Professional Documents

Culture Documents

COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646

COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646

Uploaded by

NikhilARCopyright:

Available Formats

You might also like

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- RCC 1 PDFDocument8 pagesRCC 1 PDFNgọc TuyênNo ratings yet

- Irjet V4i2350 171121070636 PDFDocument6 pagesIrjet V4i2350 171121070636 PDFachmad yakusaNo ratings yet

- Study of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingDocument6 pagesStudy of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingAkshay DobleNo ratings yet

- IJRPR16287Document6 pagesIJRPR16287B45Raj Kumar ThakurNo ratings yet

- A Review Paper On Comparetive Study of Reinforced Concrete Filled Steel Tube Structure With Traditional Reinfroced Concrete and Steel Structure 31985Document7 pagesA Review Paper On Comparetive Study of Reinforced Concrete Filled Steel Tube Structure With Traditional Reinfroced Concrete and Steel Structure 31985Editor IJAERDNo ratings yet

- Panchal (Nirma University) - Comparative Study of RCC-Steel-Composite High Rise BuildingDocument6 pagesPanchal (Nirma University) - Comparative Study of RCC-Steel-Composite High Rise Buildingnvc_vishwanathanNo ratings yet

- Compare Studu PDFDocument5 pagesCompare Studu PDFdarsu NaikNo ratings yet

- Comparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsDocument7 pagesComparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsEphrata MussieNo ratings yet

- Analysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureDocument9 pagesAnalysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureUsha EngineeringNo ratings yet

- Fin Irjmets1682867109Document5 pagesFin Irjmets1682867109B45Raj Kumar ThakurNo ratings yet

- Assignment. Engr EssayDocument4 pagesAssignment. Engr EssayGopalDhakalNo ratings yet

- Comparative Study On Dynamic Analysis of Composite, RCC & Steel StructureDocument8 pagesComparative Study On Dynamic Analysis of Composite, RCC & Steel StructureRajalakshmi JothivelNo ratings yet

- Composite Materials 2Document200 pagesComposite Materials 2Taimoor NasserNo ratings yet

- Seismic Analysis of RCC and Composite StructuresDocument9 pagesSeismic Analysis of RCC and Composite Structuresvishnumani3011No ratings yet

- Comparative Analysis of RCC and Steel-Concrete Composite Multistoried BuildingDocument7 pagesComparative Analysis of RCC and Steel-Concrete Composite Multistoried BuildingAbhishek GuptaNo ratings yet

- Research Paper On Analysis and Design ofDocument16 pagesResearch Paper On Analysis and Design ofPalesaNo ratings yet

- Comparative Study On Multi-Storey Structure of R.C.C and Composite MaterialDocument5 pagesComparative Study On Multi-Storey Structure of R.C.C and Composite MaterialBasavarajBachihalNo ratings yet

- Analysis and Design of Multi-Storeyed Bu PDFDocument8 pagesAnalysis and Design of Multi-Storeyed Bu PDFengyana engyyyNo ratings yet

- Consideration of Seismic Design of Multistoried Steel StructureDocument6 pagesConsideration of Seismic Design of Multistoried Steel StructureAnonymous KyLhn6No ratings yet

- SCS Protective StructureDocument18 pagesSCS Protective Structure안진호 / 학생 / 건설환경공학부No ratings yet

- 103820130510Document10 pages103820130510Ahmed SalemNo ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Dony DoanxNo ratings yet

- Cost-Effectiveness of Pre-Engineered and Conventional Steel FramesDocument7 pagesCost-Effectiveness of Pre-Engineered and Conventional Steel FramesBiswajit SahooNo ratings yet

- Paper 222Document12 pagesPaper 222dheerajbhawar786No ratings yet

- Composite Structure (31-38)Document48 pagesComposite Structure (31-38)Badri DadiNo ratings yet

- Steel DesignDocument131 pagesSteel DesignAndrea RamirezNo ratings yet

- Seismic Behavior of Steel-Concrete Composite Structures: December 2019Document7 pagesSeismic Behavior of Steel-Concrete Composite Structures: December 2019Usha EngineeringNo ratings yet

- Comparative Study of RCC and Steel Structures For Different Floor HeightsDocument5 pagesComparative Study of RCC and Steel Structures For Different Floor HeightsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareDocument9 pages23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareSandy KavitakeNo ratings yet

- IJCRT2106637Document8 pagesIJCRT2106637jrcruzpogi0242424No ratings yet

- "A Review On Comparative Study of Composite RCC and Steel Structure" 1Document5 pages"A Review On Comparative Study of Composite RCC and Steel Structure" 1Ephrata MussieNo ratings yet

- Steel Conc. Comp. ContDocument35 pagesSteel Conc. Comp. ContDeepak SinghNo ratings yet

- IJCRT2306026Document8 pagesIJCRT2306026pankaj645924No ratings yet

- Design of Castellated Column in Finite Element AnalysisDocument10 pagesDesign of Castellated Column in Finite Element AnalysisIJRASETPublicationsNo ratings yet

- Report Composite AnkurDocument19 pagesReport Composite AnkurAnkur DubeyNo ratings yet

- The Application of Steel Structure in Civil Engineering: Xiaodan Wei, Xiangrong HeDocument4 pagesThe Application of Steel Structure in Civil Engineering: Xiaodan Wei, Xiangrong HeKrizsel ContrerasNo ratings yet

- Profiled Steel Sheets: Sacrificial Siiuttering (Form Deck)Document2 pagesProfiled Steel Sheets: Sacrificial Siiuttering (Form Deck)Sarmishtha DeNo ratings yet

- 1 s2.0 S0141029618325768 MainDocument17 pages1 s2.0 S0141029618325768 MainAmela ShahiniNo ratings yet

- Combining Steel and ConcreteDocument2 pagesCombining Steel and ConcreteIshwarya SrikanthNo ratings yet

- 2018 - Multidimensional Comparison of Lightweight Steel and Reinforced Concrete StructuresDocument9 pages2018 - Multidimensional Comparison of Lightweight Steel and Reinforced Concrete StructuresmatheusnormandessNo ratings yet

- Strengthening of Reinforced Concrete Columns by Steel Jacketing: A State of ReviewDocument10 pagesStrengthening of Reinforced Concrete Columns by Steel Jacketing: A State of Reviewsefatwrdk21No ratings yet

- Performance of Grade 500 Steel in Concrete Structure.Document7 pagesPerformance of Grade 500 Steel in Concrete Structure.Ahetesham Uddin Ahmed TipuNo ratings yet

- Assessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProDocument8 pagesAssessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProaeoiuNo ratings yet

- Dynamic Analysis On RCC and Composite Structure For Uniform and Optimized SectionDocument16 pagesDynamic Analysis On RCC and Composite Structure For Uniform and Optimized SectionIJRASETPublicationsNo ratings yet

- Innovation in Composite ConstructionDocument6 pagesInnovation in Composite ConstructionnicholasNo ratings yet

- Jounal Composite 4Document11 pagesJounal Composite 4barath kumarNo ratings yet

- Seismic Performance of RC Flat Slab Structure With Different Types of Steel BracingDocument6 pagesSeismic Performance of RC Flat Slab Structure With Different Types of Steel BracingNovember RainNo ratings yet

- Application To Steel On BuildingDocument4 pagesApplication To Steel On BuildingCheryl GetongoNo ratings yet

- Structural Behavior of Steel-Concrete Composite BeamDocument12 pagesStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaNo ratings yet

- Research Chapter 1 and 2Document15 pagesResearch Chapter 1 and 2Jeorzelle Alexa OrtegaNo ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Sushant WaghmareNo ratings yet

- Ijciet 08 04 143Document11 pagesIjciet 08 04 143Filmon SolomonNo ratings yet

- Journal Article - Comparison RCC - CompositeDocument6 pagesJournal Article - Comparison RCC - CompositeSri KayNo ratings yet

- Guidelines For Composite Construction and Shear ConnectorsDocument25 pagesGuidelines For Composite Construction and Shear Connectorsradhakrishnang100% (1)

- Pre Engg BuildingDocument7 pagesPre Engg BuildingAkhilesh B.MNo ratings yet

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDocument27 pagesComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNo ratings yet

- Concrete Filled Steel Tubular (CFST) Columns in Composite StructuresDocument8 pagesConcrete Filled Steel Tubular (CFST) Columns in Composite Structuresashish SindhuNo ratings yet

- Steel Seismic DesignDocument24 pagesSteel Seismic DesignsenthilcivilNo ratings yet

- FULLTEXT02Document95 pagesFULLTEXT02NikhilARNo ratings yet

- Energy Audit Types and MethodologyDocument7 pagesEnergy Audit Types and MethodologyNikhilARNo ratings yet

- G&R ArchitectureDocument34 pagesG&R ArchitectureNikhilARNo ratings yet

- Santushti VelvettDocument130 pagesSantushti VelvettNikhilARNo ratings yet

- Renaissance Architecture: Donato Bramante Leon Battista Alberti Palazzo RiccardiDocument14 pagesRenaissance Architecture: Donato Bramante Leon Battista Alberti Palazzo RiccardiNikhilARNo ratings yet

- Concrete Concrete Water Cement Aggregate AdmixtureDocument2 pagesConcrete Concrete Water Cement Aggregate AdmixtureRoihans Muhammad IqbalNo ratings yet

- Dawit GebreDocument88 pagesDawit GebreabadittadesseNo ratings yet

- 4 - O-Pitblast - Topography ModuleDocument29 pages4 - O-Pitblast - Topography ModuleDANINo ratings yet

- Aquaarm Spu SPL Ver 8 1Document3 pagesAquaarm Spu SPL Ver 8 1Paladi RaviNo ratings yet

- Crossection of A RoadDocument27 pagesCrossection of A RoadFatima KamranNo ratings yet

- JNTUH B.tech 3 Year CE R16 SyllabusDocument33 pagesJNTUH B.tech 3 Year CE R16 SyllabusJANADHANNo ratings yet

- Concrete Mix DesignDocument24 pagesConcrete Mix Designvishnumani3011No ratings yet

- Contoh Soal ViskositasDocument2 pagesContoh Soal ViskositaswsdodoNo ratings yet

- AISI Standard For Cold-Formed Steel Framing - Wall Stud Design, 2004 EditionDocument35 pagesAISI Standard For Cold-Formed Steel Framing - Wall Stud Design, 2004 EditionSudip ShresthaNo ratings yet

- Foundation DesignDocument15 pagesFoundation Designvikash kumarNo ratings yet

- 6 Types of EngineersDocument5 pages6 Types of EngineersAsad NawazNo ratings yet

- Izracunat Moment Inercije T Profila 175x90x30Document1 pageIzracunat Moment Inercije T Profila 175x90x30cakizemunac4577No ratings yet

- Design CalcDocument308 pagesDesign CalcPeja Jusoh100% (1)

- Assignment I. FinalDocument9 pagesAssignment I. FinalMaulid67% (6)

- 103552Document31 pages103552Anbarasan SivarajNo ratings yet

- Design Consideration Pressure VesselDocument17 pagesDesign Consideration Pressure VesselQasim JavedNo ratings yet

- Equations For A Newtonian Fluid: Newtonian Versus Non-Newtonian FluidsDocument1 pageEquations For A Newtonian Fluid: Newtonian Versus Non-Newtonian FluidsYrrah StylesNo ratings yet

- Chapter 2: Cable Stayed Bridge ComponentsDocument9 pagesChapter 2: Cable Stayed Bridge Componentsdebjyoti_das_6100% (1)

- Water Distribution SystemDocument45 pagesWater Distribution SystemSrihari DasariNo ratings yet

- Woodland Trust Headquarters, Grantham, LincolnshireDocument8 pagesWoodland Trust Headquarters, Grantham, Lincolnshiredesign25mNo ratings yet

- Statics & FluidsDocument9 pagesStatics & FluidsShu RubioNo ratings yet

- Working Stress Method and Limit State MethodDocument5 pagesWorking Stress Method and Limit State MethodDeep DebnathNo ratings yet

- Bülent Akbaş - Advanced Steel StructuresDocument68 pagesBülent Akbaş - Advanced Steel StructuresMert SarıNo ratings yet

- Effect of Stiffeners On Shear Lag in Steel Box GirdersDocument14 pagesEffect of Stiffeners On Shear Lag in Steel Box Girderserky arkvathonejhNo ratings yet

- Radiator-Baseboard Product Data SheetDocument4 pagesRadiator-Baseboard Product Data SheetMohamed Feisal PatelNo ratings yet

- Module 5 TOSDocument8 pagesModule 5 TOSPrince IbanezNo ratings yet

- 3 R16 PDFDocument440 pages3 R16 PDFprashanthNo ratings yet

- ENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1Document15 pagesENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1jimyNo ratings yet

- Design of Short Column (Biaxial Bending)Document3 pagesDesign of Short Column (Biaxial Bending)meenu100% (2)

- FF1814 FinnframeDocument36 pagesFF1814 FinnframemilasanNo ratings yet

COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646

COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646

Uploaded by

NikhilAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646

COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646

Uploaded by

NikhilARCopyright:

Available Formats

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

COMPARATIVE STUDY OF RCC, STEEL

AND COMPOSITE STRUCTURES FOR

INDUSTRIAL BUILDING

Mr. Anil S. Savadi1, Dr. Vinod Hosur.2

1

M.Tech Student,Dept. of Civil Engineering, Visvesvaraya Technological University, Belagavi,India

2

Professor, Dept. of Civil Engineering, KLS Gogte Institute of Technology, Belagavi, India

ABSTRACT

Steel Concrete Composite construction has gained wide acceptance world wide as an alternative to RCC

construction. However, this system is relatively new concept for the construction industry. Reinforced concrete

members are used in the framing system for most of the buildings since this is the most convenient & economic

system for one storey buildings. However, for multi storeyed building this type of structure is no longer economic

because of increased dead load, less stiffness,, span restriction and hazardous formwork. And steel structure is also

good for low load but Steel concrete composite frame system can provide an effective and economic solution to most

of these problems in medium to high rise buildings. In the present work Concrete composite with RCC, Steel

structure options are considered for comparative study of G+2 storey of Industrial building which is situated in

earthquake zone-3 of IS 1893-2002 earth quake loading. Equivalent static method of analysis is used for modeling

of composite, Steel and RCC structures; STAAD-pro V8i Finite element software is used. In the composite structure

Steel column is encased in PCC and RCC slab on steel girder are employed. The dead load and live load are

considered as per IS-875(part-1&2) and wind load is considered as per IS-875(part-3). The result of this work

shown that, the cost of the composite is less than the RCC structure as well as steel structure. The critical bending

moment and Shear force values are less in composite structure compared to RCC structure and more than steel

structures due to decreased dead load. Composite structure is best solution for the multi storeyed Structure

compared to RCC and Steel structure.

Keyword : - Industrial Building, Cost Difference, Axial Force, Node Displacement, Max Bending Moment and

shear Force etc….

1. INTRODUCTION

In past structural engineer has d the choice of masonry building and multi stories building with RCC

framed structure or steel structure. Recently trend of going towards composite structure has started and going [1].

Now a days in India to fulfill the requirements and needs of high rise buildings the composite is best suited for

infrastructural growth other than the RCC and steel structures, and steel concrete composite system have become

quite popular in recent time because of their advantages against convention construction, composite construction

combines the better properties of both material such as concrete and steel [2].

1.1 Advantages of Composite structure

i. Increased strength for a given cross sectional dimension.

ii. Increased stiffness, leading to reduced slenderness and increased buckling resistance.

iii. Good fire resistance in the case of concrete encased.

iv. Corrosion protection in encased member.

10646 www.ijariie.com 637

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

v. Superior seismic performance for lateral load.

vi. Significant economic advantages over either pure structural steel or reinforced concrete alternatives.

vii. Identical cross sections with different load and moment resistances can be produced by varying steel

thickness, the concrete strength and reinforcement. This allows the outer dimensions of a column to be

held constant over a number of floors in a building, thus simplifying the construction and architectural

detailing.

viii. Erection of high rise building in an extremely efficient manner.

ix. Formwork is not required for concrete filled tubular sections

x. Economical for High rise buildings

1.2 Components of Composite structure

Composite deck slab- Composite floor system consists of steel beams metal decking and concrete. They are

combined in very efficient way so that the best properties of each material can be used to optimize construction

techniques. The most common arrangement found in composite floor systems is a rolled or build up steel beam

connected to a formed steel deck and concrete slab. The metal deck typically span unsupported between steel

members, while also providing a working platform for concreting work. The composite floor system produce a

rigid horizontal diaphragm, providing stability to the over all building system, while distributing wind and

seismic shear to the lateral load-resisting system

Composite beams- In conventional composite construction, concrete slabs rest over steel beams and are

supported by beam. Under load these to components act independently and a relative slip occurs at the interface

if there is no connection between them. With the help of a deliberate and appropriate connection provided

between them can be eliminated. In this case the steel beam and the slab act as a “composite beam” and there

action is similar to that of a monolithic Tee beam. Though steel and concrete are the most commonly used

materials for composite beams, other materials such as pre-stressed concrete and timber can also be used.

Concrete is stronger Compression than in tension, and steel is susceptible to buckling in Compression. By the

composite action between the two, We can utilize there respective advantage to the fullest extent. General in

steel concrete composite beams, steel beams are integrally connected to pre fabricated or cast in situ reinforced

concrete slabs.

Composite columns- A steel concrete composite column is a Compression member, Comprising either of a

concrete incased hot rolled steel section or a concrete filled hallow section of hot rolled steel. It is generally

used as a load bearing member in a composite framed structure. Composite members are mainly subjected to

compression and bending. At present there is no Indian standard code covering design of composite column.

The method of design in this report largely fallows EC4, Which incorporate latest research on composite

construction. Indian standard for composite construction IS 11384-1985 does not make any specific reference

to composite column. This method also adopt the European buckling curve for steel column as a basic of

column design

Shear connector- The total shear force at the interface between concrete slab and steel beam is

approximately 8 times the total load carried by the beam. There for, mechanical shear connector is required at

the steel concrete interface. These connector are designed to (a) transmit longitudinal shear along the interface,

and (b) prevent separation of steel bean and concrete slab at the interface. Commonly used types of shear

connector as per IS:11384-1985. There are three main types of shear connectors., rigid shear connector, flexible

shear connector and Anchorage shear connectors.

2. METHODOLOGY

1) In the present work it is proposed to prepare a finite element models of G+2 Storey Industrial building using

STAAD Pro V8i with fixed base at ground level.

a) R.C.C structure

b) Steel Structure

c) Composite Structure

2) Apply Dead load, Live load and Wind load/Earth quake load as per IS 875-1987and IS 1893-2002 and Carry

out the equivalent Static method of analysis.

3) Carry out Designs by Limit state method using IS 456-2000 and SP16-1980

4) Carry out quantity surveying for all the three type of buildings.

5) Estimate the cost using Karnataka State Schedule Rate – 2018 Book

6) Compares the result of all three types of structures.

10646 www.ijariie.com 638

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

3. MODELING AND ANALYSIS

The study has been carried out with some basic assumption in design criteria/parameters for (G+2) storied

industrial building for RCC, Steel as well as Composite including relevant soil parameters, wind speed, landscape

class and topography, earthquake zone and value of coefficient and acceleration based on available local data and

stipulations of bureau of Indian standards and euro codes. The dead burden and live burden has been consider

dependent on the IS 875(part-1 and 2), wind load depends on IS-875(Part-3). For tremor stacking, the arrangement

of IS-1893:2002 was considered.

The study has been carried out for the three variant

i. G+2 RCC, 4.5m height.

ii. G+2 Steel Structure, 4.5m height.

iii. G+2 Steel concrete Composite, 4.5m height

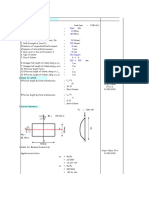

3.1 Building Detail

The building considered here is an Industrial building having G+2 storied located in seismic zone 3 and for

earthquake loading, the provisions of IS:1893(Part1)-2002 is considered. The wind velocity 39m/s. The line diagram

plan of building is shown in fig.1 the building is planned to facilitate the basic requirements of an Industrial

building. he plan dimension of the building is 12X42 m. Height of each storey for Composite, RCC and steel

structure is 4.5 m. The study is carried out on the same building plan for RCC, steel and composite construction with

some basic assumptions made for deciding preliminary sections of both the structures. The basic loading on all three

type of structure types of structures are kept same, other relevant data is tabulated in table1,2 &3

Fig -1: Typical Plan of RCC Building

10646 www.ijariie.com 639

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

Fig-2: 3D Model of Building

Table no-1: Data for the analysis of RCC structure

Plan Dimensions 12x42 m

Total height of the structure 15 m

Height of each storey 4.5 m

Height of parapet 1m

Size of beams at plinth level 1x0.3 m

Size of beam at floor level 1x0.3 m

Size of column 0.6x0.3m

Thickness of the slab 0.150 m

Thickness of wall 0.230 m

Seismic Zone III

Wind speed 33 m/s

Importance factor 1

Zone factor 0.16

Floor Finish 1.5 KN/m2

Live load 7 KN/m2

Grade of concrete for slabs M 30

Grade of concrete for beams and columns M 30

Grade of reinforcement steel Fe415

Density of concrete 25 KN/m3

Density of brick 20 KN/m3

Damping Ratio 5%

Grade of structural steel Fe250

Concrete cover to reinforcement for slab 0.025 m

Concrete cover to reinforcement for beam 0.025 m

Concrete cover to reinforcement for column 0.040 m

Table no-2: Data for the analysis of Steel structure

Plan Dimensions 12x42 m

Total height of the structure 15 m

Height of each storey 4.5 m

Height of parapet 1m

Size of beams at plinth level ISMB-450

Size of beam at floor level ISMB-450

Size of column ISMB-500

Thickness of the slab 0.150 mm

Thickness of wall 0.230 m

Seismic Zone III

10646 www.ijariie.com 640

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

Wind speed 33 m/s

Importance factor 1

Zone factor 0.16

Floor Finish 1.5 KN/m2

Live load 7 KN/m2

Grade of concrete for slabs M 30

Density of concrete 25 KN/m3

Density of brick 20 KN/m3

Damping Ratio 5%

Grade of structural steel Fe250

Concrete cover to reinforcement for slab 0.025 m

Table no-3: Data for the analysis of Steel structure

Plan Dimensions 12x42 m

Total height of the structure 15 m

Height of each storey 4.5 m

Height of parapet 1m

Size of beams at plinth level ISMB-300

Size of beam at floor level ISMB-300

Size of column ISMB-400

Thickness of the slab 0.150 m

Thickness of wall 0.230 m

Seismic Zone III

Wind speed 33 m/s

Importance factor 1

Zone factor 0.16

Floor Finish 1.5 KN/m2

Live load 7 KN/m2

Grade of concrete for slabs M 30

Grade of concrete for beams and columns M 30

Grade of reinforcement steel Fe415

Density of concrete 25 KN/m3

Density of brick 20 KN/m3

Damping Ratio 5%

Grade of structural steel Fe250

Concrete cover to reinforcement for slab 0.025 m

Concrete cover to reinforcement for beam 0.025 m

Concrete cover to reinforcement for column 0.040 m

3.2 Analysis

The explained 3D building model is analyzed using Equivalent Static Method. The buildings models are

analyzed by using Staad-Pro V8i software. In composite structure the beam is modeled as composite beam element

and column is modeled as encased steel composite element. In RCC structure the beam and column is modeled as

RCC beam element. In Steel structure the beam and column is modeled as Steel beam element. The different

parameters such as node displacement, maximum shear force, axial force and maximum bending moment, Cost are

studied for the models. The dead load and live load are considered as per IS-875(part 1 &2) and wind load is

considered as per IS-875(part 3).For earthquake loading IS:1893(Part1)-2002 is used.

4. RESULTS AND DISCUSSION

In the present study the G+2 composite, steel and RCC multistory Industrial building is considered. An

effort has been made to calculate the cost effectiveness of composite, steel and RCC structure elements. The

parameter considered is nodal displacement, maximum shear force, axial force and maximum bending moment is

considered and their variation in the form of graph is shown.

10646 www.ijariie.com 641

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

4.2 Cost of Beam

The quantity of composite, steel and RCC Beams is taken from design and calculated total quantity as

shown below. The rate of Reinforcement steel, Structural Steel and concrete is obtained from the present market.

The Cost of RCC beams, Steel beams and Composite beams as given in table-4 and graph variation of the cost of

beam is shown in graph

Table no-4: Cost of beams in different structures.

Material Composite Structure Steel Structure RCC Structure

Quantity Quantity Quantity

of beam Rate Amount of beam Rate Amount of beam Rate Amount

Structural

60.81 60000 3648600 60.81 60000 3648600 - 60000

Steel

62000

Reinforce

(include

ment 10.58 56000 592480 13.6 56000 761600 43.76 2713120

bar

Steel

bending)

4000

(form

Concrete 302.4 1209600 226.8 5000 1134000 410.4 8500 3488400

work is

not)

Total

Amount 5450680 5544200 6201520

Fig-6: Cost Variation Graph of Beams for Composite, Steel and RCC Related

4.3 Cost of Column

The quantity of column for Composite, Steel and RCC structure are taken from the design and total

quantity is shown below. The rate of reinforcing steel ,Structural steel and concrete are taken from market. The table

5 show the total cost of columns for RCC, Steel and composite structure.

10646 www.ijariie.com 642

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

Table no-5: Cost of Columns in different structures.

Composite Structure Steel Structure RCC Structure

Material Quantity Quantity Quantity

of of of

column Rate Amount column Rate Amount column Rate Amount

Structural Steel 16.5 60000 960000 24.97 60000 1498200 - 60000 0

Reinforcement

- 56000 0 - 56000 0 17.25 62000 1069500

Steel

Concrete 36.3 4000 145200 - 5000 0 5.7 8500 48450

Total Amount 1105200 1498200 1117950

Fig-7: Cost Variation Graph of Columns for Composite, Steel and RCC Related

4.4 Axial Force

From the analysis results axial forces are taken for composite, Steel and RCC structure at different floor.

The table 6 shows the maximum axial forces in Composite and RCC structure.

Table no-6: Maximum Axial force in different structures.

Maximum Maximum Maximum

Type of floor Axial Force in Axial Force Axial Force

Composite in Steel in RCC

Plinth 1800 1600 2500

Gr. Floor 1450 1450 1850

1st Floor 1260 900 1200

2nd Floor 900 520 426

10646 www.ijariie.com 643

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

Fig-8: Axial forces variation graph for RCC, Steel and composite structure

4.5 Node Displacement

From the analysis results of node displacement are taken for composite, Steel and RCC structure. The node

displacement for composite and RCC structure are given in table-7

Table no-7: Node Displacement in different structures.

Composite Steel RCC

Type of floor

Structure Structure Structure

Plinth 1.5 2.3 1.1

Gr. Floor 15 24 12

1st Floor 27 31 21

2nd Floor 41 49 37

Fig-9: Node Displacement for RCC, Steel and composite structure

10646 www.ijariie.com 644

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

4.6 Maximum Bending Moment And Shear Force

From the analysis results maximum bending moment and shear force are taken for composite, Steel and

RCC structure. The table 8 shows the maximum bending moment and shear force in composite and RCC structure.

Table-8: Max BM and SF in RCC, steel and composite structure

Comparison property Composite beam Steel beam RCC beam

Max Shear force (KN) 370 280 460

Max Bending moment in Z-direction (KN-m) 410 321 510

Fig-10: Max shear force and Max Bending Moment for RCC Steel and composite structure

4.7 Discussion

1. From the beam cost comparison chart and table it is clear that the cost of the Composite beam is 1.7% less

than Steel Structure beam and 13.7% less than the RCC beam. This is because, the Composite beam does

not required bar bending and form work.

2. From the Column cost comparison chart and table it is clear that the cost of the Composite beam is 35%

less than Steel Structure Column and 1.7% less than the RCC Column. This is because, the Composite

beam does not require bar bending and steel binding of column.

3. Fr0m the Axial force chart and table it is clear that axial f0rce is less than the RCC structure but quite more

than the Steel Structure.

4. From node displacement table and chart, it is clear that C0mposite Structure has less displace of node

compare to Steel Structure but More than the RCC structure.

5. From the maximum bending moment and shear force chart and table it is clear that the max bending

moment and shear force in composite beam is less compared to RCC and quite more than the Steel

structure

5. CONCLUSION

In this work. The comparative study of R.C.C, Steel and Composite Structure for industrial building (G+2)

is presented. The parameter considered are cost of beam, cost of column, node displacement, member deflection,

maximum bending moment, maximum shear force is considered. Thus based on the analysis results discussed in

previous chapter fallowing conclusions drawn.

1. The axial force in R.C.C structure is higher than the Composite Structure.

2. Composite Structures are more economical than the RCC and steel Structure.

3. mass of composite structure is less than RCC structure but more than the Steel structure

4. Speed of work and speedy erection facilitates quicker return on the invested capital and benefit in terms of

rent.

5. For the erection work labor requirement is very less in composite structure compare to RCC structure

6. Deflection in composite structure is more compared to RCC structure and less compared to steel structure.

7. The maximum bending moment and shear force is more than the RCC structure and less than the steel

structure.

10646 www.ijariie.com 645

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

6. REFERENCES

[1] D.R. Panchal, P. M. Marathe, “Comparative Study of R.C.C, Steel and Composite (G+30 Storey)

Building”, Institite of Technology, Nirma University, Ahmedavada-ISSN:382481,vol-4, Jully, 2011, pp.

08-10.

[2] Shashikala.Koppad, Dr. S.V.Itti, “Comparative Study of RCC and Composite Multistoried

Building(B+G+15)”, International journal of Engineering and Innovative Technology(IJEIT)- Volume 3,

Issue 5, November 2013

[3] Sandeep Chaudhary, Umesh Pendakar and A.K nagpal, “hybrid procedure for cracking and time dependant

effects in composite frames at service load” American Society of Civil Engineers 10.1061(ASCE) 0733-

9445(2007) 133:2(166)

[4] Nitish A.Mohite, Mr. P.K J0shi, Dr. W.N.Deulkar. “Comparative Analysis of RCC and Steel Concrete

Composite (B+G+11 Storey) Building” International journal of Scientific and Research Publications, ISSN

2250-3153, VOl-5 Issue 10,p--.1-6 October 2015

[5] Rahul Pandey, “ Comparative Seismic Analysis of RCC, Steel &Steel Concrete Composite Frame”,

Department of Civil Engineering National Institute of Technology Rourkela,2014

[6] Nitin M. Warade, P.J. Salunke, “Comparative Study on Analysis and Design of Composite Structure”,

International Journal of Advance Research in Science And Engineering, IJARSE, ISSN-2319-8354(E),

Vol-2, Issue-12, pp. 41-50, December,2013

[7] Bhavin H. Et al., “Comparative Study of Steel, RCC and Composite Building” International journal of

Innovative Research in Science, Engineering and Technology, IJIRSET, ISSN, Vol-5, Issue-1,pp.354365,

January,2016

[8] Enric Spacone et al., “ Non Linear Analysis of Composite Structures” American Society of Civil

Engineers, 10.1061/(ASCE)0733-9445(2004)

[9] IS456-2000- “Indian slandered Code of Practice for Reinforcement Concrete” (4th revision) Bureau of

Indian Standard (BIS) New Delhi

[10] SP16:1980 “Design Aids for Reinf0rced C0ncrete to IS-456-1978” Bureau 0f Indian Slandered, New Delhi

[11] IS-800-2007 –“Indian standard code practice for general construction in steel”, bureau of Indian standard

(BIS) new Delhi

[12] IS-875 (1987 part-1) “C0de of Practice for Design L0ads( other than Earth quake) for Building and

Structures, Dead Loads”, Bureau of Indian Standard (BIS) New Delhi

[13] IS-875 ( 987 part-II) “Code Practice for Live Load”, Bureau of Indian Standard (BIS) New Delhi.

[14] IS-1893(P-I, P-II) -2002 “Creiteria for Earthquake Resistant Design of Structure” General Provisions and

Buildings, Bureau of Indian Standards, New Delhi

[15] IS11384:1985 “ code practice or design of comp0site structures” bureau of Indian standard (BIS) New

Delhi.

[16] Euro code 3 “design of steel structure” European committee for standardizati0n committee European

den0rmalization europaisches committee fur normung.

[17] Euro code 4 “design of C0mposite structure” European committee for standardization committee Eur0pean

denormalization europaisches committee fur normung.

10646 www.ijariie.com 646

Vol-5 Issue-4 2019 IJARIIE-ISSN(O)-2395-4396

[18] S. Ramamurutham “Design of Reinforced Concrete Structures”, Text Book, Fourth Edition, Dhanapat rai

Publications.

[19] R.P. Johnson, “Compositexstructures of steel and concrete elements” (beams, Slabs, Column and Frames

for building) , Text Book, Blackwell publications UK-1994

[20] G.W Owens, P R knowels and P J d0wling, “Steel design manual of 5th addition-the steel construction

institute”, Text Book, Published -blackwell science.

[21] “Handbook of c0mposite construction multi-st0rey building” INSDAG publications N0.INS/PUB/022

[22] S K Duggal “design of steel structure” the McGraw-hill companies publications, new York-2010

[23] R.Narayanan “Composite steel Structures” Advances design and construction, Elsevier, Applied Science,

UK-1987

[24] S.ramamrutham, “Steel table” Dhanpat Rai Publications.

10646 www.ijariie.com 647

You might also like

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- RCC 1 PDFDocument8 pagesRCC 1 PDFNgọc TuyênNo ratings yet

- Irjet V4i2350 171121070636 PDFDocument6 pagesIrjet V4i2350 171121070636 PDFachmad yakusaNo ratings yet

- Study of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingDocument6 pagesStudy of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingAkshay DobleNo ratings yet

- IJRPR16287Document6 pagesIJRPR16287B45Raj Kumar ThakurNo ratings yet

- A Review Paper On Comparetive Study of Reinforced Concrete Filled Steel Tube Structure With Traditional Reinfroced Concrete and Steel Structure 31985Document7 pagesA Review Paper On Comparetive Study of Reinforced Concrete Filled Steel Tube Structure With Traditional Reinfroced Concrete and Steel Structure 31985Editor IJAERDNo ratings yet

- Panchal (Nirma University) - Comparative Study of RCC-Steel-Composite High Rise BuildingDocument6 pagesPanchal (Nirma University) - Comparative Study of RCC-Steel-Composite High Rise Buildingnvc_vishwanathanNo ratings yet

- Compare Studu PDFDocument5 pagesCompare Studu PDFdarsu NaikNo ratings yet

- Comparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsDocument7 pagesComparison of Seismic Behavior of A Structure With Composite and Conventional ColumnsEphrata MussieNo ratings yet

- Analysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureDocument9 pagesAnalysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureUsha EngineeringNo ratings yet

- Fin Irjmets1682867109Document5 pagesFin Irjmets1682867109B45Raj Kumar ThakurNo ratings yet

- Assignment. Engr EssayDocument4 pagesAssignment. Engr EssayGopalDhakalNo ratings yet

- Comparative Study On Dynamic Analysis of Composite, RCC & Steel StructureDocument8 pagesComparative Study On Dynamic Analysis of Composite, RCC & Steel StructureRajalakshmi JothivelNo ratings yet

- Composite Materials 2Document200 pagesComposite Materials 2Taimoor NasserNo ratings yet

- Seismic Analysis of RCC and Composite StructuresDocument9 pagesSeismic Analysis of RCC and Composite Structuresvishnumani3011No ratings yet

- Comparative Analysis of RCC and Steel-Concrete Composite Multistoried BuildingDocument7 pagesComparative Analysis of RCC and Steel-Concrete Composite Multistoried BuildingAbhishek GuptaNo ratings yet

- Research Paper On Analysis and Design ofDocument16 pagesResearch Paper On Analysis and Design ofPalesaNo ratings yet

- Comparative Study On Multi-Storey Structure of R.C.C and Composite MaterialDocument5 pagesComparative Study On Multi-Storey Structure of R.C.C and Composite MaterialBasavarajBachihalNo ratings yet

- Analysis and Design of Multi-Storeyed Bu PDFDocument8 pagesAnalysis and Design of Multi-Storeyed Bu PDFengyana engyyyNo ratings yet

- Consideration of Seismic Design of Multistoried Steel StructureDocument6 pagesConsideration of Seismic Design of Multistoried Steel StructureAnonymous KyLhn6No ratings yet

- SCS Protective StructureDocument18 pagesSCS Protective Structure안진호 / 학생 / 건설환경공학부No ratings yet

- 103820130510Document10 pages103820130510Ahmed SalemNo ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Dony DoanxNo ratings yet

- Cost-Effectiveness of Pre-Engineered and Conventional Steel FramesDocument7 pagesCost-Effectiveness of Pre-Engineered and Conventional Steel FramesBiswajit SahooNo ratings yet

- Paper 222Document12 pagesPaper 222dheerajbhawar786No ratings yet

- Composite Structure (31-38)Document48 pagesComposite Structure (31-38)Badri DadiNo ratings yet

- Steel DesignDocument131 pagesSteel DesignAndrea RamirezNo ratings yet

- Seismic Behavior of Steel-Concrete Composite Structures: December 2019Document7 pagesSeismic Behavior of Steel-Concrete Composite Structures: December 2019Usha EngineeringNo ratings yet

- Comparative Study of RCC and Steel Structures For Different Floor HeightsDocument5 pagesComparative Study of RCC and Steel Structures For Different Floor HeightsIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareDocument9 pages23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareSandy KavitakeNo ratings yet

- IJCRT2106637Document8 pagesIJCRT2106637jrcruzpogi0242424No ratings yet

- "A Review On Comparative Study of Composite RCC and Steel Structure" 1Document5 pages"A Review On Comparative Study of Composite RCC and Steel Structure" 1Ephrata MussieNo ratings yet

- Steel Conc. Comp. ContDocument35 pagesSteel Conc. Comp. ContDeepak SinghNo ratings yet

- IJCRT2306026Document8 pagesIJCRT2306026pankaj645924No ratings yet

- Design of Castellated Column in Finite Element AnalysisDocument10 pagesDesign of Castellated Column in Finite Element AnalysisIJRASETPublicationsNo ratings yet

- Report Composite AnkurDocument19 pagesReport Composite AnkurAnkur DubeyNo ratings yet

- The Application of Steel Structure in Civil Engineering: Xiaodan Wei, Xiangrong HeDocument4 pagesThe Application of Steel Structure in Civil Engineering: Xiaodan Wei, Xiangrong HeKrizsel ContrerasNo ratings yet

- Profiled Steel Sheets: Sacrificial Siiuttering (Form Deck)Document2 pagesProfiled Steel Sheets: Sacrificial Siiuttering (Form Deck)Sarmishtha DeNo ratings yet

- 1 s2.0 S0141029618325768 MainDocument17 pages1 s2.0 S0141029618325768 MainAmela ShahiniNo ratings yet

- Combining Steel and ConcreteDocument2 pagesCombining Steel and ConcreteIshwarya SrikanthNo ratings yet

- 2018 - Multidimensional Comparison of Lightweight Steel and Reinforced Concrete StructuresDocument9 pages2018 - Multidimensional Comparison of Lightweight Steel and Reinforced Concrete StructuresmatheusnormandessNo ratings yet

- Strengthening of Reinforced Concrete Columns by Steel Jacketing: A State of ReviewDocument10 pagesStrengthening of Reinforced Concrete Columns by Steel Jacketing: A State of Reviewsefatwrdk21No ratings yet

- Performance of Grade 500 Steel in Concrete Structure.Document7 pagesPerformance of Grade 500 Steel in Concrete Structure.Ahetesham Uddin Ahmed TipuNo ratings yet

- Assessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProDocument8 pagesAssessment and Design of Steel Frame Structure, Consists Performance of Connection Joints With Tekla & Staad ProaeoiuNo ratings yet

- Dynamic Analysis On RCC and Composite Structure For Uniform and Optimized SectionDocument16 pagesDynamic Analysis On RCC and Composite Structure For Uniform and Optimized SectionIJRASETPublicationsNo ratings yet

- Innovation in Composite ConstructionDocument6 pagesInnovation in Composite ConstructionnicholasNo ratings yet

- Jounal Composite 4Document11 pagesJounal Composite 4barath kumarNo ratings yet

- Seismic Performance of RC Flat Slab Structure With Different Types of Steel BracingDocument6 pagesSeismic Performance of RC Flat Slab Structure With Different Types of Steel BracingNovember RainNo ratings yet

- Application To Steel On BuildingDocument4 pagesApplication To Steel On BuildingCheryl GetongoNo ratings yet

- Structural Behavior of Steel-Concrete Composite BeamDocument12 pagesStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaNo ratings yet

- Research Chapter 1 and 2Document15 pagesResearch Chapter 1 and 2Jeorzelle Alexa OrtegaNo ratings yet

- A Review On Concrete Filled Steel Tubes Column: December 2015Document7 pagesA Review On Concrete Filled Steel Tubes Column: December 2015Sushant WaghmareNo ratings yet

- Ijciet 08 04 143Document11 pagesIjciet 08 04 143Filmon SolomonNo ratings yet

- Journal Article - Comparison RCC - CompositeDocument6 pagesJournal Article - Comparison RCC - CompositeSri KayNo ratings yet

- Guidelines For Composite Construction and Shear ConnectorsDocument25 pagesGuidelines For Composite Construction and Shear Connectorsradhakrishnang100% (1)

- Pre Engg BuildingDocument7 pagesPre Engg BuildingAkhilesh B.MNo ratings yet

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDocument27 pagesComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNo ratings yet

- Concrete Filled Steel Tubular (CFST) Columns in Composite StructuresDocument8 pagesConcrete Filled Steel Tubular (CFST) Columns in Composite Structuresashish SindhuNo ratings yet

- Steel Seismic DesignDocument24 pagesSteel Seismic DesignsenthilcivilNo ratings yet

- FULLTEXT02Document95 pagesFULLTEXT02NikhilARNo ratings yet

- Energy Audit Types and MethodologyDocument7 pagesEnergy Audit Types and MethodologyNikhilARNo ratings yet

- G&R ArchitectureDocument34 pagesG&R ArchitectureNikhilARNo ratings yet

- Santushti VelvettDocument130 pagesSantushti VelvettNikhilARNo ratings yet

- Renaissance Architecture: Donato Bramante Leon Battista Alberti Palazzo RiccardiDocument14 pagesRenaissance Architecture: Donato Bramante Leon Battista Alberti Palazzo RiccardiNikhilARNo ratings yet

- Concrete Concrete Water Cement Aggregate AdmixtureDocument2 pagesConcrete Concrete Water Cement Aggregate AdmixtureRoihans Muhammad IqbalNo ratings yet

- Dawit GebreDocument88 pagesDawit GebreabadittadesseNo ratings yet

- 4 - O-Pitblast - Topography ModuleDocument29 pages4 - O-Pitblast - Topography ModuleDANINo ratings yet

- Aquaarm Spu SPL Ver 8 1Document3 pagesAquaarm Spu SPL Ver 8 1Paladi RaviNo ratings yet

- Crossection of A RoadDocument27 pagesCrossection of A RoadFatima KamranNo ratings yet

- JNTUH B.tech 3 Year CE R16 SyllabusDocument33 pagesJNTUH B.tech 3 Year CE R16 SyllabusJANADHANNo ratings yet

- Concrete Mix DesignDocument24 pagesConcrete Mix Designvishnumani3011No ratings yet

- Contoh Soal ViskositasDocument2 pagesContoh Soal ViskositaswsdodoNo ratings yet

- AISI Standard For Cold-Formed Steel Framing - Wall Stud Design, 2004 EditionDocument35 pagesAISI Standard For Cold-Formed Steel Framing - Wall Stud Design, 2004 EditionSudip ShresthaNo ratings yet

- Foundation DesignDocument15 pagesFoundation Designvikash kumarNo ratings yet

- 6 Types of EngineersDocument5 pages6 Types of EngineersAsad NawazNo ratings yet

- Izracunat Moment Inercije T Profila 175x90x30Document1 pageIzracunat Moment Inercije T Profila 175x90x30cakizemunac4577No ratings yet

- Design CalcDocument308 pagesDesign CalcPeja Jusoh100% (1)

- Assignment I. FinalDocument9 pagesAssignment I. FinalMaulid67% (6)

- 103552Document31 pages103552Anbarasan SivarajNo ratings yet

- Design Consideration Pressure VesselDocument17 pagesDesign Consideration Pressure VesselQasim JavedNo ratings yet

- Equations For A Newtonian Fluid: Newtonian Versus Non-Newtonian FluidsDocument1 pageEquations For A Newtonian Fluid: Newtonian Versus Non-Newtonian FluidsYrrah StylesNo ratings yet

- Chapter 2: Cable Stayed Bridge ComponentsDocument9 pagesChapter 2: Cable Stayed Bridge Componentsdebjyoti_das_6100% (1)

- Water Distribution SystemDocument45 pagesWater Distribution SystemSrihari DasariNo ratings yet

- Woodland Trust Headquarters, Grantham, LincolnshireDocument8 pagesWoodland Trust Headquarters, Grantham, Lincolnshiredesign25mNo ratings yet

- Statics & FluidsDocument9 pagesStatics & FluidsShu RubioNo ratings yet

- Working Stress Method and Limit State MethodDocument5 pagesWorking Stress Method and Limit State MethodDeep DebnathNo ratings yet

- Bülent Akbaş - Advanced Steel StructuresDocument68 pagesBülent Akbaş - Advanced Steel StructuresMert SarıNo ratings yet

- Effect of Stiffeners On Shear Lag in Steel Box GirdersDocument14 pagesEffect of Stiffeners On Shear Lag in Steel Box Girderserky arkvathonejhNo ratings yet

- Radiator-Baseboard Product Data SheetDocument4 pagesRadiator-Baseboard Product Data SheetMohamed Feisal PatelNo ratings yet

- Module 5 TOSDocument8 pagesModule 5 TOSPrince IbanezNo ratings yet

- 3 R16 PDFDocument440 pages3 R16 PDFprashanthNo ratings yet

- ENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1Document15 pagesENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1jimyNo ratings yet

- Design of Short Column (Biaxial Bending)Document3 pagesDesign of Short Column (Biaxial Bending)meenu100% (2)

- FF1814 FinnframeDocument36 pagesFF1814 FinnframemilasanNo ratings yet