Professional Documents

Culture Documents

10MM - 60.960 Ton

10MM - 60.960 Ton

Uploaded by

RAJKUMAR CHATTERJEE. (RAJA.)Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10MM - 60.960 Ton

10MM - 60.960 Ton

Uploaded by

RAJKUMAR CHATTERJEE. (RAJA.)Copyright:

Available Formats

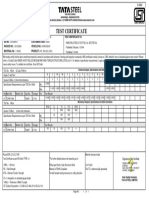

IS 1786

STEEL AUTHORITY OF INDIA LIMITED

IISCO STEEL PLANT

BURNPUR - 713325, WEST BENGAL, INDIA

(Registered Office: Ispat Bhawan, Lodi Road, New Delhi - 110003) CM/L-0183135

TEST CERTIFICATE FOR HIGH STRENGTH DEFORMED STEEL BARS AND WIRES FOR CONCRETE REINFORCEMENT

TEST CERTIFICATE NO. : TC_8000101453 TC DATE : 27.11.2021 Page No. : 1 of 4

SHIPPING ADVICE NO. : 8000101453 SHIPPING DATE : 27.11.2021

CONSIGNEE NAME & ADDRESS : JAGDISH RAI CHAMAN LAL WAGON/TRAILER NO. : ECOR21120957241

PLOT NO.3,FLORA INTERNATIONAL, PANIPAT-132103, HARYANA

It is certified that the material described below fully conforms to IS 1786 : 2008. Chemical composition and Mechanical properties of the product, as tested in accordance with the

Scheme of Inspection and Testing contained in the BIS Certification Marks Licence No. CM/L-0183135 are as indicated below against each Order/Cast No.

(Please refer to IS 1786 : 2008 for details of specification requirements)

TEST RESULTS

Order / MP No. & Date : 1500107652 (11.11.2021) Total weight : 60.960 MT

Material : TMT BAR Nominal Size : 10 mm, Length : 12m

Grade and Quality : IS 1786 : 2008 Fe 500D Brand Name : SAIL SeQR

CAST NO QTY Chemical composition

(MT) C% Mn% S% P% S+P% Si% Al% Cu% Cr% Cu+Cr% Nb% V% Ti% B% Nb+V+ Mo% N2 CE%

Ti+B% (ppm)

Specification Min - - - - - - - - - - -

Max 0.25 - 0.040 0.040 0.075 - - - - 0.30 0.50

12112845 3.354 0.21 0.81 0.024 0.026 0.050 0.25 NS 0.01 0.01 0.02 NS NS NS NS Tr NS NS 0.35

Cast No. Mechanical Properties

YS ( N/mm2) min YS ( N/mm2) max Tensile Strength TS/YS ratio Elongation % (Std GL) Total elongation at Bend Test Rebend Test

N/mm2 maximum force %

Specification 500 min 565 min 1.10 min 16.0 min 3d min 4d min

12112845 566 575 668 1.18 19.1 NS OK OK

Surface Defects (Piping / Other Defects): Absent

The material supplied conforms to the standard rolling and mass tolerance. Process Route : BF-BOF-LF-CC-Bar Mill

Remarks: Chemical Composition reported is Ladle Analysis. AUTHORISED SIGNATORY

Legend (where applicable) : NS/- = Not Specified; Tr = Traces; YS = Yield Strength;

TS = Tensile Strength; Std GL = Standard Gauge Length

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

IS 1786

STEEL AUTHORITY OF INDIA LIMITED

IISCO STEEL PLANT

BURNPUR - 713325, WEST BENGAL, INDIA

(Registered Office: Ispat Bhawan, Lodi Road, New Delhi - 110003) CM/L-0183135

TEST CERTIFICATE FOR HIGH STRENGTH DEFORMED STEEL BARS AND WIRES FOR CONCRETE REINFORCEMENT

TEST CERTIFICATE NO. : TC_8000101453 TC DATE : 27.11.2021 Page No. : 2 of 4

SHIPPING ADVICE NO. : 8000101453 SHIPPING DATE : 27.11.2021

CONSIGNEE NAME & ADDRESS : JAGDISH RAI CHAMAN LAL WAGON/TRAILER NO. : ECOR21120957241

PLOT NO.3,FLORA INTERNATIONAL, PANIPAT-132103, HARYANA

It is certified that the material described below fully conforms to IS 1786 : 2008. Chemical composition and Mechanical properties of the product, as tested in accordance with the

Scheme of Inspection and Testing contained in the BIS Certification Marks Licence No. CM/L-0183135 are as indicated below against each Order/Cast No.

(Please refer to IS 1786 : 2008 for details of specification requirements)

TEST RESULTS

Order / MP No. & Date : 1500107652 (11.11.2021) Total weight : 60.960 MT

Material : TMT BAR Nominal Size : 10 mm, Length : 12m

Grade and Quality : IS 1786 : 2008 Fe 500D Brand Name : SAIL SeQR

CAST NO QTY Chemical composition

(MT) C% Mn% S% P% S+P% Si% Al% Cu% Cr% Cu+Cr% Nb% V% Ti% B% Nb+V+ Mo% N2 CE%

Ti+B% (ppm)

Specification Min - - - - - - - - - - -

Max 0.25 - 0.040 0.040 0.075 - - - - 0.30 0.50

22112889 32.405 0.21 0.87 0.015 0.029 0.044 0.25 NS 0.01 0.02 0.03 NS NS NS NS Tr NS NS 0.36

Cast No. Mechanical Properties

YS ( N/mm2) min YS ( N/mm2) max Tensile Strength TS/YS ratio Elongation % (Std GL) Total elongation at Bend Test Rebend Test

N/mm2 maximum force %

Specification 500 min 565 min 1.10 min 16.0 min 3d min 4d min

22112889 560 573 661 1.18 19.8 NS OK OK

Surface Defects (Piping / Other Defects): Absent

The material supplied conforms to the standard rolling and mass tolerance. Process Route : BF-BOF-LF-CC-Bar Mill

Remarks: Chemical Composition reported is Ladle Analysis. AUTHORISED SIGNATORY

Legend (where applicable) : NS/- = Not Specified; Tr = Traces; YS = Yield Strength;

TS = Tensile Strength; Std GL = Standard Gauge Length

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

IS 1786

STEEL AUTHORITY OF INDIA LIMITED

IISCO STEEL PLANT

BURNPUR - 713325, WEST BENGAL, INDIA

(Registered Office: Ispat Bhawan, Lodi Road, New Delhi - 110003) CM/L-0183135

TEST CERTIFICATE FOR HIGH STRENGTH DEFORMED STEEL BARS AND WIRES FOR CONCRETE REINFORCEMENT

TEST CERTIFICATE NO. : TC_8000101453 TC DATE : 27.11.2021 Page No. : 3 of 4

SHIPPING ADVICE NO. : 8000101453 SHIPPING DATE : 27.11.2021

CONSIGNEE NAME & ADDRESS : JAGDISH RAI CHAMAN LAL WAGON/TRAILER NO. : ECOR21120957241

PLOT NO.3,FLORA INTERNATIONAL, PANIPAT-132103, HARYANA

It is certified that the material described below fully conforms to IS 1786 : 2008. Chemical composition and Mechanical properties of the product, as tested in accordance with the

Scheme of Inspection and Testing contained in the BIS Certification Marks Licence No. CM/L-0183135 are as indicated below against each Order/Cast No.

(Please refer to IS 1786 : 2008 for details of specification requirements)

TEST RESULTS

Order / MP No. & Date : 1500107652 (11.11.2021) Total weight : 60.960 MT

Material : TMT BAR Nominal Size : 10 mm, Length : 12m

Grade and Quality : IS 1786 : 2008 Fe 500D Brand Name : SAIL SeQR

CAST NO QTY Chemical composition

(MT) C% Mn% S% P% S+P% Si% Al% Cu% Cr% Cu+Cr% Nb% V% Ti% B% Nb+V+ Mo% N2 CE%

Ti+B% (ppm)

Specification Min - - - - - - - - - - -

Max 0.25 - 0.040 0.040 0.075 - - - - 0.30 0.50

32112318 14.085 0.22 0.83 0.018 0.028 0.046 0.18 NS 0.01 0.01 0.02 NS NS NS NS Tr NS NS 0.36

Cast No. Mechanical Properties

YS ( N/mm2) min YS ( N/mm2) max Tensile Strength TS/YS ratio Elongation % (Std GL) Total elongation at Bend Test Rebend Test

N/mm2 maximum force %

Specification 500 min 565 min 1.10 min 16.0 min 3d min 4d min

32112318 567 578 675 1.19 18.6 NS OK OK

Surface Defects (Piping / Other Defects): Absent

The material supplied conforms to the standard rolling and mass tolerance. Process Route : BF-BOF-LF-CC-Bar Mill

Remarks: Chemical Composition reported is Ladle Analysis. AUTHORISED SIGNATORY

Legend (where applicable) : NS/- = Not Specified; Tr = Traces; YS = Yield Strength;

TS = Tensile Strength; Std GL = Standard Gauge Length

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

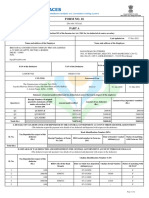

IS 1786

STEEL AUTHORITY OF INDIA LIMITED

IISCO STEEL PLANT

BURNPUR - 713325, WEST BENGAL, INDIA

(Registered Office: Ispat Bhawan, Lodi Road, New Delhi - 110003) CM/L-0183135

TEST CERTIFICATE FOR HIGH STRENGTH DEFORMED STEEL BARS AND WIRES FOR CONCRETE REINFORCEMENT

TEST CERTIFICATE NO. : TC_8000101453 TC DATE : 27.11.2021 Page No. : 4 of 4

SHIPPING ADVICE NO. : 8000101453 SHIPPING DATE : 27.11.2021

CONSIGNEE NAME & ADDRESS : JAGDISH RAI CHAMAN LAL WAGON/TRAILER NO. : ECOR21120957241

PLOT NO.3,FLORA INTERNATIONAL, PANIPAT-132103, HARYANA

It is certified that the material described below fully conforms to IS 1786 : 2008. Chemical composition and Mechanical properties of the product, as tested in accordance with the

Scheme of Inspection and Testing contained in the BIS Certification Marks Licence No. CM/L-0183135 are as indicated below against each Order/Cast No.

(Please refer to IS 1786 : 2008 for details of specification requirements)

TEST RESULTS

Order / MP No. & Date : 1500107652 (11.11.2021) Total weight : 60.960 MT

Material : TMT BAR Nominal Size : 10 mm, Length : 12m

Grade and Quality : IS 1786 : 2008 Fe 500D Brand Name : SAIL SeQR

CAST NO QTY Chemical composition

(MT) C% Mn% S% P% S+P% Si% Al% Cu% Cr% Cu+Cr% Nb% V% Ti% B% Nb+V+ Mo% N2 CE%

Ti+B% (ppm)

Specification Min - - - - - - - - - - -

Max 0.25 - 0.040 0.040 0.075 - - - - 0.30 0.50

32112917 11.116 0.20 0.87 0.015 0.022 0.037 0.21 NS 0.01 0.02 0.03 NS NS NS NS Tr NS NS 0.35

Cast No. Mechanical Properties

YS ( N/mm2) min YS ( N/mm2) max Tensile Strength TS/YS ratio Elongation % (Std GL) Total elongation at Bend Test Rebend Test

N/mm2 maximum force %

Specification 500 min 565 min 1.10 min 16.0 min 3d min 4d min

32112917 561 584 668 1.19 19.8 NS OK OK

Surface Defects (Piping / Other Defects): Absent

The material supplied conforms to the standard rolling and mass tolerance. Process Route : BF-BOF-LF-CC-Bar Mill

Remarks: Chemical Composition reported is Ladle Analysis. AUTHORISED SIGNATORY

Legend (where applicable) : NS/- = Not Specified; Tr = Traces; YS = Yield Strength;

TS = Tensile Strength; Std GL = Standard Gauge Length

CE = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

You might also like

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech09920050% (2)

- Test Certificate 12mmDocument1 pageTest Certificate 12mmSabyasachi Bangal67% (9)

- Fazendo Canivete PDFDocument112 pagesFazendo Canivete PDFsibalde67% (3)

- CWI - Part A Fundamentals Examination (Full) PDFDocument43 pagesCWI - Part A Fundamentals Examination (Full) PDFJulian Ramirez Ospina100% (5)

- Test Certificate - Ms ChannelsDocument1 pageTest Certificate - Ms Channelsaselabollegala100% (9)

- Test Certificate For Galvanized Steel CoilsDocument1 pageTest Certificate For Galvanized Steel CoilsS.SHANMUGA SABAREESAN100% (1)

- Test Certificate 16mmDocument1 pageTest Certificate 16mmSabyasachi Bangal50% (4)

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 pageJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- Apl Apollo Tubes LTD.: Manufacture Test Certificate For Steel Tubes For Structural PurposesDocument1 pageApl Apollo Tubes LTD.: Manufacture Test Certificate For Steel Tubes For Structural Purposestarun kaushal43% (7)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- 2452169253-6x1500mm E250Document1 page2452169253-6x1500mm E250Mohd YaskeenNo ratings yet

- MTC Inv 053 PDFDocument1 pageMTC Inv 053 PDFBeshnu Garanaik100% (2)

- Essar MTCDocument1 pageEssar MTCGowtham Vishvakarma33% (3)

- Test Certificate: Ferro Steel SolutionDocument1 pageTest Certificate: Ferro Steel SolutionNeeraj Singh80% (5)

- Test CertificateDocument7 pagesTest CertificateTARUNKUMAR100% (3)

- MTC For BoltDocument2 pagesMTC For Boltrizwan40% (5)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Sumaja MTC 40 RNDDocument1 pageSumaja MTC 40 RNDRINL GZB0% (1)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- R.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete ReinforcementDocument2 pagesR.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete Reinforcementnanda kishopre100% (4)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Jindal Steel & Power LTD: Test CertificateDocument2 pagesJindal Steel & Power LTD: Test CertificateAmandeep Singh50% (2)

- Test CertificateDocument1 pageTest CertificateAvinash JadhavNo ratings yet

- MTC - Al JazeeraDocument1 pageMTC - Al JazeeraArmağan DemirelNo ratings yet

- A941Document7 pagesA941rohit kumarNo ratings yet

- PIANC - Report No 162 - 2016 Recommendations For Increased Durability and Service Life of New Marine Concrete InfrastructureDocument95 pagesPIANC - Report No 162 - 2016 Recommendations For Increased Durability and Service Life of New Marine Concrete InfrastructureHauDucNguyenNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 pageTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- Test Certificate Hot Rolled, Medium High Tensile Steel: SailDocument3 pagesTest Certificate Hot Rolled, Medium High Tensile Steel: SailJignesh Jagjivanbhai PatelNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (2)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- Jindal Steel & Power Limited: Page 1 of 6Document1 pageJindal Steel & Power Limited: Page 1 of 6pranesh kadam100% (3)

- 65X M L - 211224 - 180120 - Converted - by - AbcdpdfDocument1 page65X M L - 211224 - 180120 - Converted - by - AbcdpdfVidhyarthi Photocopy KhargoneNo ratings yet

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- Test CertificateDocument2 pagesTest CertificatePRITESH100% (2)

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDocument1 pageMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNo ratings yet

- TC 1419 McnallyDocument2 pagesTC 1419 McnallymtlhwhNo ratings yet

- Test Certificate b8mDocument2 pagesTest Certificate b8msingaravelan narayanasamy50% (2)

- Test Certificates Stainless SteelDocument4 pagesTest Certificates Stainless SteelSurajPandey50% (4)

- 6 - Pipe MTCDocument1 page6 - Pipe MTCsnehalmdeshmukh100% (2)

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- MTC FITTINGSDocument5 pagesMTC FITTINGSAzee TitouNo ratings yet

- Batch Test Certificate: For Berger Paints India LTDDocument1 pageBatch Test Certificate: For Berger Paints India LTDtarun kaushal100% (1)

- Raw Material MTC - API 5L GR B PSL 2Document3 pagesRaw Material MTC - API 5L GR B PSL 2ClarkFedele27No ratings yet

- Quality Assurance Plan For Is 2062 E250 GR BRDocument2 pagesQuality Assurance Plan For Is 2062 E250 GR BRSUBHOMOYNo ratings yet

- Atul 30,36-LoescheDocument16 pagesAtul 30,36-LoescheSales ITANo ratings yet

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pages1jsl Ltd. TPI 3 (31803) MMPratik KarekarNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- AC ULTRATECH OPC 43 WeekNo 46Document1 pageAC ULTRATECH OPC 43 WeekNo 46jatin mradul3137gmail.comNo ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Revised IMIR ReportDocument2 pagesRevised IMIR ReportSimbu ArasanNo ratings yet

- Fme Mesaieed MTC 1103Document1 pageFme Mesaieed MTC 1103KyNo ratings yet

- Essar AluminiumDocument1 pageEssar Aluminiumiqlaskamtikar1No ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- 2211J5444 90mm WeldablesDocument1 page2211J5444 90mm WeldablesChethan Nagaraju KumbarNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Banjo Beam - MTC 3.5 MM E 46Document1 pageBanjo Beam - MTC 3.5 MM E 46Rajhans PressingNo ratings yet

- DFS %Document4 pagesDFS %RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Wire BasketDocument1 pageWire BasketRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- BGCC PKG-2 265Document1 pageBGCC PKG-2 265RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Casagrande ApparatusDocument1 pageCasagrande ApparatusRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Fine Value AppaturausDocument1 pageFine Value AppaturausRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Sehedule GDocument1 pageSehedule GRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- GI SIEVE 31.5aDocument1 pageGI SIEVE 31.5aRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Find The Quantity of Cement For 1 m3 of Concrete 6220a0fb68fa98206b0879b2Document2 pagesFind The Quantity of Cement For 1 m3 of Concrete 6220a0fb68fa98206b0879b2RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Beaker 500 MLDocument1 pageBeaker 500 MLRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- BGCC 23+362 Dynamic Test ReportDocument15 pagesBGCC 23+362 Dynamic Test ReportRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Silt ContentDocument2 pagesSilt ContentRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- DPR NewDocument166 pagesDPR NewRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Pankaj DocumentDocument11 pagesPankaj DocumentRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- LateralDocument2 pagesLateralRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Methodology of Dynamic PileDocument10 pagesMethodology of Dynamic PileRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Nitya Lab Profile 05.5Document34 pagesNitya Lab Profile 05.5RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Cube Strength & Cylinder StrengthDocument5 pagesCube Strength & Cylinder StrengthRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 1BGCC Jind12092022Document1 page1BGCC Jind12092022RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Settlement Analysis For Shallow Foundations Elastic Settlement Computed From Theory of ElasticityDocument7 pagesSettlement Analysis For Shallow Foundations Elastic Settlement Computed From Theory of ElasticityRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Report GSBDocument1 pageReport GSBRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 3BGCC Jind12092022Document1 page3BGCC Jind12092022RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- PDF - SolverDocument7 pagesPDF - SolverRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Report Emulsion SS-1Document1 pageReport Emulsion SS-1RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- BGCC M01495Document2 pagesBGCC M01495RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Reports SoilDocument3 pagesReports SoilRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- LQM - Ec': A. L/4aterial Source No: Sample Rnforrrration BDocument2 pagesLQM - Ec': A. L/4aterial Source No: Sample Rnforrrration BRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Steel: The Indian Steel IndustryDocument43 pagesSteel: The Indian Steel IndustrySylvia GraceNo ratings yet

- JDM V22Document14 pagesJDM V22X800XLNo ratings yet

- 1990ASM - Handb - Vol1 - Classification and Basic Metallurgy of Cast IronDocument10 pages1990ASM - Handb - Vol1 - Classification and Basic Metallurgy of Cast IronFátima GouveiaNo ratings yet

- American Society of Mechanical Engineers (ASME) CodesDocument11 pagesAmerican Society of Mechanical Engineers (ASME) CodesfrdnNo ratings yet

- Structural Shapes: Arcelormittal International North AmericaDocument16 pagesStructural Shapes: Arcelormittal International North AmericaLeonardo SarriaNo ratings yet

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDocument15 pagesInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- Metallurgy SyllabusDocument1 pageMetallurgy SyllabusSathrudhan ChoudharyNo ratings yet

- Interstitial Free Steels - IspatGuruDocument6 pagesInterstitial Free Steels - IspatGuruSilverio AcuñaNo ratings yet

- BP304T Pe Unit VDocument24 pagesBP304T Pe Unit VArghadeep BhattacharjeeNo ratings yet

- Classification Exercises Materials PDFDocument6 pagesClassification Exercises Materials PDFmatina14100% (1)

- 3D Printing For Sand Casting Patterns PDFDocument3 pages3D Printing For Sand Casting Patterns PDFskrgoelNo ratings yet

- Singh Pandey 2022 Effect of Cryogenic Treatment On Properties of Materials A ReviewDocument16 pagesSingh Pandey 2022 Effect of Cryogenic Treatment On Properties of Materials A ReviewShradharghya Shankar AdhikaryNo ratings yet

- WIS Plate Exe NV (TWI)Document26 pagesWIS Plate Exe NV (TWI)Wisüttisäk Peäröön0% (1)

- Alloy 800H Material and Fabrication Challenges Associated With The Mitigation of Stress Relaxation CrackingDocument11 pagesAlloy 800H Material and Fabrication Challenges Associated With The Mitigation of Stress Relaxation CrackingGeorge SalsburyNo ratings yet

- Mini ProjectDocument3 pagesMini ProjectSyafiq KamilNo ratings yet

- EN 10025 Grade S355J2C Normalized or Normalized Formed (+N)Document3 pagesEN 10025 Grade S355J2C Normalized or Normalized Formed (+N)melvin ekboteNo ratings yet

- Hilirisasi Produk Dan Kandungan Lokal: Aluminium Billet & Alloy PT Inalum (Persero) Location: Kuala Tanjung, Sum-UtDocument15 pagesHilirisasi Produk Dan Kandungan Lokal: Aluminium Billet & Alloy PT Inalum (Persero) Location: Kuala Tanjung, Sum-Utfarhan fahmiNo ratings yet

- 3D - CparDocument32 pages3D - CparKristine AllejeNo ratings yet

- SPH TozenDocument10 pagesSPH TozenVano WardhanaNo ratings yet

- 03 Composite HoseDocument23 pages03 Composite HoseVilius BukysNo ratings yet

- Curriculum Vitae: Dr. Tapas LahaDocument8 pagesCurriculum Vitae: Dr. Tapas LahaDeepak KNo ratings yet

- Ittefaq 2018 PDFDocument103 pagesIttefaq 2018 PDFSyed Ali DebajNo ratings yet

- ASTLTIMD. Module 5a. Design of Steel BeamsDocument7 pagesASTLTIMD. Module 5a. Design of Steel BeamsvaneNo ratings yet

- Chapter 9 - Metal Extraction and The Reactivity SeriesDocument30 pagesChapter 9 - Metal Extraction and The Reactivity SeriesBiologyNo ratings yet

- Heat Treatment & Phase Transformations: Laboratory Manual Cum Observation BookDocument45 pagesHeat Treatment & Phase Transformations: Laboratory Manual Cum Observation Book035K Ayush ChoudharyNo ratings yet

- Wire Welded Fabric Mesh PDFDocument2 pagesWire Welded Fabric Mesh PDFHarish RajaramNo ratings yet