Professional Documents

Culture Documents

Lay Out AWS Plate Test 1 Inch SMAW D1.1

Lay Out AWS Plate Test 1 Inch SMAW D1.1

Uploaded by

TyreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lay Out AWS Plate Test 1 Inch SMAW D1.1

Lay Out AWS Plate Test 1 Inch SMAW D1.1

Uploaded by

TyreCopyright:

Available Formats

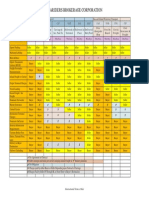

AWS Structural Welder Qualification Test

“AWS QC7” National Certification Program Welding Test Center

Using Welding Procedure Specification (WPS) per Thomas Giles – Lab Director

American Welding Society D1.1 Code 354 Hogan Road, Bangor, ME 04401

(207) 974-4662 – tgiles@emcc.edu

http://www.weldingtestcenter.org

Test #: D1-SM-F4-P-A-U - Shielded Metal Arc Welding (SMAW) - E7018

1" Unlimited Thickness Test (positions: 3G-vertical & 4G-overhead or 1G flat option)

5"

4"

1/4" x 1" Backing Strap

● Plate material: A36 - 1" x 5" stock cut into 4" lengths with a 22 ½ degree bevel.

● The plates and backing should be ground and cleaned of any mill covering a minimum of 1” front and back and are then gaped

1/4" apart and tacked on the ends where the backing (1/4" minimum x 1" x 9") meets the plate.

● The welder decides which position they want to do first and may begin after an initial inspection. Time limit is 1 ½ hours per

position (material prep, fit-up and tack and any warm up practice is not counted in the 1 ½ hours).

● Root pass may be welded with 3/32" or 1/8" diameter E7018 electrode. Fill and cover passes are welded with 1/8" diameter

E7018 electrode

● Power brushing is allowed.

● Grinding is allowed except on the cover passes which will be visually inspected.

The visual inspection consists of the following:

Weld metal on cover passes must be a minimum of flush with plate and no more than 1/8” reinforcement.

Bead width should be no more than 3x the core diameter of the electrode.

(Example: 1/8" E7018, maximum bead width = 3/8")

Undercut shall not exceed 1/32” (if undercut is greater than 1/32” an extra pass is allowed but caution should be

taken to avoid repeating the problem on this extra pass)

1” Plate Test Joint details

You might also like

- Macroeconomics 6th Edition Williamson Test Bank DownloadDocument21 pagesMacroeconomics 6th Edition Williamson Test Bank DownloadDarrell Davis100% (19)

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- A938-07 (2013) Standard Test Method For Torsion Testing of WireDocument3 pagesA938-07 (2013) Standard Test Method For Torsion Testing of Wiretjt4779100% (2)

- ASTM F88-07 STD TM For Seal Strength of Flexible Barrier MaterialsDocument11 pagesASTM F88-07 STD TM For Seal Strength of Flexible Barrier Materialstiliad5871% (7)

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDeny Cahyo N100% (2)

- Astm F680Document3 pagesAstm F680urielgamizNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- E190.29610 AstmDocument4 pagesE190.29610 AstmMassab JunaidNo ratings yet

- Astm D 1002Document5 pagesAstm D 1002Aisya IbrahimNo ratings yet

- Manu 135 04 041004 PDFDocument6 pagesManu 135 04 041004 PDFGabrielle ScottNo ratings yet

- E662 Specimen Preparation InstructionsDocument2 pagesE662 Specimen Preparation InstructionsHarits AnggawiNo ratings yet

- Ensayo de Doblez GuiadoDocument4 pagesEnsayo de Doblez GuiadoJulio Alejandro GómezNo ratings yet

- Methodology For Pile Load Test (Dynamic) 1Document5 pagesMethodology For Pile Load Test (Dynamic) 1rohit singhNo ratings yet

- GIW WI-HQ1-036 - ASTM D4437 Bonded Seam StrengthDocument2 pagesGIW WI-HQ1-036 - ASTM D4437 Bonded Seam StrengthMohamed RashidNo ratings yet

- Servo Hydraulic Universal Testing Machine Brand: JNG Model: JG-600L Capacity: 600kNDocument11 pagesServo Hydraulic Universal Testing Machine Brand: JNG Model: JG-600L Capacity: 600kNQc BPSNo ratings yet

- How To Perform An Adhesive Lap Joint Shear Strength Test - ASTM D1002Document5 pagesHow To Perform An Adhesive Lap Joint Shear Strength Test - ASTM D1002FAIQNo ratings yet

- Guided Bend Test For Ductility of WeldsDocument3 pagesGuided Bend Test For Ductility of WeldsErlinawati Bintu SupiyoNo ratings yet

- E190 1044228-1Document4 pagesE190 1044228-1mantra2010No ratings yet

- Adams Testing Module August 29 PDFDocument46 pagesAdams Testing Module August 29 PDFSubbalakshmi Yeleswarapu 010311No ratings yet

- Slickline BasicsDocument86 pagesSlickline BasicsAmiromaan100% (8)

- Model PNL CatalogDocument1 pageModel PNL CatalogThomas StempienNo ratings yet

- ASTM E190 Doblamiento Guiado SoldaduraDocument3 pagesASTM E190 Doblamiento Guiado Soldadurapatmos666No ratings yet

- Introduction To Geohazard Standard Specification For Simple DraperyDocument51 pagesIntroduction To Geohazard Standard Specification For Simple DraperyThanh Dinh QuangNo ratings yet

- Experiment 04 MOSLDocument12 pagesExperiment 04 MOSLRock ManNo ratings yet

- Aramco Specific Evaluations For WeldingDocument6 pagesAramco Specific Evaluations For WeldingTrived MahankaliNo ratings yet

- TSN - LB - Wall - Construction - Guide-STELL STUD LOAD BEARING WALLDocument30 pagesTSN - LB - Wall - Construction - Guide-STELL STUD LOAD BEARING WALLYang LiNo ratings yet

- Astm-A938-07 (2016 - 08 - 28 20 - 42 - 39 Utc)Document3 pagesAstm-A938-07 (2016 - 08 - 28 20 - 42 - 39 Utc)aldoking202028No ratings yet

- Cable Bolt Anchorage CharacteristicsDocument8 pagesCable Bolt Anchorage CharacteristicsPaul GauthierNo ratings yet

- Steel TestsDocument4 pagesSteel TestsSaradhiJannNo ratings yet

- Grounding Equipment: Catalog 3000 March 2013Document32 pagesGrounding Equipment: Catalog 3000 March 2013Deny SafariNo ratings yet

- ASTM D 5035 Breaking Strength Elongation StripDocument1 pageASTM D 5035 Breaking Strength Elongation StripAfzal SarfarazNo ratings yet

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDharma Pratap Lamgade100% (1)

- Is 12592Document6 pagesIs 12592sagarNo ratings yet

- 12" Span, Four Point Flexure Fixture For Specimens Up To 2" Wide (SS)Document2 pages12" Span, Four Point Flexure Fixture For Specimens Up To 2" Wide (SS)mailrahultanwarNo ratings yet

- Section 5 - Material - StrengthsDocument32 pagesSection 5 - Material - StrengthsChris MedeirosNo ratings yet

- Determining Geonet Breaking Force: Standard Test Method ForDocument2 pagesDetermining Geonet Breaking Force: Standard Test Method ForEdmundo Jaita Cuellar100% (1)

- Is 1367 Bolt TestingDocument2 pagesIs 1367 Bolt TestingLakshmi NarayananNo ratings yet

- 2005 PSS Road MeshDocument4 pages2005 PSS Road MeshJim Arturo Rivera VidalNo ratings yet

- Dynamic Test - Method StatementDocument4 pagesDynamic Test - Method StatementNilay Gandhi100% (1)

- ASTM D6241 (Static Puncture Strength)Document6 pagesASTM D6241 (Static Puncture Strength)Rahmadika Arizal NugrahaNo ratings yet

- Hardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method ForDocument2 pagesHardness of Mineral Aggregate Used On Built-Up Roofs: Standard Test Method FordaovandongpktNo ratings yet

- Montgomery ASTM Belfast 2014Document34 pagesMontgomery ASTM Belfast 2014WiryantoNo ratings yet

- STM Lab ManualDocument36 pagesSTM Lab ManualAmrut Raj PurohitNo ratings yet

- Unit 3Document31 pagesUnit 3RED EYENo ratings yet

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Bend Test SummaryDocument4 pagesBend Test SummaryManish MNo ratings yet

- Carmel1400M-Brochure 09.2261Document2 pagesCarmel1400M-Brochure 09.2261Ragil AjiNo ratings yet

- SCC 760 PSDocument2 pagesSCC 760 PSjuanrebollolino1No ratings yet

- Tuft Height of Pile Floor Coverings: Standard Test Method ForDocument5 pagesTuft Height of Pile Floor Coverings: Standard Test Method ForJuanNo ratings yet

- ShaftDocument4 pagesShafts pradhanNo ratings yet

- TP913 Coating Thickness CheckDocument5 pagesTP913 Coating Thickness CheckShahril ZainulNo ratings yet

- Parker TechSeal ParFab Design Guide TSD 5420Document44 pagesParker TechSeal ParFab Design Guide TSD 5420Christopher GarciaNo ratings yet

- D994Document4 pagesD994smanoj354No ratings yet

- ASTM D 5034 Breaking Strength/Elongation Grab MethodDocument9 pagesASTM D 5034 Breaking Strength/Elongation Grab MethodsaminaNo ratings yet

- Cable Tray 27Document37 pagesCable Tray 27Sri Ravindra Yadav PattapogulaNo ratings yet

- Telecom Carriers 2006Document28 pagesTelecom Carriers 2006Brian ScarellaNo ratings yet

- MTS 3013 Asg1Document5 pagesMTS 3013 Asg1Shinzo NytNo ratings yet

- Scribd Paid Access End User License AgreementDocument7 pagesScribd Paid Access End User License Agreementrad rumNo ratings yet

- Official Form 206sum: Summary of Assets and Liabilities For Non-IndividualsDocument1 pageOfficial Form 206sum: Summary of Assets and Liabilities For Non-IndividualsReading_EagleNo ratings yet

- Specifications: PartsDocument1 pageSpecifications: PartsIsaac LopezNo ratings yet

- Sol. Man. - Chapter 15 - Ppe Part 1 - Ia Part 1B 1Document9 pagesSol. Man. - Chapter 15 - Ppe Part 1 - Ia Part 1B 1Rezzan Joy Camara Mejia100% (1)

- An Analytical Study On Factors Affecting Employee Attrition & Retention in IT Industry in The Context of Herzberg's Hy-Giene and Motivational FactorDocument10 pagesAn Analytical Study On Factors Affecting Employee Attrition & Retention in IT Industry in The Context of Herzberg's Hy-Giene and Motivational FactorJavaria IftekharNo ratings yet

- Insights Factorresearch Com Research Trend Following Factor Investing Unexpected CousinsDocument1 pageInsights Factorresearch Com Research Trend Following Factor Investing Unexpected CousinssdfghNo ratings yet

- Research Proposal PDFDocument10 pagesResearch Proposal PDFhanoseNo ratings yet

- Unit Price Contracts: Agreements. While A Standing Offer Can Provide For Unit Pricing, ItDocument3 pagesUnit Price Contracts: Agreements. While A Standing Offer Can Provide For Unit Pricing, ItHari PrakashNo ratings yet

- AIP 2021 With Forms 1-7Document15 pagesAIP 2021 With Forms 1-7harlenemaybalacysaloNo ratings yet

- STC Growing: in Scale and ScopeDocument56 pagesSTC Growing: in Scale and Scopexnelson9No ratings yet

- Incoterms 2011Document1 pageIncoterms 2011barath1986No ratings yet

- (Demand, Supply and Market Equilibrium) (Autosaved)Document27 pages(Demand, Supply and Market Equilibrium) (Autosaved)Janelle Gollaba100% (1)

- Bacolod SEProfile 2012Document138 pagesBacolod SEProfile 2012winmarcella100% (2)

- Sem 3 - Intermediate-Macroeconomics - Part 1Document4 pagesSem 3 - Intermediate-Macroeconomics - Part 1Maverick SinghNo ratings yet

- Business Cycles and InflationDocument23 pagesBusiness Cycles and InflationBuen Caloy LlavoreNo ratings yet

- Flexible Budget ExampleDocument2 pagesFlexible Budget Examplebrenica_2000No ratings yet

- Ace Hardware Holy WeekDocument6 pagesAce Hardware Holy WeekHappen MediaNo ratings yet

- Cross Reference 2015Document78 pagesCross Reference 2015José AyalaNo ratings yet

- BoD - Bearbeitet Bis Inkl 5Document130 pagesBoD - Bearbeitet Bis Inkl 5PatNo ratings yet

- Throughput AccountingDocument5 pagesThroughput AccountingMohammad Faizan Farooq Qadri AttariNo ratings yet

- ACTG22 - Lecture 2 (Partnership Formation)Document23 pagesACTG22 - Lecture 2 (Partnership Formation)Maroden Sanchez GarciaNo ratings yet

- Case Study 1Document5 pagesCase Study 1Frances Mary BareñoNo ratings yet

- Business Organisations and Their StakeholdersDocument11 pagesBusiness Organisations and Their StakeholdersamirNo ratings yet

- Operations and Production Management MGMT 405 Answer Set 1Document3 pagesOperations and Production Management MGMT 405 Answer Set 1Anissa Negra AkroutNo ratings yet

- Metro Network: Christchurch Bus RoutesDocument1 pageMetro Network: Christchurch Bus RoutesKhemHuangNo ratings yet

- B.O 2033 DGC Aee - II Data Sor 2014Document3 pagesB.O 2033 DGC Aee - II Data Sor 2014nisajamesNo ratings yet

- (DOC) UNIQUE - Gina Cruz - Academia - EduDocument18 pages(DOC) UNIQUE - Gina Cruz - Academia - EduAbelardo Ramos DiasNo ratings yet