMP Periodic Preventive Mainte‐ SW Software Maintenance

nance

PMA Preventive Maintenance Ad‐ CSE Customer Service Engineer

justments

© Siemens, 2013 XPD3-380.832.20.06.02 Page 3 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

4 Protocol Date: 26/11/2021 Serial-No.: 31274

Measuring Equipment and Measuring Instruments Used

Measuring instruments and measuring devices (phantoms, MR coils, etc.) may not be en‐

tered in the table if they have already been entered in the mobile device.

Measuring equipment / -instruments Serial No. Date used

Multímetro 179 37290538 26/11/21

Luminos Fusion XPD3-380.832.20.06.02 Page 4 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 5

OK not n.a.

OK

2 General Visual Check

2.1 Visual Check per IEC 62353

SI Checking the cover panels ✔

SI Required operator documents present ✔

SI Checking the Cables, Corrugated Hoses ✔

SI Check the cable corrugated hoses (of mobile components). ✔

SI Checking the radiation protective panels ✔

SI Checking warning labels ✔

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

3 Cleaning the Components

PM Inspection of internal heat dissipation ✔

PM Cleaning ✔

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

4 Polydoros

4.2 Inspection and Maintenance

4.2.1 General Information

4.2.2 Checking the external Connections

SI Checking the external Voltage ✔

4.2.3 Checking the High Voltage Cables

SI Check the shielding on the HV cables. ✔

4.2.4 Radiation Displays

SI Check the radiation displays. ✔

© Siemens, 2013 XPD3-380.832.20.06.02 Page 5 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

6 Protocol Date: 26/11/2021 Serial-No.: 31274

OK not n.a.

OK

4.2.5 Performing Tube adjustment, Conditioning the X-Ray Tube(s)

PMA Tube adjustment performed. ✔

Work steps in this section were performed by:

Signature:

Date: Name:

4.3 IQ indirect technique (not necessary when constancy test is performed)

Option present: Yes: No:

Signature:

Date: Name:

4.3.1 Dose Rate IQ Initial Values

4.3.2 Indirect Technique Dose Rate

QIQ Indirect Technique ✔

Work steps in this section were performed by:

Signature:

Date: Name:

4.4 IQ IONTOMAT fields (not necessary when constancy test is performed)

Option present: Yes: No:

Signature:

Date: Name:

PM Selecting and Checking the Sensitivity of the IONTOMAT ✔

Fields

Work steps in this section were performed by:

Signature:

Date: Name:

Luminos Fusion XPD3-380.832.20.06.02 Page 6 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 7

OK not n.a.

OK

5 Luminos Fusion

5.2 Inspection and Maintenance

5.2.1 Check for Collision Damage on Units with the Tilting Base

SIM Check of the Basic Unit for Damage ✔

5.2.2 Unit Base (Tilting Base)

PM Evaluating the error log ✔

SIMCheck the cables and corrugated hoses ✔

SIMCheck of the tilt Chain and cover Band and Lubrication ✔

SIMCheck the chain segment and tilt drive ✔

SIMChecking the floor mounting ✔

SIECheck the spacing of the limit switches and the potentiome‐ ✔

ter play.

5.2.3 Unit carrier

SIM Checking installation of the linear guide ✔

SI Check the gear shaft for any cracks. ✔

PMP Cleaning and Lubricating the Unit Support ✔

5.2.4 Tabletop

PMP

Clean and lubricate the tabletop, longitudinally and trans‐ ✔

versely

5.2.5 Tabletop with Aluminum Profile Rails

SI Deburr the tabletop ✔

PM Roll Pins/Threaded Inserts in the Profile Rail ✔

5.2.6 Column Longitudinal Drive

PMP Clean and lubricate the column longitudinal drive. ✔

SIM Tilt Drive - Checking the Safety Distances ✔

SI Spotfilm Device and Column Longitudinal Drive - Checking ✔

the Safety Distances

SI Tabletop Longitudinal - Checking the Safety Distances ✔

PMP Tabletop Transverse - Function Test ✔

PMP SID - Function Test ✔

SI Option: Compression, Checking the Friction Wheel ✔

SI Option: Compression, Checking the Safety Distances ✔

5.2.7 Unit, General Operation

SI Electrical / Mechanical Function Test of the Safety Devices ✔

5.2.7.1 Footrest

SI Perform a mechanical function test of the safety devices. ✔

5.2.7.2 Options:

PM Checking the Unit Control Console for Function and Damage ✔

© Siemens, 2013 XPD3-380.832.20.06.02 Page 7 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

8 Protocol Date: 26/11/2021 Serial-No.: 31274

OK not n.a.

OK

PM Checking the Unit Tableside Control Console for Function ✔

and Damage

PM Check the fluoro and exposure footswitch for function and ✔

damage.

Work steps in this section were performed by:

Signature:

Date: Name:

6 Spotfilm Device

Option present: Yes: No: ✔

Signature:

Date: Name:

6.2 Inspection and Maintenance

6.2.1 Spotfilm Device (Cassette Technique)

SI Cover Panels on the Spotfilm Device

PMP Spotfilm Device Function Test

Work steps in this section were performed by:

Signature:

Date: Name:

7 Multileaf Collimator/Universal Collimator

Option present: Yes: No: ✔

Signature:

Date: Name:

Material No.:

Serial no.:

Luminos Fusion XPD3-380.832.20.06.02 Page 8 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 9

OK not n.a.

OK

7.2 Inspection and Maintenance

SIM Checking the collimator mounting

PM Checking the Rotation Flange (if configured)

PMF Checking the Control Elements on the Collimator (if config‐

ured)

SIM Accessory rails under the collimator checked for wear.

PM Checking the Light Localizer Lamp (if configured)

Work steps in this section were performed by:

Signature:

Date: Name:

7 Multileaf Collimator/Universal Collimator

Option present: Yes: ✔ No:

Signature:

Date: Name:

Material No.:

Serial no.:

7.2 Inspection and Maintenance

SIM Checking the collimator mounting ✔

PM Checking the Rotation Flange (if configured) ✔

PMF Checking the Control Elements on the Collimator (if config‐ ✔

ured)

SIM Accessory rails under the collimator checked for wear. ✔

PM Checking the Light Localizer Lamp (if configured) ✔

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

© Siemens, 2013 XPD3-380.832.20.06.02 Page 9 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

10 Protocol Date: 26/11/2021 Serial-No.: 31274

OK not n.a.

OK

8 Monitor Carriage

Option present: Yes: ✔ No:

Signature:

Date: Name:

8.2 Inspection and Maintenance

SIM Checking the mounting of the monitors ✔

Work steps in this section were performed by:

Signature:

Date: Name:

9 DCS-F

Option present: Yes: No: ✔

Signature:

Date: Name:

9.2 Inspection and Maintenance

PMA Weight Compensation

PM Cover Panels

SI Stand, Display Support

PM Ceiling rails

SIM Ceiling Rail Mounting

SIM Carriage, Roller Bearings, Stops, Brakes

SIM Support Arm and Articulated Head

SIM Display Mount and Rotation

SIM Cables

SIM Displays

SIM Brakes

PM Cleaning

PM Electrical Connections

PM Cover Panels

Luminos Fusion XPD3-380.832.20.06.02 Page 10 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 11

OK not n.a.

OK

PMF Stand Movements

Work steps in this section were performed by:

Signature:

Date: Name:

10 Support Arm System (Radiation Shield, Injector Head...)

Option present: Yes: No: ✔

Signature:

Date: Name:

10.2 Safety Inspection

SIM Check the mounting screws of the ceiling rails

PMP Mechanical Inspection

SI Check that the collision labels are legible

10.3 Cleaning

QSQ Clean the contact surface of the ceiling rails

Work steps in this section were performed by:

Signature:

Date: Name:

11 VERTIX PRO/TOP

Option present: Yes: No: ✔

Signature:

Date: Name:

11.2 Inspection and Maintenance

SIM Floor and Wall Mounting

SIM Support cable for vertical carriage

© Siemens, 2013 XPD3-380.832.20.06.02 Page 11 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

12 Protocol Date: 26/11/2021 Serial-No.: 31274

OK not n.a.

OK

SIM Steel support cable replaced (required every 3 years)

Startup Date: . .

Date of Last Replacement DD MMM YYYY

SIM VERTIX TOP support and safety cable, tilt mechanism

SIM Brakes and Stops

SIM Cover Panels and Accessories

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

12 Wall Stand

Option present: Yes: ✔ No:

Signature:

Date: 26/11/2021 Name: Julio Camacho

12.2 Inspection and Maintenance

PMP Cover Panels and Accessories ✔

SIM Wall Stand Mounting ✔

PMP Check and clean the contact surfaces. ✔

SIE Checking the Chain Break Switch ✔

PMF Checking the Movement Range ✔

PMF Checking the Chain ✔

PMF Checking the Braking Force ✔

PMF Checking the Control Elements ✔

PMF Checking the Springs and the Chain in the Pivot Unit ✔

PMP Check of the Cassette Bucky ✔

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

Luminos Fusion XPD3-380.832.20.06.02 Page 12 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 13

OK not n.a.

OK

13 3D V Ceiling Stand

Option present: Yes: ✔ No:

Signature:

Date: 26/11/2021 Name: Julio Camacho

13.3 Inspection and Maintenance

13.3.1 Cleaning

PM Cleaning the Handgrips ✔

13.3.2 Cables and flexible, corrugated hoses

SI Checking the Cables, flexible, corrugated Hoses ✔

13.3.3 Longitudinal Rails and Transverse Track

PM Cleaning ✔

SIM Check the condition of the longitudinal rails, mounting ✔

screws and toothed belts.

PMP In addition, with the semi-automatic ceiling stand: stop de‐ ✔

tents and brake assembly in the longitudinal rail

PMP In addition, with the semi-automatic ceiling stand: Stop de‐ ✔

tents in the transverse track

SIM In addition, with the semi-automatic ceiling stand: Check ✔

the pivot arm on the corrugated hose holder.

SIM Check the condition of the transverse track and toothed ✔

belts.

SIM Flexible plastic chain plate, check the condition and installa‐ ✔

tion

SIM Check whether the dowel pins are installed correctly. ✔

SIM In the telescope carriage, check the position of the roller in ✔

the rail, and make sure the roller is properly secured.

SIM In the transverse carriage, check the position of the roller in ✔

the rail, and make sure the roller is properly secured.

SIM Checking the telescope carriage rollers in the rails ✔

SIM Checking the transverse carriage rollers in the rails ✔

SIM Check the screw torque. ✔

13.3.4 Telescope carriage

SIM Check the roller bearings on the telescope carriage for se‐ ✔

cure installation.

PMP Only with the semi-automatic ceiling stand: Check the brake ✔

assembly.

PMF Checking the Function of Lift Motor with Lift Brake. ✔

PMF Gas springs ✔

© Siemens, 2013 XPD3-380.832.20.06.02 Page 13 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

14 Protocol Date: 26/11/2021 Serial-No.: 31274

OK not n.a.

OK

SIM Weight compensation (spring-loaded mechanism) replaced ✔

(required every 8 years)

Startup Date: . .

Date of Last Replacement DD MMM YYYY

SIM Checking the Weight Compensation (spring-loaded mecha‐ ✔

nism)

SIM Check of the Safety Cable Length, only if no Gondola is in‐ ✔

stalled.

SIM Function Check of the Safety Switch (only if a safety ✔

switches are installed)

SIM Checking the plastic-coated Support and Safety Cables ✔

SIM Check of the Cable Break Safety Mechanism ✔

13.3.5 Support Arm

PMA Only with the fully automatic ceiling stand: Check the rota‐ ✔

tion movements of the support arm.

PMA Only with the semi-automatic ceiling stand: Rotation around ✔

the horizontal and vertical axis

SIM Mounting on the telescope ✔

PMP Check the movement and braking forces ✔

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

14 Fluoro Detector

14.2 Inspection and Maintenance

QIQ Calibration performed ✔

Startup Date: . .

Date of Last Procedure: DD MMM YYYY

Work steps in this section were performed by:

Signature:

Date: Name:

Luminos Fusion XPD3-380.832.20.06.02 Page 14 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 15

OK not n.a.

OK

15 Tomography

Option present: Yes: No: ✔

Signature:

Date: Name:

15.2 Inspection and Maintenance

15.2.1 Tomography Direct Technique

QIQ Checking the Tomo Device ✔

Work steps in this section were performed by:

Signature:

Date: Name:

16 Automatic format selection direct technique (not necessa‐

ry when constancy test is performed)

Option present: Yes: No: ✔

Signature:

Date: Name:

16.2 Inspection and Maintenance

16.2.2 Checking the Light Field - Radiation Field

QIQ Checking the Light Field - Radiation Field

16.2.3 Checking the Center of Radiation Field - Center of Film

QIQ Coincidence of the Center of Radiation Field - Center of Film

16.2.4 Checking the Cassette Format - Radiation Field Size (for ACSS Systems only)

QIQ Checking the Cassette Format - Radiation Field Size

© Siemens, 2013 XPD3-380.832.20.06.02 Page 15 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

16 Protocol Date: 26/11/2021 Serial-No.: 31274

OK not n.a.

OK

16.2.5 Checking the Radiation Field Size to the Displayed Field Size

QIQ Checking the Radiation Field Size to the Displayed Field Size

Work steps in this section were performed by:

Signature:

Date: Name:

17 UPS / APC Smart 1500 VA UPS

Option present: Yes: No: ✔

Signature:

Date: Name:

17.2 Inspection and Maintenance

17.2.1 Replacing the Batteries

PMP Battery replacement required with every maintenance call.

17.2.2 Room Emergency Off

PMP Room Emergency Off

Work steps in this section were performed by:

Signature:

Date: Name:

18 IQ Test

18.2 Perform an IQ Test

QIQ IQ test performed ✔

Work steps in this section were performed by:

Signature:

Date: Name:

Luminos Fusion XPD3-380.832.20.06.02 Page 16 of 18 © Siemens, 2013

08.17 HC SV CS SLM XP PDM

Protocol Date: 26/11/2021 Serial-No.: 31274 17

OK not n.a.

OK

19 Final Work Steps

19.2 Safety Check according to IEC 62353

19.2.1 Ground Wire Measurement

SIE Maximum ground wire resistance (in milli Ohm) ✔

value:

19.2.2 Phase to ground loop impedance measurement

SI Loop impedance in ohms ✔

value:

SI Contact voltage in volts ✔

value:

19.2.2.1 Alternative measurement for loop impedance.

SI Voltage phase 1 to the protective conductor in volts. ✔

value:

SI Voltage phase 2 to the protective conductor in volts. ✔

value:

SI Voltage phase 3 to the protective conductor in volts. ✔

value:

19.3 Function Test

SI Perform the final function check. ✔

Work steps in this section were performed by:

Signature:

Date: 26/11/2021 Name: Julio Camacho

© Siemens, 2013 XPD3-380.832.20.06.02 Page 17 of 18 Luminos Fusion

08.17 HC SV CS SLM XP PDM

All documents may only be used for

rendering services on Siemens

Healthcare Products. Any document

in electronic form may be printed

once. Copy and distribution of elec‐

tronic documents and hardcopies is

prohibited. Offenders will be liable

for damages. All other rights are re‐

served.

healthcare.siemens.com/services

Siemens Healthineers Headquarters

Siemens Healthcare GmbH

Henkestr. 127

91052 Erlangen

Germany

Telephone: +49 9131 84-0

siemens.com/healthineers

Print No.: XPD3-380.832.20.06.02 | Replaces: XPD3-380.832.20.05.02

Doc. Gen. Date: 08.17 | Language: English

© Siemens Healthcare GmbH, 2013

siemens.com/healthineers

You might also like

- Quality Control (QC) Manual: Planmed Nuance & Nuance Excel FFDM SystemsDocument132 pagesQuality Control (QC) Manual: Planmed Nuance & Nuance Excel FFDM SystemsRoshi_11No ratings yet

- MW512 GW512 MW612 GW612 GW712 MWC12 GWC12 GWM12 GWL12 Service Manual PDFDocument62 pagesMW512 GW512 MW612 GW612 GW712 MWC12 GWC12 GWM12 GWL12 Service Manual PDFpowersonicNo ratings yet

- Spek HelianthusDocument12 pagesSpek HelianthusMeachel MartiosoNo ratings yet

- CANIS5A Operation ManualDocument14 pagesCANIS5A Operation Manualdaniel muñozNo ratings yet

- GE Healthcare Aespire 7900 SmartVent BrochureDocument6 pagesGE Healthcare Aespire 7900 SmartVent BrochureVladimir OsunaNo ratings yet

- CG Data Management SystemDocument2 pagesCG Data Management SystemKhwaja MaqsoodNo ratings yet

- Document Information For:: 5339157TST 5339157TSTDocument19 pagesDocument Information For:: 5339157TST 5339157TSTMkrtich AltunyanNo ratings yet

- Opti Vantage Dual-Head Contrast Delivery System V-5 and AboveDocument2 pagesOpti Vantage Dual-Head Contrast Delivery System V-5 and AboveMuratOguz UcakNo ratings yet

- Proven Track Record and Advanced Image Resolution: X-Ray Tubes For CT SystemsDocument2 pagesProven Track Record and Advanced Image Resolution: X-Ray Tubes For CT SystemsIan Bruno Rodriguez CenturionNo ratings yet

- L23 Interaction Between AC-DC SystemsDocument55 pagesL23 Interaction Between AC-DC Systemssin_laugh100% (9)

- Assembly, Installation, Adjustment & Testing (AIAT) PrerequisitesDocument4 pagesAssembly, Installation, Adjustment & Testing (AIAT) PrerequisitesJames Giancola100% (1)

- GEHC DICOM Conformance - BrivoOEC715 785 865 VWKS1 XX - DOC1188156 - Rev3Document123 pagesGEHC DICOM Conformance - BrivoOEC715 785 865 VWKS1 XX - DOC1188156 - Rev3sec.ivbNo ratings yet

- Monoblock E-40R-XR05Document9 pagesMonoblock E-40R-XR05wellsuNo ratings yet

- 03-V1-ECLOS 16 Daily Check ROI Instruction Manual (US)Document26 pages03-V1-ECLOS 16 Daily Check ROI Instruction Manual (US)José Manuel Valdez RevillaNo ratings yet

- Installation Procedure - CR 30-X 2nd CR30-XmDocument101 pagesInstallation Procedure - CR 30-X 2nd CR30-XmIranildo BarbosaNo ratings yet

- System Manual BV Family R1.2 General IntroductionDocument31 pagesSystem Manual BV Family R1.2 General IntroductionRSX SNo ratings yet

- RefrigeranteDocument7 pagesRefrigeranteDiasarmaNo ratings yet

- TH EN VisionVario 28299 28263 01 08 2015Document198 pagesTH EN VisionVario 28299 28263 01 08 2015mukaNo ratings yet

- MedRad Service Manual Mark V PDFDocument242 pagesMedRad Service Manual Mark V PDFAnthony T. BennaNo ratings yet

- MAN-01057 Rev 001 PanelCert User ManualDocument14 pagesMAN-01057 Rev 001 PanelCert User Manualwilton alves da silvaNo ratings yet

- Texas Microsystems P5200HX 512 Datasheet 201526125556Document4 pagesTexas Microsystems P5200HX 512 Datasheet 201526125556uzairNo ratings yet

- PLX5100 - 2020Document1 pagePLX5100 - 2020Jorge GranadosNo ratings yet

- Omega Air-Rdp - en - 950376 - 06-2020 - A4Document8 pagesOmega Air-Rdp - en - 950376 - 06-2020 - A4Taufan JustvandsNo ratings yet

- Elara MaxDocument11 pagesElara MaxErhan DersNo ratings yet

- CT BR Aquilion One PrismDocument26 pagesCT BR Aquilion One PrismXi WangNo ratings yet

- Planning GuideDocument47 pagesPlanning GuideGon LizaNo ratings yet

- Artromot K3 Knee CPM Service Manual SN Over 10000 PDFDocument17 pagesArtromot K3 Knee CPM Service Manual SN Over 10000 PDFمركز ريلاكس للعلاج الطبيعيNo ratings yet

- Aquilion PC Parts ListDocument348 pagesAquilion PC Parts ListvitapabloNo ratings yet

- Parker-Hannifin Spindleblok Troubleshooting Guide: Philips P/N Parker P/N Motor HP Stator Application Parker FirmwareDocument1 pageParker-Hannifin Spindleblok Troubleshooting Guide: Philips P/N Parker P/N Motor HP Stator Application Parker FirmwareAndreyNo ratings yet

- ISERV For Revolution ACT SM DOC2056202 2Document25 pagesISERV For Revolution ACT SM DOC2056202 2gyannkNo ratings yet

- Senographe 2000 DDocument174 pagesSenographe 2000 DReneNo ratings yet

- O-D4000dr C Ser en V4.1Document152 pagesO-D4000dr C Ser en V4.1Petko EnchevNo ratings yet

- Spesifikasi Mammomat RevelationDocument2 pagesSpesifikasi Mammomat RevelationMfkNo ratings yet

- Polimobil PlusDocument8 pagesPolimobil Plusrossi100% (1)

- Manual S50 Elite Basic User ManualDocument178 pagesManual S50 Elite Basic User ManualSoporte Centro Radiologico Plaza Baquedano S.p.ANo ratings yet

- PR Shimadzu Opescope Acteno PDFDocument3 pagesPR Shimadzu Opescope Acteno PDFYouness Ben TibariNo ratings yet

- Operating Manual Ergometrics ER 900 (English) PDFDocument84 pagesOperating Manual Ergometrics ER 900 (English) PDFmiryangelNo ratings yet

- Philips 190s8 - 190v8Document71 pagesPhilips 190s8 - 190v8Marek ZettíkNo ratings yet

- No. 2D621-230E D: 0 Toshiba Medical Manufacturing CO., LTD. 2003-2008 All Rights ReservedDocument88 pagesNo. 2D621-230E D: 0 Toshiba Medical Manufacturing CO., LTD. 2003-2008 All Rights ReservedAriangel Maso100% (1)

- API User Manual-V4.8.0Document120 pagesAPI User Manual-V4.8.0Girish SNo ratings yet

- Gehc SP - Brivo XR385 - 1 146FDocument9 pagesGehc SP - Brivo XR385 - 1 146FRodrigo Botelho de LimaNo ratings yet

- CT 2014aDocument352 pagesCT 2014aCristiGabrielFocsaNo ratings yet

- MTHELI-U01-CB Cap1Document21 pagesMTHELI-U01-CB Cap1blaisejeanNo ratings yet

- Rws Service PDFDocument288 pagesRws Service PDFbruce huNo ratings yet

- 1.1. Firecr Calibration: ArningDocument11 pages1.1. Firecr Calibration: ArningAndresNo ratings yet

- Prospeed Error 117 XG FailDocument12 pagesProspeed Error 117 XG FailvitapabloNo ratings yet

- Ealth ARE: Service Manual SE Suite 2.0Document400 pagesEalth ARE: Service Manual SE Suite 2.0Svilen PopovNo ratings yet

- 02-1529 - U - Bucky ManualDocument39 pages02-1529 - U - Bucky ManualJosabeth galicia de jesusNo ratings yet

- Brochure Mammomat InspirationDocument8 pagesBrochure Mammomat InspirationJenny LayunwiraNo ratings yet

- Cifrovaya Mobiljnaya Sduga GE OEC Fluorostar GE HealthcareDocument6 pagesCifrovaya Mobiljnaya Sduga GE OEC Fluorostar GE HealthcareНиколай ШереметьевNo ratings yet

- Operation Manual APO100M A1-2018.3.27Document36 pagesOperation Manual APO100M A1-2018.3.27Gabriela GheorgheNo ratings yet

- Siremobil Compact L Troubleshooting GuideDocument273 pagesSiremobil Compact L Troubleshooting GuideRuben Dario Vazquez VeraNo ratings yet

- Italray Digital-MammographDocument17 pagesItalray Digital-MammographBrahim lahmaid100% (1)

- Siemens ManualDocument10 pagesSiemens ManualFrancisco AvilaNo ratings yet

- Tda Optima 01Document12 pagesTda Optima 01vincenzoNo ratings yet

- ENG - 6984924503 - Rev2 (Service Manual)Document440 pagesENG - 6984924503 - Rev2 (Service Manual)l.n.a.92100% (1)

- Function Description SoftwareDocument96 pagesFunction Description Softwareaytek ertuncNo ratings yet

- S9 Series Service ManualDocument122 pagesS9 Series Service ManualRadovan JakovljevicNo ratings yet

- 04-V1 (Q1E-BW1311) - ECLOS Daily QC Phantom Instruction Manual (Japan)Document31 pages04-V1 (Q1E-BW1311) - ECLOS Daily QC Phantom Instruction Manual (Japan)José Manuel Valdez RevillaNo ratings yet

- 00-441128-02 - IPC1000 BIOS Setup - IBT - MB885 - 091203Document29 pages00-441128-02 - IPC1000 BIOS Setup - IBT - MB885 - 091203Badr QubatiNo ratings yet

- Maintenance Protocol Siemens Iconos R200Document21 pagesMaintenance Protocol Siemens Iconos R200cankutayhotmail.comNo ratings yet

- Dcim-B02 832 01 07 02Document12 pagesDcim-B02 832 01 07 02ОлександрNo ratings yet

- RT - SCADA - FY2019 - v5Document18 pagesRT - SCADA - FY2019 - v5Mas Ahmad Safwan Masbah100% (1)

- Phy HHW Xii BDocument6 pagesPhy HHW Xii BSubhendu KumarNo ratings yet

- Application Note CORR-4 PDFDocument15 pagesApplication Note CORR-4 PDFaneesh19inNo ratings yet

- Verifiarea - Motoarelor - Electrice - IP-11 - v25Document6 pagesVerifiarea - Motoarelor - Electrice - IP-11 - v25AlinaIordacheNo ratings yet

- FlowCAD App NoteDocument10 pagesFlowCAD App NotePavan KumarNo ratings yet

- Lecture #1 Resistance - The Property of A Material Tending To Prevent The Flow of ElectronsDocument3 pagesLecture #1 Resistance - The Property of A Material Tending To Prevent The Flow of ElectronsBolocon, Harvey Jon DelfinNo ratings yet

- 100-Watt + 100-Watt Dual BTL Class-D Audio Amplifier: FeaturesDocument22 pages100-Watt + 100-Watt Dual BTL Class-D Audio Amplifier: FeaturesAli NaderolasliNo ratings yet

- ASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignDocument38 pagesASIL D Safety Concept-Assessed High-Speed Traction, Bi-Directional DC/DC Conversion Reference DesignNguyễn Hữu TàiNo ratings yet

- Substation Name Location Relay Model Number Relay Serial NumberDocument8 pagesSubstation Name Location Relay Model Number Relay Serial NumberAssistant executive engineerNo ratings yet

- Guidelines For PCB Layout DesignDocument5 pagesGuidelines For PCB Layout DesigncooksandNo ratings yet

- TKR 720 NDocument116 pagesTKR 720 NJose Gregorio GomezNo ratings yet

- AME Lab ManualDocument68 pagesAME Lab ManualNagaraju DevajjiNo ratings yet

- Electric Wiring DiagramDocument1 pageElectric Wiring DiagramaliNo ratings yet

- LG 43UJ6200 Chassis UA71PDocument62 pagesLG 43UJ6200 Chassis UA71PMIGUEL FRANCONo ratings yet

- Interpret Drawing and Symbols FactsheetDocument7 pagesInterpret Drawing and Symbols FactsheetnoyNo ratings yet

- Data SheetDocument4 pagesData SheetLeonardoNo ratings yet

- Technical Program Schedule PDFDocument39 pagesTechnical Program Schedule PDFSoumitra MehrotraNo ratings yet

- Homework Solutions 4Document4 pagesHomework Solutions 4Minh HoangNo ratings yet

- 577-Leakage Current and Flashover Onset With Various Conductivities-577 Paper 1Document7 pages577-Leakage Current and Flashover Onset With Various Conductivities-577 Paper 1chandraippa2No ratings yet

- Usb 3100Document2 pagesUsb 3100terenceNo ratings yet

- Instruction - Resistance Heating Element ProjectDocument6 pagesInstruction - Resistance Heating Element Projectarg0nautNo ratings yet

- 34-Samss-718 (12-02-2015)Document14 pages34-Samss-718 (12-02-2015)Mubin100% (1)

- Plasma DrillingDocument31 pagesPlasma DrillingSaurav SenguptaNo ratings yet

- Different Types of Transducers - Characteristics, Classification, Applications PDFDocument18 pagesDifferent Types of Transducers - Characteristics, Classification, Applications PDFAAKASHNo ratings yet

- The 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsDocument45 pagesThe 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsFrancisco EstrellaNo ratings yet

- Power Distribution System Master Plan Study For GhanaDocument82 pagesPower Distribution System Master Plan Study For Ghanabudi hermawanNo ratings yet

- 2020 Full Exam SolutionDocument6 pages2020 Full Exam SolutionAhmed AliNo ratings yet

- Gamatronic - Modular UPS SystemsDocument5 pagesGamatronic - Modular UPS SystemsFELIXDEJNo ratings yet