Professional Documents

Culture Documents

Element Harzards and Precautions

Element Harzards and Precautions

Uploaded by

Harshal ChimankarCopyright:

Available Formats

You might also like

- Fire Training Manual SOLASDocument23 pagesFire Training Manual SOLASKrešimir PoljakNo ratings yet

- ANSUL - Fire Protection Solutions For LNGDocument29 pagesANSUL - Fire Protection Solutions For LNGErwinNo ratings yet

- Chemical Reaction Engineering: Third EditionDocument684 pagesChemical Reaction Engineering: Third Editionharsh mohaneNo ratings yet

- Cs15 Gas Tank Cleaning Degassing 1997Document12 pagesCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- AIChE Design LNG Facilities To Minimize Risks From Cryogenic Exposure, 2009Document17 pagesAIChE Design LNG Facilities To Minimize Risks From Cryogenic Exposure, 2009jeremyg998100% (1)

- Prugh ModelDocument17 pagesPrugh ModelakilanNo ratings yet

- Cargo Area Fire Onboard LPG Carrier - How To Tackle ?Document10 pagesCargo Area Fire Onboard LPG Carrier - How To Tackle ?Ářvíňď PřášáďNo ratings yet

- Safety & Fire Fighting For LNGDocument7 pagesSafety & Fire Fighting For LNGmohb100% (2)

- Safety Technical Problems AssociateDocument10 pagesSafety Technical Problems Associate5.s.5.c1633No ratings yet

- Part 9 - Fire FightingDocument10 pagesPart 9 - Fire FightingJohnSmithNo ratings yet

- Safety Aspects of LNGDocument10 pagesSafety Aspects of LNGNeil AlexNo ratings yet

- Main Type of LNG HazardDocument3 pagesMain Type of LNG HazardWildan IrfansyahNo ratings yet

- ConsequenciasDocument6 pagesConsequenciasdennisroldanNo ratings yet

- LPG Fire Characteristics Fire Control PDFDocument4 pagesLPG Fire Characteristics Fire Control PDFAnandababuNo ratings yet

- LNG PDFDocument5 pagesLNG PDFhanloveNo ratings yet

- Rollover in Gas CarrierDocument3 pagesRollover in Gas CarrierTuhin Kumar DevNo ratings yet

- Liquefied Natural Gas in California: History, Risks, and SitingDocument26 pagesLiquefied Natural Gas in California: History, Risks, and SitingScribdSnake123No ratings yet

- oIL REFINERY FIRE NOTESDocument6 pagesoIL REFINERY FIRE NOTESAlabi GodfavourNo ratings yet

- Hazards 26 Poster 16 Hazards Within LNG Floating Facilities Topside DesignDocument5 pagesHazards 26 Poster 16 Hazards Within LNG Floating Facilities Topside DesignDon SheensNo ratings yet

- Gas Detection at LNG Facilities ETA - MARDocument7 pagesGas Detection at LNG Facilities ETA - MARSaBilScondNo ratings yet

- EHS Guidelines For LNG Facilities-SummaryDocument15 pagesEHS Guidelines For LNG Facilities-SummaryKivutiNo ratings yet

- What - Is - LNGDocument19 pagesWhat - Is - LNGAhmed ZNo ratings yet

- LNG Safety ReportDocument14 pagesLNG Safety ReportDavid Lincoln100% (2)

- Ftops 2a - LPG-LNG Hazards and ControlDocument26 pagesFtops 2a - LPG-LNG Hazards and ControlmyscriblkNo ratings yet

- Pdf-Lng-Terminal-Fasilitas Facilities - CompressDocument25 pagesPdf-Lng-Terminal-Fasilitas Facilities - CompressAndriansyahNo ratings yet

- Marine and Offshore Water Mist SolutionsDocument4 pagesMarine and Offshore Water Mist Solutionsmister_no34No ratings yet

- LNG Safety Document Final PDFDocument10 pagesLNG Safety Document Final PDFAnonymous 6Ozj8Jmp1ZNo ratings yet

- Selected Problems of Boil-Off Gas Utilization On LNG CarriersDocument8 pagesSelected Problems of Boil-Off Gas Utilization On LNG CarriersJuan Diego Guerrero MateoNo ratings yet

- Design Methods For FLNG Safety Engineering - Jerome - HocquetDocument11 pagesDesign Methods For FLNG Safety Engineering - Jerome - HocquetRichard HollidayNo ratings yet

- LNG Density StratificationDocument0 pagesLNG Density StratificationamirlngNo ratings yet

- LNGBunkering - UK - Club - FinalDocument12 pagesLNGBunkering - UK - Club - FinalMr-SmithNo ratings yet

- Fire in Dry DockDocument4 pagesFire in Dry DocknikhilNo ratings yet

- LNG - Zonas de ExclusiónDocument15 pagesLNG - Zonas de ExclusiónDavid Santaria VargasNo ratings yet

- Understand LNG Fire Hazards: An Iomosaic Corporation WhitepaperDocument26 pagesUnderstand LNG Fire Hazards: An Iomosaic Corporation WhitepaperRebekah Lim Ching YiNo ratings yet

- XV Paper 09Document16 pagesXV Paper 09a.h.saberbaghban001No ratings yet

- LNG Density StratificationDocument3 pagesLNG Density StratificationmimoNo ratings yet

- Protocol CryogenicsDocument2 pagesProtocol CryogenicsHatimNo ratings yet

- Is9 2008Document5 pagesIs9 2008eng.tomasoniNo ratings yet

- LNG Terminal FacilitiesDocument25 pagesLNG Terminal Facilitieselfantasma100% (6)

- 12 PDFDocument12 pages12 PDFAndi SungNo ratings yet

- History of LNGDocument9 pagesHistory of LNGNick Tarr0% (1)

- Hazards Associated With LNGDocument2 pagesHazards Associated With LNGKimNo ratings yet

- Appendix 2. LPG Road Tank Wagon Parking Risk Assessment: Kevin Bailey LPG & Safety Consultants LTD June 2007Document26 pagesAppendix 2. LPG Road Tank Wagon Parking Risk Assessment: Kevin Bailey LPG & Safety Consultants LTD June 2007lichigo_perezNo ratings yet

- Response Considerations For LNG Spills: January 2006Document16 pagesResponse Considerations For LNG Spills: January 2006Manna PintoNo ratings yet

- FTPDocument6 pagesFTPGabi BarzăNo ratings yet

- Bleve: Boiling Liquid Expanding Vapor ExplosionDocument54 pagesBleve: Boiling Liquid Expanding Vapor ExplosionGalih Sukma100% (3)

- LNG FamiliarisationDocument80 pagesLNG FamiliarisationGee Villadarez100% (1)

- BLEVE - Cause and EffectsDocument28 pagesBLEVE - Cause and EffectsMariano GaldamesNo ratings yet

- SFPC Ch3 1Document6 pagesSFPC Ch3 1Tejas KanagiNo ratings yet

- Hydrogen LawsDocument4 pagesHydrogen Lawsmuneeb34No ratings yet

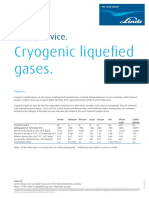

- Safety Advice 04 Cryogenic Liquefied Gases - tcm17-410827Document3 pagesSafety Advice 04 Cryogenic Liquefied Gases - tcm17-410827rajeevNo ratings yet

- Cargo Handling in LNG CarriersDocument86 pagesCargo Handling in LNG Carriersfarshid_b100% (4)

- Myths and Facts About Hydrogen Hazards: C H E M I C A L E N G I N E E R I N GDocument6 pagesMyths and Facts About Hydrogen Hazards: C H E M I C A L E N G I N E E R I N GZbigNo ratings yet

- Smelt Water ExplosionsDocument19 pagesSmelt Water Explosionsnmehta67100% (1)

- FireFighting On Container VesselDocument6 pagesFireFighting On Container VesselAnakin SkywalkerNo ratings yet

- CryogenicLiquidGuidelines PDFDocument15 pagesCryogenicLiquidGuidelines PDFMichel LopezNo ratings yet

- Warsash - AFF Course PDFDocument103 pagesWarsash - AFF Course PDFrenzwar100% (4)

- Hazards in LNG StorageDocument12 pagesHazards in LNG StorageAnuj SinhaNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Marvels of Scientific Invention An Interesting Account in Non-technical Language of the Invention of Guns, Torpedoes, Submarine Mines, Up-to-date Smelting, Freezing, Colour Photography, and many other recent Discoveries of ScienceFrom EverandMarvels of Scientific Invention An Interesting Account in Non-technical Language of the Invention of Guns, Torpedoes, Submarine Mines, Up-to-date Smelting, Freezing, Colour Photography, and many other recent Discoveries of ScienceNo ratings yet

- Tanks DetialsDocument11 pagesTanks DetialsHarshal ChimankarNo ratings yet

- Carrying Liquefied Natural Gases by Various Type LNG Ships Liquefied Natural Gas (LNG) CarriersDocument14 pagesCarrying Liquefied Natural Gases by Various Type LNG Ships Liquefied Natural Gas (LNG) CarriersHarshal ChimankarNo ratings yet

- Loading and Unloading Rules&dataDocument5 pagesLoading and Unloading Rules&dataHarshal ChimankarNo ratings yet

- Details of Inert Gas, Dry Air & Nitrogen GeneratorDocument8 pagesDetails of Inert Gas, Dry Air & Nitrogen GeneratorHarshal ChimankarNo ratings yet

- TurbidexDocument2 pagesTurbidexJANCARLONo ratings yet

- Aromatic WaterDocument6 pagesAromatic Watersamiveni100% (2)

- Organics 1 Triple 2Document46 pagesOrganics 1 Triple 2AnonymousNo ratings yet

- Cover Proces Flow Diagram Flowline B-2104: PT Pertamina Ep Zona 10Document28 pagesCover Proces Flow Diagram Flowline B-2104: PT Pertamina Ep Zona 10rizkiNo ratings yet

- Guia de Uso Lubrificantes RefrigeraçãoDocument4 pagesGuia de Uso Lubrificantes RefrigeraçãoOtto José SimasNo ratings yet

- Ammonia Plant Equipment List: UNIT 000 - Air CompressorDocument6 pagesAmmonia Plant Equipment List: UNIT 000 - Air CompressorJopha S DevaNo ratings yet

- AQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDocument2 pagesAQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDEVANDRAN A/L MOHAN MoeNo ratings yet

- Assignment Questions (I)Document2 pagesAssignment Questions (I)Thirunavuk KarasuNo ratings yet

- HOOSEKI Fire Extinguisher 2017Document1 pageHOOSEKI Fire Extinguisher 2017Jarwo SutedjoNo ratings yet

- 1 Nps - Itpl-2021/22/Term Ii-ChemDocument5 pages1 Nps - Itpl-2021/22/Term Ii-ChemMidhun JayachandranNo ratings yet

- Tugas 1 Pengendalian ProsesDocument9 pagesTugas 1 Pengendalian ProsesAldo HoseaNo ratings yet

- Dear SirDocument11 pagesDear SirJelore James CumlaNo ratings yet

- Ways To Control CorrosionDocument37 pagesWays To Control CorrosionKyle DugayoNo ratings yet

- Alternate Routes To Produce Paraxylene PDFDocument19 pagesAlternate Routes To Produce Paraxylene PDFRavikumar K YNo ratings yet

- Experiment 4 CODDocument3 pagesExperiment 4 CODNurul Noorfazleen78% (9)

- Experiment 5 CHM 476Document13 pagesExperiment 5 CHM 476insyirah shazrinNo ratings yet

- Identifying The Problem: 1. A Lot of Garbage Is Discarded in and Around The Water BodyDocument6 pagesIdentifying The Problem: 1. A Lot of Garbage Is Discarded in and Around The Water BodyBjhay BasilioNo ratings yet

- 5.1 ASME Sec II Part C Ed 2015Document1 page5.1 ASME Sec II Part C Ed 2015Anbarasan PerumalNo ratings yet

- Open Pan EvaporatorDocument5 pagesOpen Pan EvaporatorAshish Verma0% (3)

- Colligative PropertiesDocument31 pagesColligative PropertiesKasandra AprestoNo ratings yet

- Fired HeatersDocument24 pagesFired HeatersCynthia Magali Márquez Ramírez100% (1)

- DsdsDocument10 pagesDsdsLinh GiangNo ratings yet

- Us8075870b2 PDFDocument13 pagesUs8075870b2 PDFNelsonNo ratings yet

- Tabla de TokensDocument1 pageTabla de TokensAnonymous uCYIu1No ratings yet

- Fluid Catalytic CrackingDocument16 pagesFluid Catalytic Crackingbubalazi100% (1)

- FTP 200.19.144.11 Luis Books Equilibrium-Stage Separation Operations in Chemical EngineeringDocument384 pagesFTP 200.19.144.11 Luis Books Equilibrium-Stage Separation Operations in Chemical EngineeringDavid BarreraNo ratings yet

- Danfoss Eliminator With Replaceable Solid Core: Type DCRDocument16 pagesDanfoss Eliminator With Replaceable Solid Core: Type DCRGogaNo ratings yet

- Distillation Technology and Need of Simultaneous Design and Control A ReviewDocument24 pagesDistillation Technology and Need of Simultaneous Design and Control A ReviewHesam AhmadianNo ratings yet

- Batch Reactive DistillationDocument7 pagesBatch Reactive DistillationChalmer BelaroNo ratings yet

Element Harzards and Precautions

Element Harzards and Precautions

Uploaded by

Harshal ChimankarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Element Harzards and Precautions

Element Harzards and Precautions

Uploaded by

Harshal ChimankarCopyright:

Available Formats

Potential hazards of a large liquefied natural gas spill during

marine transportation

The potential hazards of a large LNG spill over water includes

asphyxiation, cryogenic burns, and cryogenic damage to the ship

from the very cold LNG, dispersion, fires, and explosions.

Based on expert review, the most likely hazards to people and

property would be thermal hazards from an LNG fire. Cryogenic and

fire damage to an LNG ship were also identified as concerns that

could cause additional damage to LNG cargo tanks following an

initial cargo tank breach, though the additional impact on public

safety would be limited.

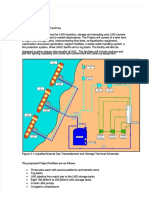

Fig: consequences of LNG spill over water

Risks and hazards from a potential marine LNG spill can be reduced

through a combination of approaches, including reducing the

potential for a spill, reducing the consequences of a spill, or

improving LNG transportation safety equipment, security, or

operations to prevent or mitigate a spill.

Explosions in confined spaces, either combustion events or events

of rapid phase transition, may have the potential for causing

secondary damage that could lead to further spillage of LNG.

Other proactive risk management approaches can help reduce both

the potential for and hazards of such events. These include:

i) improvements in ship and terminal safety/security systems

including improved surveillance, tank and insulation upgrades,

tanker standoff protection systems;

ii) modifications and improvements in LNG tanker escorts, extension

of vessel movement control zones, and safety operations near ports

and terminals;

iii) improved surveillance and searches of tugs, ship crews, and

vessels;

iv) redundant or offshore mooring and offloading systems; and

v) improved emergency response systems to reduce fire and

dispersion hazards and improved emergency response coordination

and communication.

Fig:LNG carrier underway

Risk prevention and mitigation techniques are especially useful in

zones where the potential impact on public safety and property can

be high. The hazards of brittle fracture, rapid phase transitions, and

explosions in confined ship spaces, as well as cascading events that

may result from the extreme fire exposure a ship would experience

if a nominal 12,500 m3 spill on water around the ship was ignited,

will require careful consideration. The definition of

The majority of liquefied gases are clean, non-polluting, products

and create no danger to the marine environment. If however certain

liquefied gases spill on to the sea you should be aware that they

may:

create large quantities of vapour sea water rapidly vapourises

the liquid gas- which may cause a fire or explosion or a health

hazard.

generate toxic vapours, which can drift, sometimes over a

considerable distance.

dissolve in seawater and cause local pollution

The Data Sheets will give information on pollution, if any Pollution is

most likely to occur during cargo or bunkering operations:

· if the operation is not correctly monitored

· if the cargo hose or loading arm connections are not properly

made

· when disconnecting cargo lines that have not been drained.

· if moorings are not checked and excessive strain is placed on the

cargo connections or the ship "breaks out" of the berth.

· if cargo equipment is not properly maintained

Any spillage of LNG on any steelwork, unless stainless steel or

wood-sheathed, will cause stresses and it is most likely serious

brittle fractures will occur.

As soon as any leak or spill of LNG is exposed to ambient

temperatures, the liquid will vaporise or ‘boil-off’. This vaporisation

will occur in two phases. Initially, for a period of from 20-30

seconds, there will normally be a high rate of boiling as the heat for

vaporisation is taken from the liquid spill itself and the immediate

surrounding areas. Secondly, the cold vaporised gas begins to

insulate the liquid surface and the evaporation rate will level off at a

lower steady rate depending on how quickly heat can be transferred

to the LNG from the surrounding area. This vaporisation rate may

be increased by:

Continuing leakage, i.e. greater volume exposed to

atmosphere.

Wind.

Application of water.

Ignition, i.e. greater heat flow to the liquid.

Agitation of the surface.

Thus, spraying an un-ignited spillage of LNG with water will speed

up the vaporisation and reduce the hazards of cold fractures, fire or

ignition. Alternatively, spraying with water on to LNG which has

been ignited will increase the vaporisation rate and hence the

burning rate. The use of solid water jets on LNG spills may cause

splashing, leading to cold fractures or frost burns or, if ignited, may

seriously aggravate the fire.

Immediately after vaporisation, natural gas is 1·4 times heavier

than air. As the gas warms, its density will decrease, becoming the

same as air at approximately –120°C and reaching the value of 0·55

at 15oC. There may, therefore, be a tendency for cold vapours to

form a layer around the spill in a similar manner to other

hydrocarbon gases. Fortunately, this layering will normally be visible

due to the condensation of atmospheric moisture.

However, unlike other hydrocarbon gases, natural gas quickly

becomes buoyant and, except in enclosed spaces, will rise and

disperse rapidly as it warms. This dispersion is further aided by the

very rapid diffusion properties of methane in air. Where spills may

have entered enclosed spaces, it is important to recognise that gas

pockets may become trapped near deckhead structures, etc.

In the case of a leakage or spillage of LNG, the following general

procedure should be followed:

Isolate source of LNG. If loading/discharging, the ESD system

should be activated.

Summon assistance.

Protect the hull from risk of cold fracture.

Speed vaporisation to minimise ignition risk.

SSSS

What happens with if LNG spilled on water?

LNG pool vaporizes rapidly (faster than an equal sized pool on

land)

LNG spill on or within hull can cause brittle fracture (carbon &

low alloy steel) fracture

LNG can undergo “rapid phase transition”, a physical vapor

explosion (not combustion)

LNG pool formation accompanied by ignition

Natural gas cloud formation with subsequent burn back

Fire involving LNG & LPG cargo - various fire fighting agents

& safety aspects

Natural gas contains numerous component gases but by far the

greater percentage is methane (CH4), which represents between 60

and 95 per cent of the total volume. This fact is important when

considering the safety aspects for fire-fighters tackling an LNG fire.

During the initial period of vaporisation of the gas, ignition may be

accompanied by a flash of varying proportions.However, because

the velocity of propagation of a flame is lower in methane than in

other hydro-carbon gases, it is unlikely that future ignition will have

flash effect. The fire-fighting plan should be well thought out in

advance and a concentrated effort made rather than ‘hit and run’

tactics, as these will only consume the vessel’s extinguishing

facilities without extinguishing the fire. Before attempting to tackle

a large fire, you should seriously consider allowing the fire to burn

itself out.

Should an attempt to extinguish the fire be made, extensive use of

‘dry powder’ should be employed from as many dispensers as can

be brought to bear. Fire-fighters should be well protected against

heat radiation and possible flash burns, and approach the fire from

an upwind direction. Power dispensers should sweep the entire area

of the fire, but direct pressure of powder jets on to the surface of

the liquid should be avoided. Should dry powder guns be used, fire-

fighters should be well practised in their use and be prepared for

some kick-back effect.They should also be made aware that there is

no cooling effect from the use of dry powder, and that re-ignition

after a fire has been extinguished is a distinct possibility.

In the initial stages it is always preferable to isolate the fire by

shutting off the source of fuel.This may not, however, always be

possible. A final warning when tackling an LNG fire is that water

should not be used directly, as this will accelerate vaporisation of

the liquid.This is not to say that surrounding bulkheads and decks

cannot be cooled down with water sprays, provided that water

running off is not allowed to mix with burning LNG.

Dry powder :

Dry powder is provided both in large fixed installations and portable

extinguishers. Any part of the deck can be reached by at least two

hoses from the fixed installations.

Water extinguishing :

Water is not a suitable medium for fighting an LNG fire directly as it

will cause a massive expansion of the fire, through an increase in

the rate of vaporisation of the liquid to gaseous state. Water is

however essential as a cooling medium for the area surrounding an

LNG fire and to protect personnel who may need to approach the

site. Water is also essential for protecting steel work from the

effects of extreme cold in the event of a liquid spill.

CO2 :

A CO2 extinguisher system is available for cargo compressor rooms,

electric motor rooms, inert gas dryer room and on some ships cargo

control room. Ships plans should be consulted for what is applicable

to the concerned vessel.

How to tackle LNG fire ?

The rapid vaporisation of any exposed LNG prevents any ignition of

the liquid itself and an LNG fire is thus a cold vapour fire.

Ignition of a flammable mixture of natural gas vapour requires a

spark of similar ignition energy as would ignite other hydrocarbon

vapours. The auto-ignition temperature of methane in air (650°C) is

higher than other hydrocarbons.

Electrostatic ignition of LNG is not a hazard during normal

operations. This is because the permanent, positive pressure in LNG

tanks maintained by gas boil-off prevents air entering these spaces

to form flammable mixtures in tanks or lines.

The velocity of propagation of a flame is lower in methane than

nearly all other hydrocarbons. Unless ignition occurs during the

initial rapid vaporisation period, it is most unlikely that any flash will

accompany an ignition. The term ‘lazy flame’ has been aptly used to

describe the spreading characteristics of an LNG fire.

Burning of LNG vapours produces a similar flame size and heat

radiation to other hydrocarbon fires, but little smoke is produced.

From a fire fighting viewpoint, LNG/cold vapour fires have the

characteristics of both liquid and gaseous hydrocarbon fires.

The procedure for fighting these fires is:

1. Isolate the source of leak, stop loading/discharging, and shut

all manifold valves.

2. Sound the alarm.

3. Provide protection for adjacent equipment and for fire-fighters.

4. Attack fire with a maximum rate of application of dry powder.

Do not agitate the surface of any pool of LNG.

5. Remain on guard against possible re-ignition.

The exact procedure will depend upon the nature of the incident.

Before attempting to fight large fires, thought should be given to

the desirability of letting a fire burn itself out. Such strategy runs

the risk of the fire spreading and greater damage being caused, but

other factors to take into account are:

The possibility that the dry powder capacity may be exhausted

before the fire is extinguished, or, if the fire is extinguished,

reserves have been run so low that any reignition could not be

contained.

The risk of damage to life and property if an un-ignited

flammable mixture drifted in light wind conditions to an area of

high ignition risk.

The following fire fighting agents may be used:

Water spray systems

It is a requirement that a series of water spray nozzles are located

at each tank liquid and vapour dome, at the midships manifold, on

the compressor house, on the forward bulkhead of the

accommodation block and around the midships cargo control room if

applicable. The water for the operation of these nozzles is fed from

a pump and line system independent from, but crossconnected with,

the ship's fire main. In addition to the above system, the sides of

the accommodation block may be protected by spray nozzles

supplied with water from the fire main via isolating valves.

Water should NOT be used to extinguish LNG fires as it increases

the vaporisation rate and hence the burning rate. However a water

spray or fog should be used to protect personnel and to cool areas

adjacent to the fire. The qualities that make water unsuitable for

fighting LNG fires make it an ideal medium for spraying LNG

spillages to increase evaporation rate and prevent re-ignition,

provided that the LNG is not actually burning.

Care is necessary to avoid water running off adjacent structures and

aggravating burning LNG, or splashing into spill trays which may

contain LNG, thus causing it to overflow onto unprotected

steelwork. Spill trays and areas under manifolds are in any case

floodable with water to protect hull steelwork from damage due to

exposure to the intense cold of LNG.

Water jets can be used to deflect burning jets from impinging on

other tanks. Care should be taken to avoid extinguishing the fire

with the consequent danger of re-ignition of large volumes of

flammable gas.

Dry chemical powder

Dry chemical fixed installations are provided on Gas Carriers.

Manufacturer’s instructions should be referred to for details of

operation and maintenance procedures. Whenever a dry powder

hose has been in use, it should be blown clear with nitrogen to

prevent any possibility of blockage. The extinguishing power of dry

chemical powders depends on the chemical reaction of the small

particles when exposed to flame. They are flame inhibiting agents

and have been widely proven in LNG fire tests.

The maximum possible rate of application of dry powder is

desirable. As many high velocity jets as possible should be brought

to bear at once, preferably in a down wind direction. Jets should be

aimed with the objective of reducing boil-off rate by sweeping over

the whole fire area and on no account must the surface of an LNG

pool be agitated. Possible re-ignition must be guarded against.

Correct use of dry chemical powder equipment is essential if

reserves are not to be wasted and the fire is to be successfully

extinguished. Extinction with dry powder is obtained by maximising

the rate of application and minimising any agitation of pools of LNG.

This may be achieved by coordinating a simultaneous attack with all

available applicators. A first-aid shot with only one hose or monitor

may be warranted with small fires, but continuous individual efforts

can never be as successful as a simultaneous attack with as many

applicators as possible being brought to bear.

Operators must be adequately protected and positioned to obtain

down wind line-of-sight application, with the powder jet slightly

depressed below the horizontal. Powder jets should be swept rapidly

back and forth over the entire fire area. The direct impact of powder

jets on pool surfaces or leaks should be avoided. Where possible,

powder should be aimed at vertical surfaces immediately behind the

seat of the fire.

The high discharge rate hoses are as much as one man can handle

and the reaction force and consequences of wasting or misdirecting

powder requires that great care be taken in their use. If the above

techniques are adopted, tests have shown that LNG fires can be

readily extinguished. In fact extinction has often proved

unexpectedly easy.

Re-ignition of LNG and vapour by burning paintwork, or other

sources, must be expected. Water sprays should be activated as

soon as possible to cool steel work and speed vaporisation.

Gas smothering systems

Although CO2 and nitrogen smothering systems are not suitable for

use in exposed open air applications, they are otherwise the most

efficient agent for fighting liquid and vapour fires. By diffusing in a

burning mixture, they lower the oxygen content and render the

mixture inert. If the flames can be separated from the liquid, the

boil-off rate will also be reduced.

Nitrogen is more effective and less dangerous to personnel than

CO2 but CO2 is more easily stored.

You might also like

- Fire Training Manual SOLASDocument23 pagesFire Training Manual SOLASKrešimir PoljakNo ratings yet

- ANSUL - Fire Protection Solutions For LNGDocument29 pagesANSUL - Fire Protection Solutions For LNGErwinNo ratings yet

- Chemical Reaction Engineering: Third EditionDocument684 pagesChemical Reaction Engineering: Third Editionharsh mohaneNo ratings yet

- Cs15 Gas Tank Cleaning Degassing 1997Document12 pagesCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- AIChE Design LNG Facilities To Minimize Risks From Cryogenic Exposure, 2009Document17 pagesAIChE Design LNG Facilities To Minimize Risks From Cryogenic Exposure, 2009jeremyg998100% (1)

- Prugh ModelDocument17 pagesPrugh ModelakilanNo ratings yet

- Cargo Area Fire Onboard LPG Carrier - How To Tackle ?Document10 pagesCargo Area Fire Onboard LPG Carrier - How To Tackle ?Ářvíňď PřášáďNo ratings yet

- Safety & Fire Fighting For LNGDocument7 pagesSafety & Fire Fighting For LNGmohb100% (2)

- Safety Technical Problems AssociateDocument10 pagesSafety Technical Problems Associate5.s.5.c1633No ratings yet

- Part 9 - Fire FightingDocument10 pagesPart 9 - Fire FightingJohnSmithNo ratings yet

- Safety Aspects of LNGDocument10 pagesSafety Aspects of LNGNeil AlexNo ratings yet

- Main Type of LNG HazardDocument3 pagesMain Type of LNG HazardWildan IrfansyahNo ratings yet

- ConsequenciasDocument6 pagesConsequenciasdennisroldanNo ratings yet

- LPG Fire Characteristics Fire Control PDFDocument4 pagesLPG Fire Characteristics Fire Control PDFAnandababuNo ratings yet

- LNG PDFDocument5 pagesLNG PDFhanloveNo ratings yet

- Rollover in Gas CarrierDocument3 pagesRollover in Gas CarrierTuhin Kumar DevNo ratings yet

- Liquefied Natural Gas in California: History, Risks, and SitingDocument26 pagesLiquefied Natural Gas in California: History, Risks, and SitingScribdSnake123No ratings yet

- oIL REFINERY FIRE NOTESDocument6 pagesoIL REFINERY FIRE NOTESAlabi GodfavourNo ratings yet

- Hazards 26 Poster 16 Hazards Within LNG Floating Facilities Topside DesignDocument5 pagesHazards 26 Poster 16 Hazards Within LNG Floating Facilities Topside DesignDon SheensNo ratings yet

- Gas Detection at LNG Facilities ETA - MARDocument7 pagesGas Detection at LNG Facilities ETA - MARSaBilScondNo ratings yet

- EHS Guidelines For LNG Facilities-SummaryDocument15 pagesEHS Guidelines For LNG Facilities-SummaryKivutiNo ratings yet

- What - Is - LNGDocument19 pagesWhat - Is - LNGAhmed ZNo ratings yet

- LNG Safety ReportDocument14 pagesLNG Safety ReportDavid Lincoln100% (2)

- Ftops 2a - LPG-LNG Hazards and ControlDocument26 pagesFtops 2a - LPG-LNG Hazards and ControlmyscriblkNo ratings yet

- Pdf-Lng-Terminal-Fasilitas Facilities - CompressDocument25 pagesPdf-Lng-Terminal-Fasilitas Facilities - CompressAndriansyahNo ratings yet

- Marine and Offshore Water Mist SolutionsDocument4 pagesMarine and Offshore Water Mist Solutionsmister_no34No ratings yet

- LNG Safety Document Final PDFDocument10 pagesLNG Safety Document Final PDFAnonymous 6Ozj8Jmp1ZNo ratings yet

- Selected Problems of Boil-Off Gas Utilization On LNG CarriersDocument8 pagesSelected Problems of Boil-Off Gas Utilization On LNG CarriersJuan Diego Guerrero MateoNo ratings yet

- Design Methods For FLNG Safety Engineering - Jerome - HocquetDocument11 pagesDesign Methods For FLNG Safety Engineering - Jerome - HocquetRichard HollidayNo ratings yet

- LNG Density StratificationDocument0 pagesLNG Density StratificationamirlngNo ratings yet

- LNGBunkering - UK - Club - FinalDocument12 pagesLNGBunkering - UK - Club - FinalMr-SmithNo ratings yet

- Fire in Dry DockDocument4 pagesFire in Dry DocknikhilNo ratings yet

- LNG - Zonas de ExclusiónDocument15 pagesLNG - Zonas de ExclusiónDavid Santaria VargasNo ratings yet

- Understand LNG Fire Hazards: An Iomosaic Corporation WhitepaperDocument26 pagesUnderstand LNG Fire Hazards: An Iomosaic Corporation WhitepaperRebekah Lim Ching YiNo ratings yet

- XV Paper 09Document16 pagesXV Paper 09a.h.saberbaghban001No ratings yet

- LNG Density StratificationDocument3 pagesLNG Density StratificationmimoNo ratings yet

- Protocol CryogenicsDocument2 pagesProtocol CryogenicsHatimNo ratings yet

- Is9 2008Document5 pagesIs9 2008eng.tomasoniNo ratings yet

- LNG Terminal FacilitiesDocument25 pagesLNG Terminal Facilitieselfantasma100% (6)

- 12 PDFDocument12 pages12 PDFAndi SungNo ratings yet

- History of LNGDocument9 pagesHistory of LNGNick Tarr0% (1)

- Hazards Associated With LNGDocument2 pagesHazards Associated With LNGKimNo ratings yet

- Appendix 2. LPG Road Tank Wagon Parking Risk Assessment: Kevin Bailey LPG & Safety Consultants LTD June 2007Document26 pagesAppendix 2. LPG Road Tank Wagon Parking Risk Assessment: Kevin Bailey LPG & Safety Consultants LTD June 2007lichigo_perezNo ratings yet

- Response Considerations For LNG Spills: January 2006Document16 pagesResponse Considerations For LNG Spills: January 2006Manna PintoNo ratings yet

- FTPDocument6 pagesFTPGabi BarzăNo ratings yet

- Bleve: Boiling Liquid Expanding Vapor ExplosionDocument54 pagesBleve: Boiling Liquid Expanding Vapor ExplosionGalih Sukma100% (3)

- LNG FamiliarisationDocument80 pagesLNG FamiliarisationGee Villadarez100% (1)

- BLEVE - Cause and EffectsDocument28 pagesBLEVE - Cause and EffectsMariano GaldamesNo ratings yet

- SFPC Ch3 1Document6 pagesSFPC Ch3 1Tejas KanagiNo ratings yet

- Hydrogen LawsDocument4 pagesHydrogen Lawsmuneeb34No ratings yet

- Safety Advice 04 Cryogenic Liquefied Gases - tcm17-410827Document3 pagesSafety Advice 04 Cryogenic Liquefied Gases - tcm17-410827rajeevNo ratings yet

- Cargo Handling in LNG CarriersDocument86 pagesCargo Handling in LNG Carriersfarshid_b100% (4)

- Myths and Facts About Hydrogen Hazards: C H E M I C A L E N G I N E E R I N GDocument6 pagesMyths and Facts About Hydrogen Hazards: C H E M I C A L E N G I N E E R I N GZbigNo ratings yet

- Smelt Water ExplosionsDocument19 pagesSmelt Water Explosionsnmehta67100% (1)

- FireFighting On Container VesselDocument6 pagesFireFighting On Container VesselAnakin SkywalkerNo ratings yet

- CryogenicLiquidGuidelines PDFDocument15 pagesCryogenicLiquidGuidelines PDFMichel LopezNo ratings yet

- Warsash - AFF Course PDFDocument103 pagesWarsash - AFF Course PDFrenzwar100% (4)

- Hazards in LNG StorageDocument12 pagesHazards in LNG StorageAnuj SinhaNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Marvels of Scientific Invention An Interesting Account in Non-technical Language of the Invention of Guns, Torpedoes, Submarine Mines, Up-to-date Smelting, Freezing, Colour Photography, and many other recent Discoveries of ScienceFrom EverandMarvels of Scientific Invention An Interesting Account in Non-technical Language of the Invention of Guns, Torpedoes, Submarine Mines, Up-to-date Smelting, Freezing, Colour Photography, and many other recent Discoveries of ScienceNo ratings yet

- Tanks DetialsDocument11 pagesTanks DetialsHarshal ChimankarNo ratings yet

- Carrying Liquefied Natural Gases by Various Type LNG Ships Liquefied Natural Gas (LNG) CarriersDocument14 pagesCarrying Liquefied Natural Gases by Various Type LNG Ships Liquefied Natural Gas (LNG) CarriersHarshal ChimankarNo ratings yet

- Loading and Unloading Rules&dataDocument5 pagesLoading and Unloading Rules&dataHarshal ChimankarNo ratings yet

- Details of Inert Gas, Dry Air & Nitrogen GeneratorDocument8 pagesDetails of Inert Gas, Dry Air & Nitrogen GeneratorHarshal ChimankarNo ratings yet

- TurbidexDocument2 pagesTurbidexJANCARLONo ratings yet

- Aromatic WaterDocument6 pagesAromatic Watersamiveni100% (2)

- Organics 1 Triple 2Document46 pagesOrganics 1 Triple 2AnonymousNo ratings yet

- Cover Proces Flow Diagram Flowline B-2104: PT Pertamina Ep Zona 10Document28 pagesCover Proces Flow Diagram Flowline B-2104: PT Pertamina Ep Zona 10rizkiNo ratings yet

- Guia de Uso Lubrificantes RefrigeraçãoDocument4 pagesGuia de Uso Lubrificantes RefrigeraçãoOtto José SimasNo ratings yet

- Ammonia Plant Equipment List: UNIT 000 - Air CompressorDocument6 pagesAmmonia Plant Equipment List: UNIT 000 - Air CompressorJopha S DevaNo ratings yet

- AQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDocument2 pagesAQA GCSE Chemistry Combined U7 Organic Chemistry Knowledge OrganiserDEVANDRAN A/L MOHAN MoeNo ratings yet

- Assignment Questions (I)Document2 pagesAssignment Questions (I)Thirunavuk KarasuNo ratings yet

- HOOSEKI Fire Extinguisher 2017Document1 pageHOOSEKI Fire Extinguisher 2017Jarwo SutedjoNo ratings yet

- 1 Nps - Itpl-2021/22/Term Ii-ChemDocument5 pages1 Nps - Itpl-2021/22/Term Ii-ChemMidhun JayachandranNo ratings yet

- Tugas 1 Pengendalian ProsesDocument9 pagesTugas 1 Pengendalian ProsesAldo HoseaNo ratings yet

- Dear SirDocument11 pagesDear SirJelore James CumlaNo ratings yet

- Ways To Control CorrosionDocument37 pagesWays To Control CorrosionKyle DugayoNo ratings yet

- Alternate Routes To Produce Paraxylene PDFDocument19 pagesAlternate Routes To Produce Paraxylene PDFRavikumar K YNo ratings yet

- Experiment 4 CODDocument3 pagesExperiment 4 CODNurul Noorfazleen78% (9)

- Experiment 5 CHM 476Document13 pagesExperiment 5 CHM 476insyirah shazrinNo ratings yet

- Identifying The Problem: 1. A Lot of Garbage Is Discarded in and Around The Water BodyDocument6 pagesIdentifying The Problem: 1. A Lot of Garbage Is Discarded in and Around The Water BodyBjhay BasilioNo ratings yet

- 5.1 ASME Sec II Part C Ed 2015Document1 page5.1 ASME Sec II Part C Ed 2015Anbarasan PerumalNo ratings yet

- Open Pan EvaporatorDocument5 pagesOpen Pan EvaporatorAshish Verma0% (3)

- Colligative PropertiesDocument31 pagesColligative PropertiesKasandra AprestoNo ratings yet

- Fired HeatersDocument24 pagesFired HeatersCynthia Magali Márquez Ramírez100% (1)

- DsdsDocument10 pagesDsdsLinh GiangNo ratings yet

- Us8075870b2 PDFDocument13 pagesUs8075870b2 PDFNelsonNo ratings yet

- Tabla de TokensDocument1 pageTabla de TokensAnonymous uCYIu1No ratings yet

- Fluid Catalytic CrackingDocument16 pagesFluid Catalytic Crackingbubalazi100% (1)

- FTP 200.19.144.11 Luis Books Equilibrium-Stage Separation Operations in Chemical EngineeringDocument384 pagesFTP 200.19.144.11 Luis Books Equilibrium-Stage Separation Operations in Chemical EngineeringDavid BarreraNo ratings yet

- Danfoss Eliminator With Replaceable Solid Core: Type DCRDocument16 pagesDanfoss Eliminator With Replaceable Solid Core: Type DCRGogaNo ratings yet

- Distillation Technology and Need of Simultaneous Design and Control A ReviewDocument24 pagesDistillation Technology and Need of Simultaneous Design and Control A ReviewHesam AhmadianNo ratings yet

- Batch Reactive DistillationDocument7 pagesBatch Reactive DistillationChalmer BelaroNo ratings yet