Professional Documents

Culture Documents

Publik 287833

Publik 287833

Uploaded by

Allagui AmalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Publik 287833

Publik 287833

Uploaded by

Allagui AmalCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

IFAC PapersOnLine 52-25 (2019) 509–512

Trends in Production Automation

Trends

Trends in

in Production

P. Kopacek. Automation

Production Automation

Trends in Production

P. Kopacek.

P. Kopacek. Automation

TU Wien, Institute for Mechanics

P. Kopacek. and Mechatronics, IHRT

TU Wien,

Favoritenstrasse Institute

9-11/E325 A4,for

A

Mechanics

– 1040 and Mechatronics, IHRT

Wien.(e-mail:kopacek@ihrt.tuwien.ac.at)

TU Wien, Institute for Mechanics and Mechatronics, IHRT

Favoritenstrasse 9-11/E325

TU Wien, A – 1040 Wien.(e-mail:kopacek@ihrt.tuwien.ac.at)

A4,for

Institute

Favoritenstrasse 9-11/E325 A4, A –Mechanics and Mechatronics, IHRT

1040 Wien.(e-mail:kopacek@ihrt.tuwien.ac.at)

Favoritenstrasse 9-11/E325 A4, A – 1040 Wien.(e-mail:kopacek@ihrt.tuwien.ac.at)

Abstract: Process – and manufacturing automation as well as robotics are currently one of the fastest

Abstract:

growing Process – and manufacturing automation as industry

well as robotics are currently one are

of the

not fastest

Abstract:fields

Processin automation. Cyber-physical

– and manufacturing systems,

automation 4.0 and “advanced

as well as robotics are currentlyrobots”

one of the longer

fastest

growing

aAbstract: fields

headline.Processin automation.

Production

– and4.0 is inCyber-physical

realization

manufacturing butsystems,

automation industry

production

as well5.0

as 4.0

is and “advanced

knocking

robotics are on the robots”

currentlydoor.

one are

Production

of the longer

not fastest

4.5

growing fields in automation. Cyber-physical systems, industry 4.0 and “advanced robots” are not longer

awasheadline.

growing Production

introduced

fields one

in year4.0

ago

automation.is in

as realization

an immediate

Cyber-physical but production

step for

systems, small 5.0

and

industry is knocking

medium

4.0 and on the

enterprises.

“advanced door.

They

robots” Production

are some

not 4.5

first

longer

a headline. Production 4.0 is in realization but production 5.0 is knocking on the door. Production 4.5

was

dreams

awas introduced one

on production

headline. Production year ago

6.0.

4.0 as an immediate step for small and medium enterprises. They are some first

introduced one year agoisasinan

realization

immediatebut production

step for small 5.0

andismedium

knocking on the door.

enterprises. TheyProduction 4.5

are some first

Andreams

was on production

important

introduced part

one of 6.0.ago as anautomation

production

year immediate is (semi)

step for automated

small and assembly.

medium This

enterprises.topic is

They currently

are some only

first

dreams on production 6.0.

An important

outlined

dreams thepart

inproduction

on of production

literature

6.0.with some automation

descriptionis (semi) automated

of laboratory assembly.

tests. ConcerningThisoftopic

one isof currently

the scopes only

of

An important part of production automation is (semi) automated assembly. This topic is currently only

outlined

TECIS

An in theof

“End

important literature

partlife

of with some

management

production – description

EoL”

automation an of laboratory

important

is (semi) part tests.

(semi)

automated Concerning

automated

assembly. This oftopic

one is

disassemblyof currently

theis scopes of

currently

only

outlined in the literature with some description of laboratory tests. Concerning of one of the scopes of

TECIS

outlined

missing “End

in theofliterature

all lifethese

of management

with some

concepts. – description

EoL” an important

Therefore in

of this part

laboratory (semi)

contribution

tests. automated

first ideas

Concerning disassembly

of on

one(semi)

of theisautomated

currently

scopes of

TECIS “End of life management – EoL” an important part (semi) automated disassembly is currently

missing

TECIS in all

“End

disassembly of

4.0 of

lifethese

including concepts.

management

new –

tasks Therefore

EoL”

for an in this

important

“advanced” robotscontribution

part

will(semi)

be first

automated

given and ideas ondiscussed.

(semi) isautomated

disassembly

shortly currently

missing in all of these concepts. Therefore in this contribution first ideas on (semi) automated

disassembly

missing

As 4.0 including

in all

a consequence these new

ofofthese tasks for

concepts.

developments “advanced”

Therefore robots

in this

new social, will

andbe

contribution

ethical given

human andideas

first shortly

questions ondiscussed.

(semi) automated

appear.

disassembly 4.0 including new tasks for “advanced” robots will be given and shortly discussed.

As a consequence

Keywords:

disassembly 4.0 of

Manufacturingthese

including developments

Automation,

new tasks for new

Robots,social,

Social

“advanced” ethical and

aspects,

robots will human

Ethics.

be given questions

and appear.

shortly discussed.

© 2019,

As a consequence

Keywords:

As

IFAC of these developments

(International

Manufacturing

a consequence

Federation of new

of these Automation,

developmentsRobots,

social,Control)

Automatic

Social

new social,

ethical and

aspects,

ethical

human

Hosting

andEthics.

questions

by Elsevier appear.

Ltd.

human questions appear.

All rights reserved.

Keywords: Manufacturing Automation, Robots, Social aspects, Ethics.

Keywords: Manufacturing Automation, Robots, Social aspects, Ethics.

1. INTRODUCTION (Kopacek, 2015)

1. INTRODUCTION (Kopacek, 2015)

1. INTRODUCTION

The main Manufacturing (Kopacek,

Systems2015) Evolution Drivers are: Internet protocol IPv62 introduced in 2012 sufficient

1.

The INTRODUCTION

main Manufacturing (Kopacek,

Systems 2015)

Evolution Drivers are: Internet

addresses protocol

are available IPv62 introduced

to enable universal in direct

2012 sufficient

- Global growth & competition,

The main Manufacturing Systems Evolution Drivers are: Internet protocol IPv62 introduced in 2012 networking

sufficient

addresses are available to enable universal direct

2012 networking

The main --- Knowledge

Global growth

Manufacturing

Global growth

&Systems

competition,

Economy,

& competition, Evolution Drivers are: Internet

of

addresses protocol

smart objects via IPv62

are available introduced

the toInternet.

enable Now isinpossible

universal direct tosufficient

network

networking

of smart objects via the toInternet. Now is possible to network

--- Environmental

Knowledge

Global growth

Knowledge Economy,

Economy,

& competition,

pressures, addresses

resources, are available

information, enable

objects universal

and people

of smart objects via the Internet. Now is possible to network direct

to networking

create the

-- Molecular

Environmental

Knowledge pressures,

Economy, resources,

of smart

“Internet of information,

objects

Things via the

and objects

Internet.

Services”. and

Now people

is to

possible create

to the

network

manufacture,

- Environmental pressures, resources, information, objects and people to create the

-- Conflict

Molecular manufacture, “Internet

resources, of Things

information,and Services”.

objects and people to create the

- Environmental

Molecular over pressures,

resources,

manufacture, “Internet of Things

Environmentally and Services”.

Conscious Manufacturing. Efficient use of

-- Ideology,

Conflict over resources, “Internet of Things and Services”.

- Molecular

Conflict over &manufacture,

culture,

resources, ICT- ambient & networked, Environmentally

materials and natural Conscious

resources Manufacturing.

in production, Efficient

Minimize use the

of

--- Global

Ideology,

Conflict & culture,

over resources,

competition

Ideology, & culture, ICT- inICT- ambient & networked,

services,

ambient & networked,

Environmentally

materials and

Conscious

natural resources

Manufacturing.

intheproduction,

Efficient

Minimize

use of

the

Environmentally

negative Conscious

consequences onManufacturing. Efficient

environment use of

(green

--- Human

Global

Ideology, competition

& culture,in

need,

Global competition

services,

inICT- ambient & networked,

services,

materials and natural resources in production, Minimize the

negative consequences on theproduction,

environment (green

-- Human need, materials

manufacturing,and natural resources

cleaner in

production

negative consequences on the environment (green and Minimize

sustainablethe

- Physical

Global Product in services,

Human competition

need, manufacturing,

negative

manufacturing). consequencescleaner on production and sustainable

the environment (green

-- Physical

Human Product

need, manufacturing, cleaner production and sustainable

- Physical Product manufacturing).

manufacturing, cleaner production and sustainable

A manufacturing - Physical Product

process consists of processing operations Design manufacturing).

for environment (DFE). Select materials that require

A manufacturing process consists of processing operations manufacturing).

which transforms a work material from one state of Design forenergy

minimum environment (DFE).

to produce, Select

select materials

processes thatthat require

minimize

A manufacturing process consists of processing operations Design for environment (DFE). Select materials that require

which

completion

A transforms

manufacturing to a more a advanced

processwork material

consistsstate that

of from

is oneto

closer

processing state

the of waste

final

operations minimum energy to produce, select processes that minimize

which transforms a work material from one state of Design minimum forenergy

of environment

materials to and (DFE).

produce,energy, Select

select design materials

partsthat

processes that

that require

can

minimize be

completion

which to a more

transforms advanced

by ameans state thatfrom

workofmaterial is closer

oneto the final

of waste of or materials and energy, design thatparts that can be

desired

completion product

to a more advanced shaping

state thatoperations,

is closer to state

property

the final recycled

minimum

waste of energyreused,

materials design

to produce,

and products

select

energy, processes

design can

parts that beminimize

that readily

can be

desired

completion

enhancing product

to a by means

more

operations, advanced

surface ofprocessing

shaping

state that operations,

is closer

operations. to property

the final recycled

waste of

disassembled or reused,

materials

to design

and

recover products

energy,

the design

parts, thatparts

design can be can

that

products readily

be

that

desired product by means of shaping operations, property recycled or reused, design products that can be readily

enhancing

desired operations,

product by surfaceofprocessing

means shaping operations. property minimize

operations, disassembled

recycled orthe to

reused,

use recover

of design theproducts

hazardous parts,

and design

that

toxic products

can be

materials, that

readily

give

enhancing operations

Assembly operations, surface twoprocessing operations. to create disassembled to recover the parts, design products that

enhancing operations,joins surface or more components

processing operations. minimize

disassembled the use

to ofproduct

recoverhazardous

the beand

willparts, toxic of

design materials,

products give

that

Assembly

aAssembly

new entity, operations

called joins

an two

assembly or more

by components

means of to create attention

permanently minimizetothe

attention to

how

how

usethe

the

of hazardous

product will be

disposed

and

disposed of

at the end

toxic materials,

at the end

of

give

of

operations joins two or more components to create its minimize

useful the

life. use of hazardous and toxic

attention to how the product will be disposed of at the end of materials, give

aAssembly

new entity,

(welding, calledsoldering,

operations

brazing, an assembly

joins two or

and by means

more

adhesive of permanently

components

bonding) to

or create

semi- its useful life.

a new entity, called an assembly by means of permanently attention to how the product will be disposed of at the end of

its usefulFactories

life.

(welding,

a(welding,

new entity,

permanently brazing,

calledsoldering,

(screws, an bolts

assembly and

or adhesive

by means

rivets, bonding) or semi-

of permanently

press fitting, and Smart Beginning to appear and employ a

brazing, soldering, and adhesive bonding) or semi- its useful

Smart life.

Factories Beginning to appear

permanently

(welding,

expansion

permanently

(screws,

brazing, bolts

soldering,

fits).(screws, bolts and

or rivets,

or adhesive

press fitting,

bonding)

rivets, press

and

or semi-

fitting, completely

and Smart new approach

Factories Beginning to production.

to appear Suchand

and

employ

factories

employ allowaa

expansion

permanently fits).(screws, bolts or rivets, press fitting, and to completely

Smart

fulfill new approach

Factories

individual Beginning

customer to production.

to appear

requirements. SuchBecause

factories

and employ

of allow

theira

expansion fits). completely new approach to production. Such factories allow

This yields,

expansion fits). in the past, to the development of Computer to fulfill

completely

flexibility individual

new customer

approach

last-minute to

changes requirements.

production.

in Such

production Because

factories

are of their

allow

possible.

This yields,Manufacturing

Integrated in the past, to the development

(CIM), Intelligent of Computer to

Manufacturing to

fulfill individual customer requirements. Because of their

flexibility

fulfill last-minute changes in production are possible.

This yields, in the past, to the development of Computer The mainindividual

flexibility goal

last-minute customer

of a smart changes requirements.

factory inis to produce

production Because

“lot

are sizeof One”

their

possible.

Integrated

Systems

This yields, ( Manufacturing

imsin ),theAgile (CIM),

past,Manufacturing

to Intelligent

Systems

the development Manufacturing

of(AMS).

Computer At in The main

flexibility goal of away.

last-minute smart factory

changes inis to produce

production “lot

are size One”

possible.

Integrated Manufacturing (CIM), Intelligent Manufacturing an economic This yield to a higher number of

Systems

time(( the

Integrated

that ims hard-

), Agile

Manufacturing andManufacturing

(CIM),

softwareIntelligentSystems (AMS).

Manufacturing

possibilities were very At Thein

The

main goal of a smart factory is to produce “lot size One”

anmain

economic

goal of away.

smart This yield

factory is toproduce

to a onhigher“lot number

size One”of

Systems ims ), Agile Manufacturing Systems (AMS). At variants, a high flexible production

in an economic way. This yield to a higher number of based market needs, an

that

limited timeand

Systems ( the

ims hard-

), Agile

therefore and software

Manufacturing

industrial possibilities

Systems

applications of were

(AMS).

AMS very

At

not variants,

“on

in a

demand”

an high

economic flexible

production,

way. production

preventive

This yield based on

maintenance

to a market

higher needs,

planning

number an

in

of

that time the hard- and software possibilities were very variants, a high flexible production based on market needs, an

limited andthetherefore industrial applications of were

AMS very not “on

limited and therefore industrial applications of AMS not “on demand” production, preventive maintenance planning in

that time

economic. hard- and software possibilities demand”

variants,

production, a high production,

flexible

“smart” preventive

production

robots communication maintenance

based on market planning

needs, an

in

economic.

limited and therefore industrial applications of AMS not Smart production,

“on demand” “smart” robotspreventive

production, communication maintenance planning in

economic.

Agile products

production, “smart”

manufacturing systems are now realized based on Smart products are uniquely identifiable, may be easily are uniquely

robots identifiable,

communication may be easily

economic. production, “smart” robots communication

Agile manufacturing systems are now

CPS realized based on located at all times, are know theiridentifiable,

own history,may currentbe status,

Cyberphysical

Agile manufacturing systems systems(CPS). are now comprise

realized based on Smart

smart located

products

alternative

Smart at all times,

routes

products

uniquely

to know

are achieving

uniquelytheiridentifiable,

own target

their history, current

state.

may

easily

be status,

(Kopacek,

easily

Cyberphysical

machines,

Agile storage

manufacturing systems

systems

systems(CPS).

and are CPS realized

production

now comprise

facilitiesbasedsmart

capableon located at all times, know their own history, current status,

Cyberphysical systems (CPS). CPS comprise smart 2018). alternative

located at routes

all times, to achieving

know their their

own target

history, state. (Kopacek,

current status,

ofmachines,

Cyberphysical

autonomously storagesystems

systems (CPS).

and production facilities capable

CPS triggering

comprise smart alternative routes to achieving their target state. (Kopacek,

machines, storageexchanging

systems andinformation,

production actions

facilities capable 2018).

alternative routes to achieving their target state. (Kopacek,

of

and autonomously

machines,

controlling storage exchanging

each systems

other and information,

production

independently. triggering

facilities

Based on the actions

capable

new 2018).

of autonomously exchanging information, triggering actions 2018).

and

of controlling each other independently. Based on the new

andautonomously

controlling

2405-8963 © 2019,each

exchanging

IFACother

information,Based

independently.

(International

triggering

on theactions

Federation of Automatic new

Control) Hosting by Elsevier Ltd. All rights reserved.

and controlling each other independently. Based on the new

Peer review under responsibility of International Federation of Automatic Control.

10.1016/j.ifacol.2019.12.595

510 P. Kopacek / IFAC PapersOnLine 52-25 (2019) 509–512

humans. The communication between humans and non-

humans is the sharing of information and data regarding the

2. PRODUCTION 4.0 system. It is important that to design and generate

The Industry 4.0 vision is not limited to automation of a organizations, data-sharing platform and technologies which

single production facility. It incorporates integration across support the system to interact for the goal.

core functions, from production, materials sourcing, supply

chain, and warehousing all the way to sale of the final 4. ROBOTS IN INDUSTRY 5.0

product. This high level of integration and visibility across Cobots will play the primary role in industry 5.0

business processes will enable greater operational efficiency, (a) The machine tending: The robot moves parts for

responsive manufacturing, and improved product design. machining inside and outside the machine. While the robot is

loading and unloading the workpiece, the operator can do

3. PRODUCTION 5.0 other tasks.

(b) Pick-and-place. The robot moves from the process to the

We are now in manufacturing automation in the field of input of another. For instance, it could be grabbed and placed

Production 4.0 and Production 5.0 is knocking on the door. on a tray.

Industry 5.0 focuses to validate creativity, high-quality (c) Assembly: (d) Quality tests: the robot loads the products

custom-made products and life standard. It aims to increase in a quality test machine and takes away them once the test is

the life quality of human and not only to increase the finished.

technology. It can be called as the fifth revolution of (d) Other lightweight weighing applications: The robot

mankind. Smart services are for both communication of performs basic packaging, refining, gluing and other tasks.

humans and non-humans. The communication between Evoke that Cobots can do most of the thing’s humans do if

humans and non-humans is the sharing of information and they do not require great skill.

data regarding the system. It is important that to design and Most of these applications include tasks without added value

generate organizations, data-sharing platform and (i.e., functions that are not added something about a product

technologies which support the system to interact for the that the customer would be ready to pay for). Because it has

goal. no added value, the functions are accessible for the Cobots to

For Industry 5.0, it is necessary to turn regular machines into do and free the man from boring and repetitive work. For the

safe and self-learning devices to improve their overall implementation of Cobot, it is best to start small and keep it

performance and maintenance management with the modest. They can accumulate more complicated applications

surrounding interaction. Industry 5.0 seeks to build an open after you have more experience with Cobots. (Karabegović,

and intelligent manufacturing platform for industrial network P. D. 2018)

information applications. The critical requirements of

Industry revolution are real-time data monitoring and product

location, as well as instructions to control manufacturing. 5. ASSEMBLY 4.0

Assembly represents the last phase of production processes.

Industry 5.0 is based on four principles

Thus, assembly operations manage the whole product

differentiation and customization.

• Interoperability: The collaboration of machines, tools, and

Assembly Automation was introduced 1978 with the

computers in a system.

realization of the first Semi-automatized Assembly Cells

• Information clarity: The capacity of the sensor-stocked

(Kopacek, Probst; 1992), (Kopacek, Noe; 1994).

computer systems to create a virtual version of real machines

Later the first mostly theoretical papers were published like

and objects.

(Bortolini et.al, 2017)

• Technical support: Computer systems and artificial

The robot performs simple tasks when assembling parts that

intelligence to support workers with strategy, decision

require little skill. (On the same time, assembly tasks that

making, and work.

require high skill are perfect for human-robot collaboration:

• Fragmented decision: The computer systems can complete

the robot can accomplish the simplest assembly tasks and

several and specific task on their own.

then move the parts into an area where the man can do the

Industry 5.0 focuses to validate creativity, high-quality

job.

custom-made products and life standard. It aims to increase

the life quality of human and not only to increase the

technology. It can be called as the fifth revolution of 6. DISASSEMBLY 4.0

mankind. Smart services are for both communication of

humans and non-humans. The communication between Disassembly automation came up in 1998 with the realization

humans and non-humans is the sharing of information and of the first industrial semi-automatized disassembly cells.

data regarding the system. It is important that to design and (Kopacek, Noe; 1994), (Kopacek, Gschwendtner; 1998),

generate organizations, data-sharing platform and (Kopacek, 2000).

technologies which support the system to interact for the Semi- or fully automatized disassembly especially of

goal. electr(on)ic devices was not only because of the

It can be called as the fifth revolution of mankind. Smart standardization by the European Commission (directive on

services are for both communication of humans and non- waste from electrical and electronic equipment – WEEE) at

that time a hot topic. Usually only the toxic components were

P. Kopacek / IFAC PapersOnLine 52-25 (2019) 509–512 511

removed manually and the rest of the materials were shred are new. This is not the case for disassembly because usually

and deposed. Manual disassembly of such devices is today the parts could be deformed, corroded …

the state of the art. Because of this EC regulation and the Otherwise in disassembly we can destroy some parts and

increasing amount of electronic scrap manual disassembly get fixtures.

more and more inefficient in the nearest future. Hence Disassembly 4.0 requires new types of robots because they

automation of the disassembly process was absolutely must be able to communicate with other parts and machine

necessary. tools……….. Furthermore for cracking operations they have

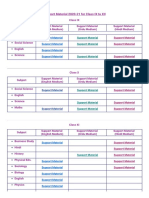

Fig.1 shows all different parts of a modular, flexible to be very robust. This will be the necessary features of

disassembly cell. According to the figure the main modules Cobots in the future.

of such a cell are: These novel disassembly systems are modularly structured as

“smart disassembly stations” and “smart part logistic”. These

Industrial robots or handling devices with special features

system elements communicate and cooperate with each other

like high accuracy, path- and force control (disassembly

and with humans in real time, monitoring physical processes

robot).

and creating a virtual copy of the physical disassembly

Special gripping devices for a broad spectrum of parts process to enable quick and decentralized decisions.

with different geometries and dimensions. Beneficial effects are a significant improvement of flexibility

and speed of the whole system that enables more customized

Disassembly tools especially developed for robots. products, an efficient and scalable production, and a high

Feeding systems for the products to be disassembled. variance in production control. Finally, proper optimization

models, control algorithms, automation technologies and

Transport systems – similar as for assembly cells. management methods have to be developed to allow the

aforementioned smart cyber physical systems of self-

Fixture systems for parts with different geometries and optimization, self-configuration, self-diagnosis and intelligent

dimensions. support to workers in their increasingly complex tasks.

Manual disassembly stations.

Intelligent control units able to process information from

extended sensors. 7. INFLUENCES FOR TECIS

Component database including data of reusable and

There are also many hitches stand in the implementation of

remanufacturable parts.

Industry 4.0

(„cost oriented“) vision systems for part recognition.

Various sensors for force and moment limitations, • If the Industry 4.0 is once fully implemented, many

position, distance, etc. uneducated or not educated workers to get jobless.

Storage systems for tools and parts.

• To implement Industry 4.0, high skilled factory engineers

are needed, so highly educated people are required.

(Intell.) Cell

Control Unit • IT security problems: since Industry 4.0 is highly depended

on IT, it is essential to keep the IT security efficiently.

Disassembly Storage

• Fear of IT bugs: There are chances for sudden temporary

Robot Devices malfunctions of IT, so many of the essential and confidential

processes may get misshapen.

Robot Transport

Gripper System

Disassembly • Reliability problems with the machine to machine

Cell communication, still it is not reliable at the level of stability

Disassembly Clamping

Tools Device and overall performance according to Industry 4.0 standards.

Components Manual Disas- Shortly, it is expected that advanced detection potential in

Database sembly station cyber-human technology will abolish the risk of defects

which increases the chances of adoption Industry 4.0 by

many companies. Now, many of the participants are agreeing

Sensors

that cyber systems are more reliable than manually operated

Force Visual Pos. systems producing exact precision.

Torque Dist.

The view that the 5.0 industry is a new form of collaboration

between humans and robots is to harness the capabilities of

Fig. 1 Modules of an intelligent flexible disassembly cell. machines and people. The machines are more precise and

(Kopacek P. & B.; 1999) efficient, and the workers have skills, reasoning, and critical

The differences between semi-automatized assembly and thinking. This mode is appropriate for jobs that lie between

disassembly are: In assembly we can assume that all the parts fully manual and fully automatic manufacturing lines.

Working with Cobotics enables companies of all sizes, the

512 P. Kopacek / IFAC PapersOnLine 52-25 (2019) 509–512

implementation of automation and in places where this is not Kopacek, P. and G. Gschwendtner (1996): A new method for

profitable or difficult to implement. This is also due to the the assessment of products for automated

rising demand of customers for personalized products that disassembling. In: Preprints of the 13th World

meet their needs and desires. Congress of IFAC, June 30-July 5, 1996, San

Francisco, Vol. B, S. 241-246.

In general, four key components (CPS, Internet of Things

(IoT), Internet of Services and Smart Factory) and six Kopacek P. and B.Kopacek (1998): Intelligent Disassembly

significant technologies artificial intelligence (AI), Big Data, of Electronic Equipment. Proceedings of the 1st IFAC

virtual reality, (Internet Industrial of Things (IIoT), CPS, Workshop on Intelligent Assembly and Disassembly –

additive manufacturing (3D printing) and collaboration robot IAD’98, Bled, Slovenia, p. 87-92

(CoBot) and) to advance Industry 4.0. The focus is on the

technical aspects of the application. The main thing is human P.Kopacek (2000) Hierarchical Control of Disassembly Cells.

resources exist only in possible changes in the labour market In: Preprints of the 4th IFAC Symposium on Intelligent

produced by Industry 4.0. This situation is unacceptable and Components and Instruments for Control

is reflected in several articles related to Industry 4.0. Applications, Buenos Aires, p.265-272.

Although Industry 4.0 is only in the early phases of growth

and the main achievements cannot be expected before 2020- Kopacek, P.(2015): Automation and TECIS. Proceedings of

2025, you can see the image of a new model of Industry 5.0. the 16th IFAC Conference on “Technology, Culture

It means the entrance of artificial intelligence into the and International Stability”, September 24-27, 2015,

common life of man, his "cooperation" with the goal of Sozopol, Bulgaria. Published by Elsevier Science

improving man's ability and man's return to the "centre of the Publishers, IFAC Papers On-line, Volume 48 (2015),

universe." (Vuksanović, Dragan & Vešić, Jelena & Korčok, Issue 24, p. 021 - 027. DOI

Davor. 2016) 10.1016/j.ifacol.2015.12.050.

Kopacek,P. and M. Hersh (2015): Roboethics; In: "Ethical

Engineering for International Development and

8.SUMMARY AND FURTHER DEVELOPMENTS Environmental Sustainability", M. Hersh (Ed.);

Springer London, 2015, p. 65 – 102; ISBN: 978-1-

In this paper some trends of production or manufacturing

4471-6617-7, DOI.10.1007/978-1-4471-6618-4.

automation, based on previous works, are presented with are

Kopacek

or will be in the future of interest for TECIS.

After a short introduction in the fundamentals of Production P. Kopacek (2018): Development Trends in Cost Oriented

4.0 an outlook on further developments – Production 5.0 Production Automation. Proceedings of the "18th

(6.0) – is given. This subject is currently influenced by a IFAC Conference on Technology, Culture and

overwhelming digitalization. International Stability TECIS 2018; IFAC-

PapersOnLine, Elsevier, Netherlands, 2018, p. 39 - 43.

According to the scope of TECIS special emphasis is on DOI 10.1016/j.ifacol.2018.11.242

assembly and disassembly automation 4.0 not only because

of the replacement of “low cost” working places which yields Vuksanović, Dragan & Vešić, Jelena & Korčok, Davor.

to social problems. (2016): Industry 4.0: The Future Concepts and New

Visions of Factory of the Future Development. 293-

On common workplaces because of human – robot 298. 10.15308/Sinteza-2016-293-298.

collaboration ethical problems arises.

REFERENCES

Bortolini, M.et al (2017): Assembly design in the Industry

4.0 era a general framework. IFAC PapersOnLine 50-

1 (2017)5700–5705. 10.1016/j.ifacol.2017.08.1121.

Karabegović, P. D. (2018): The Role of Industrial and

Service Robots in Fourth Industrial Revolution with

Focus on China. Journal of Engineering and

Architecture, 6(1). doi:10.15640/jea.v5n2a9.

Kopacek P. and D.Noe (1994): Knowledge Based Selecting of

the Components in the Robotized Assembly Cells. In:

Proceedings of the 10th IFAC Conference on CAD/CAM,

Robotics and factories of the Future, Ottawa, p.812-817.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Music Video Analysis: David Bowie - Let's DanceDocument10 pagesMusic Video Analysis: David Bowie - Let's DanceClaire AngusNo ratings yet

- ZVEI Industrie 40 Component EnglishDocument2 pagesZVEI Industrie 40 Component EnglishAllagui AmalNo ratings yet

- J Addma 2016 01 001Document20 pagesJ Addma 2016 01 001Allagui AmalNo ratings yet

- Smart Parts Fabrication Using Powder Bed Fusion Additive Manufacturing TechnologiesDocument14 pagesSmart Parts Fabrication Using Powder Bed Fusion Additive Manufacturing TechnologiesAllagui AmalNo ratings yet

- DETC2005-85561: A Knowledge-Based System Engineering Process For Obtaining Engineering Design SolutionsDocument12 pagesDETC2005-85561: A Knowledge-Based System Engineering Process For Obtaining Engineering Design SolutionsAllagui AmalNo ratings yet

- An Approach For Assembly Process Case Discovery Using Multimediainformation SourceDocument15 pagesAn Approach For Assembly Process Case Discovery Using Multimediainformation SourceAllagui AmalNo ratings yet

- CAD Parts-Based Assembly Modeling by Probabilistic ReasoningDocument8 pagesCAD Parts-Based Assembly Modeling by Probabilistic ReasoningAllagui AmalNo ratings yet

- TC2971en-Ed01 Installation Procedure For OmniVista8770 R5.0.24.00Document88 pagesTC2971en-Ed01 Installation Procedure For OmniVista8770 R5.0.24.00K Mei.No ratings yet

- V PCDocument14 pagesV PCGiga Networkers100% (1)

- HanumanstaleDocument449 pagesHanumanstaleBhaskar Gundu100% (2)

- Link of Support Material Link 2020-21CLASSES 9 1 - 11 12Document2 pagesLink of Support Material Link 2020-21CLASSES 9 1 - 11 12naman mahawerNo ratings yet

- LBO ModelingDocument66 pagesLBO Modelingalexander ThielNo ratings yet

- Darby's Appellate BriefDocument69 pagesDarby's Appellate BriefDevin PavlouNo ratings yet

- Activitiesclasswork Unit 2 Lesson 3 Great Civilizations Emerge Maya Religion Ans Social HierarchyDocument25 pagesActivitiesclasswork Unit 2 Lesson 3 Great Civilizations Emerge Maya Religion Ans Social Hierarchyapi-240724606No ratings yet

- Science5 Q4 Module5 Week5 18pDocument18 pagesScience5 Q4 Module5 Week5 18praymondcapeNo ratings yet

- Letra de CancionesDocument9 pagesLetra de CancionesArt Van Der MartinNo ratings yet

- Dinalog VU An Exploratory Analysis of The Dutch Pharmaceutical Supply ChainDocument47 pagesDinalog VU An Exploratory Analysis of The Dutch Pharmaceutical Supply ChainTim van ReesNo ratings yet

- Mca MaterialDocument30 pagesMca MaterialsharmilaNo ratings yet

- Finance Batch 2022-24Document20 pagesFinance Batch 2022-24LAKHAN TRIVEDINo ratings yet

- CAN - CGSB 39.19 - 98 CalipersDocument17 pagesCAN - CGSB 39.19 - 98 CalipersChristian LefroitNo ratings yet

- Cutting Opera Tion Takes Onl Y 24HRS: User ListDocument2 pagesCutting Opera Tion Takes Onl Y 24HRS: User ListNurSarahNo ratings yet

- CLASS-OBSERVATION1 - Types of Communicative StrategiesDocument4 pagesCLASS-OBSERVATION1 - Types of Communicative StrategiesFernandez AnjoNo ratings yet

- Paleolithic: Rehistoric Estern UropeDocument13 pagesPaleolithic: Rehistoric Estern UropeAhmed MohammedNo ratings yet

- LAO PDR's ENERGY SECTOR ASSESSMENT, STRATEGY, AND ROAD MAP PDFDocument91 pagesLAO PDR's ENERGY SECTOR ASSESSMENT, STRATEGY, AND ROAD MAP PDFKizuna L. ChanthavongNo ratings yet

- SAP EAM/ PM Certification Questions & Answers: For More Books VisitDocument38 pagesSAP EAM/ PM Certification Questions & Answers: For More Books Visitismail mohammed100% (1)

- VPN-FORM202404050172Document3 pagesVPN-FORM202404050172jatin kharbNo ratings yet

- Technical Report Writing in The Maritime & Offshore IndustryDocument4 pagesTechnical Report Writing in The Maritime & Offshore IndustryIke MaduforoNo ratings yet

- 114 Layout Secrets For Your Framing Square PDFDocument2 pages114 Layout Secrets For Your Framing Square PDFHomerSimsonnakis100% (1)

- Le1 Aio LT6 S AkDocument1 pageLe1 Aio LT6 S AkbesamundoNo ratings yet

- Auden The Quest HeroDocument24 pagesAuden The Quest HeroFlavianNo ratings yet

- IELTS General Task 1 Formal Letter Sample Feedback Band 6Document3 pagesIELTS General Task 1 Formal Letter Sample Feedback Band 6alinaemmeaNo ratings yet

- Bachelor Thesis Presentation ExampleDocument4 pagesBachelor Thesis Presentation ExampleFiona Phillips100% (2)

- 1-To-8 4K HDMI Distribution Amplifier: HD-DA8-4K-EDocument3 pages1-To-8 4K HDMI Distribution Amplifier: HD-DA8-4K-EthomvalensiNo ratings yet

- CFIHOS RDL Development GuideDocument19 pagesCFIHOS RDL Development GuideselvarajvijayakumarNo ratings yet

- Test 1 Rectification and Subsidiary Books 21.05.2019Document2 pagesTest 1 Rectification and Subsidiary Books 21.05.2019bhumikaaNo ratings yet

- Case 1 - Article 3 of The R.P.C.Document10 pagesCase 1 - Article 3 of The R.P.C.Rochelle GablinesNo ratings yet