Professional Documents

Culture Documents

No. Defect Descriptions Office Comments Ship Repy: SCORA/DR/18/010

No. Defect Descriptions Office Comments Ship Repy: SCORA/DR/18/010

Uploaded by

Chowdhury MithilaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No. Defect Descriptions Office Comments Ship Repy: SCORA/DR/18/010

No. Defect Descriptions Office Comments Ship Repy: SCORA/DR/18/010

Uploaded by

Chowdhury MithilaCopyright:

Available Formats

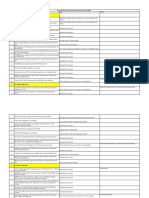

No.

Defect descriptions Office Comments Ship repy

1 Echo sounder : Forward one not working Repair requisition raised? If no. raise. If raised, please re-

send to office.

2 Public Addresser : Not working Repair requisition raised? If no. raise. If raised, please re-

send to office.

3 Anemometer : Not working Repair requisition raised? If no. raise. If raised, please re-

send to office.

4 Doppler : Not working Repair requisition raised? If no. raise. If raised, please re- After restart the Master Unit,

send to office. resummed to normal condition.

5 Air horn : Not working Are you referring to ship air whitsle? If yes, how many ship air

whistle on board? 1 or 2 sets? Only waiting for MR or need

shore technical assistance?

6 Main engine: Remote control out of order. Repair requisition raised? If no. raise. If raised, please re-

send to office.

7 No.3 G/E exhaust line - serious corroded on funnel. MR raised? If no. raise. If raised, please revert MR no.

8 DG Remote start failure due to jet system malfunction. MR raised? If no. raise. If raised, please revert MR no.

9 Auto load sharing unreliable (between no.2 G/E and no.3 G/E). Repair requisition raised? If no. raise. If raised, please re-

send to office.

10 No.2 A/BLR- Temp’ indicator problem (Malfunction). Repair requisition raised? If no. raise. If raised, please re-

send to office.

11 Both A/BLR- Mounting valves are leaking (main steam valves, Ship crew to carry out valve repair. Raise MR if necessary. If

blow down valves & feed water valves.) MR is raised, please revert MR no..

12 F.O Flow meter malfunction. Ship crew to carry out valve repair. Raise MR if necessary. If

MR is raised, please revert MR no..

13 Main steam line leaking, we need a day breakdown for repair. Once everything is prepared/ available on board, to send

downtime request to office (cc to Operation Dept).

14 No.2 IG blower casing has been applied putty. It is need to renew Repair requisition raised? If no. raise. If raised, please re-

at dry docking. send to office.

15 The scrubber wet & dry demister damaged & deck seal demister MR raised? If no. raise. If raised, please revert MR no.

need to replace at dry dock.

16 Various I.G line valves were manual operation. Spare parts MR raised? If no. raise. If raised, please revert MR no.

required.

17 Air compressors: Control Air Compressor- Oil seal leaking. Spare MR raised? If no. raise. If raised, please revert MR no.

parts required.

18 Air cond’ system: NO.2 Compressor- L.O small leakage. MR raised? If no. raise. If raised, please revert MR no.

Spare parts required.

19 Provision fridge system: Auto Defrost system malfunction.

20 Main/Vacuum cond’ C.S.W. Pump – M-seal leaking

21 Aux. C.S.W. Pump – M-seal leaking MR raised? If no. raise. If raised, please revert MR no.

22 A/C Air Cond’ C.S.W. Pump – Impeller need to renew MR raised? If no. raise. If raised, please revert MR no.

23 Atomizer C.S.W. Pump – Motor Capacity no enough & M-seal What do you mean motor capacity no enough? Please revert

leaking drawing and technical specifications for the pump. MR

raised? If no. raise. I raised, please revert MR no.

24 Boiler water feed pump: Shaft seal leaking & it seems to be

overhauled.

25 F O Purifiers:No.1 F.O Purifier – There is nothing inside. MR raised? If no. raise. If raised, please revert MR no.

26 F.O Purifier – Spare parts required. MR raised? If no. raise. If raised, please revert MR no.

27 F.O Purifier – Spare parts required. MR raised? If no. raise. If raised, please revert MR no.

28 Cent.C.W.cooler: Some of heat exchange hot plate removed. MR raised? If no. raise. If raised, please revert MR no.

Spare parts required.

29 Mooring winches: Hydraulic oil leaking from operation lever and

spring applied cylinder for brake

30 Sewage treatment plant : No.1 Ejector pump – There was MR raised? If no. raise. If raised, please revert MR no.

installed motor only.

31 MID ship cargo crane : Leaking from the hoisting winch gear

case, Waiting for spare part to repair

32 Cargo oil stripping pump : Steam supply valve only control by Repair requisition raised? If no. raise. If raised, please re-

local, remote control valve was not operational send to office.

33 Ballast pipe line : 1S, 2S, 4S double bottom ballast pipe line

leaking

34 Hydraulic line minor leaking in COT but not confirm due to load Deck crew need to spend time and effort to isolate section by

condition, about 20 ltr per day during normal operation section, group by group, valve by valve; so as to check, test Ship crew had repaired 5 leaking

and confirm which valve(s)/ bydraulic line(s) in COTs is/ are position during COT 5P valve

actually leaking. repairing on 01-Jun-2018, Now,

The leaking q'ty from 54ltr to 20ltr

per day, wait for next opporunity to

check.

35 COW line: Partly pipes were serious corroded

36 Cargo/ballast/COW/IG valves : The worm gear for Deck seal

outlet butterfly valve and IG-Cargo Connection valve were not

operational

37 Cargo valve in Pump room CL128, CL129, CL130 were leaking Spare seat rings and all required repair items readily

available on board? If yes, to send downtime request to office

(cc to Operation Dept dept). Please refer to SCORA/DR/18/010

38 Inert gas system in use: Control panel was not operational, control Repair requisition raised? If no. raise. If raised, please re-

from local by manual send to office.

39 Majority of the anodes were bad condition, and the stairway were MR raised (with drawing for anode)? If no. raise. If raised,

serious corroded please revert MR no. Please refer to Dock MRs

You might also like

- Generator PM ChecklistDocument2 pagesGenerator PM ChecklistYan's Senora Bescoro100% (3)

- 30 Common 4L60E Transmission ProblemsDocument4 pages30 Common 4L60E Transmission ProblemsJorge Pires100% (6)

- 4L60E Common ProblemsDocument4 pages4L60E Common ProblemsTransmisiones Automáticas Chepe100% (4)

- Alarmas Thermoking PrecedentDocument4 pagesAlarmas Thermoking PrecedentSaMos AdRiian100% (3)

- D7G Series 2 Track-Type Tractor Hydraulic System: Component LocationsDocument2 pagesD7G Series 2 Track-Type Tractor Hydraulic System: Component LocationsRendy Pratama50% (4)

- Mecc Alte Portable Ts GuideDocument9 pagesMecc Alte Portable Ts GuidesfeNo ratings yet

- 204 CL10079 11 PDFDocument18 pages204 CL10079 11 PDFJonathanDavidDeLosSantosAdorno100% (1)

- Gas Engineering CH 3-1Document37 pagesGas Engineering CH 3-1m sohailNo ratings yet

- Weekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor SignatureDocument2 pagesWeekly Lift Truck Pre-Use Check Sheet: Operator Signature: Supervisor Signaturetemter gandaNo ratings yet

- PIR Power Swivel 1 23.02.2023Document6 pagesPIR Power Swivel 1 23.02.2023aymanNo ratings yet

- Emergency Instructions For Total Power FailureDocument11 pagesEmergency Instructions For Total Power FailureSelvaNo ratings yet

- Pending Points of EngDocument7 pagesPending Points of EngAbduljabbar SayedNo ratings yet

- 4 L60 DiagnosisDocument4 pages4 L60 DiagnosisGypsyR75% (4)

- Rear Wipermasher: - ) Wreen I LtooDocument21 pagesRear Wipermasher: - ) Wreen I LtooDante amezquitaNo ratings yet

- Trouble Shooting Case Study (Hydraulics)Document14 pagesTrouble Shooting Case Study (Hydraulics)Riahi Rezeg0% (1)

- 4L60E Transmission Info. RepairDocument3 pages4L60E Transmission Info. RepairMike L.No ratings yet

- FYI 4L60E Common Problems FailuresDocument3 pagesFYI 4L60E Common Problems Failurescyber_nauticaNo ratings yet

- Case Study of Reverse Rotation of Centrifugal CompressorsDocument18 pagesCase Study of Reverse Rotation of Centrifugal CompressorsMohammad RezaeiNo ratings yet

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- Defect List CommentDocument2 pagesDefect List Commentmohammed TabrezNo ratings yet

- HNL PM Audit Oct 2023Document7 pagesHNL PM Audit Oct 2023ahmadiqbal3322No ratings yet

- S1 Maintenance DetailsDocument6 pagesS1 Maintenance DetailsHemanthNo ratings yet

- Comp.a Troubleshooting Report 1-12-2023Document4 pagesComp.a Troubleshooting Report 1-12-2023hamadaNo ratings yet

- TDC - YER.1.00000 Updated (TDS-3)Document4 pagesTDC - YER.1.00000 Updated (TDS-3)Mohamed AnwarNo ratings yet

- Leak Test - Information and FormDocument4 pagesLeak Test - Information and FormthaynaNo ratings yet

- 1 - Hand Over A.Scarpete SurvilleDocument9 pages1 - Hand Over A.Scarpete Survillealex.verdzadze98No ratings yet

- RWRG0038 - Transmission Overheating: Roadranger Warranty Repair Guideline RWRG0038Document1 pageRWRG0038 - Transmission Overheating: Roadranger Warranty Repair Guideline RWRG0038Bart JohnNo ratings yet

- MGVCL in House Transformer Repairing Center at DahodDocument11 pagesMGVCL in House Transformer Repairing Center at DahodHusain BhabhrawalaNo ratings yet

- Work Planning Schedule For Season 2076-2077 of Electrical DepartmentDocument8 pagesWork Planning Schedule For Season 2076-2077 of Electrical DepartmentEngineer Reliance Sugar Pvt. Ltd.No ratings yet

- E-380kVA KOEL DG Set drg.-R1 15.09.2022Document2 pagesE-380kVA KOEL DG Set drg.-R1 15.09.2022Electrical RadicalNo ratings yet

- Transformer Failure DetailsDocument6 pagesTransformer Failure DetailsSantosh BagadeNo ratings yet

- Lucas Generator and Control Box TestsDocument28 pagesLucas Generator and Control Box TestsAnonymous aOXD9JuqdNo ratings yet

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- 15905+05902 With 06 TC PreshopingDocument13 pages15905+05902 With 06 TC Preshopingmanish karshNo ratings yet

- Inside This Issue: Faq'S TechtipsDocument6 pagesInside This Issue: Faq'S TechtipscarmaNo ratings yet

- Ahmed A'nasser Hitch ReportDocument3 pagesAhmed A'nasser Hitch Reportmohamed hamedNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - Finalrambihari100% (1)

- 2nd TA Modification Work List Rev1Document71 pages2nd TA Modification Work List Rev1Vy NguyenNo ratings yet

- Mets 2 Case Study 10Document23 pagesMets 2 Case Study 10ThariqNo ratings yet

- Lucas Generator and Control Box TestsDocument28 pagesLucas Generator and Control Box TestssunhuynhNo ratings yet

- Common Failures For The 4L60EDocument2 pagesCommon Failures For The 4L60Esmallbeans111No ratings yet

- Walk Around Inspection ChecklistDocument13 pagesWalk Around Inspection ChecklistAilyn MercadoNo ratings yet

- 12M PM Das Bombas de IncendioDocument4 pages12M PM Das Bombas de IncendioMarciokronembergerNo ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar Tatwawadi100% (1)

- Answer To Any 4l60e Problem - Ls1tech - Camaro and Firebird Forum DiscussionDocument11 pagesAnswer To Any 4l60e Problem - Ls1tech - Camaro and Firebird Forum Discussionravenhotrods64No ratings yet

- SOP For Grid FailureDocument9 pagesSOP For Grid FailureAmit BiswasNo ratings yet

- 3 - Hand Over I.LEFTERDocument9 pages3 - Hand Over I.LEFTERalex.verdzadze98No ratings yet

- Lay Up Repairs - Engine 2017Document4 pagesLay Up Repairs - Engine 2017Mariyath Muraleedharan KiranNo ratings yet

- Lay Up Repairs - Engine 17 Nov 2017Document6 pagesLay Up Repairs - Engine 17 Nov 2017Mariyath Muraleedharan KiranNo ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- DryerDocument9 pagesDryerReonNo ratings yet

- AT Half Yearly Maintenance ContractorDocument3 pagesAT Half Yearly Maintenance ContractorKrishna Mohan KolliparaNo ratings yet

- ProductionTech Trip HandoverDocument20 pagesProductionTech Trip HandoverDaniel GrabovskyNo ratings yet

- Diagrama Motosoldadora bb400Document10 pagesDiagrama Motosoldadora bb400llBELCEBUllNo ratings yet

- E39 Ahsop 06Document11 pagesE39 Ahsop 06Sanjit SinghNo ratings yet

- Technical Audit ReportDocument25 pagesTechnical Audit Reporttalha100% (1)

- Turbine Punch Point Closeout Status-For HURLDocument7 pagesTurbine Punch Point Closeout Status-For HURLpriyajit sahooNo ratings yet

- Compliance Report John-6 RigDocument1 pageCompliance Report John-6 RigMohammad Awees SanadiNo ratings yet

- FH00020R00H PSBDocument4 pagesFH00020R00H PSBBrian HillNo ratings yet

- Electric Hydraulic Troubleshooting GuideDocument3 pagesElectric Hydraulic Troubleshooting GuideFERNSNo ratings yet

- The Next Level For The Internal Combustion EngineDocument12 pagesThe Next Level For The Internal Combustion EngineSmoking Wheels100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Pump Assessment PDFDocument20 pagesPump Assessment PDFJonas ArifinNo ratings yet

- 506792-1 Compressor Installation. 2Document50 pages506792-1 Compressor Installation. 2nestor coaquiraNo ratings yet

- Air Compressor ProblemsDocument10 pagesAir Compressor ProblemslynNo ratings yet

- CED Class TestDocument18 pagesCED Class TestJay RanjanNo ratings yet

- Regulator With NRVDocument2 pagesRegulator With NRVBiswanath LenkaNo ratings yet

- Backhoe (709) (709FDS) (Control Valve) (W - 8 Sections) - (S - N A54M00101 & Above, A5F300101 & Above) - BackhoeDocument3 pagesBackhoe (709) (709FDS) (Control Valve) (W - 8 Sections) - (S - N A54M00101 & Above, A5F300101 & Above) - BackhoeFacu MarianiNo ratings yet

- Standard Data Cleaning ADocument37 pagesStandard Data Cleaning Acharhack0% (1)

- Hameichal LTD.: Design Data of Steam BoilerDocument8 pagesHameichal LTD.: Design Data of Steam BoilerfelixNo ratings yet

- A Presentation On Control Valves: G - Sridhar Instrumentation NFCLDocument71 pagesA Presentation On Control Valves: G - Sridhar Instrumentation NFCLSridhar GudapatiNo ratings yet

- Ansi B16-104Document1 pageAnsi B16-104Daniel Sierra0% (1)

- Verification of Bernoulli's Theorem Fluid Mechanics ReportDocument8 pagesVerification of Bernoulli's Theorem Fluid Mechanics Reportprajwal mNo ratings yet

- Lista de Instrumentos Precom-Com - PDF ParapetiDocument3 pagesLista de Instrumentos Precom-Com - PDF ParapetiRoy RamosNo ratings yet

- Pipeline Blockage Removal Methods - Invasive OptionsDocument18 pagesPipeline Blockage Removal Methods - Invasive OptionsMohamed TarekNo ratings yet

- Water Ring Vacuum PumpDocument11 pagesWater Ring Vacuum Pumpgigi gigiNo ratings yet

- 4.16 Clear Water High Lift Pump HouseDocument4 pages4.16 Clear Water High Lift Pump HousePrasenjit DeyNo ratings yet

- Landscape Standard DetailsDocument5 pagesLandscape Standard DetailsDharani GowdNo ratings yet

- What Is A Gas CompressorDocument5 pagesWhat Is A Gas CompressorI AM NOT CHINESENo ratings yet

- Compressor Cross ReferencesDocument324 pagesCompressor Cross ReferencesRomanCHuba100% (1)

- Artificial Lift MethodsDocument7 pagesArtificial Lift MethodsusmanNo ratings yet

- Pressure Reliefe DevicesDocument12 pagesPressure Reliefe DevicesMuhammad GhufranNo ratings yet

- VA1 YEA 02100 I I1 PID 0001 - RevA PDFDocument7 pagesVA1 YEA 02100 I I1 PID 0001 - RevA PDFAnonymous JtYvKt5XENo ratings yet

- CompressorsDocument55 pagesCompressorsSumit JoshiNo ratings yet

- Air Operated Grease Ratio Pumps 50-1Document3 pagesAir Operated Grease Ratio Pumps 50-1balasubramanyam kotaNo ratings yet

- 4we10d31b CW220RN9Z5LDocument12 pages4we10d31b CW220RN9Z5LElenilton MelchiorsNo ratings yet

- Steam Boiler Operation and AuxiliariesDocument9 pagesSteam Boiler Operation and Auxiliariesshin deiruNo ratings yet

- HHF-1600HL Drilling Pump Parts ListDocument27 pagesHHF-1600HL Drilling Pump Parts ListDaniel RinconNo ratings yet

- Unit 3 - Steam NozzlesDocument27 pagesUnit 3 - Steam NozzlesMad MaxNo ratings yet

- VenturiDocument2 pagesVenturiJIANo ratings yet