Professional Documents

Culture Documents

Makita Service Note

Makita Service Note

Uploaded by

Marcin LosyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Makita Service Note

Makita Service Note

Uploaded by

Marcin LosyCopyright:

Available Formats

*****************************

MAKITA SERVICE NOTE

*****************************

MAKITA CORPORATION

ISSUED August 22, 2007

Testing Section

Quality Assurance Dept.

DRAWN NO. MWSN-061-01 Technical Div.

General Manager N.Takeuchi

Dept. Manager K.Kubo

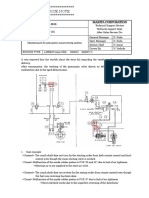

Breakage of the tightening bolts for piston crown.

Section Chief K.Sasaki

Drawn By S.Okamura

ENGINE TYPE All type.

First revision : Review of contents

Recently, we were reported the breakage of the tightening bolts for piston crown form the vessels.

The breakage had been found at neck part of the bolt head.

Those bolts were analyzed by the examining institution. And there were no abnormality about the

material which was chemical and metallic composition, strength, etc.

It is estimated that the breakage is caused by the fatigued destruction which was

occurred/progressed from the hair crack caused by corrosion pit. It is hard that a corrosion factor

break into the neck part of bolt head. Because this position is closed space and clear the pressure

test.

So, take care as follows when overhauling and/or maintenance.

1. Cleaning of bolt.

Take care of mixing water like sweat, when assembling especially high temperature and/or

humidity.

2. Correct usage of torque wrench.

As you know, torque wrench will give the clink sound when reach the setting torque. But this

clink sound is only signal. That is to say, you can tight more. It is very dangerous to over torque.

It brings about the fracture.

We recommend to change the bolt with new one, if you tight with the over torque. So, there is

the possibility to have the wrong condition like lengthening.

You might also like

- YANMAR YM Service ManualDocument231 pagesYANMAR YM Service ManualMarcin Losy33% (3)

- YANMAR 6LY2 Operation ManualDocument51 pagesYANMAR 6LY2 Operation ManualMarcin LosyNo ratings yet

- Circular Letter: For InformationDocument4 pagesCircular Letter: For Informationargentum19619692No ratings yet

- List of ME Shut Down and Slow Down: MAN B&W DieselDocument1 pageList of ME Shut Down and Slow Down: MAN B&W Dieselcengiz kutukcuNo ratings yet

- MWSN 135eDocument3 pagesMWSN 135eMarcin LosyNo ratings yet

- MWSN 123 02eDocument3 pagesMWSN 123 02eMarcin LosyNo ratings yet

- MWSN 132eDocument4 pagesMWSN 132eMarcin LosyNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- MWSN 111 03eDocument5 pagesMWSN 111 03eSilvio CaceNo ratings yet

- Makita Service NoteDocument2 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- Cylinder Lubrication Rta EngineDocument16 pagesCylinder Lubrication Rta Enginecengiz kutukcuNo ratings yet

- Check of Camshaft Coupling: Service Letter SL2012-567/AABDocument5 pagesCheck of Camshaft Coupling: Service Letter SL2012-567/AABAKINMOLADUN OMOLADE100% (1)

- Bwear CeDocument4 pagesBwear CeMic UtuNo ratings yet

- SN183Document18 pagesSN183papaki2No ratings yet

- Instruction of Adjustment For Tacho System: 2016.03.10 Diesel Engine DepartmentDocument8 pagesInstruction of Adjustment For Tacho System: 2016.03.10 Diesel Engine DepartmentDurgesh k singhNo ratings yet

- MWSN 111 02eDocument5 pagesMWSN 111 02eMarcin LosyNo ratings yet

- Makita Service NoteDocument3 pagesMakita Service NoteMarcin LosyNo ratings yet

- MAN SL2017-654 - JNN (2017.11) - Crankshaft Torsional Vibration DamperDocument1 pageMAN SL2017-654 - JNN (2017.11) - Crankshaft Torsional Vibration DamperGrandpa100% (1)

- Service Details Man BW PDFDocument7 pagesService Details Man BW PDFTapas ChaudhuriNo ratings yet

- Hitachi-Man B&W Diesel Engine Service Data: Stroke Sensor For Electronically Controlled Valve (FIVA/ELFI Valve)Document1 pageHitachi-Man B&W Diesel Engine Service Data: Stroke Sensor For Electronically Controlled Valve (FIVA/ELFI Valve)g arvNo ratings yet

- Service Letter SL2019-673/PRP: Accumulators All Makes, Brands and Types in The Hydraulic SystemDocument6 pagesService Letter SL2019-673/PRP: Accumulators All Makes, Brands and Types in The Hydraulic Systembhaswath2000No ratings yet

- 4E Hand Over - JUNE 2023Document10 pages4E Hand Over - JUNE 2023Harshavardhan KatariNo ratings yet

- Techno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVADocument6 pagesTechno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVASrivatsanNo ratings yet

- Piston Cleaning Ring Sl2016-620Document2 pagesPiston Cleaning Ring Sl2016-620Parthiban Nagarajan100% (2)

- 14 - Condition Monitoring of Your Cargo Pumping System PDFDocument4 pages14 - Condition Monitoring of Your Cargo Pumping System PDFrpicho100% (1)

- Manual Diseñar Paso VariableDocument22 pagesManual Diseñar Paso VariableJose Luis HoraNo ratings yet

- Fuel Injection Valve Condition: Service Letter SL2016-628/KELDocument4 pagesFuel Injection Valve Condition: Service Letter SL2016-628/KELVitalii KorolNo ratings yet

- Report On The Surveys Concerning International Oil Pollution Prevention CertificateDocument3 pagesReport On The Surveys Concerning International Oil Pollution Prevention CertificateSUNILNo ratings yet

- B19103-R1E - Ylinder Lrication Guideline On 0.1% ULSFO and 0.5% VLSFODocument6 pagesB19103-R1E - Ylinder Lrication Guideline On 0.1% ULSFO and 0.5% VLSFOS.K.SEONo ratings yet

- Service Experience 2009Document19 pagesService Experience 2009Alexandru AlexNo ratings yet

- Parami METC: Alpha Lubricator Alpha ACCDocument5 pagesParami METC: Alpha Lubricator Alpha ACCHtet Wai Yan AungNo ratings yet

- BearingsDocument58 pagesBearingsSarath RaghavNo ratings yet

- Me Engine Simulator Handout Jan End 2016 Rev 2Document268 pagesMe Engine Simulator Handout Jan End 2016 Rev 2Михаил БузаNo ratings yet

- Wear Limit of Fuel Pump Suction ValveDocument2 pagesWear Limit of Fuel Pump Suction Valvestergios meletisNo ratings yet

- HGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)Document5 pagesHGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)ajshsu5682No ratings yet

- TI 42 - Auxiliary Engine Counterweights & Connecting Rod Stud Retightening ProcedureDocument11 pagesTI 42 - Auxiliary Engine Counterweights & Connecting Rod Stud Retightening ProcedurealoordominicNo ratings yet

- ME Cyloil DosingDocument8 pagesME Cyloil DosingLucian Iftemie100% (2)

- High Temperature Corrosion Exh ValvesDocument6 pagesHigh Temperature Corrosion Exh ValvesCvita CvitićNo ratings yet

- 513 613 L28 32H Compressed Air SystemDocument9 pages513 613 L28 32H Compressed Air SystemFlo MarineNo ratings yet

- DefDocument6 pagesDefMohammad Tushar BhuyanNo ratings yet

- SL98 356 B W Service Letter PDFDocument14 pagesSL98 356 B W Service Letter PDFKamlakarPatwariNo ratings yet

- MT VICTORY Report On Decarbonization of Auxiliary EnginesDocument3 pagesMT VICTORY Report On Decarbonization of Auxiliary Engineskailash behera100% (1)

- MWSN 107 04eDocument4 pagesMWSN 107 04eSilvio CaceNo ratings yet

- MAN B&W K98mec6Document345 pagesMAN B&W K98mec6alex_alexutzuuNo ratings yet

- Black Smoke From The Funnel What To Do CDocument3 pagesBlack Smoke From The Funnel What To Do CsaraashunNo ratings yet

- Slide Type Fuel Valves PDFDocument5 pagesSlide Type Fuel Valves PDFThusith AlexanderNo ratings yet

- REEDS - BOILERS - PAGES 01 To 40Document40 pagesREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuNo ratings yet

- Case Study 5Document5 pagesCase Study 5stopless_dalian685No ratings yet

- EKM Dec 2016Document2 pagesEKM Dec 2016Arun SNo ratings yet

- 2-Stroke Engines Cylinder ConditionDocument9 pages2-Stroke Engines Cylinder ConditionKaushalNo ratings yet

- Crosshead Bearing InspectionDocument7 pagesCrosshead Bearing InspectionShaif uddin rifatNo ratings yet

- Service Experience 2011Document32 pagesService Experience 2011Alexandru AlexNo ratings yet

- IM WinGD X92-B 2023-09-01Document990 pagesIM WinGD X92-B 2023-09-01konstantinos.tsitsilonisNo ratings yet

- 0506 Main BearingsDocument19 pages0506 Main BearingschNo ratings yet

- Duq1 184e PDFDocument5 pagesDuq1 184e PDFRajiv RanjanNo ratings yet

- What Actions Will You Follow To Ensure That The Crank Case Oil of The Main Engine Is Always in Satisfactory Condition?Document16 pagesWhat Actions Will You Follow To Ensure That The Crank Case Oil of The Main Engine Is Always in Satisfactory Condition?arjun singhNo ratings yet

- GUIDING OVERHAUL INTERVALS sl2017-643 PDFDocument13 pagesGUIDING OVERHAUL INTERVALS sl2017-643 PDFKyriakos LamprinakisNo ratings yet

- RT-flex MechanicalDocument60 pagesRT-flex MechanicalAlok KumarNo ratings yet

- Hitachi Man-B&w Diesel Engine Service DataDocument4 pagesHitachi Man-B&w Diesel Engine Service Datar100% (2)

- Makita Service NoteDocument2 pagesMakita Service NoteMarcin LosyNo ratings yet

- MWSN 126eDocument5 pagesMWSN 126eMarcin LosyNo ratings yet

- MWSN 127eDocument5 pagesMWSN 127eMarcin LosyNo ratings yet

- MWSN 132eDocument4 pagesMWSN 132eMarcin LosyNo ratings yet

- MWSN 111 02eDocument5 pagesMWSN 111 02eMarcin LosyNo ratings yet

- MWSN 135eDocument3 pagesMWSN 135eMarcin LosyNo ratings yet

- MWSN 121 01eDocument2 pagesMWSN 121 01eMarcin LosyNo ratings yet

- Makita Service NoteDocument3 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument2 pagesMakita Service NoteMarcin LosyNo ratings yet

- MWSN 131 02eDocument3 pagesMWSN 131 02eMarcin LosyNo ratings yet

- Makita Service NoteDocument3 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- MWSN 120eDocument2 pagesMWSN 120eMarcin LosyNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument4 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument2 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument5 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument3 pagesMakita Service NoteMarcin LosyNo ratings yet

- Makita Service NoteDocument2 pagesMakita Service NoteMarcin LosyNo ratings yet

- YANMAR 6LYA Operation ManualDocument48 pagesYANMAR 6LYA Operation ManualMarcin LosyNo ratings yet

- YANMAR SD20&31 Operation ManualDocument51 pagesYANMAR SD20&31 Operation ManualMarcin LosyNo ratings yet

- Gas Fluxing of Molten Aluminum: An Overview and Update: LiquidDocument8 pagesGas Fluxing of Molten Aluminum: An Overview and Update: LiquidMarcin LosyNo ratings yet