Professional Documents

Culture Documents

Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007

Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007

Uploaded by

Vatsal DarjiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007

Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007

Uploaded by

Vatsal DarjiCopyright:

Available Formats

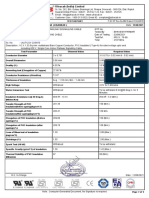

TEST REPORT

Page 1 of 3

Name & Address of the Customer :M/s. SUYOG ELECTRICALS LTD.

1,Madhuvan Apartment, 24, Arunodaya Society,

Alkapuri, Vadodara -390 007

Name & Address of the Manufacturer :M/s. SUYOG ELECTRICALS LTD.

A2/2205, C1/2204, A2/2206, 1701/2 &

2106/6 GIDC Estate, Halol Dist. Panchmahal

Reference No./Date : BRD/HC/21-22/801 Dated : 10/01/2021

Sample Code No./ Report No. : 100-211111-22

Report Date : 09/12/2021

Sample Received On : 11/11/2021

Analysis Date : 11/11/2021 to 08/12/2021

Report Prepared On : 09/12/2021

Sampled By : Customer

Sample Description : AWG (32/1) Silver Plated Copper Conductor PTFE Insulated 600V (E)

Electrical Wire

Test Specification : [As per JSS 51034 : 1992]

Style Reference : WH2P-1A 132

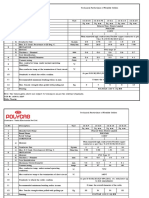

Report No. : 100-211111-22 Page 2 of 3

Respective Clause of Requirement

S. No. Test Conducted JSS -51034-1992 JSS: 51034-1992 Test Result

Reaffirmed-2002 Reaffirmed-2002

1. Visual Examination 13.1.1 Free From any defect Complies

2. Dimensions 13.1.2 As per specification Complies

(a) Silver Plated

Inner Conductor Material Silver Plated Copper

Copper

(b) No. of Strands 1 1

3. Max : 0.229 mm

Conductor dia (mm) 13.1.2.1 0.201 mm

Min : 0.190 mm

4. Max : 0.86 mm

Finished wire diameter (mm) 13.1.2.2 0.81

Min : 0.64 mm

5. Concentricity of Insulation, (%) 13.2 Min : 70 % 92.4

6. Conductor Continuity 13.5 No discontinuity in Conductor Complies

7. (a) Continuity of Coating

There should not be any trace of

13.9/ 7.2.1.2 blackening (of copper) at any point Complies

throughout the specimen length

(b) Coating Thickness 13.9/ 7.2.1.2 Min : 1.0 micron 1.08

8. Conductor Resistance at 20 °C

13.6 Max : 557.7 536.2

(ohm/km)

9. Conductor Breaking Strength Test 6 2 6

2 13.10 Max : 303 x 10 N/m 264.8 x 10

(N/m )

10. Conductor Elongation On Strand

13.10 Min : 9.0 % 14.0

Length of 250 mm, (%)

11. Dielectric with Standing Voltage 13.7 2 kV (rms) for one Minute With-Stood

4

12. Insulation Resistance (M.ohm/km) 13.8 Min : 9254.7 3.2 x 10

13. Insulation Dielectric Constant 13.11 Max : 2.2 1.94

14. Insulation Tensile Strength, (N/m )

2

13.12 Min : 21 x 10

6

24.6 x 10

6

15. Insulation Elongation, (%) 13.12 Min : 150 290

16. Insulation Power Factor 13.11 Max : 0.005 0.0034

17. Surface Resistance, (M.ohm.mm) 13.13 Min : 0.20 0.42

18. At -65 °C ± 1 °C for 4 Hours. No

readily visible derangement shall

result from this conditioning and

Cold-Bend Test 13.15 Complies

bending. The specimen shall

withstand for one minute the

dielectric test.

Report No. : 100-211111-22 Page 3 of 3

Respective Clause

Requirement

S.No. Test Conducted of JSS -51034-1992 Test Result

JSS: 51034-1992

Reaffirmed-2002

19.

At 290 °C for 96 Hours. No readily visible

(a)

derangement. There shall be no cracking or

delamination of the insulation. No

Heat Resistance Test 13.16 Complies

discolouration or colour change. The wire

shall withstand the dielectric withstanding

voltage test.

(b)

Shrinkage Test - Max. : 3.17 mm 2.70 mm

20. At 307 °C ± 5 °C for 2 Hours. There shall be

no evidence of cracks and wire shall

Wrap back Test 13.17 Complies

withstand the dielectric withstanding voltage

test.

21.

At 320 °C for 5 sec-maximum Insulation

Resistance to Soldering Heat 13.18 Complies

shrinkage 3.17 mm

22.

After removal the flame the wire shall cease

Flammability Test 13.19 to burn within 10 seconds Total Length Complies

burned shall not exceed 75 mm

Remarks: Sample meets the requirement as per specified limits as laid down in JSS: 51034-1992 as observed for the

above test parameters only.

*******End of Report******

Note:

This Test report /certificate refers only to the particular sample/s submitted for testing.

The sample description is not verified in all cases and is given as described by the customer.

Samples not drawn by us and the analysis conducted as received basis unless specified otherwise.

Tested sample will be disposed off after 90 days / 15 days / Same date in case of perishable item from

date of issue of test report unless until specified by customer.

Complaints about this report should be communicated in writing within seven days of issue date of this report.

This report is not to be reproduced wholly or in part and cannot be used as an evidence in the Court of law and

shall not be used in the advertising media without our prior permission from the Director.

Laboratory shall maintain the confidentiality of all information related to the samples & Test Reports.

You might also like

- Electrospeed Advantage VSD Troubleshooting and Applications Manual May 2018Document158 pagesElectrospeed Advantage VSD Troubleshooting and Applications Manual May 2018Novan WP100% (1)

- Datasheet - Ducab Cables - 3 & 4 CoreDocument19 pagesDatasheet - Ducab Cables - 3 & 4 Coreraj xNo ratings yet

- Handbook of Antenna Design, Vol. 1Document722 pagesHandbook of Antenna Design, Vol. 1Anonymous zBSE9M100% (6)

- MEP Design Verification Report-Report No. 1-Underground Services-Final - Rev 1Document292 pagesMEP Design Verification Report-Report No. 1-Underground Services-Final - Rev 1uddinnadeem100% (4)

- General Physics 2: Quarter 3 - Module 5BDocument31 pagesGeneral Physics 2: Quarter 3 - Module 5BHazel EncarnacionNo ratings yet

- Cable Drawing and Specification Data SheetDocument4 pagesCable Drawing and Specification Data SheetJack FrostNo ratings yet

- (N) TMCGEH3S 3x120sqmm Orange TPU JacketDocument3 pages(N) TMCGEH3S 3x120sqmm Orange TPU JacketAbl Jara MamaniNo ratings yet

- SLC Signaling Line CircuitDocument76 pagesSLC Signaling Line CircuitYuri SanchezNo ratings yet

- Harris Microwave Radio PDFDocument154 pagesHarris Microwave Radio PDFtimilehin500% (2)

- Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Document3 pagesTest Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Vatsal DarjiNo ratings yet

- Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Document3 pagesTest Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Vatsal DarjiNo ratings yet

- 220 KV Cable Inspection ReportDocument4 pages220 KV Cable Inspection Report9782279059No ratings yet

- Technical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)Document2 pagesTechnical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)William CalleNo ratings yet

- Gtp-Opgw CableDocument1 pageGtp-Opgw CableManish KumarNo ratings yet

- Breb, Dhaka.: Supplier: M/S SQ Wire & Cable Co. Ltd. Sub-Package No: Lot-4Document3 pagesBreb, Dhaka.: Supplier: M/S SQ Wire & Cable Co. Ltd. Sub-Package No: Lot-4Shahriar AhmedNo ratings yet

- Radio: 3D-2V 5D-2V 5D-2W 8D-2V 10D-2V 5D-FB 8D-FB 10D-FBDocument3 pagesRadio: 3D-2V 5D-2V 5D-2W 8D-2V 10D-2V 5D-FB 8D-FB 10D-FBOreolNo ratings yet

- ZF40907TCDocument1 pageZF40907TCMurugan AlbumsNo ratings yet

- Ficha Tecnica - 3X70+50 MM y 3X95+50 MMDocument1 pageFicha Tecnica - 3X70+50 MM y 3X95+50 MMjohana leonNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- Ducab: Technical DataDocument1 pageDucab: Technical DataGhiles AOUICHENo ratings yet

- STD - Cu-Pvc 450-750 V BS en 50525-2-31Document2 pagesSTD - Cu-Pvc 450-750 V BS en 50525-2-31Angelina JunioNo ratings yet

- 08 - Instrument CableDocument15 pages08 - Instrument CablemlutfimaNo ratings yet

- 1CX 1.33 SQ - MM. 21 CoilDocument2 pages1CX 1.33 SQ - MM. 21 CoilLaboratory UltracabNo ratings yet

- 1.5sqmm X 3C Arm DatasheetDocument2 pages1.5sqmm X 3C Arm DatasheetAshwin SupeNo ratings yet

- FICHA TECNICA - 3X 35+50 SQ - MM AB CableDocument1 pageFICHA TECNICA - 3X 35+50 SQ - MM AB Cablejohana leonNo ratings yet

- Pengerang Sub Mcb-602-48coreDocument49 pagesPengerang Sub Mcb-602-48coreARIFIN BIN SALLEHNo ratings yet

- Adss Span 100Document2 pagesAdss Span 100KFD KFDNo ratings yet

- Polycab WireDocument4 pagesPolycab WireMAYUR GENSET100% (1)

- 0 5PX1CBLKFLX100Document4 pages0 5PX1CBLKFLX100P.p. Arul IlancheeranNo ratings yet

- Polycab Wire PDFDocument4 pagesPolycab Wire PDFMAYUR GENSETNo ratings yet

- Polycab Wire PDFDocument4 pagesPolycab Wire PDFMAYUR GENSET100% (1)

- Perhitungan Elektrikal TrashrakeDocument4 pagesPerhitungan Elektrikal Trashrakeclays piezkaal setyabudiNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- Pages From PowerPlusLowres2Document50 pagesPages From PowerPlusLowres2veljal6317No ratings yet

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- OPGW Design Data Sheet (SFSJ-J-11090) - LUXDocument2 pagesOPGW Design Data Sheet (SFSJ-J-11090) - LUXandersonNo ratings yet

- 3x50 RM N2xSEYFGbY (24.09.2020)Document1 page3x50 RM N2xSEYFGbY (24.09.2020)Jamil SharifNo ratings yet

- Sr. No. 3B Datasheet 1.5PX6CYWY 100Document2 pagesSr. No. 3B Datasheet 1.5PX6CYWY 100hemantmech099200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Anonymous SDeSP1No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- B3 - CablesDocument2 pagesB3 - CablesMichalis AltousNo ratings yet

- GTP-GPIL-ENERFRA-ACSR DOG With Current RatingDocument2 pagesGTP-GPIL-ENERFRA-ACSR DOG With Current RatingShashikumar SNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedNo ratings yet

- 88kV Copper Large Conductor XLPE CSA PE HS CablesDocument1 page88kV Copper Large Conductor XLPE CSA PE HS CablesIppiNo ratings yet

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESNo ratings yet

- FSBS07CXSWLS002C2 5saDocument1 pageFSBS07CXSWLS002C2 5sapradeepyellurNo ratings yet

- CM Fc9000-Eng-Int-F-CatalogueDocument20 pagesCM Fc9000-Eng-Int-F-CatalogueEdgardo Ariel RodriguezNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- XLPE Cu 115kV, 300mm2 1-Core, CuXLPECWS (31.5ka) APL HDPE Data SheetDocument2 pagesXLPE Cu 115kV, 300mm2 1-Core, CuXLPECWS (31.5ka) APL HDPE Data SheetJean CarlosNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- Earthing System Design Tool For Low Voltage InstallationsDocument36 pagesEarthing System Design Tool For Low Voltage InstallationsLim BoraNo ratings yet

- Federal NYAF 300 500 VDocument1 pageFederal NYAF 300 500 VDICKYNo ratings yet

- T 190152Document27 pagesT 190152Mohd Izham IdrisNo ratings yet

- Aerial Cable ADSS-12FO G.652D Span 120mDocument4 pagesAerial Cable ADSS-12FO G.652D Span 120mWDCNET WORKSNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- PO1541 - Ojas Infra - GSF MV TDS-v1.1Document16 pagesPO1541 - Ojas Infra - GSF MV TDS-v1.1Sanjay GadhaveNo ratings yet

- ZTT ACS Strand 7x3.21-1Document4 pagesZTT ACS Strand 7x3.21-1tees220510No ratings yet

- OPGW SpecDocument28 pagesOPGW SpecvikasmikkuNo ratings yet

- Cable DatasheetDocument16 pagesCable Datasheetdilipnayak101406No ratings yet

- Vol-Ii (PART-II) : Guaranteed Technical ParticularsDocument70 pagesVol-Ii (PART-II) : Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Derivation 3.1 Energy Conservation - Magnetic Field Cannot Change ParticleDocument12 pagesDerivation 3.1 Energy Conservation - Magnetic Field Cannot Change ParticleRoy VeseyNo ratings yet

- Amety Gen Protection1Document27 pagesAmety Gen Protection1Lalit KR NeerajNo ratings yet

- Magnetic Particle Testing Method: Questions AnswersDocument35 pagesMagnetic Particle Testing Method: Questions AnswersSYED FADZIL SYED MOHAMEDNo ratings yet

- 2.chapter2 CMOS Model Behaviour CharacteristicDocument85 pages2.chapter2 CMOS Model Behaviour Characteristicngominhnhan543No ratings yet

- The Most Friendly Bench Instruments: Appa 200 Series VersameterDocument2 pagesThe Most Friendly Bench Instruments: Appa 200 Series Versametermarcelo zarateNo ratings yet

- B. Fault-FindingDocument29 pagesB. Fault-FindingJesús David Diaz MontesNo ratings yet

- Electrical LT Load List For Sub Station-ADocument2 pagesElectrical LT Load List For Sub Station-AVikram DalalNo ratings yet

- An 8 KW, 230 V, 1200 RPM DC Shunt Motor Has Ra 0...Document3 pagesAn 8 KW, 230 V, 1200 RPM DC Shunt Motor Has Ra 0...2K20EE171 Mudit TripathiNo ratings yet

- MXR Blue BJLHDocument1 pageMXR Blue BJLHEdmário Oliveira SantosNo ratings yet

- AME65x UI OutputsDocument8 pagesAME65x UI OutputsFareethAbdullahNo ratings yet

- Wikipedia, The Free Encyclopedia Volate StabilizerDocument9 pagesWikipedia, The Free Encyclopedia Volate StabilizerJayadevDamodaranNo ratings yet

- Vol 2 Sec 5.2 - Generator Bus Ducts Neutral Grounding EquipmentDocument14 pagesVol 2 Sec 5.2 - Generator Bus Ducts Neutral Grounding EquipmentBijaya Kumar MohantyNo ratings yet

- 5054 w16 Ms 21Document5 pages5054 w16 Ms 21Imran ZafarNo ratings yet

- NTC71 5Document15 pagesNTC71 5Joao LucasNo ratings yet

- Autoform Analysis in Sheet Metal FormingDocument15 pagesAutoform Analysis in Sheet Metal FormingNhan LeNo ratings yet

- Turbina PeltonDocument22 pagesTurbina PeltonManuel CaipoNo ratings yet

- Seminar On MramDocument28 pagesSeminar On MramShibojyoti BhattacharjeeNo ratings yet

- Single-Phase SOGI-PLL Based Reference Current Extraction For Three-Phase Four-WireDocument8 pagesSingle-Phase SOGI-PLL Based Reference Current Extraction For Three-Phase Four-WireAlex EscribáNo ratings yet

- Tds 24dp-550 Crown EngDocument2 pagesTds 24dp-550 Crown EngDraganNo ratings yet

- Load Calculation NewDocument1 pageLoad Calculation NewUtkarsh VermaNo ratings yet

- 01 REFRESHER EE 1 - CLB - CompressedDocument12 pages01 REFRESHER EE 1 - CLB - CompressedJuphil PletoNo ratings yet

- Gas Insulated MV Circuit Breakers Up To: 40.5 KV 4000 A 50 KaDocument76 pagesGas Insulated MV Circuit Breakers Up To: 40.5 KV 4000 A 50 KaDevy MangimbaNo ratings yet

- Magnetic Particle Level IIDocument3 pagesMagnetic Particle Level IIaravindanNo ratings yet

- Imscim v1 ManualDocument8 pagesImscim v1 ManualFiroDjinsoNanoNo ratings yet