Professional Documents

Culture Documents

Cryogenic Valves: Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Cryogenic Valves: Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Uploaded by

ecihatCopyright:

Available Formats

You might also like

- Advent 200 Manual 2005Document20 pagesAdvent 200 Manual 2005Cristian Pedraza Beltran100% (1)

- SPC-81524-0102 Tba-8 110VDocument833 pagesSPC-81524-0102 Tba-8 110VAnibal Franca100% (5)

- Crosman Mark I and 2 Factory Service Manual Year 1966Document10 pagesCrosman Mark I and 2 Factory Service Manual Year 1966Just4Him100% (2)

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- Application For Witness Inspection: Ly Hong Huan Hong River Surface Water Treatment Plant ProjectDocument2 pagesApplication For Witness Inspection: Ly Hong Huan Hong River Surface Water Treatment Plant ProjectPhu PhuocNo ratings yet

- KDE13SS3 Spare Parts ListDocument36 pagesKDE13SS3 Spare Parts ListyajairaNo ratings yet

- Quick Coupling DatasheetDocument1 pageQuick Coupling DatasheetfaridferdiansyahNo ratings yet

- F3086Document5 pagesF3086sqc1No ratings yet

- (31000 - 31200) Series: Butterfly Valve Wafer TypeDocument9 pages(31000 - 31200) Series: Butterfly Valve Wafer TypefotopredicNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Application For Witness Inspection: (Kesv Application No. 20O036/20-PM-18 MQ-KESV-002)Document2 pagesApplication For Witness Inspection: (Kesv Application No. 20O036/20-PM-18 MQ-KESV-002)Phu PhuocNo ratings yet

- Extracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Document3 pagesExtracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Mo OsNo ratings yet

- Riegler Pneumatikspeicher Sicherheitsventil GBDocument10 pagesRiegler Pneumatikspeicher Sicherheitsventil GBGyörgy MurvaiNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- Booster Pump Rainwater, 1 HP 1x230v, 60hzDocument4 pagesBooster Pump Rainwater, 1 HP 1x230v, 60hzRutchelle BrunoNo ratings yet

- Distillation Column: Data Sheet ForDocument2 pagesDistillation Column: Data Sheet ForAmanNo ratings yet

- Biztonsági SzelepDocument2 pagesBiztonsági SzelepSándor PetrovicsNo ratings yet

- Surface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16Document16 pagesSurface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16tuynvNo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- LM WartsilaDocument1 pageLM Wartsilakemal kansuNo ratings yet

- Series: Unidirectional Seal Knife Gate ValveDocument2 pagesSeries: Unidirectional Seal Knife Gate ValveAnnie De WildeNo ratings yet

- Gfps Datasheet 561 562 Cone Check Valve enDocument8 pagesGfps Datasheet 561 562 Cone Check Valve encarnaticshankNo ratings yet

- Ys SLS4Document2 pagesYs SLS4Norman MendozaNo ratings yet

- Castel Magn O8Document14 pagesCastel Magn O8Daniel Fancis Amabran BarrientosNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Parts List 20 254 21 00: Spiroplan Gear Unit WA20, WAF20Document3 pagesParts List 20 254 21 00: Spiroplan Gear Unit WA20, WAF20luis terronesNo ratings yet

- MPXDocument11 pagesMPXapi-3700460100% (1)

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Control LiDocument5 pagesControl LiLuis TeixeiraNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Storage Tank: Data Sheet ForDocument2 pagesStorage Tank: Data Sheet ForAmanNo ratings yet

- 84-45-003 Avk002ax Eni 432444Document3 pages84-45-003 Avk002ax Eni 432444Gotica ManagementNo ratings yet

- RICPI21ATP550-Atlas Fire Hydrant Non Traffic Symetric OutletsDocument7 pagesRICPI21ATP550-Atlas Fire Hydrant Non Traffic Symetric OutletsHKC EQUIPEMENTSNo ratings yet

- Re 17342 2022-07Document52 pagesRe 17342 2022-07Ali Emre YıldırımNo ratings yet

- RGV250 Part List VJ22Document76 pagesRGV250 Part List VJ22satfred78No ratings yet

- VICTRIX Zeus Superior 32 KW I Schema Explodata en 37DEDocument2 pagesVICTRIX Zeus Superior 32 KW I Schema Explodata en 37DEVlad AlexandruNo ratings yet

- DS 02995Document2 pagesDS 02995Giovanni ValentinoNo ratings yet

- Eyewash & Safety ShowerDocument5 pagesEyewash & Safety Showershiekh faizNo ratings yet

- TFP1540 02 2017Document6 pagesTFP1540 02 2017Rashel HasanNo ratings yet

- CTD Rock DrillsDocument11 pagesCTD Rock DrillsmoisesNo ratings yet

- En 1 5 235 PRA 822000 M EXDocument16 pagesEn 1 5 235 PRA 822000 M EXAlessandro Pereira CunhaNo ratings yet

- Calculation For Rectangular Tank Rev.CDocument19 pagesCalculation For Rectangular Tank Rev.Clongle.lt10No ratings yet

- 250cc (RMX250S SJ13A 1989-1996)Document86 pages250cc (RMX250S SJ13A 1989-1996)CarolinaMuñozAvalos100% (1)

- Ari 23046 - Stop ValvesDocument1 pageAri 23046 - Stop ValvesPedro Montes MarinNo ratings yet

- Air Receiver DesignDocument3 pagesAir Receiver DesigngksakthiNo ratings yet

- Kelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10Document2 pagesKelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10JafarNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- 1980 KZ550 Standard AIR CLEANER ('80-'81 A1 - A2)Document2 pages1980 KZ550 Standard AIR CLEANER ('80-'81 A1 - A2)Vamesu GabiNo ratings yet

- DBL 810514 05 ZK29-DIN enDocument4 pagesDBL 810514 05 ZK29-DIN enIlic SlobodanNo ratings yet

- Storage Tank: Data Sheet ForDocument3 pagesStorage Tank: Data Sheet ForAmanNo ratings yet

- Tork Solenoid ValveDocument3 pagesTork Solenoid ValveRajat KumarNo ratings yet

- Design Data Sheet For Air ReceiverDocument3 pagesDesign Data Sheet For Air ReceivergksakthiNo ratings yet

- CTO Rock DrillsDocument11 pagesCTO Rock DrillsmoisesNo ratings yet

- Bucher Hydraulics Coil Information 520-P-100010-EnDocument4 pagesBucher Hydraulics Coil Information 520-P-100010-EnJustinNo ratings yet

- 938KW Evaporative Condenser Proposal (Combined Flow)Document3 pages938KW Evaporative Condenser Proposal (Combined Flow)Rogger Gamboa AnayhuamanNo ratings yet

- Техническая спецификация S21-IG10-33-TK-SteamDocument1 pageТехническая спецификация S21-IG10-33-TK-SteamArtur AsaturyanNo ratings yet

- General Twin Seal 4 Way Diverter Iom 2007 PDFDocument20 pagesGeneral Twin Seal 4 Way Diverter Iom 2007 PDFtxlucky80100% (1)

- Single Wide Master Catalog: Goss Community Unit Goss Community FolderDocument109 pagesSingle Wide Master Catalog: Goss Community Unit Goss Community FolderRaudol Raúl Camacho EspinozaNo ratings yet

- Lecture 19Document27 pagesLecture 19alvinNo ratings yet

- Tronxy x1 Assembly GuideDocument26 pagesTronxy x1 Assembly GuideВайсер Евгений100% (1)

- Titan-RTR (Ready To Run)Document34 pagesTitan-RTR (Ready To Run)caller10023No ratings yet

- P15026-Actuator ManualDocument14 pagesP15026-Actuator ManualAlex RamirezNo ratings yet

- TTMCDocument4 pagesTTMCkhoshya7No ratings yet

- Taperlock Dodge ManualDocument2 pagesTaperlock Dodge Manualchristopher nanlalNo ratings yet

- BX-1000 BXG-1000 Operation Manual0 PDFDocument36 pagesBX-1000 BXG-1000 Operation Manual0 PDFMariangel Rodríguez GómezNo ratings yet

- Trend Thermistor DataDocument4 pagesTrend Thermistor DataMike KeilyNo ratings yet

- Catalogo RHPDocument83 pagesCatalogo RHPLuisNovoaRivera100% (1)

- General Principles: Limb Lengthening and Deformity Correction With Truelok Ring Fixation SystemDocument28 pagesGeneral Principles: Limb Lengthening and Deformity Correction With Truelok Ring Fixation SystemFlorin MacarieNo ratings yet

- EDOC 0110 - BENS NRME ZN - Parts Rev3Document67 pagesEDOC 0110 - BENS NRME ZN - Parts Rev3marcos ortizNo ratings yet

- Spinning Wrench Ssw-10Document10 pagesSpinning Wrench Ssw-10George Hans SterlingNo ratings yet

- Owners Manual Allen Truss Screed 12hedDocument32 pagesOwners Manual Allen Truss Screed 12hedJalaluddin MacadatoNo ratings yet

- S600 Parts Catalog: Outer Casing ComponentsDocument11 pagesS600 Parts Catalog: Outer Casing ComponentsaureliofernendesNo ratings yet

- Cople Jse1-0237aea-03-16Document15 pagesCople Jse1-0237aea-03-16Jorge GascaNo ratings yet

- VE460 Roll Grooving ToolDocument16 pagesVE460 Roll Grooving Toolyasi heeruNo ratings yet

- Instruction Manual Juki LK-1900ADocument124 pagesInstruction Manual Juki LK-1900AMaskusyani100% (2)

- Global King 5 Thru 15Document26 pagesGlobal King 5 Thru 15MARTIN FLORESNo ratings yet

- Despiece cp12951 1933420735Document2 pagesDespiece cp12951 1933420735Jerry BryNo ratings yet

- Manual - AR2 Robot Arm AssemblyDocument53 pagesManual - AR2 Robot Arm AssemblyNelson Rey Laura0% (1)

- Borehole O&M - 0Document36 pagesBorehole O&M - 0Tafireyi TeveraNo ratings yet

- Computer Aided Machine Drawing ManualDocument74 pagesComputer Aided Machine Drawing ManualSengottaiyan Malaisamy0% (1)

- Partslist Brother RH-981ADocument109 pagesPartslist Brother RH-981AMaskusyaniNo ratings yet

- Diagrama 389453Document214 pagesDiagrama 389453sandro ronaldNo ratings yet

- Elna2600 RED Part ListDocument22 pagesElna2600 RED Part ListZeljko SofijanicNo ratings yet

Cryogenic Valves: Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Cryogenic Valves: Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Uploaded by

ecihatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cryogenic Valves: Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Cryogenic Valves: Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Uploaded by

ecihatCopyright:

Available Formats

MANAGEMENT SERVICE

0036

W 0 / TRD 100

CRYOGENIC VALVES

YKJ TSE

2018 - 01

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Yakacık

Cryogenic Valves

Application Examples

Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Yakacık

Cryogenic Valves

Technical Specifications

Socket welded

Operating Temperature : -196°C , +200°C

Operating Pressure Max : 63 bar

Size : DN15 - DN25 - DN40 - DN50

Application Areas

Cryogenic lines

LNG (liquified natural gas) industry

Advantages

Quick and easy maintenance

Long life

Stem can be rotated with a low momentum

One piece body casted by precision epoxy casting

Electrostatic painted hand wheel

100% assurance for sealing reliability

Special nut design to prevent the plug damaging KFC ring

Cryogenic Valve Application Areas

Transportation and storage of liquified gases like oxygen,

azote, carbon dioxide, argon, krypton, ethane, methane,

ethylen, nitrogen, LNG, hydrogen.

Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Yakacık

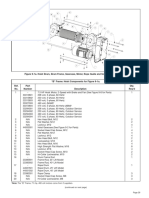

Cryogenic Valves

(22) Hand Wheel Nut

(21) Lock washer

(20) Hand Wheel

(18) Stuffing Nut

(16) Gland Retainer

(19) Stuffing Teflon

(17) Washer

(15) Stuffing Ring

(2) Cover

(24) PTFE Gasket

(25) Graphite Gasket

(26) Stuffing Washer

(12) Nut

(14) Stem

(9) Setscrew (23) Screw Bushing

(7) Plug

(10) Double Piece Nut

(13) Stud

(8) Sliding Washer

(4) Plug Teflon

(11) Cover Gasket (3) Plug Teflon Fixing Washer

(5) Washer

(1) Body

(6) Nut

Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Cryogenic Valves

DN 15 - 50

Type : YKJ Socket

Size DN15-50

Pressure PN 63

Dimension DIN EN 558/1. serie

Socket according to

Connection Type

DIN EN 12760

Temperature -196°C +200°C

Valve Order YKJ.9S.__.00

P.No Part Name Material

1 Body 1.4408

2 Cover 1.4408

3 Plug Teflon Fixing Washer 1.4401

4 Plug Teflon KFC+%25 C

5 Washer 1.4401

6 Nut A2-70

7 Plug 1.4401

8 Sliding Washer 1.4401

9 Setscrew 1.4401

10 Double Piece Nut 1.4401

11 Cover Gasket Acid PTFE

12 Nut A2-70

13 Stud 1.4401

14 Stem 1.4401

15 Stuffing Ring Graphite

16 Gland Retainer 1.4401

17 Washer 1.4401

18 Stuffing Nut 1.4401

19 Stuffing Teflon YFC+%25 C

20 Hand Wheel Aluminium

21 Lock washer A2-70

22 Nut A2-70

23 Screw Bushing 12 Sn Bronze

24 PTFE Gasket PTFE

25 Graphite Gasket 9655-PR

26 Stuffing Washer A2-70

DN Dimensions Assembly Size

mm inch Type L H G D d1 t1

15 1/2'' YKJ 15 85 270 97 30 22 10

25 1'' YKJ 25 115 270 97 42 34,5 13

40 1 1/2'' YKJ 40 130 270 120 57 49 13

50 2'' YKJ 50 155 270 120 69 61,5 16

Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Cryojenic Valves with

Pneumatic Actuators

DN15 - DN50

Type: YKJ Socket

Actuator Types:

1.. Single acting spring return

2.. Double acting

Standard Air Connection:

NPT 1/4" - 18

Upon request other

connections (BSP 1/4", ...)

are available.

Control Types:

1.. On/off

2.. Proportional

Suitable to mount positioner

Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Maintenance Directives

Fluid Types

Allowable fluids are nitrogen, argon, krypton, carbon dioxide, dinitrogen monoxide,

chlorinetrifluorinemethane, trifluorinemethane, methane, ethane and ethylene.

Operating Principle

Cryogenic valves are of plug and seat type. The hand wheel is rotated to the right for

closing and to the left for opening.

Important Notes

Fluid type, pressure and temperature specifications should be checked for suitability.

Do not remove the valve from its package till it is necessary to use it.

Keep it dry and prevent from humidity.

Valves are cleaned and the oil remnants are removed to prevent from meeting with oxygen.

Before installation, please remove protection cap if there is any.

The valves should be visually checked before installation. If any damage is observed, they

should not be assembled.

All parts should be cleaned before installation. No foreign materials should be left in the valve.

Qualified engineers or technicians should be responsible for mounting.

Professional mounting and safety equipment should be used during installation.

Correct mounting position should be selected according to the flow direction shown on valve body.

Should be operated in vertical or horizontal lines.

Painting is not allowed.

Do not apply excessive tightening moment.

Before welding or soldering, the upper cover should be removed.

Thermal expansion of the piping system should be adjusted by expansion joints.

Strainer with filter should be used.

Pay attention to the general directives, safety rules and installation standards of the pipeline.

If the above points are not obeyed:

1. Warranty will be void.

2. Severe injury or death and substantial property loss may be inflicted. Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

Maintenance and Repair

Maintenance periods should be determined according to the working conditions.

If the valve has leakage through the stuffing ring (Pos.1), please tighten the stuffing nut

(Pos.2) until the leakage disappears. Do not apply excessive moment to the nut.

If leakage is not fixed by just tightening the stufing nut, the valve should be sen to

YAKACIK VALF for maintenance and repair.

Dismounting

Only qualified technical staff is allowed for dismounting.

Piping system should be cleaned from aggressive or dangerous remnants.

The valve must be in room temperature.

There should be no fluid left inside the valve.

Parameters Used for Valve Orders

It is important that you should specify the parameters stated below

to choose the suitable valve. Please contact us for unclear issues.

1- Quantity

2- Size

3- Max. Operating Pressure

4- Max. and Min. Operating Temperature

5- Connection Type and Norm

6- Fluid

7- Actuation Type

VALVE ORDER YKJ 9S 40 00

You can use the following encoding system in your orders. Product Code

Cryogenic Valve

YKJ

Example: YKJ.9S.40.00 Material Code Dimensions Norms

9 Stainless Steel DN 15 00 DIN

Cryogenic Valve, Stainless Steel, Socket, DN40, DIN Norm DN 25

Connection Type DN 40

S Socket DN 50

Design and modification rights are reserved

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

YAKACIK VALF Products

Piston Valves DN15 - DN50 Manometer Cocks 1/2''

Balanced Piston Valves DN65 - DN200 Ball Valves (for natural gas) DN15 - DN400

YX - GT Ring Sets DN15 - DN200 Ball Valves Monoball DN15 - DN100

Bellows Sealed Globe Valves DN15 - DN300 Check Valves DN15 - DN300

Globe Valves DN15 - DN300 Disc Check Valves DN25 - DN100

Boiler Blowdown Valves DN32 - DN50 Dual Plate Check Valves DN40 - DN400

Ball Valves DN15 - DN400 Butterfly Valves DN32 - DN500

T Type Strainers DN15 - DN300 Level Gauges YPBR - YUPR - YUPT

Y Type Strainers DN15 - DN500 Transparent Gauge Glass

Expansion Joints DN25 - DN2500 Safety Valves DN 20x32 - DN 100x150

Cryogenic Valves DN15 - DN50 Fire Hydrants DN80 - DN150

ISO 9001-2015 AD 2000 - W 0 CE 0045

QUALITY MANAGEMENT SYSTEM MANUFACTURING QUALIFIED CERTIFICATE PED 2014/68/EU

FIRE SAFE ATEX TA LUFT EAC

BALL / PISTON VALVES

YAKACIK VALF SAN. ve TİC. A.Ş.

İstanbul Deri Organize Sanayi Bölgesi

Tabak Sk. No:4 N7-2 Özel Parsel Ankara Gsm :+90 530 497 51 08

34956 Tuzla / iSTANBUL / TÜRKİYE Kocaeli Gsm :+90 532 453 25 27 https://twitter.com/yakacikvalf

Tel: +90 216 309 72 50 (Pbx) Faks: +90 216 377 98 01 İzmir Gsm :+90 533 591 93 98

Trakya Gsm :+90 530 370 40 96 https://facebook.com/yakacikvalf

www.yakacikvalf.com.tr info@yakacikvalf.com.tr

Phone:+90 216 309 72 50 Fax: +90 216 377 98 01

You might also like

- Advent 200 Manual 2005Document20 pagesAdvent 200 Manual 2005Cristian Pedraza Beltran100% (1)

- SPC-81524-0102 Tba-8 110VDocument833 pagesSPC-81524-0102 Tba-8 110VAnibal Franca100% (5)

- Crosman Mark I and 2 Factory Service Manual Year 1966Document10 pagesCrosman Mark I and 2 Factory Service Manual Year 1966Just4Him100% (2)

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetYosua ChangNo ratings yet

- Application For Witness Inspection: Ly Hong Huan Hong River Surface Water Treatment Plant ProjectDocument2 pagesApplication For Witness Inspection: Ly Hong Huan Hong River Surface Water Treatment Plant ProjectPhu PhuocNo ratings yet

- KDE13SS3 Spare Parts ListDocument36 pagesKDE13SS3 Spare Parts ListyajairaNo ratings yet

- Quick Coupling DatasheetDocument1 pageQuick Coupling DatasheetfaridferdiansyahNo ratings yet

- F3086Document5 pagesF3086sqc1No ratings yet

- (31000 - 31200) Series: Butterfly Valve Wafer TypeDocument9 pages(31000 - 31200) Series: Butterfly Valve Wafer TypefotopredicNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Application For Witness Inspection: (Kesv Application No. 20O036/20-PM-18 MQ-KESV-002)Document2 pagesApplication For Witness Inspection: (Kesv Application No. 20O036/20-PM-18 MQ-KESV-002)Phu PhuocNo ratings yet

- Extracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Document3 pagesExtracted Pages From NAFD-CPFXXX-ECME-DSME-0042-AB - Data Sheet For Pressurized Deaerator (v-13550)Mo OsNo ratings yet

- Riegler Pneumatikspeicher Sicherheitsventil GBDocument10 pagesRiegler Pneumatikspeicher Sicherheitsventil GBGyörgy MurvaiNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- Booster Pump Rainwater, 1 HP 1x230v, 60hzDocument4 pagesBooster Pump Rainwater, 1 HP 1x230v, 60hzRutchelle BrunoNo ratings yet

- Distillation Column: Data Sheet ForDocument2 pagesDistillation Column: Data Sheet ForAmanNo ratings yet

- Biztonsági SzelepDocument2 pagesBiztonsági SzelepSándor PetrovicsNo ratings yet

- Surface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16Document16 pagesSurface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16tuynvNo ratings yet

- Heat Exchanger Specification Sheet SI-BARG UnitsDocument2 pagesHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNo ratings yet

- LM WartsilaDocument1 pageLM Wartsilakemal kansuNo ratings yet

- Series: Unidirectional Seal Knife Gate ValveDocument2 pagesSeries: Unidirectional Seal Knife Gate ValveAnnie De WildeNo ratings yet

- Gfps Datasheet 561 562 Cone Check Valve enDocument8 pagesGfps Datasheet 561 562 Cone Check Valve encarnaticshankNo ratings yet

- Ys SLS4Document2 pagesYs SLS4Norman MendozaNo ratings yet

- Castel Magn O8Document14 pagesCastel Magn O8Daniel Fancis Amabran BarrientosNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Parts List 20 254 21 00: Spiroplan Gear Unit WA20, WAF20Document3 pagesParts List 20 254 21 00: Spiroplan Gear Unit WA20, WAF20luis terronesNo ratings yet

- MPXDocument11 pagesMPXapi-3700460100% (1)

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Control LiDocument5 pagesControl LiLuis TeixeiraNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- Storage Tank: Data Sheet ForDocument2 pagesStorage Tank: Data Sheet ForAmanNo ratings yet

- 84-45-003 Avk002ax Eni 432444Document3 pages84-45-003 Avk002ax Eni 432444Gotica ManagementNo ratings yet

- RICPI21ATP550-Atlas Fire Hydrant Non Traffic Symetric OutletsDocument7 pagesRICPI21ATP550-Atlas Fire Hydrant Non Traffic Symetric OutletsHKC EQUIPEMENTSNo ratings yet

- Re 17342 2022-07Document52 pagesRe 17342 2022-07Ali Emre YıldırımNo ratings yet

- RGV250 Part List VJ22Document76 pagesRGV250 Part List VJ22satfred78No ratings yet

- VICTRIX Zeus Superior 32 KW I Schema Explodata en 37DEDocument2 pagesVICTRIX Zeus Superior 32 KW I Schema Explodata en 37DEVlad AlexandruNo ratings yet

- DS 02995Document2 pagesDS 02995Giovanni ValentinoNo ratings yet

- Eyewash & Safety ShowerDocument5 pagesEyewash & Safety Showershiekh faizNo ratings yet

- TFP1540 02 2017Document6 pagesTFP1540 02 2017Rashel HasanNo ratings yet

- CTD Rock DrillsDocument11 pagesCTD Rock DrillsmoisesNo ratings yet

- En 1 5 235 PRA 822000 M EXDocument16 pagesEn 1 5 235 PRA 822000 M EXAlessandro Pereira CunhaNo ratings yet

- Calculation For Rectangular Tank Rev.CDocument19 pagesCalculation For Rectangular Tank Rev.Clongle.lt10No ratings yet

- 250cc (RMX250S SJ13A 1989-1996)Document86 pages250cc (RMX250S SJ13A 1989-1996)CarolinaMuñozAvalos100% (1)

- Ari 23046 - Stop ValvesDocument1 pageAri 23046 - Stop ValvesPedro Montes MarinNo ratings yet

- Air Receiver DesignDocument3 pagesAir Receiver DesigngksakthiNo ratings yet

- Kelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10Document2 pagesKelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10JafarNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- 1980 KZ550 Standard AIR CLEANER ('80-'81 A1 - A2)Document2 pages1980 KZ550 Standard AIR CLEANER ('80-'81 A1 - A2)Vamesu GabiNo ratings yet

- DBL 810514 05 ZK29-DIN enDocument4 pagesDBL 810514 05 ZK29-DIN enIlic SlobodanNo ratings yet

- Storage Tank: Data Sheet ForDocument3 pagesStorage Tank: Data Sheet ForAmanNo ratings yet

- Tork Solenoid ValveDocument3 pagesTork Solenoid ValveRajat KumarNo ratings yet

- Design Data Sheet For Air ReceiverDocument3 pagesDesign Data Sheet For Air ReceivergksakthiNo ratings yet

- CTO Rock DrillsDocument11 pagesCTO Rock DrillsmoisesNo ratings yet

- Bucher Hydraulics Coil Information 520-P-100010-EnDocument4 pagesBucher Hydraulics Coil Information 520-P-100010-EnJustinNo ratings yet

- 938KW Evaporative Condenser Proposal (Combined Flow)Document3 pages938KW Evaporative Condenser Proposal (Combined Flow)Rogger Gamboa AnayhuamanNo ratings yet

- Техническая спецификация S21-IG10-33-TK-SteamDocument1 pageТехническая спецификация S21-IG10-33-TK-SteamArtur AsaturyanNo ratings yet

- General Twin Seal 4 Way Diverter Iom 2007 PDFDocument20 pagesGeneral Twin Seal 4 Way Diverter Iom 2007 PDFtxlucky80100% (1)

- Single Wide Master Catalog: Goss Community Unit Goss Community FolderDocument109 pagesSingle Wide Master Catalog: Goss Community Unit Goss Community FolderRaudol Raúl Camacho EspinozaNo ratings yet

- Lecture 19Document27 pagesLecture 19alvinNo ratings yet

- Tronxy x1 Assembly GuideDocument26 pagesTronxy x1 Assembly GuideВайсер Евгений100% (1)

- Titan-RTR (Ready To Run)Document34 pagesTitan-RTR (Ready To Run)caller10023No ratings yet

- P15026-Actuator ManualDocument14 pagesP15026-Actuator ManualAlex RamirezNo ratings yet

- TTMCDocument4 pagesTTMCkhoshya7No ratings yet

- Taperlock Dodge ManualDocument2 pagesTaperlock Dodge Manualchristopher nanlalNo ratings yet

- BX-1000 BXG-1000 Operation Manual0 PDFDocument36 pagesBX-1000 BXG-1000 Operation Manual0 PDFMariangel Rodríguez GómezNo ratings yet

- Trend Thermistor DataDocument4 pagesTrend Thermistor DataMike KeilyNo ratings yet

- Catalogo RHPDocument83 pagesCatalogo RHPLuisNovoaRivera100% (1)

- General Principles: Limb Lengthening and Deformity Correction With Truelok Ring Fixation SystemDocument28 pagesGeneral Principles: Limb Lengthening and Deformity Correction With Truelok Ring Fixation SystemFlorin MacarieNo ratings yet

- EDOC 0110 - BENS NRME ZN - Parts Rev3Document67 pagesEDOC 0110 - BENS NRME ZN - Parts Rev3marcos ortizNo ratings yet

- Spinning Wrench Ssw-10Document10 pagesSpinning Wrench Ssw-10George Hans SterlingNo ratings yet

- Owners Manual Allen Truss Screed 12hedDocument32 pagesOwners Manual Allen Truss Screed 12hedJalaluddin MacadatoNo ratings yet

- S600 Parts Catalog: Outer Casing ComponentsDocument11 pagesS600 Parts Catalog: Outer Casing ComponentsaureliofernendesNo ratings yet

- Cople Jse1-0237aea-03-16Document15 pagesCople Jse1-0237aea-03-16Jorge GascaNo ratings yet

- VE460 Roll Grooving ToolDocument16 pagesVE460 Roll Grooving Toolyasi heeruNo ratings yet

- Instruction Manual Juki LK-1900ADocument124 pagesInstruction Manual Juki LK-1900AMaskusyani100% (2)

- Global King 5 Thru 15Document26 pagesGlobal King 5 Thru 15MARTIN FLORESNo ratings yet

- Despiece cp12951 1933420735Document2 pagesDespiece cp12951 1933420735Jerry BryNo ratings yet

- Manual - AR2 Robot Arm AssemblyDocument53 pagesManual - AR2 Robot Arm AssemblyNelson Rey Laura0% (1)

- Borehole O&M - 0Document36 pagesBorehole O&M - 0Tafireyi TeveraNo ratings yet

- Computer Aided Machine Drawing ManualDocument74 pagesComputer Aided Machine Drawing ManualSengottaiyan Malaisamy0% (1)

- Partslist Brother RH-981ADocument109 pagesPartslist Brother RH-981AMaskusyaniNo ratings yet

- Diagrama 389453Document214 pagesDiagrama 389453sandro ronaldNo ratings yet

- Elna2600 RED Part ListDocument22 pagesElna2600 RED Part ListZeljko SofijanicNo ratings yet