Professional Documents

Culture Documents

Vibrating Screen QAP-17

Vibrating Screen QAP-17

Uploaded by

Mohammad AdilCopyright:

Available Formats

You might also like

- Afrox Product CatalogueDocument92 pagesAfrox Product CataloguedhurushaNo ratings yet

- 0400 - Corrosion Protection Specification - Rev0 - 20180606Document22 pages0400 - Corrosion Protection Specification - Rev0 - 20180606brandonNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Painting System C3 PDFDocument4 pagesPainting System C3 PDFFelipe Resende de OliveiraNo ratings yet

- AI I 4145 Allo Teel (UN G41450) : Topics CoveredDocument3 pagesAI I 4145 Allo Teel (UN G41450) : Topics CoveredUmerNo ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- QAP - Reclaimer Feeder - Haldia - R (0) - 17.09.2021Document3 pagesQAP - Reclaimer Feeder - Haldia - R (0) - 17.09.2021Mohammad AdilNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- PSP-ITP For Vibrating Screens ExciterDocument37 pagesPSP-ITP For Vibrating Screens ExciterMohammad AdilNo ratings yet

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- En19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/TDocument7 pagesEn19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/THugh O'Brien GwazeNo ratings yet

- Fepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmDocument4 pagesFepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmapi-19654224No ratings yet

- Wps For Casting Steel With Normal SteelDocument11 pagesWps For Casting Steel With Normal SteelNguyen Huu TriNo ratings yet

- Belt Conveyor Draw FinishDocument1 pageBelt Conveyor Draw FinishRizki FauziNo ratings yet

- Hardox 500 PDFDocument2 pagesHardox 500 PDFMustafa Mahmoud ElsayedNo ratings yet

- Quality Control Plan Static EquipmentDocument1 pageQuality Control Plan Static EquipmentdhasdjNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- Material Conversation TableDocument1 pageMaterial Conversation TableSerdar BıyıktaşNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- FLS - Procedure - Pre-Heating & Pre-Heat Maintenance (Post Weld Heating) of Weld JointsDocument2 pagesFLS - Procedure - Pre-Heating & Pre-Heat Maintenance (Post Weld Heating) of Weld JointsMohammad AdilNo ratings yet

- Mill Test Certificate: Run Date 21/12/2021 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 21/12/2021 OR0019M - JAZ User ID E1037RakeshParikhNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Pneumatic Test Procedure DT 29112017 CompressDocument7 pagesPneumatic Test Procedure DT 29112017 Compressjamesvarghese2812No ratings yet

- Torque Calculation For BoltDocument3 pagesTorque Calculation For BoltNaga Manikanta TatikondaNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- Baseplate Jib CraneDocument1 pageBaseplate Jib CraneCalvien Pradiptha0% (1)

- Welding Procedure Data SheetDocument2 pagesWelding Procedure Data SheetAmanSharmaNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Is 4894 Standard PDFDocument21 pagesIs 4894 Standard PDFDharmendra PanchalNo ratings yet

- Sales Training: Mobile Crushing and ScreeningDocument22 pagesSales Training: Mobile Crushing and ScreeningMf LuiNo ratings yet

- Shell Rolling Report 1Document6 pagesShell Rolling Report 1Hanuman RaoNo ratings yet

- Welding Consumable Comparison ListDocument7 pagesWelding Consumable Comparison ListMPCReader100% (1)

- China Structural Steel and Alloy Steel GBT Q345Document3 pagesChina Structural Steel and Alloy Steel GBT Q345bkprodhNo ratings yet

- MST-Structural Steel RepairDocument11 pagesMST-Structural Steel RepairDelta akathehuskyNo ratings yet

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- Low Hydrogen Electrode BakingDocument1 pageLow Hydrogen Electrode BakingnksNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon SteelDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparajNo ratings yet

- Pressure Reducing Station Qap Alfa LavalDocument1 pagePressure Reducing Station Qap Alfa LavalajmainNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- Weld MapDocument1 pageWeld MapFerdie OS100% (1)

- Bul SAE J2044 PDFDocument8 pagesBul SAE J2044 PDFthailanNo ratings yet

- Impact Crusher SheetDocument2 pagesImpact Crusher SheetStephanie SanchezNo ratings yet

- IS Materail Specification For General ApplicationDocument1 pageIS Materail Specification For General Applicationravindranathanne100% (1)

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- 21.02.15 Tuv Visit ReportDocument5 pages21.02.15 Tuv Visit ReportssmullaNo ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- QAP-General Fabrication & Machining ItemsDocument1 pageQAP-General Fabrication & Machining ItemsMohammad AdilNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- List of Qualified Welder Summary BLCPDocument2 pagesList of Qualified Welder Summary BLCPpstechnical_43312697No ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- QAP LotahalDocument1 pageQAP LotahalRahul YadavNo ratings yet

- QAP FormatsDocument13 pagesQAP Formatsavvari sureshNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- TC NylonDocument1 pageTC NylonMohammad AdilNo ratings yet

- Arcoplate BrouchureDocument112 pagesArcoplate BrouchureMohammad AdilNo ratings yet

- 660D14 Painting Schedule For Silo 1 - Rev 0Document1 page660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilNo ratings yet

- RT Part-4Document80 pagesRT Part-4Mohammad AdilNo ratings yet

- Ut 02Document132 pagesUt 02Mohammad AdilNo ratings yet

- Skirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyDocument4 pagesSkirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyMohammad AdilNo ratings yet

- Skirt Board Assembly-5810 Skirt Board Assembly-5810Document3 pagesSkirt Board Assembly-5810 Skirt Board Assembly-5810Mohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- 18 - 18 HOLES 10 - 17.5 HOLES CSK 90 X 8 Deep Refer Section A-A 805Document2 pages18 - 18 HOLES 10 - 17.5 HOLES CSK 90 X 8 Deep Refer Section A-A 805Mohammad AdilNo ratings yet

- FAb Enq-BRU-2-3061H-2xHEV100LSDocument2 pagesFAb Enq-BRU-2-3061H-2xHEV100LSMohammad Adil100% (1)

- Experiment 1Document9 pagesExperiment 1TAFSIR UDDINNo ratings yet

- Inspection and Test Plan - PipingDocument15 pagesInspection and Test Plan - PipingFerdie OS100% (5)

- Plasma Cutting 1530-200ADocument16 pagesPlasma Cutting 1530-200Ajr.velasquez.jarvtNo ratings yet

- Report RobotDocument10 pagesReport RobotAimy SufeaNo ratings yet

- ABC Pola QttyDocument147 pagesABC Pola QttyELMERNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BDocument6 pagesHFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BMohamed FarisNo ratings yet

- Smaw NC IIDocument42 pagesSmaw NC IILloyd Arnold Catabona100% (1)

- Materials Today: Proceedings: Rishabh Narang, Vibhu Maheshwari, Pradeep KhannaDocument9 pagesMaterials Today: Proceedings: Rishabh Narang, Vibhu Maheshwari, Pradeep KhannaLê Văn ThảoNo ratings yet

- Surface PreparationDocument9 pagesSurface PreparationIsabelo AbaoNo ratings yet

- Dreams: Shaping A World ofDocument24 pagesDreams: Shaping A World ofAkshobhya SharmaNo ratings yet

- Technical Specifications (Batcoda)Document201 pagesTechnical Specifications (Batcoda)mihretu hailemichael100% (2)

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Company Profile Power PointDocument12 pagesCompany Profile Power PointAzzus BkhaNo ratings yet

- MakuriDocument11 pagesMakuriJhoncastilloNo ratings yet

- Hr+Oxspec+ +Laser+Cut+Screen+SetupsDocument10 pagesHr+Oxspec+ +Laser+Cut+Screen+SetupstibisortNo ratings yet

- 202004160626023155prashant Engg Powder Metrollpgy 1Document8 pages202004160626023155prashant Engg Powder Metrollpgy 1Rabi Narayana SahuNo ratings yet

- Chapter 12 CompositesDocument40 pagesChapter 12 CompositesAbood AtiyatNo ratings yet

- Fitter Mechanical Assembly (CSCQ0304)Document7 pagesFitter Mechanical Assembly (CSCQ0304)yudiar djamaldilliahNo ratings yet

- Plate Sample Cap: Welding Process MMA (SMAW)Document14 pagesPlate Sample Cap: Welding Process MMA (SMAW)Readersmo0% (1)

- 2019 Rolleri-Bending IntDocument155 pages2019 Rolleri-Bending IntSladjana TrninicNo ratings yet

- Jam Production MachinesDocument4 pagesJam Production MachinesSajid MughalNo ratings yet

- AcousticDocument10 pagesAcousticKurnianda Dian WulandariNo ratings yet

- Kian Joo Can Factory: Good Things Come in A Long-Term PackageDocument13 pagesKian Joo Can Factory: Good Things Come in A Long-Term PackageEcho WackoNo ratings yet

- 873 - 52 - 473 - Module 1 Wood SubstitutesDocument18 pages873 - 52 - 473 - Module 1 Wood SubstitutesAlexNo ratings yet

- Astm A325Document8 pagesAstm A325Nacer KisyNo ratings yet

- Stainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDocument2 pagesStainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDewandanuNo ratings yet

- Unit 3Document98 pagesUnit 3Sudharshan IyengarNo ratings yet

- EL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsDocument60 pagesEL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsPlanet RED39No ratings yet

- Brief Industrial Profile of VISAKHAPATNAM District - DC MsmeDocument26 pagesBrief Industrial Profile of VISAKHAPATNAM District - DC MsmeParas AgarwalNo ratings yet

Vibrating Screen QAP-17

Vibrating Screen QAP-17

Uploaded by

Mohammad AdilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vibrating Screen QAP-17

Vibrating Screen QAP-17

Uploaded by

Mohammad AdilCopyright:

Available Formats

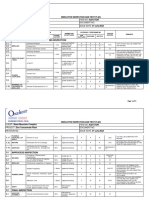

FLSMIDTH PRIVATE Ltd - SPD FACTORY.

Page 1 of 3

QUALITY CONTROL PLAN FOR VIBRATING BANANA SCREEN ASSEMBLY

QCP No : QCP/FLS-17 A R(2)

PART: PEDESTAL , BACK PLATE,LIFTING BEAMS, DRIVE BEAMDECK SUPPORT FRAME Date : 17/12/2016

STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY

Remarks

SL.NO. METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD Supplier FLS

1 Raw Material

1.1 Plates 1) Verification of Mill TC for 100%

As per material As per material spec / QSE Manufacturer's test

Corelation of plate detials ,chemical W R

spec./As per drawing SOP 7134 certificates

Mechanical & other parameters.

(or)

2) Check Test ( If Mill TC is not 100%

As per material Manufacturer's test

available / No Co -relation between As per material spec. W W/R

spec./As per drawing certificates

Mill TC & Plate)

3) Raw Material Dimensions 100% As per Mill Tc As per Rolling Tolerance Inspection report W W

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

4) Visual 100% Inspection report W W

AS/NZS 1554.5 1554.5

5) UT on plates - 16 Tk & above 100% SA 578 level B SA 578 level B Inspection report W R

2 In Process

2.1 Marking and Cutting 1) Orientation 100% As per Drawing As per Drawing Inspection report W R

2) Dimensions 100% As per Drawing As per Drawing Inspection report W R

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

2.2 Welding 1) Verification of WPS,PQR & WPQ 100% Inspection report W R

AS/NZS 1554.5 1554.5

2) Welding parameter verification to

include checks on

• Consumable – gas and filler metal

• Check preheat (only oxy propane to be

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

used for heating (no acetylene permitted) 100% Inspection report W W

AS/NZS 1554.5 1554.5

• Check amp, volts, travel speed, run

placement

• Check position conforms to WPS

3) Stop/Starts to be in accordance with QSE SOP 7134 / QSE SOP 7134 / AS/NZS

100% Inspection report W W

clause 5.8.4 of AS 1554.5 - 2011 AS/NZS 1554.5 1554.5

1) Water Level , Strigthness, twist and

100% As per Drawing As per Drawing Inspection report W R/W

2.1 Fitup bend

2) Orientation 100% As per Drawing As per Drawing Inspection report W R/W

3) Dimensions - ensure enough stock for

100% As per Drawing As per Drawing Inspection report W R/W

machining.

4) Stiffners position and its orientation

100% As per Drawing As per Drawing Inspection report W R/W

and dimensions

5) Weld joint configuration 100% As per Drawing As per Drawing Inspection report W R/W

*Drive beam Fitup to be offered for Inspection.

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

FLSMIDTH PRIVATE Ltd - SPD FACTORY.

Page 2 of 3

QUALITY CONTROL PLAN FOR VIBRATING BANANA SCREEN ASSEMBLY

QCP No : QCP/FLS-17 A R(2)

PART: PEDESTAL , BACK PLATE,LIFTING BEAMS, DRIVE BEAMDECK SUPPORT FRAME Date : 17/12/2016

STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY

Remarks

SL.NO. METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD Supplier FLS

2.3 After Welding

1) Water Level , Strigthness, twist and

100% As per Drawing As per Drawing Inspection report W W

bend

2) Orientation 100% As per Drawing As per Drawing Inspection report W W

3) Dimensions - ensure enough stock for

100% As per Drawing As per Drawing Inspection report W W

machining.

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

Inspection report W H

4) NDT - On weld joints 100% AS/NZS 1554.5 1554.5

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

2.4 Stress Releving Verification of SR chart 100% Heat Treatment chart R R

AS/NZS 1554.5 1554.5

2.5 After Stress Relieving

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

1) Visual 100% Inspection report W W

AS/NZS 1554.5 1554.5

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

Inspection report W H

2) NDT - On weld joints 100% AS/NZS 1554.5 1554.5

3) Dimensions and Distorsion check 100% As per Drawing AS per Drawing Inspection report W R

2.6 Machining & Drilling *

1) Orientation 100% As per Drawing AS per Drawing Inspection report W H

2) Geometrical tolerance on machine, 100% As per Drawing AS per Drawing Inspection report W H

3) Dimensions 100% As per Drawing AS per Drawing Inspection report W H

4) Ensure drilled hole perpendiculaty with

100% As per Drawing AS per Drawing Inspection report W H

machined pad surface.

5) End plate holes to be match drilled with

100% As per Drawing AS per Drawing Inspection report W H

Side plates

* - All Machining Shall be Completed using CNC machines unless ohterwise approved by FLS Engineering.

2.7 Rubber Lagging 1) Material Test Certificate 100% As per Drawing AS per Drawing Test Certificate R R

2) Shore Hardness 100% As per Drawing AS per Drawing Test Certificate W H

No puncture or Un bonding

Random IS 4682-1 Inspection report

of rubber allowed.

3) Spark Test W H

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

4 .1 Surface Preparation Check for surface finish and visual 100% Inspection report W H

AS/NZS 1554.5 1554.5

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

4.2 Final painting Check for visual , painting DFT,adhession 100% Inspection report W H

AS/NZS 1554.5 1554.5

test , RPO application on M/c area

R : REVIEW W: WITNESSING H: HOLD POINT

Notes:

1. All materials shall be new and unused, free from rust and excessive mill scale (Refer SOP 7134).

2. Cutting of all beams and columns to be done with cold cut saw no oxy fuel cutting.

3. All cut edges to be ground with 2mm radius, all flame cut edges to be minimum class 1 cut and ground to remove all notches and scale,

only oxy propane to be used for cutting (no acetylene permitted)

4) Even UT checked at Mill itself & specified in MILL TC, Once again UT shall be carried out by Supplier and Random plates will be witnessed by FLS - QC.

5a) If additional Joint provided ,approval to be obtained from FLS Engg. and those welds to be UT and MT Tested.

b) In case of any difference in interpretation of UT results and or any doubt in evaluation and or any Constraints in carrying out UT due to geographical Positioning of

joints ,RT of the joints shall be done for which acceptance criteria shall be ASME SEC VIII Div 1 ,Clause UV-51.

6) a) Weld procedure ( WPS & PQR ) shall be as per SOP 7134.

b) Qualified welder only shall be used.

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

FLSMIDTH PRIVATE Ltd - SPD FACTORY.

Page 3 of 3

QUALITY CONTROL PLAN FOR VIBRATING BANANA SCREEN ASSEMBLY

QCP No : QCP/FLS-17 A R(2)

PART: PEDESTAL , BACK PLATE,LIFTING BEAMS, DRIVE BEAMDECK SUPPORT FRAME Date : 17/12/2016

7a) Welding electrode / Pre heating requirement shall be as per drg requirement / WPS requirement.

b) Use of Temperary attachment shall be minimised & Arc strike at outside area of the weld shall be minimised.

c) Proper weld sequence shall be followed.

8 a) All Machine / Drilling activities shall be done after completion of welding.

b) Match Drilling shall be done wherever required or as per drawing Requirement.

9 a) Mating components dimension / fitment to be checked before assembly.

1. Read this QCP along wth PO,Drawing and Relavent Engineering Documents.

Prepared by: C.Venkatesan Approved by: Lakshmanan Ramasamy

Asst. Manager Sr.Manager - QC

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

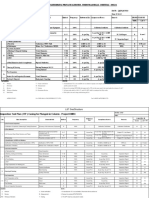

FLSMIDTH PRIVATE Ltd

Page 1 of 2

QUALITY CONTROL PLAN FOR VIBRATING BANANA SCREEN ASSEMBLY

QCP No : QCP/FLS-17B R(0)

PART: SIDE PLATE ASSEMBLY (SIDE PLATE, TOP AND BOTTOM FLANGE, STIFFNERS, SUPPORTING ANGLE) Date : 27/3/2014

STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY

SL.NO. Remarks

METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD Supplier FLS

1 Raw Material

1.1 Plates and Pipes 1) Verification of Mill TC for 100%

As per material As per material spec / QSE Manufacturer's test

Corelation of plate detials ,chemical R R

spec./As per drawing SOP 7134 certificates

Mechanical & other parameters.

(or)

2) Check Test ( If Mill TC is not 100%

As per material Manufacturer's test

available / No Co -relation between As per material spec. W W/R

spec./As per drawing certificates

Mill TC & Plate)

3) Raw Material Dimensions 100% As per Mill Tc As per Rolling Tolerance Inspection report W W

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

4) Visual 100% Inspection report W W

AS/NZS 1554.5 1554.5

5) UT on plates - 16 Tk & above 100% SA 578 level B SA 578 level B Inspection report W W

2 In Process

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

2.1 Welding 1) Verification of WPS,PQR & WPQ 100% Inspection report W R

AS/NZS 1554.5 1554.5

2) Welding parameter verification to

include checks on

• Consumable – gas and filler metal

• Check preheat (only oxy propane to be

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

used for heating (no acetylene permitted) 100% Inspection report W W

AS/NZS 1554.5 1554.5

• Check amp, volts, travel speed, run

placement

• Check position conforms to WPS

3) Stop/Starts to be in accordance with QSE SOP 7134 / QSE SOP 7134 / AS/NZS

100% Inspection report W W

clause 5.8.4 of AS 1554.5 - 2011 AS/NZS 1554.5 1554.5

2.2 Fitup 1) Marking and Cutting 100% As per Drawing As per Drawing Inspection report W R

2) Orientation 100% As per Drawing As per Drawing Inspection report W R

3) Dimensions 100% As per Drawing As per Drawing Inspection report W R

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

FLSMIDTH PRIVATE Ltd

Page 2 of 2

QUALITY CONTROL PLAN FOR VIBRATING BANANA SCREEN ASSEMBLY

QCP No : QCP/FLS-17B R(0)

PART: SIDE PLATE ASSEMBLY (SIDE PLATE, TOP AND BOTTOM FLANGE, STIFFNERS, SUPPORTING ANGLE) Date : 27/3/2014

STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY

SL.NO. Remarks

METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD Supplier FLS

2.6 Match Drilling of Side

plates * 1) Orientation 100% As per Drawing AS per Drawing Inspection report W W

2) Dimensions 100% As per Drawing AS per Drawing Inspection report W W

3)All Flanges, Support Angle, Stiffners to

100% As per Drawing AS per Drawing Inspection report W W

be Match Drilled

* - All Machining Shall be Completed using CNC machines unless otherwise approved by FLS Engineering.

Assly of Side plate, Flanges,

3 Fitment and holes macthing 100% As per Drawing As per Drawing Inspection report W W

Support angles, Stiffners

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

4 .1 Surface Preparation Check for surface finish and visual 100% Inspection report W W

AS/NZS 1554.5 1554.5

Rubber strip addesion 100% As per Drawing No peal off Inspection report W W

QSE SOP 7134 / QSE SOP 7134 / AS/NZS

4.2 Final painting Check for visual , painting DFT,adhession 100% Inspection report W W

AS/NZS 1554.5 1554.5

test , RPO application on M/c area

R : REVIEW W: WITNESSING H: HOLD POINT

Notes:

1. All materials shall be new and unused, free from rust and excessive mill scale (Refer SOP 7134).

2. Cutting of all beams and columns to be done with cold cut saw no oxy fuel cutting.

3. All cut edges to be ground with 2mm radius, all flame cut edges to be minimum class 1 cut and ground to remove all notches and scale,

only oxy propane to be used for cutting (no acetylene permitted)

4) Even UT checked at Mill itself & specified in MILL TC, Once again UT shall be carried out by Supplier and Random plates will be witnessed by FLS - QC.

5a) If additional Joint provided ,approval to be obtained from FLS Engg. and those welds to be UT and MT Tested.

b) In case of any difference in interpretation of UT results and or any doubt in evaluation and or any Constraints in carrying out UT due to geographical Positioning

of joints ,RT of the joints shall be done for which acceptance criteria shall be ASME SEC VIII Div 1 ,Clause UV-51.

6) a) Weld procedure ( WPS & PQR ) shall be as per SOP 7134.

b) Qualified welder only shall be used.

7a) Welding electrode / Pre heating requirement shall be as per drg requirement / WPS requirement.

b) Use of Temperary attachment shall be minimised & Arc strike at outside area of the weld shall be minimised.

c) Proper weld sequence shall be followed.

8 a) All Machine / Drilling activities shall be done after completion of welding.

b) Match Drilling shall be done wherever required or as per drawing Requirement.

9 a) Mating components dimension / fitment to be checked before assembly.

1. Read this QCP along wth PO,Drawing and Relavent Engineering Documents.

Prepared by: C.Venkatesan Approved by: Lakshmanan Ramasamy

Sr.Lead Engineer Manager - QC

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

FLSMIDTH PRIVATE LIMITED - SPD FACTORY

Page 1 of 3

QUALITY CONTROL PLAN FOR VIBRATING SCREEN ASSEMBLY

QCP No : QCP/FLS-17 Rev 0

PART: Vibrating Screen Assembly Date : 14/05/2014

SL.NO. STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY Remarks

METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD FLS Customer

1 Document Verification :

Earlier stage Reports Verification

As per material As per material spec./As Inspection Report /

a) From Supplier (i) Verification of Inspection reports / IRO 100% R R

spec./As per drawing per drawing IRO

(i) Verification / review of manufacturer's As per material As per material spec./As Manufactuer TC /

b)Through Inward 100% W/R R

Test Certificate or Lab test reports spec./As per drawing per drawing Lab Test reports

(ii) Verification / Review of Dimensional As per material As per material spec./As Inspection Report /

100% W/R R

reports spec./As per drawing per drawing Dimensions Report

As per material As per material spec./As

(iii) Visual inspection 100% Inspection Report W R

spec./As per drawing per drawing

(i) Verification of Make , Model Number , Inspection report

As per material As per material spec./As

c) Bought Outs Test certificates for Bought outs - motor, 100% and QSE Form W R

spec./As per drawing per drawing

Vibrator motor, Lubrication System etc 7088

All Graded Fasteners shall be TVS or UNBROKO make

2 Visual W R

2.1 Cross Beam, Cross / Lift

(i) check for Damage, Corrosion, bends,

tubes, Drive beams, Feed Boxes,

Scratches and Sharp edges - to be 100% As per Drawing As per Drawing QSE FORM 7088 W R

Deck support ,stiffner angles and

attended before taking up for assly.

Support Brackets.

100% As per Drawing As per Drawing Inspection report W R

3 Sub Assly inspection.

3.1 Side plate with cross member (i) Assly of Side plate with stiffners /

100% QSE SOP 7133 QSE SOP 7133 Inspection report W R

assly spring plates

(ii) Visual 100% QSE SOP 7133 QSE SOP 7133 Inspection report W R

(iii) Dimensions 100% QSE SOP 7133 QSE SOP 7133 Inspection report W R

3.2 Fixing of Hucking Bolts (i) orientation of Hucking bolts 100% As per Drawing As Per Drawing Inspection Report W R

(ii) Protrusion of Hucking bolt should be 2 - As per QSE SOP

100% As per QSE SOP 7133 Inspection Report W R

10 mm 7133

As per QSE SOP 7133

3.3 Side plate with Cross member (i) Assly of side plates with Cross as per QSE SOP

100% (Dumpy level should be with Inspection Report W R

assly member with alignment Pin and Bolts 7133

in 1mm)

As per QSE SOP 7133

as per QSE SOP

(ii) Dumpy Level of cross member 100% (Dumpy level should be with Inspection Report W R

7133

in 1mm)

(iii) Dimension 100% As per Drawing As Per Drawing Inspection Report W R

(iv) Diagonal 100% As per Drawing As Per Drawing Inspection Report W R

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

FLSMIDTH PRIVATE LIMITED - SPD FACTORY

Page 2 of 3

QUALITY CONTROL PLAN FOR VIBRATING SCREEN ASSEMBLY

QCP No : QCP/FLS-17 Rev 0

PART: Vibrating Screen Assembly Date : 14/05/2014

STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY

SL.NO Remarks

METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD FLS Customer

3.4 Assly of

3.4.1 Drive beam with side plate

(i) GA Orientation 100% As per drawing As per drawing Inspection Report W R

assly.

3.4.2 Feed box with side plate

(ii) GA Dimensions 100% As per drawing As per drawing Inspection Report W R

assly.

3.4.3 Lift and cross tubes with side As per QSE SOP

(iii) Locating pin and Bolt arragement 100% As per QSE SOP 7133 Inspection Report W R

plate assly. 7133

3.4.4 Fitment of Deck support As per QSE SOP

(iv) Visual 100% As per QSE SOP 7133 Inspection Report W R

Frame 7133

As per QSE SOP

3.5 Hucking of Bots (i) Rattle the nut and bolt 100% As per QSE SOP 7133 Inspection Report W R

7133

As per QSE SOP

(ii) Ensure no gap between the surfaces 100% As per QSE SOP 7133 Inspection Report W R

7133

(iii) orientation of Hucking bolts 100% As per Drawing As Per Drawing Inspection Report W R

(iv) Protrusion of Hucking bolt should be 2 As per QSE SOP

100% As per QSE SOP 7133 Inspection Report W R

- 10 mm 7133

As per QSE SOP

3.6 application of Sealent (i) Sealing the Gaps and joints 100% As per QSE SOP 7133 Inspection Report W R

7133

3.7 Assembly of flexible disc,

(i) BOM verification 100% As per drawing As per drawing Inspection Report W R

intermeidate shaft with exciter

(ii) Orientation 100% As per drawing As per drawing Inspection Report W R

(iii) Dimensions 100% As per drawing As per drawing Inspection Report W R

(iv) Torque tightening 100% QSE SOP 7152 QSE SOP 7152 Inspection Report W R

4 Final Assembly Inspection (i) Water Level 100% As per drawing As per drawing Inspection Report W W

(ii) BOM Verification as per GA

100% As per drawing As per drawing Inspection Report W W

Drawings.

(iii) GA Orientation 100% As per drawing As per drawing Inspection Report W W

Inspection Report

(iv) GA Dimensions 100% As per drawing As per drawing & QSE FORM W W

8028

(v) Torque Tightening of Fastners 100% As per drawing As per drawing Inspection Report W W

5 No-Load Run test (i) Direction of Rotation 100% As per drawing As per drawing Inspection report H H

(ii) RPM 100% As per drawing As per drawing Inspection report H H

(iii) Vibration Amplitude As per QSE form

100% As per drawing As per drawing H H

8029

(iv) Noise Level 100% As per drawing As per drawing Inspection report H H

(v) Current Reading 100% As per drawing As per drawing Inspection report H H

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

FLSMIDTH PRIVATE LIMITED - SPD FACTORY

Page 3 of 3

QUALITY CONTROL PLAN FOR VIBRATING SCREEN ASSEMBLY

QCP No : QCP/FLS-17 Rev 0

PART: Vibrating Screen Assembly Date : 14/05/2014

STAGE INSPECTION CHARACTERISTIC / QUANTUM REFERENCE ACCEPTANCE FORMAT OF INSPECTION BY

SL.NO Remarks

METHOD OF CHECK OF CHECK DOCUMENT NORMS RECORD FLS Customer

6 Painting

a) RPO application on machined (i) Visual Painting report

100% As per Drawing As per Drawing H R

Surfaces QSE Form 8030

(ii) DFT As per customer As per customer Painting report

b) Painting 100% H R

requirement requirement QSE Form 8030

(i) Verification of Name Plate details / As per As per

7 Identification 100% Inspection report H R

Stickers Drawing/Requirement Drawing/Requirement

8 Packing

As per Customer / As per Customer /

a) Final Packing (i) Verification of Approved Packing list 100% Packing List H R

Requirement Requirement

R : REVIEW W: WITNESSING H: HOLD POINT

Note:-

1. Read this QCP along wth PO ,drawing and relavent Engineering Document - QSE SOP 7133 and QSE SOP 7152

Prepared by: C.Venkatesan Approved by: Lakshmanan Ramasamy

Sr.Lead Engineer Manager - QC

FLS/LUDO/QC-19 Rev 1 Dt 10.03.2014

You might also like

- Afrox Product CatalogueDocument92 pagesAfrox Product CataloguedhurushaNo ratings yet

- 0400 - Corrosion Protection Specification - Rev0 - 20180606Document22 pages0400 - Corrosion Protection Specification - Rev0 - 20180606brandonNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Painting System C3 PDFDocument4 pagesPainting System C3 PDFFelipe Resende de OliveiraNo ratings yet

- AI I 4145 Allo Teel (UN G41450) : Topics CoveredDocument3 pagesAI I 4145 Allo Teel (UN G41450) : Topics CoveredUmerNo ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- QAP - Reclaimer Feeder - Haldia - R (0) - 17.09.2021Document3 pagesQAP - Reclaimer Feeder - Haldia - R (0) - 17.09.2021Mohammad AdilNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- PSP-ITP For Vibrating Screens ExciterDocument37 pagesPSP-ITP For Vibrating Screens ExciterMohammad AdilNo ratings yet

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- En19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/TDocument7 pagesEn19 Steel - 4140 - 1.7225 - Scm440 - 42crmo4: Related Specifications Astm A29/A29M Din en 10083/3 Jis G4053 GB GB/THugh O'Brien GwazeNo ratings yet

- Fepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmDocument4 pagesFepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmapi-19654224No ratings yet

- Wps For Casting Steel With Normal SteelDocument11 pagesWps For Casting Steel With Normal SteelNguyen Huu TriNo ratings yet

- Belt Conveyor Draw FinishDocument1 pageBelt Conveyor Draw FinishRizki FauziNo ratings yet

- Hardox 500 PDFDocument2 pagesHardox 500 PDFMustafa Mahmoud ElsayedNo ratings yet

- Quality Control Plan Static EquipmentDocument1 pageQuality Control Plan Static EquipmentdhasdjNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- Raw Material & Bought Out Items InspectionDocument3 pagesRaw Material & Bought Out Items InspectionSuraj ShettyNo ratings yet

- Material Conversation TableDocument1 pageMaterial Conversation TableSerdar BıyıktaşNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- FLS - Procedure - Pre-Heating & Pre-Heat Maintenance (Post Weld Heating) of Weld JointsDocument2 pagesFLS - Procedure - Pre-Heating & Pre-Heat Maintenance (Post Weld Heating) of Weld JointsMohammad AdilNo ratings yet

- Mill Test Certificate: Run Date 21/12/2021 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 21/12/2021 OR0019M - JAZ User ID E1037RakeshParikhNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Pneumatic Test Procedure DT 29112017 CompressDocument7 pagesPneumatic Test Procedure DT 29112017 Compressjamesvarghese2812No ratings yet

- Torque Calculation For BoltDocument3 pagesTorque Calculation For BoltNaga Manikanta TatikondaNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- Baseplate Jib CraneDocument1 pageBaseplate Jib CraneCalvien Pradiptha0% (1)

- Welding Procedure Data SheetDocument2 pagesWelding Procedure Data SheetAmanSharmaNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Is 4894 Standard PDFDocument21 pagesIs 4894 Standard PDFDharmendra PanchalNo ratings yet

- Sales Training: Mobile Crushing and ScreeningDocument22 pagesSales Training: Mobile Crushing and ScreeningMf LuiNo ratings yet

- Shell Rolling Report 1Document6 pagesShell Rolling Report 1Hanuman RaoNo ratings yet

- Welding Consumable Comparison ListDocument7 pagesWelding Consumable Comparison ListMPCReader100% (1)

- China Structural Steel and Alloy Steel GBT Q345Document3 pagesChina Structural Steel and Alloy Steel GBT Q345bkprodhNo ratings yet

- MST-Structural Steel RepairDocument11 pagesMST-Structural Steel RepairDelta akathehuskyNo ratings yet

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- Low Hydrogen Electrode BakingDocument1 pageLow Hydrogen Electrode BakingnksNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon SteelDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 202, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparajNo ratings yet

- Pressure Reducing Station Qap Alfa LavalDocument1 pagePressure Reducing Station Qap Alfa LavalajmainNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- Weld MapDocument1 pageWeld MapFerdie OS100% (1)

- Bul SAE J2044 PDFDocument8 pagesBul SAE J2044 PDFthailanNo ratings yet

- Impact Crusher SheetDocument2 pagesImpact Crusher SheetStephanie SanchezNo ratings yet

- IS Materail Specification For General ApplicationDocument1 pageIS Materail Specification For General Applicationravindranathanne100% (1)

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- 21.02.15 Tuv Visit ReportDocument5 pages21.02.15 Tuv Visit ReportssmullaNo ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- QAP-General Fabrication & Machining ItemsDocument1 pageQAP-General Fabrication & Machining ItemsMohammad AdilNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- List of Qualified Welder Summary BLCPDocument2 pagesList of Qualified Welder Summary BLCPpstechnical_43312697No ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- QAP LotahalDocument1 pageQAP LotahalRahul YadavNo ratings yet

- QAP FormatsDocument13 pagesQAP Formatsavvari sureshNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- TC NylonDocument1 pageTC NylonMohammad AdilNo ratings yet

- Arcoplate BrouchureDocument112 pagesArcoplate BrouchureMohammad AdilNo ratings yet

- 660D14 Painting Schedule For Silo 1 - Rev 0Document1 page660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilNo ratings yet

- RT Part-4Document80 pagesRT Part-4Mohammad AdilNo ratings yet

- Ut 02Document132 pagesUt 02Mohammad AdilNo ratings yet

- Skirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyDocument4 pagesSkirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyMohammad AdilNo ratings yet

- Skirt Board Assembly-5810 Skirt Board Assembly-5810Document3 pagesSkirt Board Assembly-5810 Skirt Board Assembly-5810Mohammad AdilNo ratings yet

- Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- 18 - 18 HOLES 10 - 17.5 HOLES CSK 90 X 8 Deep Refer Section A-A 805Document2 pages18 - 18 HOLES 10 - 17.5 HOLES CSK 90 X 8 Deep Refer Section A-A 805Mohammad AdilNo ratings yet

- FAb Enq-BRU-2-3061H-2xHEV100LSDocument2 pagesFAb Enq-BRU-2-3061H-2xHEV100LSMohammad Adil100% (1)

- Experiment 1Document9 pagesExperiment 1TAFSIR UDDINNo ratings yet

- Inspection and Test Plan - PipingDocument15 pagesInspection and Test Plan - PipingFerdie OS100% (5)

- Plasma Cutting 1530-200ADocument16 pagesPlasma Cutting 1530-200Ajr.velasquez.jarvtNo ratings yet

- Report RobotDocument10 pagesReport RobotAimy SufeaNo ratings yet

- ABC Pola QttyDocument147 pagesABC Pola QttyELMERNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BDocument6 pagesHFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BMohamed FarisNo ratings yet

- Smaw NC IIDocument42 pagesSmaw NC IILloyd Arnold Catabona100% (1)

- Materials Today: Proceedings: Rishabh Narang, Vibhu Maheshwari, Pradeep KhannaDocument9 pagesMaterials Today: Proceedings: Rishabh Narang, Vibhu Maheshwari, Pradeep KhannaLê Văn ThảoNo ratings yet

- Surface PreparationDocument9 pagesSurface PreparationIsabelo AbaoNo ratings yet

- Dreams: Shaping A World ofDocument24 pagesDreams: Shaping A World ofAkshobhya SharmaNo ratings yet

- Technical Specifications (Batcoda)Document201 pagesTechnical Specifications (Batcoda)mihretu hailemichael100% (2)

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Company Profile Power PointDocument12 pagesCompany Profile Power PointAzzus BkhaNo ratings yet

- MakuriDocument11 pagesMakuriJhoncastilloNo ratings yet

- Hr+Oxspec+ +Laser+Cut+Screen+SetupsDocument10 pagesHr+Oxspec+ +Laser+Cut+Screen+SetupstibisortNo ratings yet

- 202004160626023155prashant Engg Powder Metrollpgy 1Document8 pages202004160626023155prashant Engg Powder Metrollpgy 1Rabi Narayana SahuNo ratings yet

- Chapter 12 CompositesDocument40 pagesChapter 12 CompositesAbood AtiyatNo ratings yet

- Fitter Mechanical Assembly (CSCQ0304)Document7 pagesFitter Mechanical Assembly (CSCQ0304)yudiar djamaldilliahNo ratings yet

- Plate Sample Cap: Welding Process MMA (SMAW)Document14 pagesPlate Sample Cap: Welding Process MMA (SMAW)Readersmo0% (1)

- 2019 Rolleri-Bending IntDocument155 pages2019 Rolleri-Bending IntSladjana TrninicNo ratings yet

- Jam Production MachinesDocument4 pagesJam Production MachinesSajid MughalNo ratings yet

- AcousticDocument10 pagesAcousticKurnianda Dian WulandariNo ratings yet

- Kian Joo Can Factory: Good Things Come in A Long-Term PackageDocument13 pagesKian Joo Can Factory: Good Things Come in A Long-Term PackageEcho WackoNo ratings yet

- 873 - 52 - 473 - Module 1 Wood SubstitutesDocument18 pages873 - 52 - 473 - Module 1 Wood SubstitutesAlexNo ratings yet

- Astm A325Document8 pagesAstm A325Nacer KisyNo ratings yet

- Stainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDocument2 pagesStainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDewandanuNo ratings yet

- Unit 3Document98 pagesUnit 3Sudharshan IyengarNo ratings yet

- EL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsDocument60 pagesEL-O-Matic F-Series: Rack and Pinion Pneumatic ActuatorsPlanet RED39No ratings yet

- Brief Industrial Profile of VISAKHAPATNAM District - DC MsmeDocument26 pagesBrief Industrial Profile of VISAKHAPATNAM District - DC MsmeParas AgarwalNo ratings yet