Professional Documents

Culture Documents

2017 - Formulation & Adjuvant Technology 21

2017 - Formulation & Adjuvant Technology 21

Uploaded by

Catherine TangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2017 - Formulation & Adjuvant Technology 21

2017 - Formulation & Adjuvant Technology 21

Uploaded by

Catherine TangCopyright:

Available Formats

Did you know?

VIEWPOINT

Adjuvants can be spreaders, stickers,

that the pesticide is distributed evenly and activators, or even drift control agents.

delivered properly for end use. TOFA and

TO also soften the waxy leaf surface to

improve penetration of the active ingredient.

What’s the difference between TOFA and TO? At Ingevity Corp., a rain fastness

lab test was carried out to evaluate the

A major difference between TOFA and TO is the rosin content. While TOFA consists performance of a terpene resin-based

of 1 to 5 percent rosin, TO usually has about 10 to 28 percent rosin. This composition sticker-spreader in the presence of an

difference can be utilised to tailor physical and performance properties, such as viscosity herbicide formulation. The level of active

and emulsion stability. In general, higher amounts of rosin lead to slightly higher viscosity of ingredient that remains on the surface

the compound and improved emulsification of the formulation. The agrochemical industry after the rain was determined was

typically uses TOFA. However, TO allows better emulsion stability, particularly under hard characterised by percent retention. A strip

water conditions (see Figure 2 below). of parafilm with a fixed surface area was

TOFA can also be esterified using methanol or other alkyl alcohols. TOFA esters selected to mimic the hydrophobic leaf

have a lower freezing point, compared to the acids that allow TOFA esters to be utilized surface. Rain was simulated by dipping

as solvents in both adjuvants and pesticides. TOFA esters have lower volatile organic the strip multiple times into water. The

compound (VOC) values than some petroleum-based solvents. Alternatively, TOFA can be addition of sticker-spreader to pesticide

ethoxylated and act as a non-ionic surfactant. Hydrophile-lipophile balance (HLB) values increased the retention by 30 percent,

can be varied by altering molar ratios of ethoxylate. thus increasing the pesticide’s efficacy

TOFA and TO aren’t the only “green” chemistries derived from the pine tree (see Figure 3 below).

Another important intermediate derived from the pine tree pulping process is turpentine.

It can be distilled and polymerized to yield terpene resin, which is sticky in nature and can

“Green” and effective

provide adhesion properties to pesticides. It acts as a glue between the pesticides and the

leaf surfaces. Due to the hydrophobicity of this sticky terpene resin, surfactants must be Bio-based chemistry can and does

formulated with this sticker to render an emulsifiable product. In the adjuvant space, these work. It is possible to ensure efficiency

surfactants are also known as spreaders. from naturally-sourced ingredients. From

Your active ingredients must stick TO emulsifiers to penetrants to terpene-

One of the challenges in pesticide application is that the active ingredients are washed based stickers, bio-based products

off from the leaf surface, which reduces efficacy. This occurs, as most spray solutions or provide significant benefits. If you’re ready

suspensions are water-based and have low affinity to waxy or hydrophobic leaf surfaces. to take the leap into the world of bio-based

Therefore, spray solutions or suspensions can easily bead up and run off under physical chemistry, contact us at chemicals@

forces, such as irrigation and rain. A sticker-spreader is a type of adjuvant developed to ingevity.com so we can pair you up

improve retention of pesticides on foliage, especially under rainy conditions. with the right chemistry for your unique

formulation.

Figure 3. Percent retention of an herbicide and

Figure 2. Emulsion stability of crop oil concentrates in hard water (1000 ppm) with TOFA and TO herbicide with sticker-spreader

www.agropages.com 2017 Formulation & Adjuvant Technology 19

You might also like

- Virtual Lab Physical or Chemical ChangeDocument2 pagesVirtual Lab Physical or Chemical ChangeAustin Williams83% (6)

- Flexo and Gravure Inks FormulationDocument14 pagesFlexo and Gravure Inks FormulationMd Ali RazuNo ratings yet

- Lubrizol Product GuideDocument0 pagesLubrizol Product GuidedineshdesaiNo ratings yet

- OCR Chemistry A: 4 Acids and Redox Exam-Style Mark SchemeDocument3 pagesOCR Chemistry A: 4 Acids and Redox Exam-Style Mark Schemenoreen doraniNo ratings yet

- Tegomer Da 640 0419 en Oi PiDocument2 pagesTegomer Da 640 0419 en Oi Piهیمن مNo ratings yet

- 2017 - Formulation & Adjuvant Technology 20Document1 page2017 - Formulation & Adjuvant Technology 20Catherine TangNo ratings yet

- Adjuvant Products Guide: Brandt Consolidated, IncDocument4 pagesAdjuvant Products Guide: Brandt Consolidated, IncAlejandro Herrnsdorf-SakellaridisNo ratings yet

- Dow SurfactantsDocument12 pagesDow Surfactantsv100% (1)

- Tytan - BoricaDocument3 pagesTytan - BoricaAnas AbdollahNo ratings yet

- AdjuvantsDocument16 pagesAdjuvantsrahulNo ratings yet

- Fluorinated Surfactant and RepellentDocument16 pagesFluorinated Surfactant and RepellentHadi FauziNo ratings yet

- WILFAMES-Brochure-MES ImportantDocument3 pagesWILFAMES-Brochure-MES ImportantMuhammad Iqbal ChandioNo ratings yet

- Agricultural Spray AdjuvantsDocument5 pagesAgricultural Spray AdjuvantscarlosNo ratings yet

- Adjuvants - A Guide To Oils, Surfactants & Other AdditivesDocument4 pagesAdjuvants - A Guide To Oils, Surfactants & Other AdditivesSetfree NkomoNo ratings yet

- Kobo Surface Treated Pigments and Powders Combined June2015Document9 pagesKobo Surface Treated Pigments and Powders Combined June2015anuyasane9776No ratings yet

- TDS-447 Fragrance With FixateDocument9 pagesTDS-447 Fragrance With FixateNada PetrovićNo ratings yet

- Terpenos para Estimula, Control Arena y Cementa-BjDocument8 pagesTerpenos para Estimula, Control Arena y Cementa-BjHebert FerneynesNo ratings yet

- Fixapret Resin F-ECO Plus: Technical InformationDocument5 pagesFixapret Resin F-ECO Plus: Technical Informationali4300136No ratings yet

- FRGEL 125 SINO - JDDocument1 pageFRGEL 125 SINO - JDDaniel QiuNo ratings yet

- Brochure Additives For Pesticide FormulationslDocument24 pagesBrochure Additives For Pesticide FormulationslMostafa FawzyNo ratings yet

- 0901b8038005c60e PDFDocument12 pages0901b8038005c60e PDFfsfNo ratings yet

- Adjuvant SDocument33 pagesAdjuvant SNugroho HartonoNo ratings yet

- TT 236Document4 pagesTT 236Albert hikerNo ratings yet

- Formulasi PestisidaDocument33 pagesFormulasi PestisidaFayyadh AnugerahNo ratings yet

- Pesticide Formulations - Chapter 3Document11 pagesPesticide Formulations - Chapter 3Zahid JavedNo ratings yet

- Sustainable Development of Natural Rubber and Its Environmentally Friendly CompositesDocument6 pagesSustainable Development of Natural Rubber and Its Environmentally Friendly CompositesyixuanstarNo ratings yet

- MITM12333Document3 pagesMITM12333anshul2106No ratings yet

- C E P E P: Olorado Nvironmental Esticide Ducation RogramDocument2 pagesC E P E P: Olorado Nvironmental Esticide Ducation RogramKevin EsmunaldoNo ratings yet

- TDS FennoPol K 9805 ENDocument1 pageTDS FennoPol K 9805 ENCarlos UngarettiNo ratings yet

- BASF Rheovis PU 1331Document2 pagesBASF Rheovis PU 1331seydolackNo ratings yet

- Bentone 34: Rheological Additive For Low To Intermediate Polarity Organic SystemsDocument2 pagesBentone 34: Rheological Additive For Low To Intermediate Polarity Organic Systemsمحمد مقلدNo ratings yet

- 巴斯夫抗氧剂irganox 5057产品技术资料 宝旭化工Document2 pages巴斯夫抗氧剂irganox 5057产品技术资料 宝旭化工naziri2008No ratings yet

- Technical BrochureDocument12 pagesTechnical BrochureKutluay KabadayıNo ratings yet

- Use of Polysulfone in Controlled-Release NPK Fertilizer FormulationsDocument6 pagesUse of Polysulfone in Controlled-Release NPK Fertilizer FormulationsEsperanza SalazarNo ratings yet

- Deuteron WAX ADDITIVESDocument4 pagesDeuteron WAX ADDITIVESLluís HNo ratings yet

- Dispol A40 TdsDocument1 pageDispol A40 TdsckarantoniNo ratings yet

- DS Tegopren 5878 0715Document2 pagesDS Tegopren 5878 0715Wessel WesselsNo ratings yet

- Practical Guide To AdjuvantsDocument5 pagesPractical Guide To AdjuvantsDavid SilverNo ratings yet

- Pesticide FormulationsDocument16 pagesPesticide FormulationsChau VanlamNo ratings yet

- Surf Act Ant ToolkitDocument9 pagesSurf Act Ant ToolkitDuggirala Srinivas MurtyNo ratings yet

- Acrysol rm-8w 3Document4 pagesAcrysol rm-8w 3Forever0% (1)

- A New APEO-free Surfactant Solution For The Paint - SolvayDocument24 pagesA New APEO-free Surfactant Solution For The Paint - Solvayichsan hakimNo ratings yet

- 49 Vol. 9 Issue 6 June 2018 IJPSR RA 9182Document5 pages49 Vol. 9 Issue 6 June 2018 IJPSR RA 9182contact.vbplNo ratings yet

- Anthyr PaprfeDocument29 pagesAnthyr PaprfeJOVAN HILMANSYAHNo ratings yet

- Non Ionic SurfactantsDocument12 pagesNon Ionic Surfactantsmissjj0% (2)

- HATM 11 FormAdjvDocument6 pagesHATM 11 FormAdjvcristian alvezNo ratings yet

- Dermosoft 1388 ECO. Product Info. 04.01.19Document6 pagesDermosoft 1388 ECO. Product Info. 04.01.19sairaNo ratings yet

- Recommend An Article: Home ArticlesDocument3 pagesRecommend An Article: Home ArticlesKumar GalipellyNo ratings yet

- Composition of Suspension and Suspending Agents.Document4 pagesComposition of Suspension and Suspending Agents.hira khanNo ratings yet

- Thixatrol P200X: Anti-Sagging & Anti-Settling Thixotropic Agent For Solvent Based CoatingsDocument2 pagesThixatrol P200X: Anti-Sagging & Anti-Settling Thixotropic Agent For Solvent Based CoatingsViona WidyaNo ratings yet

- Elementis Bentone 27 TdsDocument2 pagesElementis Bentone 27 Tdsmgamal1080No ratings yet

- Polyurea HUNTSMANDocument9 pagesPolyurea HUNTSMANTom AxturbNo ratings yet

- Irganox+1076 TDS ENDocument3 pagesIrganox+1076 TDS ENDanny NinhNo ratings yet

- AS FT Fixed GroDocument1 pageAS FT Fixed GroLaurel NicolásNo ratings yet

- Kathon LXDocument15 pagesKathon LXIvanovich RuizNo ratings yet

- Tds Lurapret Dispersion D 2337 EngDocument4 pagesTds Lurapret Dispersion D 2337 EngRoking KumarNo ratings yet

- Agricultural Tank Mix Adjuvants: Standard Terminology Relating ToDocument2 pagesAgricultural Tank Mix Adjuvants: Standard Terminology Relating ToROHITNo ratings yet

- Lithopone Is A White Pigment Composed of A Mixture of Barium SulfateDocument4 pagesLithopone Is A White Pigment Composed of A Mixture of Barium SulfateBenjamin PangihutanNo ratings yet

- Basonat HW 1180 PC - TDS - 30734857 - ENDocument2 pagesBasonat HW 1180 PC - TDS - 30734857 - ENI Love MusicNo ratings yet

- Sundry Chemicals Technical Data SheetDocument4 pagesSundry Chemicals Technical Data SheetDavid BellotaNo ratings yet

- Terpenoids: Recent Advances in Extraction, Biochemistry and BiotechnologyFrom EverandTerpenoids: Recent Advances in Extraction, Biochemistry and BiotechnologyNo ratings yet

- Agropage - 2019 Review 68Document1 pageAgropage - 2019 Review 68Catherine TangNo ratings yet

- Agropage - 2019 Review 67Document1 pageAgropage - 2019 Review 67Catherine TangNo ratings yet

- Agropage - 2019 Review 78Document1 pageAgropage - 2019 Review 78Catherine TangNo ratings yet

- Agropage - 2019 Review 77Document1 pageAgropage - 2019 Review 77Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 41Document1 page2021 - Seedtreatment Agropages 41Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 43Document1 page2021 - Seedtreatment Agropages 43Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 45Document1 page2021 - Seedtreatment Agropages 45Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 42Document1 page2021 - Seedtreatment Agropages 42Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 40Document1 page2021 - Seedtreatment Agropages 40Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 37Document1 page2021 - Seedtreatment Agropages 37Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 39Document1 page2021 - Seedtreatment Agropages 39Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 31Document1 page2021 - Seedtreatment Agropages 31Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 32Document1 page2021 - Seedtreatment Agropages 32Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 30Document1 page2021 - Seedtreatment Agropages 30Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 18Document1 page2021 - Seedtreatment Agropages 18Catherine TangNo ratings yet

- 2021 - Seedtreatment Agropages 19Document1 page2021 - Seedtreatment Agropages 19Catherine TangNo ratings yet

- Edelstein, F., & Haslett, R. (1974) - Heat Pipe Manufacturing Study. Grumann Aerospace Corporation, Bethpage, New York.Document320 pagesEdelstein, F., & Haslett, R. (1974) - Heat Pipe Manufacturing Study. Grumann Aerospace Corporation, Bethpage, New York.pathiNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- Thermal Shock and Thermal Fatigue On Delamination of Glass Fiber Reinforced Polymeric CompositesDocument14 pagesThermal Shock and Thermal Fatigue On Delamination of Glass Fiber Reinforced Polymeric CompositesSuresh KumarNo ratings yet

- RNR ListDocument46 pagesRNR ListvihasiNo ratings yet

- Evaluation of ShampoosDocument2 pagesEvaluation of ShampoosJai MurugeshNo ratings yet

- International Journal of PharmaceuticsDocument8 pagesInternational Journal of PharmaceuticsTrupti Powar WadkarNo ratings yet

- Mineral Ganetik BatuanDocument11 pagesMineral Ganetik BatuanASHERNo ratings yet

- Cambridge IGCSE: Combined Science 0653/23Document16 pagesCambridge IGCSE: Combined Science 0653/23annwong85No ratings yet

- EM24-001-P - Evermin - Morocco ZNPB Bulk Conc - 209,92 WMT Contract Last VersionDocument5 pagesEM24-001-P - Evermin - Morocco ZNPB Bulk Conc - 209,92 WMT Contract Last VersionSalamat KhadijaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJaineshNo ratings yet

- Toba1991 PDFDocument6 pagesToba1991 PDFGepetto ArtsNo ratings yet

- Efficient Hydrolysis of Raw Starch and Ethanol FerDocument19 pagesEfficient Hydrolysis of Raw Starch and Ethanol FerLucas DuarteNo ratings yet

- New Age' Caatalogue PDFDocument25 pagesNew Age' Caatalogue PDFajitphadkuleNo ratings yet

- Lecture - 7-8Document19 pagesLecture - 7-8Amierson TilendoNo ratings yet

- Nanocomposites: Synthesis, Structure, Properties and New Application OpportunitiesDocument40 pagesNanocomposites: Synthesis, Structure, Properties and New Application OpportunitiesAbi Warseno100% (1)

- Unit 2 Part BDocument56 pagesUnit 2 Part B소피아No ratings yet

- Syllabus Bs ChemistryDocument6 pagesSyllabus Bs ChemistryWaqas LuckyNo ratings yet

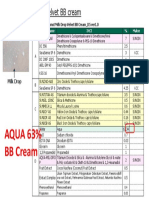

- Coconut Milk Drop Velvet BB CreamDocument1 pageCoconut Milk Drop Velvet BB CreamSandieNo ratings yet

- Working in Confined Spaces: SWP-013 D1Document6 pagesWorking in Confined Spaces: SWP-013 D1Cms Stl CmsNo ratings yet

- 6fm200se X PDFDocument2 pages6fm200se X PDFMarco Antonio Mayta ZubizarretaNo ratings yet

- Concrete Repair & Restoration (Sika)Document37 pagesConcrete Repair & Restoration (Sika)Dinn Ns100% (2)

- prc-5002 CurrentDocument10 pagesprc-5002 CurrentCONVEYOR SYSTEMSNo ratings yet

- Water Heater Catalogue 2019 PDFDocument32 pagesWater Heater Catalogue 2019 PDFHarshit SharmaNo ratings yet

- Hazardous Materials Monitoring and Detection Devices Third Edition Chris Hawley Online Ebook Texxtbook Full Chapter PDFDocument69 pagesHazardous Materials Monitoring and Detection Devices Third Edition Chris Hawley Online Ebook Texxtbook Full Chapter PDFcolleen.holtzlander814100% (12)

- Jazeera GroutexDocument2 pagesJazeera GroutexAhmad BougeisNo ratings yet

- Geological Implications and Applications of High-Velocity Two-Phase Flow ExperimentsDocument16 pagesGeological Implications and Applications of High-Velocity Two-Phase Flow ExperimentsAlbert RahardjoNo ratings yet

- Iso 1172 2023Document10 pagesIso 1172 2023URD CenterNo ratings yet

- Ref 3 PDFDocument9 pagesRef 3 PDFRukhsarAhmedNo ratings yet