Professional Documents

Culture Documents

Troubleshooting: Sterndrive Unit Will Not Slide Into Bell Housing

Troubleshooting: Sterndrive Unit Will Not Slide Into Bell Housing

Uploaded by

betabet GeorgeCopyright:

Available Formats

You might also like

- Opera Problemas y SolucionesDocument11 pagesOpera Problemas y SolucionesFermin DiazNo ratings yet

- Fault Code 951 Cylinder Power Imbalance DetectedDocument5 pagesFault Code 951 Cylinder Power Imbalance DetectedAhmedmahNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Partes GT40Document70 pagesPartes GT40JHONNATTAN RODRIGUEZNo ratings yet

- 3 A320 SLAT FLAP Introduction To Trouble Shooting KLDocument25 pages3 A320 SLAT FLAP Introduction To Trouble Shooting KLNugra RS125100% (1)

- ERAN Troubleshooting Guide (V100R010C10 - Draft A) (PDF) - enDocument225 pagesERAN Troubleshooting Guide (V100R010C10 - Draft A) (PDF) - enAhmed Ali EmaraNo ratings yet

- XBox 360 Hardware DebugDocument36 pagesXBox 360 Hardware DebugAlexander Rivas Alpizar100% (1)

- (MITSUBISHI) Manual de Taller Mitsubishi Montero 2002Document21 pages(MITSUBISHI) Manual de Taller Mitsubishi Montero 2002wnsdNo ratings yet

- Dot Matrix LP475 Service ManualDocument348 pagesDot Matrix LP475 Service ManualoralbnetworkNo ratings yet

- Drive Unit Shifts Hard: "Troubleshooting Shift Problems."Document1 pageDrive Unit Shifts Hard: "Troubleshooting Shift Problems."betabet GeorgeNo ratings yet

- PG Troubleshooting PDFDocument8 pagesPG Troubleshooting PDFCarlitox MoralesNo ratings yet

- Hino 700 Steering EquipmentDocument2 pagesHino 700 Steering EquipmentJoki MarzukiNo ratings yet

- PGA Governor TroubleshootingDocument5 pagesPGA Governor Troubleshooting1988anu100% (1)

- Ew60C - Steering System, TroubleshootingDocument2 pagesEw60C - Steering System, Troubleshootingmaintenance 2kpbNo ratings yet

- 17 - Trouble DiagnosisDocument18 pages17 - Trouble DiagnosisFrederikusNo ratings yet

- Brakes: MaintenanceDocument14 pagesBrakes: MaintenanceZoltán RozinkaNo ratings yet

- Actuator Calibration GEN IV - en-GBDocument5 pagesActuator Calibration GEN IV - en-GBIsos CellNo ratings yet

- Compact Hydraulic Steering: Important InformationDocument1 pageCompact Hydraulic Steering: Important Informationbetabet GeorgeNo ratings yet

- A Part 100Document1 pageA Part 100korogeokoroNo ratings yet

- Manual Transmission: Section 5BDocument48 pagesManual Transmission: Section 5BJose Luis Rodriguez CruzNo ratings yet

- SuspensionDocument21 pagesSuspensionEduard MachadoNo ratings yet

- A Part 38Document1 pageA Part 38korogeokoroNo ratings yet

- Service Manual - Single Reduction AxleDocument43 pagesService Manual - Single Reduction AxleEsma KarabulutNo ratings yet

- Console Remote Control Installation InstructionsDocument18 pagesConsole Remote Control Installation InstructionsJoswyn LopesNo ratings yet

- Table 7-2 - Common Problems With Governors Problem Cause Corrective ActionDocument1 pageTable 7-2 - Common Problems With Governors Problem Cause Corrective ActionBaoLCNo ratings yet

- Hq004 Hq006 Oplusm Manual Rev BDocument7 pagesHq004 Hq006 Oplusm Manual Rev BadrianioantomaNo ratings yet

- Troubleshooting: Back2MaintableofcontentsDocument4 pagesTroubleshooting: Back2MaintableofcontentsRonal MoraNo ratings yet

- Troubleshooting Manual: Analysis and Correction of PG Governing TroublesDocument8 pagesTroubleshooting Manual: Analysis and Correction of PG Governing TroublesdelgadozamudioNo ratings yet

- Two Stroke Top EndDocument66 pagesTwo Stroke Top EndPete MoonNo ratings yet

- Volvo 850 Troubleshoot GuideDocument56 pagesVolvo 850 Troubleshoot Guidedaniel veraNo ratings yet

- Installation: "Drop-In" Fork Lowering Kit Installation Instructions 02-08 VTX1800C/N/R/S/TDocument2 pagesInstallation: "Drop-In" Fork Lowering Kit Installation Instructions 02-08 VTX1800C/N/R/S/TGheorghe DanielNo ratings yet

- Harley-Davidson Custom Hand Lever KitDocument3 pagesHarley-Davidson Custom Hand Lever KitelvisandmickNo ratings yet

- SECTION 7.00: TroubleshootingDocument8 pagesSECTION 7.00: TroubleshootingLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Power Steering Gear: Section 6CDocument18 pagesPower Steering Gear: Section 6CbobNo ratings yet

- 1维修手册 Section Index - Chapter 1Document19 pages1维修手册 Section Index - Chapter 1Frank Ch CcaicoNo ratings yet

- 02+SUSPENSION JeepDocument22 pages02+SUSPENSION Jeepthomas rulduNo ratings yet

- Ezg 2Document18 pagesEzg 2GuillNo ratings yet

- Steering System Chrysler Sebring 2008Document178 pagesSteering System Chrysler Sebring 2008Juan MederosNo ratings yet

- SteeringDocument10 pagesSteeringswap2gzNo ratings yet

- UVPX 507AGT-14 - Parts - 2003Document60 pagesUVPX 507AGT-14 - Parts - 2003Centrifugal SeparatorNo ratings yet

- SuspensionDocument16 pagesSuspensionArt Doe100% (1)

- National-Oilwell: Top DriveDocument13 pagesNational-Oilwell: Top DriveAlessandra FloresfarNo ratings yet

- Grade 10 Automotive Tve q1wk5Document20 pagesGrade 10 Automotive Tve q1wk5Precious Dorothy TolentinoNo ratings yet

- Technical Bulletin: Subject Model Applied Date Region SummaryDocument4 pagesTechnical Bulletin: Subject Model Applied Date Region SummaryXuân Quang PhạmNo ratings yet

- Swhru 00012 11 TroubleshootingDocument2 pagesSwhru 00012 11 TroubleshootingTRINDADENo ratings yet

- SIS 2.0 Regulacion de ValvulasDocument2 pagesSIS 2.0 Regulacion de ValvulasJORGE ALEXIS NEIRA �LVAREZNo ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- 211-00 Steering System - General Information PICKUP JMCDocument22 pages211-00 Steering System - General Information PICKUP JMCRusonegroNo ratings yet

- Aktivatör Montaj BilgileriDocument13 pagesAktivatör Montaj BilgileriYaşar BaşerNo ratings yet

- Steering SystemDocument94 pagesSteering Systemniladam2002No ratings yet

- Engine WIll Not Crank or Cranks QST 30Document3 pagesEngine WIll Not Crank or Cranks QST 30hinggasetiawan46No ratings yet

- W85-089-000A0 DR - Max 7000 Series Maintenance ManualDocument119 pagesW85-089-000A0 DR - Max 7000 Series Maintenance ManualKiên Sơn NguyễnNo ratings yet

- Inspection & Qualification Guide: Revision BDocument54 pagesInspection & Qualification Guide: Revision Bamir barekatiNo ratings yet

- Timing Tool Kit InstructionsDocument4 pagesTiming Tool Kit Instructionsasas100% (1)

- Planetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignDocument44 pagesPlanetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignAmal TharakaNo ratings yet

- Can't Perform YM - Sheet1Document2 pagesCan't Perform YM - Sheet1Estefania Martinez RodriguezNo ratings yet

- Operating and Service Manual For Hyd. Act. Series 4000,5000,6500Document24 pagesOperating and Service Manual For Hyd. Act. Series 4000,5000,6500Mehdi Norouzi100% (1)

- Isuzu TF Series Gasoline Engine Workshop ManualDocument20 pagesIsuzu TF Series Gasoline Engine Workshop Manualjames100% (40)

- Workshop Manual: Shift On The Fly SystemDocument33 pagesWorkshop Manual: Shift On The Fly SystemVictor SanchezNo ratings yet

- Motores 4j-Series-MT-ORGDocument576 pagesMotores 4j-Series-MT-ORGCristian Hernandez MorenoNo ratings yet

- Sierra 4.8L 5.3L 6.0L 2002Document405 pagesSierra 4.8L 5.3L 6.0L 2002Jose Gonzalez VazquezNo ratings yet

- Husco™ Main Control Valve: MaintenanceDocument22 pagesHusco™ Main Control Valve: MaintenanceAnonymous 7lirmoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- A Part 57Document1 pageA Part 57betabet GeorgeNo ratings yet

- A Part 65Document1 pageA Part 65betabet GeorgeNo ratings yet

- A Part 58Document1 pageA Part 58betabet GeorgeNo ratings yet

- A Part 66Document1 pageA Part 66betabet GeorgeNo ratings yet

- A Part 60Document1 pageA Part 60betabet GeorgeNo ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- A Part 62Document1 pageA Part 62betabet GeorgeNo ratings yet

- A Part 55Document1 pageA Part 55betabet GeorgeNo ratings yet

- A Part 54Document1 pageA Part 54betabet GeorgeNo ratings yet

- Oil Foams Out of Pump Fill/Vent Screw: Cause Special InstructionsDocument1 pageOil Foams Out of Pump Fill/Vent Screw: Cause Special Instructionsbetabet GeorgeNo ratings yet

- Power Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky MovementsDocument1 pagePower Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky Movementsbetabet GeorgeNo ratings yet

- Power Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too HighDocument1 pagePower Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too Highbetabet GeorgeNo ratings yet

- Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- A Part 21Document1 pageA Part 21betabet GeorgeNo ratings yet

- Compact Hydraulic Steering: Important InformationDocument1 pageCompact Hydraulic Steering: Important Informationbetabet GeorgeNo ratings yet

- Power Trim System Wiring Diagram: Troubleshooting Service Manual Number 14Document1 pagePower Trim System Wiring Diagram: Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Power Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- Drive Unit Shifts Hard: "Troubleshooting Shift Problems."Document1 pageDrive Unit Shifts Hard: "Troubleshooting Shift Problems."betabet GeorgeNo ratings yet

- Table of Contents (Continued) : Troubleshooting Service Manual Number 14Document1 pageTable of Contents (Continued) : Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Performance Troubleshooting: Low WOT Engine RPMDocument1 pagePerformance Troubleshooting: Low WOT Engine RPMbetabet GeorgeNo ratings yet

- Important Information: Section 1C - TroubleshootingDocument1 pageImportant Information: Section 1C - Troubleshootingbetabet GeorgeNo ratings yet

- Boat Bottom Care: Maintenance Service Manual Number 14Document1 pageBoat Bottom Care: Maintenance Service Manual Number 14betabet GeorgeNo ratings yet

- Sebu6100-02 MDocument74 pagesSebu6100-02 MSa CruCerNo ratings yet

- Ir4570 Jam Codes 0205-0207-0105-0107-0108TP06Document10 pagesIr4570 Jam Codes 0205-0207-0105-0107-0108TP06Nattcha KetkakomolNo ratings yet

- TP48300-A-N07A3 Maintenance Guide (V100R001 - 04)Document53 pagesTP48300-A-N07A3 Maintenance Guide (V100R001 - 04)SamirTam0% (1)

- Dell Precision 690Document44 pagesDell Precision 690hish747No ratings yet

- TM 11-5855-214-10 Operator Manual CSW NV Antvs5Document91 pagesTM 11-5855-214-10 Operator Manual CSW NV Antvs5Steven L SobelNo ratings yet

- A Technical Report OnDocument5 pagesA Technical Report OnMichael ObisesanNo ratings yet

- EC Service ManualDocument56 pagesEC Service ManualnascalesNo ratings yet

- qs8700 - EC PDFDocument256 pagesqs8700 - EC PDFRasimAbdullayevNo ratings yet

- Brother HLl-2170w Service ManualDocument174 pagesBrother HLl-2170w Service ManualCameron ScottNo ratings yet

- Rogers Enhanced GuideDocument22 pagesRogers Enhanced Guidespaced_boyNo ratings yet

- Alesis MMT8 Service ManualDocument44 pagesAlesis MMT8 Service ManualEye1024No ratings yet

- Jaltest-Agv-Catalogue EN 125 PDFDocument17 pagesJaltest-Agv-Catalogue EN 125 PDFzadraqNo ratings yet

- PC200 7 Sn200001and UpDocument819 pagesPC200 7 Sn200001and Upnurdinzai100% (1)

- 2) General Manual LRP210Document192 pages2) General Manual LRP210Andrei Horhoianu100% (1)

- Manual Usuario Humastar 600Document152 pagesManual Usuario Humastar 600Wilson Peralta Montecinos50% (2)

- Cell Dyn 3200 Operator ManualDocument676 pagesCell Dyn 3200 Operator Manualquankdd100% (1)

- Deciding The Course of Action: Situation Analysis (Where Are We?)Document32 pagesDeciding The Course of Action: Situation Analysis (Where Are We?)PuttyErwinaNo ratings yet

- Beep CodesDocument192 pagesBeep CodesSaibal RayNo ratings yet

- ACS 2000AFE APPL SW Troubleshooting ManualDocument18 pagesACS 2000AFE APPL SW Troubleshooting ManualRaul quispe quispeNo ratings yet

- Sap Workflow TipsDocument3 pagesSap Workflow TipsBro Jeff100% (1)

- SAP WEB IDE For SAP HANA Installation Troubleshooting Guide: Public 2021-09-29Document52 pagesSAP WEB IDE For SAP HANA Installation Troubleshooting Guide: Public 2021-09-29Tariq AliNo ratings yet

- Information: System Ogl-MnDocument24 pagesInformation: System Ogl-MnMokbelNo ratings yet

- Komatsu PC200-6 Shop ManualDocument711 pagesKomatsu PC200-6 Shop ManualMạnh Dũng100% (1)

- Service and Replacement Parts Manual: WarningDocument136 pagesService and Replacement Parts Manual: WarningRodney RichardsonNo ratings yet

Troubleshooting: Sterndrive Unit Will Not Slide Into Bell Housing

Troubleshooting: Sterndrive Unit Will Not Slide Into Bell Housing

Uploaded by

betabet GeorgeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Troubleshooting: Sterndrive Unit Will Not Slide Into Bell Housing

Troubleshooting: Sterndrive Unit Will Not Slide Into Bell Housing

Uploaded by

betabet GeorgeCopyright:

Available Formats

SERVICE MANUAL NUMBER 14 TROUBLESHOOTING

Troubleshooting

This section is a guide for performance and product troubleshooting. Referrals to specific

sections of this manual are made where special tests or repair procedures are to be

performed.

Because of the relationship between Power Package components (engine and sterndrive),

it will be necessary in some cases to simultaneously refer to the appropriate Engine Service

Manual for further troubleshooting information.

Effective troubleshooting is best enhanced by:

• Personal product knowledge and experience of the trained mechanic/technician.

• Allowing adequate time for testing and analysis.

• Utilizing these charts as a “guide” - a starting point.

Sterndrive Unit Troubleshooting

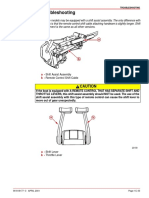

Sterndrive Unit Will Not Slide Into Bell Housing

Cause Special Instructions

U-joint shaft splines not aligned with Rotate propeller shaft

engine coupler splines. COUNTERCLOCKWISE to align splines.

Engine not aligned. Check engine alignment.

Check engine alignment to determine if

Gimbal bearing not properly installed. gimbal bearing is cocked or improperly

installed in gimbal housing.

Damaged U-joint shaft splines and/or Inspect and replace if necessary.

engine coupler splines.

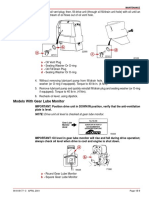

Drive Unit Does Not Shift Into Gear; Remote Control Shift Handle Moves

NOTE:For additional information on troubleshooting, refer to SECTION 2A and see

“Troubleshooting Shift Problems.”

Cause Special Instructions

Shift cables improperly adjusted. Adjust shift cables.

Shift cables not connected. Install and adjust shift cables.

Inner core wire broken or loose. Reconnect or replace inner core wire.

Drive Unit Does Not Shift Into Gear; Remote Control Shift Handle Does Not

Move

NOTE:For additional information on troubleshooting, refer to SECTION 2A and see

“Troubleshooting Shift Problems.”

Cause Special Instructions

Control box not properly assembled. Properly reassemble control box.

Broken or damaged linkage in control box. Repair linkage.

Controls improperly adjusted-cable end Adjust shift cables.

guide hitting brass barrel.

90-818177--3 APRIL 2001 Page 1C-3

You might also like

- Opera Problemas y SolucionesDocument11 pagesOpera Problemas y SolucionesFermin DiazNo ratings yet

- Fault Code 951 Cylinder Power Imbalance DetectedDocument5 pagesFault Code 951 Cylinder Power Imbalance DetectedAhmedmahNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- Partes GT40Document70 pagesPartes GT40JHONNATTAN RODRIGUEZNo ratings yet

- 3 A320 SLAT FLAP Introduction To Trouble Shooting KLDocument25 pages3 A320 SLAT FLAP Introduction To Trouble Shooting KLNugra RS125100% (1)

- ERAN Troubleshooting Guide (V100R010C10 - Draft A) (PDF) - enDocument225 pagesERAN Troubleshooting Guide (V100R010C10 - Draft A) (PDF) - enAhmed Ali EmaraNo ratings yet

- XBox 360 Hardware DebugDocument36 pagesXBox 360 Hardware DebugAlexander Rivas Alpizar100% (1)

- (MITSUBISHI) Manual de Taller Mitsubishi Montero 2002Document21 pages(MITSUBISHI) Manual de Taller Mitsubishi Montero 2002wnsdNo ratings yet

- Dot Matrix LP475 Service ManualDocument348 pagesDot Matrix LP475 Service ManualoralbnetworkNo ratings yet

- Drive Unit Shifts Hard: "Troubleshooting Shift Problems."Document1 pageDrive Unit Shifts Hard: "Troubleshooting Shift Problems."betabet GeorgeNo ratings yet

- PG Troubleshooting PDFDocument8 pagesPG Troubleshooting PDFCarlitox MoralesNo ratings yet

- Hino 700 Steering EquipmentDocument2 pagesHino 700 Steering EquipmentJoki MarzukiNo ratings yet

- PGA Governor TroubleshootingDocument5 pagesPGA Governor Troubleshooting1988anu100% (1)

- Ew60C - Steering System, TroubleshootingDocument2 pagesEw60C - Steering System, Troubleshootingmaintenance 2kpbNo ratings yet

- 17 - Trouble DiagnosisDocument18 pages17 - Trouble DiagnosisFrederikusNo ratings yet

- Brakes: MaintenanceDocument14 pagesBrakes: MaintenanceZoltán RozinkaNo ratings yet

- Actuator Calibration GEN IV - en-GBDocument5 pagesActuator Calibration GEN IV - en-GBIsos CellNo ratings yet

- Compact Hydraulic Steering: Important InformationDocument1 pageCompact Hydraulic Steering: Important Informationbetabet GeorgeNo ratings yet

- A Part 100Document1 pageA Part 100korogeokoroNo ratings yet

- Manual Transmission: Section 5BDocument48 pagesManual Transmission: Section 5BJose Luis Rodriguez CruzNo ratings yet

- SuspensionDocument21 pagesSuspensionEduard MachadoNo ratings yet

- A Part 38Document1 pageA Part 38korogeokoroNo ratings yet

- Service Manual - Single Reduction AxleDocument43 pagesService Manual - Single Reduction AxleEsma KarabulutNo ratings yet

- Console Remote Control Installation InstructionsDocument18 pagesConsole Remote Control Installation InstructionsJoswyn LopesNo ratings yet

- Table 7-2 - Common Problems With Governors Problem Cause Corrective ActionDocument1 pageTable 7-2 - Common Problems With Governors Problem Cause Corrective ActionBaoLCNo ratings yet

- Hq004 Hq006 Oplusm Manual Rev BDocument7 pagesHq004 Hq006 Oplusm Manual Rev BadrianioantomaNo ratings yet

- Troubleshooting: Back2MaintableofcontentsDocument4 pagesTroubleshooting: Back2MaintableofcontentsRonal MoraNo ratings yet

- Troubleshooting Manual: Analysis and Correction of PG Governing TroublesDocument8 pagesTroubleshooting Manual: Analysis and Correction of PG Governing TroublesdelgadozamudioNo ratings yet

- Two Stroke Top EndDocument66 pagesTwo Stroke Top EndPete MoonNo ratings yet

- Volvo 850 Troubleshoot GuideDocument56 pagesVolvo 850 Troubleshoot Guidedaniel veraNo ratings yet

- Installation: "Drop-In" Fork Lowering Kit Installation Instructions 02-08 VTX1800C/N/R/S/TDocument2 pagesInstallation: "Drop-In" Fork Lowering Kit Installation Instructions 02-08 VTX1800C/N/R/S/TGheorghe DanielNo ratings yet

- Harley-Davidson Custom Hand Lever KitDocument3 pagesHarley-Davidson Custom Hand Lever KitelvisandmickNo ratings yet

- SECTION 7.00: TroubleshootingDocument8 pagesSECTION 7.00: TroubleshootingLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Power Steering Gear: Section 6CDocument18 pagesPower Steering Gear: Section 6CbobNo ratings yet

- 1维修手册 Section Index - Chapter 1Document19 pages1维修手册 Section Index - Chapter 1Frank Ch CcaicoNo ratings yet

- 02+SUSPENSION JeepDocument22 pages02+SUSPENSION Jeepthomas rulduNo ratings yet

- Ezg 2Document18 pagesEzg 2GuillNo ratings yet

- Steering System Chrysler Sebring 2008Document178 pagesSteering System Chrysler Sebring 2008Juan MederosNo ratings yet

- SteeringDocument10 pagesSteeringswap2gzNo ratings yet

- UVPX 507AGT-14 - Parts - 2003Document60 pagesUVPX 507AGT-14 - Parts - 2003Centrifugal SeparatorNo ratings yet

- SuspensionDocument16 pagesSuspensionArt Doe100% (1)

- National-Oilwell: Top DriveDocument13 pagesNational-Oilwell: Top DriveAlessandra FloresfarNo ratings yet

- Grade 10 Automotive Tve q1wk5Document20 pagesGrade 10 Automotive Tve q1wk5Precious Dorothy TolentinoNo ratings yet

- Technical Bulletin: Subject Model Applied Date Region SummaryDocument4 pagesTechnical Bulletin: Subject Model Applied Date Region SummaryXuân Quang PhạmNo ratings yet

- Swhru 00012 11 TroubleshootingDocument2 pagesSwhru 00012 11 TroubleshootingTRINDADENo ratings yet

- SIS 2.0 Regulacion de ValvulasDocument2 pagesSIS 2.0 Regulacion de ValvulasJORGE ALEXIS NEIRA �LVAREZNo ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- 211-00 Steering System - General Information PICKUP JMCDocument22 pages211-00 Steering System - General Information PICKUP JMCRusonegroNo ratings yet

- Aktivatör Montaj BilgileriDocument13 pagesAktivatör Montaj BilgileriYaşar BaşerNo ratings yet

- Steering SystemDocument94 pagesSteering Systemniladam2002No ratings yet

- Engine WIll Not Crank or Cranks QST 30Document3 pagesEngine WIll Not Crank or Cranks QST 30hinggasetiawan46No ratings yet

- W85-089-000A0 DR - Max 7000 Series Maintenance ManualDocument119 pagesW85-089-000A0 DR - Max 7000 Series Maintenance ManualKiên Sơn NguyễnNo ratings yet

- Inspection & Qualification Guide: Revision BDocument54 pagesInspection & Qualification Guide: Revision Bamir barekatiNo ratings yet

- Timing Tool Kit InstructionsDocument4 pagesTiming Tool Kit Instructionsasas100% (1)

- Planetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignDocument44 pagesPlanetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignAmal TharakaNo ratings yet

- Can't Perform YM - Sheet1Document2 pagesCan't Perform YM - Sheet1Estefania Martinez RodriguezNo ratings yet

- Operating and Service Manual For Hyd. Act. Series 4000,5000,6500Document24 pagesOperating and Service Manual For Hyd. Act. Series 4000,5000,6500Mehdi Norouzi100% (1)

- Isuzu TF Series Gasoline Engine Workshop ManualDocument20 pagesIsuzu TF Series Gasoline Engine Workshop Manualjames100% (40)

- Workshop Manual: Shift On The Fly SystemDocument33 pagesWorkshop Manual: Shift On The Fly SystemVictor SanchezNo ratings yet

- Motores 4j-Series-MT-ORGDocument576 pagesMotores 4j-Series-MT-ORGCristian Hernandez MorenoNo ratings yet

- Sierra 4.8L 5.3L 6.0L 2002Document405 pagesSierra 4.8L 5.3L 6.0L 2002Jose Gonzalez VazquezNo ratings yet

- Husco™ Main Control Valve: MaintenanceDocument22 pagesHusco™ Main Control Valve: MaintenanceAnonymous 7lirmoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- A Part 57Document1 pageA Part 57betabet GeorgeNo ratings yet

- A Part 65Document1 pageA Part 65betabet GeorgeNo ratings yet

- A Part 58Document1 pageA Part 58betabet GeorgeNo ratings yet

- A Part 66Document1 pageA Part 66betabet GeorgeNo ratings yet

- A Part 60Document1 pageA Part 60betabet GeorgeNo ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- A Part 62Document1 pageA Part 62betabet GeorgeNo ratings yet

- A Part 55Document1 pageA Part 55betabet GeorgeNo ratings yet

- A Part 54Document1 pageA Part 54betabet GeorgeNo ratings yet

- Oil Foams Out of Pump Fill/Vent Screw: Cause Special InstructionsDocument1 pageOil Foams Out of Pump Fill/Vent Screw: Cause Special Instructionsbetabet GeorgeNo ratings yet

- Power Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky MovementsDocument1 pagePower Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky Movementsbetabet GeorgeNo ratings yet

- Power Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too HighDocument1 pagePower Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too Highbetabet GeorgeNo ratings yet

- Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- A Part 21Document1 pageA Part 21betabet GeorgeNo ratings yet

- Compact Hydraulic Steering: Important InformationDocument1 pageCompact Hydraulic Steering: Important Informationbetabet GeorgeNo ratings yet

- Power Trim System Wiring Diagram: Troubleshooting Service Manual Number 14Document1 pagePower Trim System Wiring Diagram: Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Power Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- Drive Unit Shifts Hard: "Troubleshooting Shift Problems."Document1 pageDrive Unit Shifts Hard: "Troubleshooting Shift Problems."betabet GeorgeNo ratings yet

- Table of Contents (Continued) : Troubleshooting Service Manual Number 14Document1 pageTable of Contents (Continued) : Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Performance Troubleshooting: Low WOT Engine RPMDocument1 pagePerformance Troubleshooting: Low WOT Engine RPMbetabet GeorgeNo ratings yet

- Important Information: Section 1C - TroubleshootingDocument1 pageImportant Information: Section 1C - Troubleshootingbetabet GeorgeNo ratings yet

- Boat Bottom Care: Maintenance Service Manual Number 14Document1 pageBoat Bottom Care: Maintenance Service Manual Number 14betabet GeorgeNo ratings yet

- Sebu6100-02 MDocument74 pagesSebu6100-02 MSa CruCerNo ratings yet

- Ir4570 Jam Codes 0205-0207-0105-0107-0108TP06Document10 pagesIr4570 Jam Codes 0205-0207-0105-0107-0108TP06Nattcha KetkakomolNo ratings yet

- TP48300-A-N07A3 Maintenance Guide (V100R001 - 04)Document53 pagesTP48300-A-N07A3 Maintenance Guide (V100R001 - 04)SamirTam0% (1)

- Dell Precision 690Document44 pagesDell Precision 690hish747No ratings yet

- TM 11-5855-214-10 Operator Manual CSW NV Antvs5Document91 pagesTM 11-5855-214-10 Operator Manual CSW NV Antvs5Steven L SobelNo ratings yet

- A Technical Report OnDocument5 pagesA Technical Report OnMichael ObisesanNo ratings yet

- EC Service ManualDocument56 pagesEC Service ManualnascalesNo ratings yet

- qs8700 - EC PDFDocument256 pagesqs8700 - EC PDFRasimAbdullayevNo ratings yet

- Brother HLl-2170w Service ManualDocument174 pagesBrother HLl-2170w Service ManualCameron ScottNo ratings yet

- Rogers Enhanced GuideDocument22 pagesRogers Enhanced Guidespaced_boyNo ratings yet

- Alesis MMT8 Service ManualDocument44 pagesAlesis MMT8 Service ManualEye1024No ratings yet

- Jaltest-Agv-Catalogue EN 125 PDFDocument17 pagesJaltest-Agv-Catalogue EN 125 PDFzadraqNo ratings yet

- PC200 7 Sn200001and UpDocument819 pagesPC200 7 Sn200001and Upnurdinzai100% (1)

- 2) General Manual LRP210Document192 pages2) General Manual LRP210Andrei Horhoianu100% (1)

- Manual Usuario Humastar 600Document152 pagesManual Usuario Humastar 600Wilson Peralta Montecinos50% (2)

- Cell Dyn 3200 Operator ManualDocument676 pagesCell Dyn 3200 Operator Manualquankdd100% (1)

- Deciding The Course of Action: Situation Analysis (Where Are We?)Document32 pagesDeciding The Course of Action: Situation Analysis (Where Are We?)PuttyErwinaNo ratings yet

- Beep CodesDocument192 pagesBeep CodesSaibal RayNo ratings yet

- ACS 2000AFE APPL SW Troubleshooting ManualDocument18 pagesACS 2000AFE APPL SW Troubleshooting ManualRaul quispe quispeNo ratings yet

- Sap Workflow TipsDocument3 pagesSap Workflow TipsBro Jeff100% (1)

- SAP WEB IDE For SAP HANA Installation Troubleshooting Guide: Public 2021-09-29Document52 pagesSAP WEB IDE For SAP HANA Installation Troubleshooting Guide: Public 2021-09-29Tariq AliNo ratings yet

- Information: System Ogl-MnDocument24 pagesInformation: System Ogl-MnMokbelNo ratings yet

- Komatsu PC200-6 Shop ManualDocument711 pagesKomatsu PC200-6 Shop ManualMạnh Dũng100% (1)

- Service and Replacement Parts Manual: WarningDocument136 pagesService and Replacement Parts Manual: WarningRodney RichardsonNo ratings yet