Professional Documents

Culture Documents

Guide For Design and Installation Using Rods and Meshed Conductors Guide For Design and Installation Using Rods and Meshed Conductors

Guide For Design and Installation Using Rods and Meshed Conductors Guide For Design and Installation Using Rods and Meshed Conductors

Uploaded by

Mohamed ThouseefOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide For Design and Installation Using Rods and Meshed Conductors Guide For Design and Installation Using Rods and Meshed Conductors

Guide For Design and Installation Using Rods and Meshed Conductors Guide For Design and Installation Using Rods and Meshed Conductors

Uploaded by

Mohamed ThouseefCopyright:

Available Formats

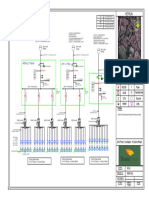

AIR TERMINALS AND ACCESSORIES

> GUIDE FOR DESIGN AND INSTALLATION USING RODS AND MESHED CONDUCTORS > GUIDE FOR DESIGN AND INSTALLATION USING RODS AND MESHED CONDUCTORS

Lightning protection using rods and meshed conductors > ROLLING SPHERE METHOD > MESH METHOD > RECOMMENDED MATERIALS

is intended to share and dissipate the lightning current

This method is based on an electrogeometric model that assumes that the last step According to this method, conductors forming a mesh should be placed

through a network of down-conductors and earth

of the downward leader can propagate in any direction. The model represents this on the structure. The separation depends on the protection level: DENOMINATION REF. TABLE

terminations.

with a sphere (of different radius depending on the required protection level) whose

The elements of a lightning protection system using centre is the end of the lightning downward leader. This sphere is rolled along the Franklin air rod AT-008A 5

rods and meshed conductors are as follows: external surface of the structure to be protected, so that the points in contact with

the sphere are susceptible to get a lightning strike. Franklin air rod base AT-116B 17

Distance

> EXTERNAL LIGHTNING PROTECTION SYSTEM Protection between

w

According to the Standard IEC 62305-3, w Self-supporting Franklin air rod AT-104A 10

impact area level down-

• Simple rods and/or meshed conductors the rolling sphere radius depends on the conductors

Expansion unit AT-012G 108

protection level: I 5m 10 m

• Down-conductors

Roof conductor holder AT-041E 66

II 10 m 10 m

• Earth Termination System • Protection level I: D = 20 m

D III 15 m 15 m Clamp AT-039F 88

• Protection level II D = 30 m D

IV 20 m 20 m

• Protection level III D = 45 m Conductor AT-057D 123

> INTERNAL LIGHTNING PROTECTION SYSTEM D

• Protection level IV D = 60 m

• A suitable surge protection installation. INTERCEPTION

• Other measures minimizing the destructive effects of

lightning (equipotential bonding, screening etc.). 1 The mesh should be applied to For buildings higher than 60 m,

the edges, overhangs and roof a level IV mesh should also

area perimeter, following the cover the upper 20% of the

described methods. outer walls.

The installation of a lightning protection system using

rods and meshed conductors must follow the standards

4

IEC62305 on Lightning Protection:

1

The volume protected by the air terminals can be

determined using 3 methods: DOWN-CONDUCTORS DENOMINATION REF. TABLE

Clip AT-240E 46

> ANGLE METHOD 2 Down-conductors should 4 For longer conductors, it

provide several parallel paths to is recommended to install Rainwater pipe bond AT-025J 87

According to this method, the protection volume is given by distribute the lightning current. expansion joints every 20 m.

a line starting at the air terminal, the angle of which depends Clamp AT-039F 88

The length of the current paths

on the height and the protection level, according to the 2

to the earthing system should be Bimetallic connector AT-094F 103

following graph:

as short and direct as possible.

A guard tube should be installed Guard tube AT-060G 107

To minimize the risk of 5

dangerous sparks, down- for each down-conductor,

Joint protection AT-060G 107

conductors should be covering at least 2 m from

connected to the grounded the floor, in order to avoid

3 Conductor AT-057D 123

metal parts of the structure if mechanical damages.

the distance between them

is shorter than the safety 6 Each down-conductor must

5

separation distance as defined be connected to the earthing

in the regulations. system. Equipotential bonding is

recommended for all the down-

6 3 The conductors should be conductors at ground level every

Protection level fixed to the structure once 20 m.

every metre.

EARTHING DENOMINATION REF. TABLE

The recommended configuration Aluminium conductors or fittings Earth electrode AT-041H 135

7 10

Franklin rods should be placed on the higher and most for the earthing system is a ring must not be used directly with

Clamp AT-020F 90

vulnerable places (corners, overhangs, etc.), as shown in the bonding all down-conductors. the earth.

figure: A disconnecting sleeve should Direct connections between Ground enhancing product AT-010L 145

be installed in each down- copper and aluminium conductors

9 8 conductor for measuring earth Earth pit AT-010H 144

or copper and galvanized steel

resistance separated from other conductors are not recommended

conductive elements. in order to avoid corrosion. Bimetal Bonding bar AT-020H 148

10 8 It is recommended that the or stainless steel clamps should

Earth clamp AT-090H 158

earthing resistance is less be used for these connections.

than 10 Ω. Conductor AT-011D 120

9 Earth conductors should be buried

at a depth of at least 50 cm.

AIR TERMINALS AND ACCESSORIES at3w.com at3w.com AIR TERMINALS AND ACCESSORIES

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- RCW Recloser Installation ManualDocument9 pagesRCW Recloser Installation ManualCesar VenturoNo ratings yet

- Travelling Waves: Transients in Transmission LinesDocument56 pagesTravelling Waves: Transients in Transmission Linesjcmee100% (2)

- 3 - Electrical-Structure-Of-ThundercloudsDocument21 pages3 - Electrical-Structure-Of-ThundercloudsMellina Lisboa100% (1)

- GUIDE ESE InstallationDocument1 pageGUIDE ESE InstallationDelkan16No ratings yet

- 7TKK000108 High-Tech Fuse Catalogue US DGTDocument76 pages7TKK000108 High-Tech Fuse Catalogue US DGTjrvvfNo ratings yet

- Projektimi I RrufepritesitDocument2 pagesProjektimi I Rrufepritesitdukagjin ramqajNo ratings yet

- 7TKK000108 - High-Tech Fuse - Catalogue - US - DGTDocument76 pages7TKK000108 - High-Tech Fuse - Catalogue - US - DGTadrian garciaNo ratings yet

- Porta Fusible Canister para 34.5 KVDocument24 pagesPorta Fusible Canister para 34.5 KVjryamNo ratings yet

- Video 5 - MCB CatalogueDocument146 pagesVideo 5 - MCB CatalogueArt RaNo ratings yet

- DEHN Protects Wind TurbinesDocument20 pagesDEHN Protects Wind TurbinesJFREY1504No ratings yet

- Fuse Holder E90 PV: Technical FeaturesDocument3 pagesFuse Holder E90 PV: Technical FeaturesArmandoVelazcoRangelNo ratings yet

- Metal Oxide Varistor Data Sheet: 14M (E, N) Tmov SeriesDocument9 pagesMetal Oxide Varistor Data Sheet: 14M (E, N) Tmov SeriesMiguel Angel Lopez CastilloNo ratings yet

- ABWTR BW701 enDocument2 pagesABWTR BW701 enАнатолий РябухаNo ratings yet

- Item 28 DS-25.8kV-Ferrule-Mount-Transformer-Protection-MersenDocument3 pagesItem 28 DS-25.8kV-Ferrule-Mount-Transformer-Protection-MersenRAJ2324No ratings yet

- LPS Design Kaushi ElectricalDocument10 pagesLPS Design Kaushi ElectricalYazhisai SelviNo ratings yet

- 2018 MCG AC Surge Protection Catalog RevDocument54 pages2018 MCG AC Surge Protection Catalog RevVenkatesh KamathNo ratings yet

- Prom Class II 230vacDocument2 pagesProm Class II 230vacCrestNo ratings yet

- AWG Cables High Voltage Marine & Offshore (5 15kV) AmercableDocument7 pagesAWG Cables High Voltage Marine & Offshore (5 15kV) Amercablemohammed atyaNo ratings yet

- Distribution Boards Protection DevicesDocument31 pagesDistribution Boards Protection DevicessasikalaNo ratings yet

- Codos FusiblesDocument6 pagesCodos Fusiblescamono2000No ratings yet

- Catalog OkoniteDocument2 pagesCatalog OkonitegedebhaskoroNo ratings yet

- DS 15.5kV Ferrule Mount Transformer Protection MersenDocument4 pagesDS 15.5kV Ferrule Mount Transformer Protection MersenAlberto OrtizNo ratings yet

- Schirtec Installation NewDocument5 pagesSchirtec Installation Newricardoalonsof29No ratings yet

- Power and Control Cables: Info InfoDocument1 pagePower and Control Cables: Info InfoAnonymous VR1d5TNo ratings yet

- FC302 - Ground SystemDocument1 pageFC302 - Ground SystemAGUIARNo ratings yet

- Single Conductor 25-35KV Shielded MV-105Document5 pagesSingle Conductor 25-35KV Shielded MV-105villanueva.texsiNo ratings yet

- Lightning and Surge Protection For Potentially Explosive AtmospheresDocument8 pagesLightning and Surge Protection For Potentially Explosive Atmospherespocetak1No ratings yet

- WDG 51 - Technical Data Sheet MV 804 RDocument7 pagesWDG 51 - Technical Data Sheet MV 804 RPowerTechNo ratings yet

- G1 - Proteccion Fusible TrafoDocument7 pagesG1 - Proteccion Fusible TrafoOperacion LoretoNo ratings yet

- Lightning Rod: Selection GuideDocument2 pagesLightning Rod: Selection GuidethuongtgNo ratings yet

- Under Ground Transformer Technical DatasheetDocument2 pagesUnder Ground Transformer Technical Datasheetmlliumingyang666No ratings yet

- SLD GcuDocument1 pageSLD GcuKhalid ZubairNo ratings yet

- 114-6053 High-Performance Modular Plug ConnectorsDocument10 pages114-6053 High-Performance Modular Plug ConnectorsDiegoNo ratings yet

- Circuit Protection Solutions: Medium Voltage DIN FusesDocument22 pagesCircuit Protection Solutions: Medium Voltage DIN FusesARUNKUMARANNANBHEDANo ratings yet

- Twisto-B: Connection SystemDocument2 pagesTwisto-B: Connection Systemheri fauziNo ratings yet

- Utb SaDocument1 pageUtb SaSơn Lê CaoNo ratings yet

- 14safety Switch & C Breaker 59-65 Eim NewDocument8 pages14safety Switch & C Breaker 59-65 Eim NewFERDINAND BANAGANo ratings yet

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocument2 pagesLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahNo ratings yet

- INGESCODocument6 pagesINGESCOsonth2858No ratings yet

- Multimedia PDFDocument32 pagesMultimedia PDFakhilNo ratings yet

- Isolated DownconductorDocument8 pagesIsolated DownconductorSherman HongNo ratings yet

- 12 Terminations - v02 PDFDocument32 pages12 Terminations - v02 PDFosvald97No ratings yet

- Distribution Boards & Protection DevicesDocument31 pagesDistribution Boards & Protection Devicessudhir raiNo ratings yet

- Circuit ProtectorDocument20 pagesCircuit ProtectorAdrian FerreyraNo ratings yet

- Single Conductor 15KV, Shielded, MV-105Document2 pagesSingle Conductor 15KV, Shielded, MV-105henry hernandezNo ratings yet

- C-L-X® Type MC-HL (XHHW-2)Document3 pagesC-L-X® Type MC-HL (XHHW-2)Xin LiNo ratings yet

- WEG DWB 50070240 en PDFDocument56 pagesWEG DWB 50070240 en PDFwil alfNo ratings yet

- DTK 120HW 191509 R9Document2 pagesDTK 120HW 191509 R9enanoedintelNo ratings yet

- Cord Reel Reel CraftDocument1 pageCord Reel Reel CraftsidrataNo ratings yet

- ADC Complete Industrial Catalog-1Document67 pagesADC Complete Industrial Catalog-11819 Roy GordonNo ratings yet

- HVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield CableDocument6 pagesHVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield Cable20353124No ratings yet

- X Limiter Full Range Current Limiting Fuse Catalog Ca132050enDocument8 pagesX Limiter Full Range Current Limiting Fuse Catalog Ca132050enFernando RodríguezNo ratings yet

- Type Tc-Er - Control & Power Tray CableDocument2 pagesType Tc-Er - Control & Power Tray CableNithyANo ratings yet

- Pfisterer Surge Arresters 11kV 33kV MV HV Medium High Voltage ArrestersDocument4 pagesPfisterer Surge Arresters 11kV 33kV MV HV Medium High Voltage Arrestersricosa00No ratings yet

- Control Cable DatasheetDocument2 pagesControl Cable DatasheetSamir RNo ratings yet

- Safely Earthing and Protecting Antenna / SAT Systems: Now With The New 16 MM Connection ClampsDocument2 pagesSafely Earthing and Protecting Antenna / SAT Systems: Now With The New 16 MM Connection Clampsvinay diwan al emaraNo ratings yet

- Neutral Section: Sicat 8WL5545-4D/4F For Overhead Contact Line SystemsDocument4 pagesNeutral Section: Sicat 8WL5545-4D/4F For Overhead Contact Line SystemsAlcides SperanzaNo ratings yet

- Surge Arresters: Storm Trapper H.E. (High Energy) Low Voltage Distribution Class MOV Surge ArresterDocument6 pagesSurge Arresters: Storm Trapper H.E. (High Energy) Low Voltage Distribution Class MOV Surge ArresterRodrigo RamirezNo ratings yet

- Especificación TécnicaDocument3 pagesEspecificación TécnicaDaniel MonsalveNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- MET 1113 - EE - Lab Simulation 2Document12 pagesMET 1113 - EE - Lab Simulation 2Mohamed ThouseefNo ratings yet

- MET 1113 - EE - Lab Simulation 1 - ThouseefDocument7 pagesMET 1113 - EE - Lab Simulation 1 - ThouseefMohamed ThouseefNo ratings yet

- Ohio Pipeline Standard and Construction SpecificationsDocument24 pagesOhio Pipeline Standard and Construction SpecificationsMohamed ThouseefNo ratings yet

- 8574543-Passive Cooled EnclosuresDocument2 pages8574543-Passive Cooled EnclosuresMohamed ThouseefNo ratings yet

- Complies With EN62019 and IEC60947-5-1Document2 pagesComplies With EN62019 and IEC60947-5-1Mohamed ThouseefNo ratings yet

- Lightning Electromagnetic Fields and Their Induced Voltages On Overhead Lines: The Effect of A Non-Flat Lossy GroundDocument4 pagesLightning Electromagnetic Fields and Their Induced Voltages On Overhead Lines: The Effect of A Non-Flat Lossy GroundJavad PaknahadNo ratings yet

- Counterpoises For Transmission LinesDocument10 pagesCounterpoises For Transmission LinesCristianNo ratings yet

- Planetophysical Function of Vacuum Domains (Dmitriev, Dyatlov)Document15 pagesPlanetophysical Function of Vacuum Domains (Dmitriev, Dyatlov)THE NIKOLA TESLA INSTITUTE100% (1)

- 2010 07 Waveform Characteristics of FaultsDocument28 pages2010 07 Waveform Characteristics of FaultsArmando MaloneNo ratings yet

- Kolli - Is It Ball LightningDocument4 pagesKolli - Is It Ball Lightningshesh_kgNo ratings yet

- Ilmuguru - Org - Soal UNBK SMP Bhs Inggris V2 - 2020Document6 pagesIlmuguru - Org - Soal UNBK SMP Bhs Inggris V2 - 2020Whendy Shukma BhuanaNo ratings yet

- Forest Fire Lesson NotesDocument10 pagesForest Fire Lesson NotesManuel Velazquez MNo ratings yet

- Officials ManualDocument38 pagesOfficials ManualMark DwyerNo ratings yet

- Comparative Analysis of Three Deities From Three MythologiesDocument2 pagesComparative Analysis of Three Deities From Three MythologiesJovy RiveraNo ratings yet

- Chapter 10: Medico - Legal Investigation of WoundsDocument10 pagesChapter 10: Medico - Legal Investigation of WoundsMuhammadIshahaqBinBenjaminNo ratings yet

- Surge Protection Devices GuidesDocument167 pagesSurge Protection Devices GuidessultanprinceNo ratings yet

- Manual Tecnico Alarma BoschDocument78 pagesManual Tecnico Alarma BoschFelizardo Favela CamachoNo ratings yet

- LightningProtectionAG PDFDocument23 pagesLightningProtectionAG PDFBrandon ChoateNo ratings yet

- Ball Lightning Fusion ReactorsDocument46 pagesBall Lightning Fusion Reactorsfbio01No ratings yet

- Definisi Explanation TextDocument2 pagesDefinisi Explanation TextWispaa Elberiaa SitorusNo ratings yet

- Lightning Studies PSCADDocument17 pagesLightning Studies PSCADAnonymous V6y1QL6hn0% (1)

- Annex 1 Revised Lightning Prot Calc REVISED PDFDocument1 pageAnnex 1 Revised Lightning Prot Calc REVISED PDFVasudevan KunjithapathamNo ratings yet

- Failure of Collection Volume Method and Attempts of ESE Lightning Rod Industry To Resurrect ItDocument11 pagesFailure of Collection Volume Method and Attempts of ESE Lightning Rod Industry To Resurrect ItanandancholaNo ratings yet

- Voltex ElectricalDocument80 pagesVoltex Electricalmustang460100% (1)

- IET Publishing Catalogue 2011 3mbDocument44 pagesIET Publishing Catalogue 2011 3mbme_vahabiNo ratings yet

- SECE411 04 OvervoltagesDocument21 pagesSECE411 04 Overvoltagesreh223No ratings yet

- Christoph Schiller Motion Mountain Vol3Document386 pagesChristoph Schiller Motion Mountain Vol3Daniel Ordean100% (1)

- Breathing TechniquesDocument18 pagesBreathing Techniqueszack.d.kaizoNo ratings yet

- Lightning ParametersDocument13 pagesLightning ParametersJorge Alberto Ayala SanchezNo ratings yet

- NBC CII VAL 30min Very SHORT PPT 21092021Document70 pagesNBC CII VAL 30min Very SHORT PPT 21092021DevasyrucNo ratings yet

- Lightning and ArrestDocument13 pagesLightning and ArrestMohammed HijaziNo ratings yet

- A Guide To Writing Poetry EssaysDocument22 pagesA Guide To Writing Poetry EssaysShanoyaNo ratings yet