Professional Documents

Culture Documents

FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 Psig

FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 Psig

Uploaded by

Mohamed RaafatCopyright:

Available Formats

You might also like

- Rachel Mitchell Task 1Document1,003 pagesRachel Mitchell Task 1nazmul Hasan100% (1)

- Manual Do BOP IEDocument18 pagesManual Do BOP IEandre vidal100% (1)

- Inspection Certificate Leser CGA (EN)Document3 pagesInspection Certificate Leser CGA (EN)Mohamed RaafatNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Hydrant SystemDocument10 pagesHydrant SystemSheikh Faiz RockerNo ratings yet

- IMI CCI Product 840seriesDocument4 pagesIMI CCI Product 840seriesArdhi WibowoNo ratings yet

- 840 SeriesDocument4 pages840 SeriesKarim Abd Al-RahimNo ratings yet

- Tyco Valves & Controls CatalogDocument6 pagesTyco Valves & Controls CatalogHasanNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- Fracking DunlopDocument4 pagesFracking DunlopLeo@spNo ratings yet

- HD 175 Varsha HF30Document2 pagesHD 175 Varsha HF30ANAS GOGAZEHNo ratings yet

- Mcnichols Trench Drain Systems SpecsDocument3 pagesMcnichols Trench Drain Systems SpecsRobert CashNo ratings yet

- Double Offset High Performance Butterfly Valves: DescriptionDocument16 pagesDouble Offset High Performance Butterfly Valves: Descriptionmanmohansingh1999No ratings yet

- Apollo-HP 215L-215WDocument16 pagesApollo-HP 215L-215WDaniel SanNo ratings yet

- FLUSH BOTTOM VALVE SERIES 500nDocument5 pagesFLUSH BOTTOM VALVE SERIES 500nvedant.pokharkarNo ratings yet

- Jamesbury 3000Document4 pagesJamesbury 3000jacquesstrappe06No ratings yet

- Watsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapDocument2 pagesWatsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapbudi utomoNo ratings yet

- BRAY F15 Ball ValveDocument12 pagesBRAY F15 Ball ValveRicardoNo ratings yet

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDocument2 pagesFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNo ratings yet

- DFT Brochure HI-100Document16 pagesDFT Brochure HI-100Gilmar A. NogueiraNo ratings yet

- Argus IntroDocument12 pagesArgus IntroJuan HernandezNo ratings yet

- Argus Introduction FlowserveDocument12 pagesArgus Introduction FlowservekuraimundNo ratings yet

- FT - HighPress Check ValveDocument1 pageFT - HighPress Check ValveJamesNo ratings yet

- Valvula Bola 3 Pzas INLINEDocument4 pagesValvula Bola 3 Pzas INLINERicNo ratings yet

- SSTC10 075Document2 pagesSSTC10 075suphanat joomjanNo ratings yet

- Hand Shut-Off Valves: Product Bulletin 80-01 K For Standard and Extended BonnetsDocument20 pagesHand Shut-Off Valves: Product Bulletin 80-01 K For Standard and Extended BonnetsАлександр ЩербаковNo ratings yet

- Noram 1 4 TurnValve ProductSheetDocument2 pagesNoram 1 4 TurnValve ProductSheetjuanjozoppettiNo ratings yet

- High Pressure FiltersDocument92 pagesHigh Pressure FiltersThabangNo ratings yet

- High Pressure FiltersDocument108 pagesHigh Pressure FiltersKristine ReyesNo ratings yet

- High Performance BFV's Buterfly ValveDocument2 pagesHigh Performance BFV's Buterfly ValverajNo ratings yet

- Fisher Globe Valve Selection Guide PDFDocument12 pagesFisher Globe Valve Selection Guide PDFAmiroucheBenlakehalNo ratings yet

- Valtek Maxflo: Control ValvesDocument11 pagesValtek Maxflo: Control Valvessaroat moongwattanaNo ratings yet

- BVC BrochureDocument16 pagesBVC BrochureMOHSINNo ratings yet

- Fanta CatalogoDocument35 pagesFanta CatalogoJohn MacioNo ratings yet

- Caustic Soda Mix Tank PsDocument2 pagesCaustic Soda Mix Tank PsDaniel Pandapotan MarpaungNo ratings yet

- P200 Series: Technical SpecificationDocument2 pagesP200 Series: Technical SpecificationHarry HonchoNo ratings yet

- VST TBV Non-Contact CATALOG 2021-HDDocument7 pagesVST TBV Non-Contact CATALOG 2021-HDJaydeep PanchalNo ratings yet

- Dynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsDocument2 pagesDynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsMohammad ZeeshanNo ratings yet

- HP Bypass Valves Type ARS: ApplicationDocument2 pagesHP Bypass Valves Type ARS: Applicationbb84sharmaNo ratings yet

- D ESD Series Installation&Maintenance PDFDocument20 pagesD ESD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- Flint and Walling Booster PumpDocument4 pagesFlint and Walling Booster Pumpinversiones del peruNo ratings yet

- 2 - Flex Bellow Assembly 304 Stainless - 2 - Stainless Flex Pipe - Ace Race PartsDocument4 pages2 - Flex Bellow Assembly 304 Stainless - 2 - Stainless Flex Pipe - Ace Race Partsait oubella marouaneNo ratings yet

- Van Bư M Tay DN250-500Document8 pagesVan Bư M Tay DN250-500Minh nhut LưuNo ratings yet

- LF310 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF310 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- G5016 G5016BP: Drench Hose Unit, Wall Mounted Drench Hose Unit, Wall Mounted, With Backflow PreventerDocument2 pagesG5016 G5016BP: Drench Hose Unit, Wall Mounted Drench Hose Unit, Wall Mounted, With Backflow Preventerمحمد اصدNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- Rovalve SB 1700 SST Knife Gate Valve 2 - 24 InchDocument4 pagesRovalve SB 1700 SST Knife Gate Valve 2 - 24 InchCapacitacion TodocatNo ratings yet

- Model S0430-AS: Wall Mounted Eyewash, All Stainless SteelDocument2 pagesModel S0430-AS: Wall Mounted Eyewash, All Stainless Steelfranki hari mNo ratings yet

- VST - RSBV Catalog - 2022.R00 (Uc)Document7 pagesVST - RSBV Catalog - 2022.R00 (Uc)Jaydeep PanchalNo ratings yet

- RF Series: Low Pressure FiltersDocument10 pagesRF Series: Low Pressure FiltersRestu OktapianaNo ratings yet

- Valvula Check de Una y MediaDocument1 pageValvula Check de Una y MediaRobertoNo ratings yet

- 500A ATF PB en 211007Document2 pages500A ATF PB en 211007kesakrishnanNo ratings yet

- Description: - Butterfly Valve DN 32 - 900Document8 pagesDescription: - Butterfly Valve DN 32 - 900thehuy015No ratings yet

- Circle Seal ControlsDocument34 pagesCircle Seal Controls朱向斌No ratings yet

- EN12845Brochure PDFDocument4 pagesEN12845Brochure PDFvaisakhpillaiNo ratings yet

- L&J 94020-2BDocument8 pagesL&J 94020-2BBureau VeritasNo ratings yet

- Fire Monitor 611 Nozzle 823bc Spartan CatalogDocument2 pagesFire Monitor 611 Nozzle 823bc Spartan CatalogFajar HidayatNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- Pressure SwitchesDocument4 pagesPressure SwitcheshaggNo ratings yet

- ANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument12 pagesANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- Globe Control Valve: TYPE 3241Document6 pagesGlobe Control Valve: TYPE 3241Mohamed RaafatNo ratings yet

- Certificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IDocument1 pageCertificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IMohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument2 pagesCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

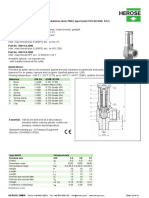

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed Raafat100% (1)

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- Zdocs - Hu 773007136-ADocument1 pageZdocs - Hu 773007136-AMohamed RaafatNo ratings yet

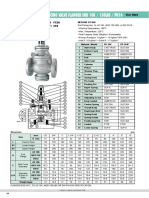

- A64 ANSI150: Flanged Type Ball Valve, Full BoreDocument1 pageA64 ANSI150: Flanged Type Ball Valve, Full BoreMohamed RaafatNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Typ 06011 1 enDocument2 pagesTyp 06011 1 enMohamed RaafatNo ratings yet

- Strainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionDocument3 pagesStrainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- We Know How: Stainless SteelDocument4 pagesWe Know How: Stainless SteelMohamed RaafatNo ratings yet

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument8 pagesDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- Check Valve: Data Sheet 003001 Englisch (English)Document12 pagesCheck Valve: Data Sheet 003001 Englisch (English)Mohamed RaafatNo ratings yet

- 1 - Body Manufactured From Extruded Aluminium Uni 6060Document3 pages1 - Body Manufactured From Extruded Aluminium Uni 6060Mohamed RaafatNo ratings yet

- KK 821 enDocument9 pagesKK 821 enMohamed RaafatNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Pressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Document1 pagePressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Mohamed RaafatNo ratings yet

- Leser Transmittal (EN)Document1 pageLeser Transmittal (EN)Mohamed RaafatNo ratings yet

- SKF WhitePaper Grease AnalysisDocument10 pagesSKF WhitePaper Grease AnalysisedgarpolNo ratings yet

- 9A L36 Phiếu BTDocument10 pages9A L36 Phiếu BTDiệu Anh Nguyễn ThịNo ratings yet

- Water Quantity EstimationDocument13 pagesWater Quantity EstimationAhsan Khan100% (4)

- Sedimentation BasinsDocument14 pagesSedimentation Basinsفردوس سليمانNo ratings yet

- Lagoon Design Guidelines, ManitobaDocument7 pagesLagoon Design Guidelines, ManitobaObaid Ur RehmanNo ratings yet

- Urbanization in Developing Countries (Cohen) PDFDocument18 pagesUrbanization in Developing Countries (Cohen) PDFrammyaaNo ratings yet

- Classification of Matter and ChangesDocument25 pagesClassification of Matter and ChangesainulavidaNo ratings yet

- Part 1 Site Selection Planning (In English)Document40 pagesPart 1 Site Selection Planning (In English)Ronald StephenNo ratings yet

- Technical SpecificationsDocument142 pagesTechnical SpecificationsNaveen NagisettiNo ratings yet

- Factors That Affect ClimateDocument3 pagesFactors That Affect Climateapi-323831182No ratings yet

- Retaining Walls and Steep Reinforced Slopes: 730.01 GeneralDocument32 pagesRetaining Walls and Steep Reinforced Slopes: 730.01 GeneralMina AdlyNo ratings yet

- Gorlov Helical Wind TurbineDocument4 pagesGorlov Helical Wind TurbineRhondaNo ratings yet

- Biogas Boiler DesignDocument6 pagesBiogas Boiler DesignEyosyas NathanNo ratings yet

- Thermal Pollution, Pollution Due To OilslickDocument18 pagesThermal Pollution, Pollution Due To OilslickSartsdfsdgNo ratings yet

- USEPA Phenol - 4-Aminoantipyrine MethodDocument8 pagesUSEPA Phenol - 4-Aminoantipyrine MethodSH KowNo ratings yet

- N13: Sanitware N13/311: Architectural Standards Product Data SheetDocument1 pageN13: Sanitware N13/311: Architectural Standards Product Data SheetNay Win MaungNo ratings yet

- Chalamaih - CRITICAL ANALYSIS OF LIFT IRRIGATION SCHEMES or OPTIMAL MANAGEMENT OF RESOURCESDocument168 pagesChalamaih - CRITICAL ANALYSIS OF LIFT IRRIGATION SCHEMES or OPTIMAL MANAGEMENT OF RESOURCESSoham SantraNo ratings yet

- CVP222 Falling Head Permeability TestDocument9 pagesCVP222 Falling Head Permeability Testjayantgupta28110No ratings yet

- Analysis of Salt Deposits From Keana LGA, Nassarawa State, NigeriaDocument11 pagesAnalysis of Salt Deposits From Keana LGA, Nassarawa State, NigeriaMusa Balarabe AbdullahiNo ratings yet

- Standard For Colour Coding of Pipework For Identification of Fluids & ServicesDocument13 pagesStandard For Colour Coding of Pipework For Identification of Fluids & Servicessudeesh kumarNo ratings yet

- Com R5-Solar EnergyDocument3 pagesCom R5-Solar EnergyTriệu Vi NguyễnNo ratings yet

- FP - Spec - 12 - Ilham Dharmawan Putra - Preliminary Study of Geotourism Plans in Geothermal Area A CaseDocument12 pagesFP - Spec - 12 - Ilham Dharmawan Putra - Preliminary Study of Geotourism Plans in Geothermal Area A CaseamiruddinNo ratings yet

- Water Resource Management Grease Trap Size Calculation Data SheetDocument1 pageWater Resource Management Grease Trap Size Calculation Data SheetsenghouNo ratings yet

- BS en 1329 PDFDocument16 pagesBS en 1329 PDFg_trifonovNo ratings yet

- Final Report 5Document5 pagesFinal Report 5Alyssa OrtegaNo ratings yet

- Cemcrete Waterproofing Overview BrochureDocument7 pagesCemcrete Waterproofing Overview BrochureJoão Athayde e MeloNo ratings yet

- Metodos Análisis OIV Vol 2Document416 pagesMetodos Análisis OIV Vol 2sevt2No ratings yet

- Tips For Fishing by Canoe & Canoe Country Nature Guide BookDocument52 pagesTips For Fishing by Canoe & Canoe Country Nature Guide BookChristopher RichardsonNo ratings yet

- Bea and Johnson ReportDocument124 pagesBea and Johnson ReportBayAreaNewsGroup100% (2)

FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 Psig

FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 Psig

Uploaded by

Mohamed RaafatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 Psig

FTC80-FB: Ball Float Steam Trap For Pressures Up To 1160 Psig

Uploaded by

Mohamed RaafatCopyright:

Available Formats

spiraxsarco.

com/global/us

FTC80-FB

ball float steam trap for pressures up to 1160 psig

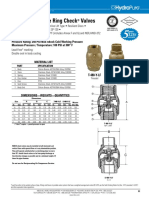

Rugged float construction

Fixed bleed air vent

Provision for lifting eye

Balanced lever &

float mechanism

Inlet connection

Crush resistant

Outlet discharge Integral strainer

connection Single seat made Drain screen

of Titanium

The FTC80-FB has been designed as a premium solution for process

applications in the chemical and hydrocarbon processing industry where

pressures can be as high as 1160 psig.

Key features:

• Self-modulating mechanism to provide soft and continuous • Constant water seal design to eliminate steam losses under

discharge, which helps to maintain stable process conditions. low-load conditions.

• Built-in, innovative strainer screen with 50% more surface area • Tight shut-off under no-load conditions, even if water seal is

to ensure extended trouble free service (Patent pending). lost, prevents steam wastage.

• Easy, in-line access to internal parts to simplify cleaning, and • Single seat manufactured from Titanium to ensure tight shut-off

lower maintenance costs. and extended service life.

• Incorporates a counter-balanced lever and float mechanism,

which makes the design compact (Patent Pending).

Steam applications up to 1160 psig:

• Drainage of process equipment including Distillation reboilers, Air heating coils, Reactors, Evaporators and

Process heat exchangers.

• Separator drainage.

• Steam turbine drainage.

FTC80-FB options

The FTC80 ball float steam trap is cast steel bodied, designed for pressures up to 1160 psig. The standard FTC80-

FB is available with the following connections (other connections are available upon request but may be subject to

extended delivery):

Pipeline connection Flanged ASME (ANSI) 600 Socket weld

Condensate inlet 1½” or 2” DN40 (1½”) or DN50 (2”)

Condensate outlet 1½” or 2” DN40 (1½”) or DN50 (2”)

Standard orientation Standard orientation

Flow direction

Right to left Right to left

Drain 3/ 8” screwed NPT with a plug 3/ 8” screwed NPT with a plug

Differential pressure 652 psig, 900 psig or 1131 psig 652 psig, 900 psig or 1160 psig

Connections suitable for lifting eyes ½” UNC x 2 ½” UNC x 2

Note that operating pressure is limited to 1131 psig with ASME (ANSI) 600 flanges.

Other options available upon request:

• Flow direction – Left to right.

• Condensate inlet / outlet connections – Screwed NPT or BSP, But weld, Flanged ASME (ANSI) Class 300 / 900,

PN63, JIS/KS 20 / 40, Ring type joint.

Spirax Sarco, Inc.

1150 Northpoint Blvd., Blythewood, SC 29016

T 1-800-883-4411

spiraxsarco.com/global/us

© Copyright 2016 Spirax Sarco is a registered trademark of Spirax-Sarco Limited

You might also like

- Rachel Mitchell Task 1Document1,003 pagesRachel Mitchell Task 1nazmul Hasan100% (1)

- Manual Do BOP IEDocument18 pagesManual Do BOP IEandre vidal100% (1)

- Inspection Certificate Leser CGA (EN)Document3 pagesInspection Certificate Leser CGA (EN)Mohamed RaafatNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Hydrant SystemDocument10 pagesHydrant SystemSheikh Faiz RockerNo ratings yet

- IMI CCI Product 840seriesDocument4 pagesIMI CCI Product 840seriesArdhi WibowoNo ratings yet

- 840 SeriesDocument4 pages840 SeriesKarim Abd Al-RahimNo ratings yet

- Tyco Valves & Controls CatalogDocument6 pagesTyco Valves & Controls CatalogHasanNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- Fracking DunlopDocument4 pagesFracking DunlopLeo@spNo ratings yet

- HD 175 Varsha HF30Document2 pagesHD 175 Varsha HF30ANAS GOGAZEHNo ratings yet

- Mcnichols Trench Drain Systems SpecsDocument3 pagesMcnichols Trench Drain Systems SpecsRobert CashNo ratings yet

- Double Offset High Performance Butterfly Valves: DescriptionDocument16 pagesDouble Offset High Performance Butterfly Valves: Descriptionmanmohansingh1999No ratings yet

- Apollo-HP 215L-215WDocument16 pagesApollo-HP 215L-215WDaniel SanNo ratings yet

- FLUSH BOTTOM VALVE SERIES 500nDocument5 pagesFLUSH BOTTOM VALVE SERIES 500nvedant.pokharkarNo ratings yet

- Jamesbury 3000Document4 pagesJamesbury 3000jacquesstrappe06No ratings yet

- Watsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapDocument2 pagesWatsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapbudi utomoNo ratings yet

- BRAY F15 Ball ValveDocument12 pagesBRAY F15 Ball ValveRicardoNo ratings yet

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDocument2 pagesFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNo ratings yet

- DFT Brochure HI-100Document16 pagesDFT Brochure HI-100Gilmar A. NogueiraNo ratings yet

- Argus IntroDocument12 pagesArgus IntroJuan HernandezNo ratings yet

- Argus Introduction FlowserveDocument12 pagesArgus Introduction FlowservekuraimundNo ratings yet

- FT - HighPress Check ValveDocument1 pageFT - HighPress Check ValveJamesNo ratings yet

- Valvula Bola 3 Pzas INLINEDocument4 pagesValvula Bola 3 Pzas INLINERicNo ratings yet

- SSTC10 075Document2 pagesSSTC10 075suphanat joomjanNo ratings yet

- Hand Shut-Off Valves: Product Bulletin 80-01 K For Standard and Extended BonnetsDocument20 pagesHand Shut-Off Valves: Product Bulletin 80-01 K For Standard and Extended BonnetsАлександр ЩербаковNo ratings yet

- Noram 1 4 TurnValve ProductSheetDocument2 pagesNoram 1 4 TurnValve ProductSheetjuanjozoppettiNo ratings yet

- High Pressure FiltersDocument92 pagesHigh Pressure FiltersThabangNo ratings yet

- High Pressure FiltersDocument108 pagesHigh Pressure FiltersKristine ReyesNo ratings yet

- High Performance BFV's Buterfly ValveDocument2 pagesHigh Performance BFV's Buterfly ValverajNo ratings yet

- Fisher Globe Valve Selection Guide PDFDocument12 pagesFisher Globe Valve Selection Guide PDFAmiroucheBenlakehalNo ratings yet

- Valtek Maxflo: Control ValvesDocument11 pagesValtek Maxflo: Control Valvessaroat moongwattanaNo ratings yet

- BVC BrochureDocument16 pagesBVC BrochureMOHSINNo ratings yet

- Fanta CatalogoDocument35 pagesFanta CatalogoJohn MacioNo ratings yet

- Caustic Soda Mix Tank PsDocument2 pagesCaustic Soda Mix Tank PsDaniel Pandapotan MarpaungNo ratings yet

- P200 Series: Technical SpecificationDocument2 pagesP200 Series: Technical SpecificationHarry HonchoNo ratings yet

- VST TBV Non-Contact CATALOG 2021-HDDocument7 pagesVST TBV Non-Contact CATALOG 2021-HDJaydeep PanchalNo ratings yet

- Dynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsDocument2 pagesDynaflo 6220 / 6230 Model Numbers: 62201, 62203 & 62303: Transfer PumpsMohammad ZeeshanNo ratings yet

- HP Bypass Valves Type ARS: ApplicationDocument2 pagesHP Bypass Valves Type ARS: Applicationbb84sharmaNo ratings yet

- D ESD Series Installation&Maintenance PDFDocument20 pagesD ESD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- Flint and Walling Booster PumpDocument4 pagesFlint and Walling Booster Pumpinversiones del peruNo ratings yet

- 2 - Flex Bellow Assembly 304 Stainless - 2 - Stainless Flex Pipe - Ace Race PartsDocument4 pages2 - Flex Bellow Assembly 304 Stainless - 2 - Stainless Flex Pipe - Ace Race Partsait oubella marouaneNo ratings yet

- Van Bư M Tay DN250-500Document8 pagesVan Bư M Tay DN250-500Minh nhut LưuNo ratings yet

- LF310 Datasheet: Low-Flow Pressure RegulatorDocument4 pagesLF310 Datasheet: Low-Flow Pressure RegulatorIdehen KelvinNo ratings yet

- G5016 G5016BP: Drench Hose Unit, Wall Mounted Drench Hose Unit, Wall Mounted, With Backflow PreventerDocument2 pagesG5016 G5016BP: Drench Hose Unit, Wall Mounted Drench Hose Unit, Wall Mounted, With Backflow Preventerمحمد اصدNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- Rovalve SB 1700 SST Knife Gate Valve 2 - 24 InchDocument4 pagesRovalve SB 1700 SST Knife Gate Valve 2 - 24 InchCapacitacion TodocatNo ratings yet

- Model S0430-AS: Wall Mounted Eyewash, All Stainless SteelDocument2 pagesModel S0430-AS: Wall Mounted Eyewash, All Stainless Steelfranki hari mNo ratings yet

- VST - RSBV Catalog - 2022.R00 (Uc)Document7 pagesVST - RSBV Catalog - 2022.R00 (Uc)Jaydeep PanchalNo ratings yet

- RF Series: Low Pressure FiltersDocument10 pagesRF Series: Low Pressure FiltersRestu OktapianaNo ratings yet

- Valvula Check de Una y MediaDocument1 pageValvula Check de Una y MediaRobertoNo ratings yet

- 500A ATF PB en 211007Document2 pages500A ATF PB en 211007kesakrishnanNo ratings yet

- Description: - Butterfly Valve DN 32 - 900Document8 pagesDescription: - Butterfly Valve DN 32 - 900thehuy015No ratings yet

- Circle Seal ControlsDocument34 pagesCircle Seal Controls朱向斌No ratings yet

- EN12845Brochure PDFDocument4 pagesEN12845Brochure PDFvaisakhpillaiNo ratings yet

- L&J 94020-2BDocument8 pagesL&J 94020-2BBureau VeritasNo ratings yet

- Fire Monitor 611 Nozzle 823bc Spartan CatalogDocument2 pagesFire Monitor 611 Nozzle 823bc Spartan CatalogFajar HidayatNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- Pressure SwitchesDocument4 pagesPressure SwitcheshaggNo ratings yet

- ANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument12 pagesANSI Version: T 8012 EN Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- Globe Control Valve: TYPE 3241Document6 pagesGlobe Control Valve: TYPE 3241Mohamed RaafatNo ratings yet

- Certificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IDocument1 pageCertificate of Origin: LH It Fai Ic:Ipal J:Ccfess J:J C'TRLL SJR C001 I I U R!:.IMohamed RaafatNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument2 pagesCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed Raafat100% (1)

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- Type 06011 - Gastight: Safety ValvesDocument2 pagesType 06011 - Gastight: Safety ValvesMohamed Raafat100% (1)

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- Zdocs - Hu 773007136-ADocument1 pageZdocs - Hu 773007136-AMohamed RaafatNo ratings yet

- A64 ANSI150: Flanged Type Ball Valve, Full BoreDocument1 pageA64 ANSI150: Flanged Type Ball Valve, Full BoreMohamed RaafatNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Typ 06011 1 enDocument2 pagesTyp 06011 1 enMohamed RaafatNo ratings yet

- Strainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionDocument3 pagesStrainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- We Know How: Stainless SteelDocument4 pagesWe Know How: Stainless SteelMohamed RaafatNo ratings yet

- DIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveDocument8 pagesDIN Version: T 8015 EN Series 240 Type 3241-1 and Type 3241-7 Pneumatic Control Valves Type 3241 Globe ValveMohamed RaafatNo ratings yet

- Check Valve: Data Sheet 003001 Englisch (English)Document12 pagesCheck Valve: Data Sheet 003001 Englisch (English)Mohamed RaafatNo ratings yet

- 1 - Body Manufactured From Extruded Aluminium Uni 6060Document3 pages1 - Body Manufactured From Extruded Aluminium Uni 6060Mohamed RaafatNo ratings yet

- KK 821 enDocument9 pagesKK 821 enMohamed RaafatNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Pressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Document1 pagePressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Mohamed RaafatNo ratings yet

- Leser Transmittal (EN)Document1 pageLeser Transmittal (EN)Mohamed RaafatNo ratings yet

- SKF WhitePaper Grease AnalysisDocument10 pagesSKF WhitePaper Grease AnalysisedgarpolNo ratings yet

- 9A L36 Phiếu BTDocument10 pages9A L36 Phiếu BTDiệu Anh Nguyễn ThịNo ratings yet

- Water Quantity EstimationDocument13 pagesWater Quantity EstimationAhsan Khan100% (4)

- Sedimentation BasinsDocument14 pagesSedimentation Basinsفردوس سليمانNo ratings yet

- Lagoon Design Guidelines, ManitobaDocument7 pagesLagoon Design Guidelines, ManitobaObaid Ur RehmanNo ratings yet

- Urbanization in Developing Countries (Cohen) PDFDocument18 pagesUrbanization in Developing Countries (Cohen) PDFrammyaaNo ratings yet

- Classification of Matter and ChangesDocument25 pagesClassification of Matter and ChangesainulavidaNo ratings yet

- Part 1 Site Selection Planning (In English)Document40 pagesPart 1 Site Selection Planning (In English)Ronald StephenNo ratings yet

- Technical SpecificationsDocument142 pagesTechnical SpecificationsNaveen NagisettiNo ratings yet

- Factors That Affect ClimateDocument3 pagesFactors That Affect Climateapi-323831182No ratings yet

- Retaining Walls and Steep Reinforced Slopes: 730.01 GeneralDocument32 pagesRetaining Walls and Steep Reinforced Slopes: 730.01 GeneralMina AdlyNo ratings yet

- Gorlov Helical Wind TurbineDocument4 pagesGorlov Helical Wind TurbineRhondaNo ratings yet

- Biogas Boiler DesignDocument6 pagesBiogas Boiler DesignEyosyas NathanNo ratings yet

- Thermal Pollution, Pollution Due To OilslickDocument18 pagesThermal Pollution, Pollution Due To OilslickSartsdfsdgNo ratings yet

- USEPA Phenol - 4-Aminoantipyrine MethodDocument8 pagesUSEPA Phenol - 4-Aminoantipyrine MethodSH KowNo ratings yet

- N13: Sanitware N13/311: Architectural Standards Product Data SheetDocument1 pageN13: Sanitware N13/311: Architectural Standards Product Data SheetNay Win MaungNo ratings yet

- Chalamaih - CRITICAL ANALYSIS OF LIFT IRRIGATION SCHEMES or OPTIMAL MANAGEMENT OF RESOURCESDocument168 pagesChalamaih - CRITICAL ANALYSIS OF LIFT IRRIGATION SCHEMES or OPTIMAL MANAGEMENT OF RESOURCESSoham SantraNo ratings yet

- CVP222 Falling Head Permeability TestDocument9 pagesCVP222 Falling Head Permeability Testjayantgupta28110No ratings yet

- Analysis of Salt Deposits From Keana LGA, Nassarawa State, NigeriaDocument11 pagesAnalysis of Salt Deposits From Keana LGA, Nassarawa State, NigeriaMusa Balarabe AbdullahiNo ratings yet

- Standard For Colour Coding of Pipework For Identification of Fluids & ServicesDocument13 pagesStandard For Colour Coding of Pipework For Identification of Fluids & Servicessudeesh kumarNo ratings yet

- Com R5-Solar EnergyDocument3 pagesCom R5-Solar EnergyTriệu Vi NguyễnNo ratings yet

- FP - Spec - 12 - Ilham Dharmawan Putra - Preliminary Study of Geotourism Plans in Geothermal Area A CaseDocument12 pagesFP - Spec - 12 - Ilham Dharmawan Putra - Preliminary Study of Geotourism Plans in Geothermal Area A CaseamiruddinNo ratings yet

- Water Resource Management Grease Trap Size Calculation Data SheetDocument1 pageWater Resource Management Grease Trap Size Calculation Data SheetsenghouNo ratings yet

- BS en 1329 PDFDocument16 pagesBS en 1329 PDFg_trifonovNo ratings yet

- Final Report 5Document5 pagesFinal Report 5Alyssa OrtegaNo ratings yet

- Cemcrete Waterproofing Overview BrochureDocument7 pagesCemcrete Waterproofing Overview BrochureJoão Athayde e MeloNo ratings yet

- Metodos Análisis OIV Vol 2Document416 pagesMetodos Análisis OIV Vol 2sevt2No ratings yet

- Tips For Fishing by Canoe & Canoe Country Nature Guide BookDocument52 pagesTips For Fishing by Canoe & Canoe Country Nature Guide BookChristopher RichardsonNo ratings yet

- Bea and Johnson ReportDocument124 pagesBea and Johnson ReportBayAreaNewsGroup100% (2)