Professional Documents

Culture Documents

Section B - Body & Framework: Centre Pivot

Section B - Body & Framework: Centre Pivot

Uploaded by

Stelian CrisanCopyright:

Available Formats

You might also like

- Mutt 250eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Document85 pagesMutt 250eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Sergio BoniNo ratings yet

- Deckel FPXNC Dialog 4 Dialog 11 Programming RkloppDocument260 pagesDeckel FPXNC Dialog 4 Dialog 11 Programming RkloppStelian Crisan100% (1)

- C-Jaw Crushers Repair InstructionDocument13 pagesC-Jaw Crushers Repair InstructionJorge Perez83% (12)

- D4B8026D002-6-Speed Manual Gearbox 0C6Document124 pagesD4B8026D002-6-Speed Manual Gearbox 0C6Roberto Garcia GodoyNo ratings yet

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang Setiawan100% (1)

- S400-S410 Tuning GuideDocument17 pagesS400-S410 Tuning GuideGuido Catello0% (1)

- Timing Chain Service and Repair Acura RSX 2.0 2004: Auto-Tensioner Removal/InstallationDocument15 pagesTiming Chain Service and Repair Acura RSX 2.0 2004: Auto-Tensioner Removal/InstallationCarlos Gunter Tamayo MoralesNo ratings yet

- CE3458 Parts ManualDocument84 pagesCE3458 Parts ManualMrbigg10No ratings yet

- Transmission Service Manual PDFDocument42 pagesTransmission Service Manual PDFsoelist teoNo ratings yet

- Repair Information: Eaton Hydrualics DivisionDocument8 pagesRepair Information: Eaton Hydrualics DivisionZafiro Feliz GalanNo ratings yet

- EC480D - Swing Gearbox, DisassemblyDocument7 pagesEC480D - Swing Gearbox, Disassemblyeck yuwanNo ratings yet

- Frenos Traseros NivaDocument3 pagesFrenos Traseros NivaFlogamagNo ratings yet

- Fuel Pump Timing Rta72Document7 pagesFuel Pump Timing Rta72Dilawar AliNo ratings yet

- 1926 Hudson Essex Shop ManualDocument266 pages1926 Hudson Essex Shop ManualCollin LintonNo ratings yet

- 6.0L Turbo Rebuild Instructions PDFDocument5 pages6.0L Turbo Rebuild Instructions PDFW MoralesNo ratings yet

- 20 06 M133en 1.0.0Document7 pages20 06 M133en 1.0.0ATILLANo ratings yet

- O. Crankcase DisassemblyDocument14 pagesO. Crankcase DisassemblyRinso PietersmaNo ratings yet

- Armado de Block Vvti DualDocument11 pagesArmado de Block Vvti DualNelsonNo ratings yet

- Gy6 Big Bore Kit and Top End Rebuild GuideDocument28 pagesGy6 Big Bore Kit and Top End Rebuild GuideDodea Nicu100% (1)

- Air Compressor - XMLDocument19 pagesAir Compressor - XMLAnjaliNo ratings yet

- Fork ServiceDocument8 pagesFork ServiceDazai KenNo ratings yet

- diff skt三一集团信息服务系统Document7 pagesdiff skt三一集团信息服务系统Al FadilNo ratings yet

- Desarmado Bomba 416Document16 pagesDesarmado Bomba 416Anword TelefonosNo ratings yet

- Model H 65sa: 1. Precautions in Disassembly and ReassemblyDocument6 pagesModel H 65sa: 1. Precautions in Disassembly and ReassemblyanthonypardoNo ratings yet

- Blurlt BearingDocument12 pagesBlurlt BearingJavi BaalNo ratings yet

- Manual de Reparación Motores Rineer M015 MACOYDocument10 pagesManual de Reparación Motores Rineer M015 MACOYEdgar ContrerasNo ratings yet

- PARKING BRAKE NissanDocument16 pagesPARKING BRAKE NissanFrederikusNo ratings yet

- XS2 First Stage Service Manual: Revised 3/2002Document14 pagesXS2 First Stage Service Manual: Revised 3/2002ValdrickNo ratings yet

- Engine Assembly-Repair ProcedurDocument24 pagesEngine Assembly-Repair Procedurfebri yuliantoNo ratings yet

- PB9900Document4 pagesPB9900Jan SoukupNo ratings yet

- Repairs Manual GV 124 GV Av 12 GV Av 14 GV Av 17Document10 pagesRepairs Manual GV 124 GV Av 12 GV Av 14 GV Av 17Juan Carlos Aldea GriñenNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument13 pagesGroup 2 Removal and Installation of Unit: 1. MastHa doan trieuNo ratings yet

- 11susp. Tras y Parte Trasera Suzuki IntruderDocument22 pages11susp. Tras y Parte Trasera Suzuki Intruderbenjapana100% (2)

- Tranmission - Clutch - 6090 PRODocument19 pagesTranmission - Clutch - 6090 PROGerman100% (1)

- Rover Diff Fitting Instructions-2009 v2Document5 pagesRover Diff Fitting Instructions-2009 v2phrasedNo ratings yet

- Cylinder Block - Repair ProcedurDocument34 pagesCylinder Block - Repair Procedurfebri yulianto100% (1)

- EC380D - Track Motor, DisassemblyDocument9 pagesEC380D - Track Motor, Disassemblymaintenance 2kpbNo ratings yet

- Sachs Fork ManualDocument48 pagesSachs Fork ManualElectromecanica RioterceroNo ratings yet

- Toyota Corolla Repair ManualDocument24 pagesToyota Corolla Repair ManualOlrac AgairdamNo ratings yet

- 06 Transmision y Caja de Cambios Suzuki IntruderDocument23 pages06 Transmision y Caja de Cambios Suzuki Intruderbenjapana100% (2)

- MX-45V - MCV - Spindle Rebuild - SBM0030Document3 pagesMX-45V - MCV - Spindle Rebuild - SBM0030mustafa kaya alp yıldırımNo ratings yet

- Ont Axle 2 PDFDocument34 pagesOnt Axle 2 PDFFrezgi BirhanuNo ratings yet

- Disassembly Manual TransmissionDocument12 pagesDisassembly Manual TransmissionRyan Jay Atilano LontocNo ratings yet

- 23gearboxDocument56 pages23gearboxcarzclassixNo ratings yet

- 20 04 M133en 1.0.0Document3 pages20 04 M133en 1.0.0ATILLANo ratings yet

- Cylinder Bloc DissasemblyDocument8 pagesCylinder Bloc DissasemblyYannick de WalqueNo ratings yet

- Assembly and Disassembly: Isave 21Document16 pagesAssembly and Disassembly: Isave 21Jan Antonius DjunaediNo ratings yet

- Cluth k2 ReconditioningDocument16 pagesCluth k2 ReconditioningPetrus Kanisius WiratnoNo ratings yet

- Planetary Gear and Low Clutch S5,02,2: Automatic TransmissionDocument9 pagesPlanetary Gear and Low Clutch S5,02,2: Automatic TransmissionAnton FortovNo ratings yet

- HPV95Document25 pagesHPV95Milad RahimiNo ratings yet

- 600 Series Roller Bearings - Installation Manual - VNwhI8sDocument3 pages600 Series Roller Bearings - Installation Manual - VNwhI8skominthitsar7474No ratings yet

- Procedimiento de Cambio de Manto y Concavo - C1540Document28 pagesProcedimiento de Cambio de Manto y Concavo - C1540Cristhian AlcedoNo ratings yet

- Connecting Rod ReplacementDocument11 pagesConnecting Rod Replacementfjafarvand100% (1)

- Manual Cajas de CambiosDocument38 pagesManual Cajas de CambiosMc GoraNo ratings yet

- Timing Chain: Service and Repair Acura TSX 2.4 L4 2008Document10 pagesTiming Chain: Service and Repair Acura TSX 2.4 L4 2008Carlos Gunter Tamayo MoralesNo ratings yet

- Rock Shox Judy Service Guide Rev - A PDFDocument9 pagesRock Shox Judy Service Guide Rev - A PDFee1993No ratings yet

- KYB and Showa Shock ServiceDocument4 pagesKYB and Showa Shock ServiceJose Luis SabinoNo ratings yet

- IMPAK3Document15 pagesIMPAK3Vasudev AgrawalNo ratings yet

- Mechanical RepairsDocument22 pagesMechanical RepairsGranoindustriaNo ratings yet

- Single Cylinder Air Compressor Repair ManualDocument13 pagesSingle Cylinder Air Compressor Repair ManualGLNo ratings yet

- GMC 1500 2500 3500 Power Steering Service Training BookletDocument20 pagesGMC 1500 2500 3500 Power Steering Service Training BookletEminentFate100No ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VNH7040AYTR DatasheetDocument48 pagesVNH7040AYTR DatasheetStelian CrisanNo ratings yet

- CAN OpenDocument111 pagesCAN OpenStelian CrisanNo ratings yet

- Pegasus Dieci 3516Document320 pagesPegasus Dieci 3516Stelian CrisanNo ratings yet

- Technical Information: JS6000 Joystick BaseDocument40 pagesTechnical Information: JS6000 Joystick BaseStelian CrisanNo ratings yet

- Technical Information: JS120 Single Axis Fingertip JoystickDocument12 pagesTechnical Information: JS120 Single Axis Fingertip JoystickStelian CrisanNo ratings yet

- JS120 Single Axis Fingertip Joystick: Features and Options Mobile Machine ManagementDocument2 pagesJS120 Single Axis Fingertip Joystick: Features and Options Mobile Machine ManagementStelian CrisanNo ratings yet

- INLINE 5 Adapter Reflash InstructionsDocument6 pagesINLINE 5 Adapter Reflash InstructionsStelian CrisanNo ratings yet

- Section C - Electrics: Page No. Technical DataDocument1 pageSection C - Electrics: Page No. Technical DataStelian CrisanNo ratings yet

- Centre Pivot: Section B - Body & FrameworkDocument1 pageCentre Pivot: Section B - Body & FrameworkStelian CrisanNo ratings yet

- Electrical System: Routine MaintenanceDocument1 pageElectrical System: Routine MaintenanceStelian CrisanNo ratings yet

- Routine Maintenance: Park Brake AdjustmentDocument1 pageRoutine Maintenance: Park Brake AdjustmentStelian CrisanNo ratings yet

- Section3 37Document1 pageSection3 37Stelian CrisanNo ratings yet

- Service Manual: Publication NoDocument1 pageService Manual: Publication NoStelian CrisanNo ratings yet

- Routine Maintenance: Testing The Foot BrakeDocument1 pageRoutine Maintenance: Testing The Foot BrakeStelian CrisanNo ratings yet

- Fluids, Lubricants and Capacities: Routine MaintenanceDocument1 pageFluids, Lubricants and Capacities: Routine MaintenanceStelian CrisanNo ratings yet

- Giving Directions Sena PDFDocument12 pagesGiving Directions Sena PDFnorlyarchboldNo ratings yet

- CNG BrochureDocument2 pagesCNG BrochureBilling EngineersNo ratings yet

- Visit Report of SeptemberDocument637 pagesVisit Report of SeptemberM. Saifur RahmanNo ratings yet

- Preservation Instructions: SCHOTTEL Hydraulic SystemsDocument2 pagesPreservation Instructions: SCHOTTEL Hydraulic SystemsmariodalNo ratings yet

- Street Crane Co. LTD: Buffer Positions & Wheel Running SurfacesDocument2 pagesStreet Crane Co. LTD: Buffer Positions & Wheel Running Surfacesmmargarita_15No ratings yet

- Section 307 01 AutomaticDocument11 pagesSection 307 01 AutomaticWillie AustineNo ratings yet

- Model Based Urban Traffic Control, Part II Coordinated Model Predictive ControllersDocument22 pagesModel Based Urban Traffic Control, Part II Coordinated Model Predictive Controllers张晗钰No ratings yet

- Us BorneDocument4 pagesUs BorneNatasya ImuniNo ratings yet

- Technical Specification (Skyway Stage3)Document277 pagesTechnical Specification (Skyway Stage3)william pasamonteNo ratings yet

- MECH-ND-2020-ME 2305-Applied Hydraulics and Pneumatics-582039598-ME2305-ME1305-APPLIED HYDRAULICS AND PNEUMATICSDocument2 pagesMECH-ND-2020-ME 2305-Applied Hydraulics and Pneumatics-582039598-ME2305-ME1305-APPLIED HYDRAULICS AND PNEUMATICSDharma RajaNo ratings yet

- World Hydrogen & Renewables Italy Green Hydrogen in Italy - Intelligence ReportDocument21 pagesWorld Hydrogen & Renewables Italy Green Hydrogen in Italy - Intelligence ReportIsmael YahmiNo ratings yet

- Shipper Information - Not Part of This B/L ContractDocument1 pageShipper Information - Not Part of This B/L ContractMelíssa AlvaradoNo ratings yet

- Malayan VS PficDocument2 pagesMalayan VS Pficjoel ayonNo ratings yet

- Catalogue AccecoriesDocument128 pagesCatalogue AccecoriesDadang KurniaNo ratings yet

- Caterpillar 299d2 Service Repair ManualDocument2,841 pagesCaterpillar 299d2 Service Repair ManualCasey100% (1)

- Volvo C70!06!2006wiring DiagramDocument20 pagesVolvo C70!06!2006wiring Diagramlinda100% (40)

- Std. X - English Paper II - 1Document4 pagesStd. X - English Paper II - 1Yashodha100% (1)

- T2850-120V Tower Crane Instruction ManualDocument575 pagesT2850-120V Tower Crane Instruction ManualJavierFernándezNo ratings yet

- MSC Thesis Coen Fikkers Overhead Sign Structures Gantry DefDocument90 pagesMSC Thesis Coen Fikkers Overhead Sign Structures Gantry DefThong NguyenNo ratings yet

- JSW - Design Basis For PipeworkDocument56 pagesJSW - Design Basis For PipeworkSarbendu Paul100% (1)

- A Lonely RoadDocument2 pagesA Lonely RoadLukas FiurNo ratings yet

- E-381-Manual - Controlador de VelocidadeDocument11 pagesE-381-Manual - Controlador de VelocidadeEdmar NascimentoNo ratings yet

- Hydraulic/Pneumatic Symbols: For System Diagrams and Component IdentificationDocument54 pagesHydraulic/Pneumatic Symbols: For System Diagrams and Component IdentificationMuhammad Qasim SajidNo ratings yet

- 凯立链条套装TIMING CHAIN KIT 编码整理 - 分车系 - 2022-10-18 UPDATEDocument49 pages凯立链条套装TIMING CHAIN KIT 编码整理 - 分车系 - 2022-10-18 UPDATEDENNIS songNo ratings yet

- Agromaxx 4045E ICT FTRDocument12 pagesAgromaxx 4045E ICT FTRhugo fernandezNo ratings yet

- En-Gb BoardingPass PN 0&Jn 1Document3 pagesEn-Gb BoardingPass PN 0&Jn 1Cristian Cotinghi100% (1)

- Internal Analysis of Emirates Airlines: SWOT AnalysisDocument11 pagesInternal Analysis of Emirates Airlines: SWOT AnalysisSirazul IslamNo ratings yet

- CV Mahmoud SiroDocument2 pagesCV Mahmoud SirosiromahmoudNo ratings yet

Section B - Body & Framework: Centre Pivot

Section B - Body & Framework: Centre Pivot

Uploaded by

Stelian CrisanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section B - Body & Framework: Centre Pivot

Section B - Body & Framework: Centre Pivot

Uploaded by

Stelian CrisanCopyright:

Available Formats

Section B - Body & Framework

Centre Pivot

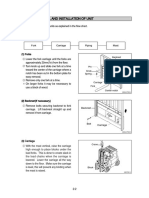

Centre Casting - Removal and Replacement

Centre Casting - Removal and Replacement

Removal Replacement

1 Separate the front and rear chassis (K Separating 1 Assemble the lower pivot pin 15 with shims 17,

the Front and Rear Chassis ( T B-1)). bearing 16 and new seals 22. Retain with spacer 20,

washer 19 and screw 18. Tighten the screw to the

2 Remove the centre driveshaft. correct torque (see below).

3 Support the centre casting using a sling X of suitable Note: Use only enough shims 17 to fill the gaps in the pivot

breaking strain as shown. housing to prevent the ingress of dirt. There must be no

loading on the shims 17.

4 Remove the pin 23 from each steering ram eye end

as follows: 2 Smear grease on to the spacer 6 and fit to the upper

pivot through the housing and boss.

a Remove the screw 18, washer 19 and spacer 20.

3 Pack the bearing 2, which is retained in the pivot

!MWARNING housing, with grease and fit to the upper pivot.

Metal Splinters Note: Ensure the bearing is completely filled with grease.

You can be injured by flying metal splinters when

driving metal pins in or out. Use a soft faced hammer 4 Fit the pivot pin 4 and a new seal 11.

or copper pin to remove and fit metal pins. Always

wear safety glasses. Note: When assembling the upper pivot take care that the

INT-3-1-3_2 lower seal 11 is not pushed out of its seat by the items

placed above it.

b Drive out the pivot pin 23, taking care to retain

shims 24 and 25, and bearing 16. Discard 5 Fit the bolt 7.

seals 27.

6 Check that the lower seal 11 is still correctly seated.

5 Remove the lower pivot pin 15 as follows: Smear the face of the keep plate 5 with grease and fit

over the bolt 7.

a Remove the screw 18, washer 19 and spacer 20.

7 Fit the washers 8 and castellated nut 9. Tighten to the

b Drive out the pivot pin 15, taking care to retain correct torque (see below)

shims 17 and bearing 16. Discard seals 22.

Note: If necessary the castellated nut 9 can be tightened

6 Remove the upper pivot 4 as follows: further until the next castellation lines up with the split pin

drilling in the bolt 7.

a Remove the split pin 10, castellated nut 9 and

washers 8. Withdraw the bolt 7. 8 Fit a new split pin 10.

b Remove the keep plate 5 from the underside of 9 Apply grease via the grease nipples 12 and 21 until it

the upper pivot. is emitted through the seals 11 and 22.

c Drive out the pivot pin 4, from the bottom 10 Refitting the steering ram pins 23 is similar to the

upwards. procedure for the lower pivot pin 15. Use new seals

27.

d Remove and discard the lip seals 11.

Table 1. Torque settings

7 Remove the casting from the machine. Item Nm kgf m lbf ft

9 68 6.9 50

18 244 24.9 180

B-3 9813-0550-1 B-3

You might also like

- Mutt 250eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Document85 pagesMutt 250eu501 (Mongrel Twin Shock) Technical Manual - V1 - 0321Sergio BoniNo ratings yet

- Deckel FPXNC Dialog 4 Dialog 11 Programming RkloppDocument260 pagesDeckel FPXNC Dialog 4 Dialog 11 Programming RkloppStelian Crisan100% (1)

- C-Jaw Crushers Repair InstructionDocument13 pagesC-Jaw Crushers Repair InstructionJorge Perez83% (12)

- D4B8026D002-6-Speed Manual Gearbox 0C6Document124 pagesD4B8026D002-6-Speed Manual Gearbox 0C6Roberto Garcia GodoyNo ratings yet

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang Setiawan100% (1)

- S400-S410 Tuning GuideDocument17 pagesS400-S410 Tuning GuideGuido Catello0% (1)

- Timing Chain Service and Repair Acura RSX 2.0 2004: Auto-Tensioner Removal/InstallationDocument15 pagesTiming Chain Service and Repair Acura RSX 2.0 2004: Auto-Tensioner Removal/InstallationCarlos Gunter Tamayo MoralesNo ratings yet

- CE3458 Parts ManualDocument84 pagesCE3458 Parts ManualMrbigg10No ratings yet

- Transmission Service Manual PDFDocument42 pagesTransmission Service Manual PDFsoelist teoNo ratings yet

- Repair Information: Eaton Hydrualics DivisionDocument8 pagesRepair Information: Eaton Hydrualics DivisionZafiro Feliz GalanNo ratings yet

- EC480D - Swing Gearbox, DisassemblyDocument7 pagesEC480D - Swing Gearbox, Disassemblyeck yuwanNo ratings yet

- Frenos Traseros NivaDocument3 pagesFrenos Traseros NivaFlogamagNo ratings yet

- Fuel Pump Timing Rta72Document7 pagesFuel Pump Timing Rta72Dilawar AliNo ratings yet

- 1926 Hudson Essex Shop ManualDocument266 pages1926 Hudson Essex Shop ManualCollin LintonNo ratings yet

- 6.0L Turbo Rebuild Instructions PDFDocument5 pages6.0L Turbo Rebuild Instructions PDFW MoralesNo ratings yet

- 20 06 M133en 1.0.0Document7 pages20 06 M133en 1.0.0ATILLANo ratings yet

- O. Crankcase DisassemblyDocument14 pagesO. Crankcase DisassemblyRinso PietersmaNo ratings yet

- Armado de Block Vvti DualDocument11 pagesArmado de Block Vvti DualNelsonNo ratings yet

- Gy6 Big Bore Kit and Top End Rebuild GuideDocument28 pagesGy6 Big Bore Kit and Top End Rebuild GuideDodea Nicu100% (1)

- Air Compressor - XMLDocument19 pagesAir Compressor - XMLAnjaliNo ratings yet

- Fork ServiceDocument8 pagesFork ServiceDazai KenNo ratings yet

- diff skt三一集团信息服务系统Document7 pagesdiff skt三一集团信息服务系统Al FadilNo ratings yet

- Desarmado Bomba 416Document16 pagesDesarmado Bomba 416Anword TelefonosNo ratings yet

- Model H 65sa: 1. Precautions in Disassembly and ReassemblyDocument6 pagesModel H 65sa: 1. Precautions in Disassembly and ReassemblyanthonypardoNo ratings yet

- Blurlt BearingDocument12 pagesBlurlt BearingJavi BaalNo ratings yet

- Manual de Reparación Motores Rineer M015 MACOYDocument10 pagesManual de Reparación Motores Rineer M015 MACOYEdgar ContrerasNo ratings yet

- PARKING BRAKE NissanDocument16 pagesPARKING BRAKE NissanFrederikusNo ratings yet

- XS2 First Stage Service Manual: Revised 3/2002Document14 pagesXS2 First Stage Service Manual: Revised 3/2002ValdrickNo ratings yet

- Engine Assembly-Repair ProcedurDocument24 pagesEngine Assembly-Repair Procedurfebri yuliantoNo ratings yet

- PB9900Document4 pagesPB9900Jan SoukupNo ratings yet

- Repairs Manual GV 124 GV Av 12 GV Av 14 GV Av 17Document10 pagesRepairs Manual GV 124 GV Av 12 GV Av 14 GV Av 17Juan Carlos Aldea GriñenNo ratings yet

- Group 2 Removal and Installation of Unit: 1. MastDocument13 pagesGroup 2 Removal and Installation of Unit: 1. MastHa doan trieuNo ratings yet

- 11susp. Tras y Parte Trasera Suzuki IntruderDocument22 pages11susp. Tras y Parte Trasera Suzuki Intruderbenjapana100% (2)

- Tranmission - Clutch - 6090 PRODocument19 pagesTranmission - Clutch - 6090 PROGerman100% (1)

- Rover Diff Fitting Instructions-2009 v2Document5 pagesRover Diff Fitting Instructions-2009 v2phrasedNo ratings yet

- Cylinder Block - Repair ProcedurDocument34 pagesCylinder Block - Repair Procedurfebri yulianto100% (1)

- EC380D - Track Motor, DisassemblyDocument9 pagesEC380D - Track Motor, Disassemblymaintenance 2kpbNo ratings yet

- Sachs Fork ManualDocument48 pagesSachs Fork ManualElectromecanica RioterceroNo ratings yet

- Toyota Corolla Repair ManualDocument24 pagesToyota Corolla Repair ManualOlrac AgairdamNo ratings yet

- 06 Transmision y Caja de Cambios Suzuki IntruderDocument23 pages06 Transmision y Caja de Cambios Suzuki Intruderbenjapana100% (2)

- MX-45V - MCV - Spindle Rebuild - SBM0030Document3 pagesMX-45V - MCV - Spindle Rebuild - SBM0030mustafa kaya alp yıldırımNo ratings yet

- Ont Axle 2 PDFDocument34 pagesOnt Axle 2 PDFFrezgi BirhanuNo ratings yet

- Disassembly Manual TransmissionDocument12 pagesDisassembly Manual TransmissionRyan Jay Atilano LontocNo ratings yet

- 23gearboxDocument56 pages23gearboxcarzclassixNo ratings yet

- 20 04 M133en 1.0.0Document3 pages20 04 M133en 1.0.0ATILLANo ratings yet

- Cylinder Bloc DissasemblyDocument8 pagesCylinder Bloc DissasemblyYannick de WalqueNo ratings yet

- Assembly and Disassembly: Isave 21Document16 pagesAssembly and Disassembly: Isave 21Jan Antonius DjunaediNo ratings yet

- Cluth k2 ReconditioningDocument16 pagesCluth k2 ReconditioningPetrus Kanisius WiratnoNo ratings yet

- Planetary Gear and Low Clutch S5,02,2: Automatic TransmissionDocument9 pagesPlanetary Gear and Low Clutch S5,02,2: Automatic TransmissionAnton FortovNo ratings yet

- HPV95Document25 pagesHPV95Milad RahimiNo ratings yet

- 600 Series Roller Bearings - Installation Manual - VNwhI8sDocument3 pages600 Series Roller Bearings - Installation Manual - VNwhI8skominthitsar7474No ratings yet

- Procedimiento de Cambio de Manto y Concavo - C1540Document28 pagesProcedimiento de Cambio de Manto y Concavo - C1540Cristhian AlcedoNo ratings yet

- Connecting Rod ReplacementDocument11 pagesConnecting Rod Replacementfjafarvand100% (1)

- Manual Cajas de CambiosDocument38 pagesManual Cajas de CambiosMc GoraNo ratings yet

- Timing Chain: Service and Repair Acura TSX 2.4 L4 2008Document10 pagesTiming Chain: Service and Repair Acura TSX 2.4 L4 2008Carlos Gunter Tamayo MoralesNo ratings yet

- Rock Shox Judy Service Guide Rev - A PDFDocument9 pagesRock Shox Judy Service Guide Rev - A PDFee1993No ratings yet

- KYB and Showa Shock ServiceDocument4 pagesKYB and Showa Shock ServiceJose Luis SabinoNo ratings yet

- IMPAK3Document15 pagesIMPAK3Vasudev AgrawalNo ratings yet

- Mechanical RepairsDocument22 pagesMechanical RepairsGranoindustriaNo ratings yet

- Single Cylinder Air Compressor Repair ManualDocument13 pagesSingle Cylinder Air Compressor Repair ManualGLNo ratings yet

- GMC 1500 2500 3500 Power Steering Service Training BookletDocument20 pagesGMC 1500 2500 3500 Power Steering Service Training BookletEminentFate100No ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- VNH7040AYTR DatasheetDocument48 pagesVNH7040AYTR DatasheetStelian CrisanNo ratings yet

- CAN OpenDocument111 pagesCAN OpenStelian CrisanNo ratings yet

- Pegasus Dieci 3516Document320 pagesPegasus Dieci 3516Stelian CrisanNo ratings yet

- Technical Information: JS6000 Joystick BaseDocument40 pagesTechnical Information: JS6000 Joystick BaseStelian CrisanNo ratings yet

- Technical Information: JS120 Single Axis Fingertip JoystickDocument12 pagesTechnical Information: JS120 Single Axis Fingertip JoystickStelian CrisanNo ratings yet

- JS120 Single Axis Fingertip Joystick: Features and Options Mobile Machine ManagementDocument2 pagesJS120 Single Axis Fingertip Joystick: Features and Options Mobile Machine ManagementStelian CrisanNo ratings yet

- INLINE 5 Adapter Reflash InstructionsDocument6 pagesINLINE 5 Adapter Reflash InstructionsStelian CrisanNo ratings yet

- Section C - Electrics: Page No. Technical DataDocument1 pageSection C - Electrics: Page No. Technical DataStelian CrisanNo ratings yet

- Centre Pivot: Section B - Body & FrameworkDocument1 pageCentre Pivot: Section B - Body & FrameworkStelian CrisanNo ratings yet

- Electrical System: Routine MaintenanceDocument1 pageElectrical System: Routine MaintenanceStelian CrisanNo ratings yet

- Routine Maintenance: Park Brake AdjustmentDocument1 pageRoutine Maintenance: Park Brake AdjustmentStelian CrisanNo ratings yet

- Section3 37Document1 pageSection3 37Stelian CrisanNo ratings yet

- Service Manual: Publication NoDocument1 pageService Manual: Publication NoStelian CrisanNo ratings yet

- Routine Maintenance: Testing The Foot BrakeDocument1 pageRoutine Maintenance: Testing The Foot BrakeStelian CrisanNo ratings yet

- Fluids, Lubricants and Capacities: Routine MaintenanceDocument1 pageFluids, Lubricants and Capacities: Routine MaintenanceStelian CrisanNo ratings yet

- Giving Directions Sena PDFDocument12 pagesGiving Directions Sena PDFnorlyarchboldNo ratings yet

- CNG BrochureDocument2 pagesCNG BrochureBilling EngineersNo ratings yet

- Visit Report of SeptemberDocument637 pagesVisit Report of SeptemberM. Saifur RahmanNo ratings yet

- Preservation Instructions: SCHOTTEL Hydraulic SystemsDocument2 pagesPreservation Instructions: SCHOTTEL Hydraulic SystemsmariodalNo ratings yet

- Street Crane Co. LTD: Buffer Positions & Wheel Running SurfacesDocument2 pagesStreet Crane Co. LTD: Buffer Positions & Wheel Running Surfacesmmargarita_15No ratings yet

- Section 307 01 AutomaticDocument11 pagesSection 307 01 AutomaticWillie AustineNo ratings yet

- Model Based Urban Traffic Control, Part II Coordinated Model Predictive ControllersDocument22 pagesModel Based Urban Traffic Control, Part II Coordinated Model Predictive Controllers张晗钰No ratings yet

- Us BorneDocument4 pagesUs BorneNatasya ImuniNo ratings yet

- Technical Specification (Skyway Stage3)Document277 pagesTechnical Specification (Skyway Stage3)william pasamonteNo ratings yet

- MECH-ND-2020-ME 2305-Applied Hydraulics and Pneumatics-582039598-ME2305-ME1305-APPLIED HYDRAULICS AND PNEUMATICSDocument2 pagesMECH-ND-2020-ME 2305-Applied Hydraulics and Pneumatics-582039598-ME2305-ME1305-APPLIED HYDRAULICS AND PNEUMATICSDharma RajaNo ratings yet

- World Hydrogen & Renewables Italy Green Hydrogen in Italy - Intelligence ReportDocument21 pagesWorld Hydrogen & Renewables Italy Green Hydrogen in Italy - Intelligence ReportIsmael YahmiNo ratings yet

- Shipper Information - Not Part of This B/L ContractDocument1 pageShipper Information - Not Part of This B/L ContractMelíssa AlvaradoNo ratings yet

- Malayan VS PficDocument2 pagesMalayan VS Pficjoel ayonNo ratings yet

- Catalogue AccecoriesDocument128 pagesCatalogue AccecoriesDadang KurniaNo ratings yet

- Caterpillar 299d2 Service Repair ManualDocument2,841 pagesCaterpillar 299d2 Service Repair ManualCasey100% (1)

- Volvo C70!06!2006wiring DiagramDocument20 pagesVolvo C70!06!2006wiring Diagramlinda100% (40)

- Std. X - English Paper II - 1Document4 pagesStd. X - English Paper II - 1Yashodha100% (1)

- T2850-120V Tower Crane Instruction ManualDocument575 pagesT2850-120V Tower Crane Instruction ManualJavierFernándezNo ratings yet

- MSC Thesis Coen Fikkers Overhead Sign Structures Gantry DefDocument90 pagesMSC Thesis Coen Fikkers Overhead Sign Structures Gantry DefThong NguyenNo ratings yet

- JSW - Design Basis For PipeworkDocument56 pagesJSW - Design Basis For PipeworkSarbendu Paul100% (1)

- A Lonely RoadDocument2 pagesA Lonely RoadLukas FiurNo ratings yet

- E-381-Manual - Controlador de VelocidadeDocument11 pagesE-381-Manual - Controlador de VelocidadeEdmar NascimentoNo ratings yet

- Hydraulic/Pneumatic Symbols: For System Diagrams and Component IdentificationDocument54 pagesHydraulic/Pneumatic Symbols: For System Diagrams and Component IdentificationMuhammad Qasim SajidNo ratings yet

- 凯立链条套装TIMING CHAIN KIT 编码整理 - 分车系 - 2022-10-18 UPDATEDocument49 pages凯立链条套装TIMING CHAIN KIT 编码整理 - 分车系 - 2022-10-18 UPDATEDENNIS songNo ratings yet

- Agromaxx 4045E ICT FTRDocument12 pagesAgromaxx 4045E ICT FTRhugo fernandezNo ratings yet

- En-Gb BoardingPass PN 0&Jn 1Document3 pagesEn-Gb BoardingPass PN 0&Jn 1Cristian Cotinghi100% (1)

- Internal Analysis of Emirates Airlines: SWOT AnalysisDocument11 pagesInternal Analysis of Emirates Airlines: SWOT AnalysisSirazul IslamNo ratings yet

- CV Mahmoud SiroDocument2 pagesCV Mahmoud SirosiromahmoudNo ratings yet