Professional Documents

Culture Documents

Corrosion Behavior Between Dental Implant Abutment

Corrosion Behavior Between Dental Implant Abutment

Uploaded by

Mika VaughnOriginal Description:

Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Corrosion Behavior Between Dental Implant Abutment

Corrosion Behavior Between Dental Implant Abutment

Uploaded by

Mika VaughnCopyright:

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/225495279

Corrosion behavior between dental implant abutment and cast gold alloy

Article in Metals and Materials International · April 2004

DOI: 10.1007/BF03027319

CITATIONS READS

9 599

3 authors, including:

Han-Cheol Choe Chae-Heon Chung

Chosun University Chosun University

253 PUBLICATIONS 2,240 CITATIONS 48 PUBLICATIONS 492 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Han-Cheol Choe on 19 May 2014.

The user has requested enhancement of the downloaded file.

METALS AND MATERIALS International, Vol. 10, No. 2 (2004), pp. 153~159

Corrosion Behavior between Dental Implant Abutment

and Cast Gold Alloy

1 2, 1

Mi-Kyoung Son , Han-Cheol Choe *, and Chae-Heon Chung

1

Department of Prosthodontics, College of Dentistry, Chosun University

375 Seoseok-dong, Dong-gu, Gwangju 501-759, Korea

2

Department of Dental Materials

Research Center of Nano-Interface Activation for Biomaterials

College of Dentistry, Chosun University

Two types of HL hexed abutments of a Steri-Oss system, gold/plastic coping and gold coping, were compared

in terms of corrosion behavior. The anodic polarization behavior and the galvanic corrosion between abutments

and Type III gold alloys, before and after casting, were analyzed. In addition, the crevice corrosion of the

casting samples was analyzed with cyclic potentiodynamic polarization tests using the |Er-Ecorr| value and

scanning electron microscopy. Before casting, gold/plastic coping and gold coping were shown to have similar

corrosion patterns in the anodic polarization test. Type III casting gold alloy was shown to have a lower

corrosion potential and passivation film. The corrosion potential of the gold/plastic coping after casting was

higher than that of gold coping, but the passive region for the gold/plastic coping was smaller than that

of gold coping. The contact current density between the cast gold alloys and gold/plastic before casting was

higher than that between gold coping and cast gold alloy. The contact current density of the samples after

casting was shown to be similar to that before casting. The crevice corrosion resistance of cast samples using

gold coping was lower than that of cast samples using gold/plastic coping, and severe corrosion was observed

by SEM at the abutment-casting gold alloy interface.

Keywords: abutments, gold/plastic coping and gold coping, crevice corrosion, galvanic corrosion

1. INTRODUCTION implant prosthesis. Failures within the interface bonding

have been shown to induce microbial colonization and cor-

Recently, the field of dentistry has witnessed remarkable rosion, ultimately resulting in dislodgment of an entire

developments in the study of implant systems for various implant prosthesis.

restorative purposes. Ever increasing demand by patients for Due to the paramount importance of strong interface

more retentive, yet, superior quality prostheses has driven bonding, there have been many studies regarding this topic

this trend, while also fueling active research into implant [3-7]. Yoshitaka [8] et al. pointed out the risks involved in

materials. Consequently, dentists have seen rapid introduc- screw retained implant prostheses, as mechanical failures

tion of new materials for implant fixtures and abutments, may occur when the casting alloy interfaces with a pre-

adding to their variety and ease of use. machined abutment coping. If incomplete adhesion occurs

Along with this positive evolution, however, many between the alloy and the abutment coping during casting,

implant failures have also been reported. These unfortunate microbial colonization within the crevice is often initiated,

situations arrive when compromises occur during a proce- causing crevice corrosion.

dure, since the success of an implant system depends on In addition to crevice corrosion, galvanic corrosion can

steadfast attention to each procedure involved from pre-sur- also endanger the success of an implant system [6,9-12].

gery evaluation to maintenance. Thus, individual assess- Galvanic corrosion is a direct result of current flow between

ments must focus on achieving proper and stable position of dissimilar metals in contact, such as those used for an

implant fixtures, screws, abutments, and suprastructure implant abutment and a suprastructure.

[1,2]. In addition, solid bonding between the implant abut- Despite this recent awareness of corrosion-induced implant

ment and its suprastructure is critical in attaining dental failures, however, a paucity of information exists regarding

the exact nature and extent of corrosion for single implant

*Corresponding author: hcchoe@chosun.ac.kr systems. Many recent articles failed to address the role of

154 Mi-Kyoung Son et al.

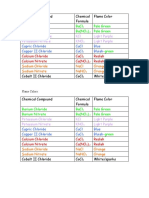

crevice and galvanic corrosion in inducing implant failures, Table 2. Constituents in modified Fusayama’s artificial saliva

as many studies concentrate only on the issue of osseointe- KCl 0.4 gm/l

gration as a primary measure of a successful implant system. NaCl 0.4 gm/l

Therefore, the purpose of our study was to ascertain the NaH2PO4·H20 0.6 gm/l

extent of galvanic and crevice corrosion on a Steri-Oss Na2S·5H2O 0.0016 gm/l

implant system by using various electrochemical techniques. Urea 0 gm/l

2. EXPERIMENTAL PROCEDURE Table 3. Electrode and scanning conditions in this study

Counter electrode : High density Carbon (C)

For implant abutments, two types of HL hexed abutment Reference electrode : Saturated calomel electrode (SCE)

for the Steri-Oss system, gold coping, and gold/plastic cop- Working electrode : sample

ing, were chosen in this study. The two types of abutment are Scanning range : −1500 mV~ +1500 mV

illustrated in Fig. 1. These copings have been widely used in Scan rate : 100 mV/min

single implant systems. The accurate compositions of the Electrolyte : modified Fusayama’s artificial saliva

o

implant abutments and type III gold alloy are listed in Table 1. Temperature : 37±1 C

To cast the gold alloy onto the gold and gold/plastic copings,

respectively, premolar wax-ups were completed on the cop- Fusayama’s Artificial Saliva). The exact composition of the

ing samples, and invested with Denti Vest (phosphate- modified Fusayama’s artificial saliva is listed in Table 2.

bonded investment, Sinji, Korea). A casting ring containing The galvanic corrosion test was carried out as shown in

the invested pattern was preheated slowly in a furnace to the Fig. 1(b). The anodic polarization test and crevice corrosion

temperature at which adequate thermal expansion of the test were preformed as shown in Fig. 1(d). A saturated

o

investment was obtained, generally 685 C. A gas-oxygen calomel electrode (SCE) and high-density carbon electrodes

torch was used to melt the metal alloy quickly and the mol- were set as a reference electrode and as a counter electrode,

ten metal was forced in the mold by centrifugal force. To respectively, according to ASTM G5-87 [13]. For imple-

simulate an oral environment, the cast samples were pol- mentation of the potentiodynamic method, the potentials

ished and subsequently exposed to artificial saliva (Modified were controlled at a scan rate of 100 mV/min. by a poten-

tiostat (EG&G Instruments Model 273A) connected to a

computer system (Table 3). The various electrochemical

methods included the use of artificial saliva deaerated by

pure Ar gas. After each electrochemical measurement, the

corrosion morphology of each sample was investigated by

scanning electron microscopy (SEM).

For the galvanic corrosion, gold/plastic coping and gold

coping were set as shown in Fig. 2. The contact current den-

sity was measured for 24 hr and mass loss was calculated by

a potentiostat connected to a computer system.

For the crevice corrosion assessment, samples were placed

under the artificial saliva. The potential of the crevice corro-

Fig. 1. Samples for this study: (a) Steri-Oss HL-Hexed abutment

(gold/plastic coping & gold coping); (b) Type III casting gold alloy;

(c) casting samples; and (d) sectioned samples.

Table 1. Chemical composition of abutments and casting gold alloy

Samples Composition Melting point

Au 60 %

Steri-Oss gold alloy* o

Pt 25 % 1400-1460 C

Abutment & coping

Pd 15 %

Au 46 %

o

Type III gold alloy** Pd 4.5 % 877-963 C

Ag 40 %

*Steri-Oss: Steri-Oss Yorba, Linda,USA Fig. 2. (a) Schematic representation of the galvanic corrosion test set-

**Type III gold alloy: We Deng Myung Dental Alloy Co., LTD up and (b) calculation of mass loss according to Faradays law.

View publication stats

You might also like

- Feasibility Study Oil Palm Apollo Farms Ver 1.0Document134 pagesFeasibility Study Oil Palm Apollo Farms Ver 1.0ebubec100% (1)

- ENGR135 - LAB05 Stephan Boltzmann's LawDocument12 pagesENGR135 - LAB05 Stephan Boltzmann's Lawgigabyte3235840No ratings yet

- CSE 474/574 Introduction To Machine Learning Fall 2011 Assignment 3Document3 pagesCSE 474/574 Introduction To Machine Learning Fall 2011 Assignment 3kwzeetNo ratings yet

- Electrical QuantitiesDocument34 pagesElectrical QuantitiesMika VaughnNo ratings yet

- CPP and CQA of Different Stages of Solid Oral Dosage Forms: Sr. No Unit Operation Process Parameter Quality AttributesDocument2 pagesCPP and CQA of Different Stages of Solid Oral Dosage Forms: Sr. No Unit Operation Process Parameter Quality AttributesAnil Anee100% (3)

- Galvanic Corrosion Behavior of Dental Alloys: Hamoon Zohdi, Mohammad Emami and Hamid Reza ShahverdiDocument12 pagesGalvanic Corrosion Behavior of Dental Alloys: Hamoon Zohdi, Mohammad Emami and Hamid Reza ShahverdiAnonymous 6tg80e6BqANo ratings yet

- 040 031JOralImplantol201504412e19 23Document6 pages040 031JOralImplantol201504412e19 23Gunasekaran KrithikaNo ratings yet

- Wjoud 9 387Document7 pagesWjoud 9 387KhalilNo ratings yet

- Technology For The Examination of Boiler Tubing Dissimilar Metal Welds, Revision 1Document198 pagesTechnology For The Examination of Boiler Tubing Dissimilar Metal Welds, Revision 1Owais MalikNo ratings yet

- On The Theory of CO2 Corrosion Reactions - Investigating Their Interrelation With The Corrosion Products and API-X100 Steel MicrostructureDocument14 pagesOn The Theory of CO2 Corrosion Reactions - Investigating Their Interrelation With The Corrosion Products and API-X100 Steel MicrostructureFaysal F. EliyanNo ratings yet

- LuSiYuan JApplElectrochem2015Document10 pagesLuSiYuan JApplElectrochem2015Süleyman GüneyNo ratings yet

- Article WJPR 15135744041Document16 pagesArticle WJPR 15135744041SkAliHassanNo ratings yet

- Thin Solid Films: Ying Zhao, Guosong Wu, Qiuyuan Lu, Jun Wu, Ruizhen Xu, Kelvin W.K. Yeung, Paul K. ChuDocument5 pagesThin Solid Films: Ying Zhao, Guosong Wu, Qiuyuan Lu, Jun Wu, Ruizhen Xu, Kelvin W.K. Yeung, Paul K. Chuahmed awadNo ratings yet

- Chemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa EbeidDocument12 pagesChemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa Ebeid3bdallah.mseNo ratings yet

- Glass Coatings On Stainless Steels For High-Temperature Oxidation Protection MechanismDocument12 pagesGlass Coatings On Stainless Steels For High-Temperature Oxidation Protection MechanismJabbar AljanabyNo ratings yet

- Experimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagDocument6 pagesExperimental Study On The Effects of Corrosion in Reinforced Concrete Incorporating Steel Fiber and Ultra-Fine SlagIJRASETPublicationsNo ratings yet

- Case Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeDocument7 pagesCase Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeGina BerríoNo ratings yet

- Normal Concrete ReviewDocument29 pagesNormal Concrete ReviewYash PatelNo ratings yet

- Properties of Super Stainless Steels For Orthodontic ApplicationsDocument13 pagesProperties of Super Stainless Steels For Orthodontic ApplicationsDr.kaviyarasuNo ratings yet

- Pikkarainen 2016 IOP Conf. Ser. Mater. Sci. Eng. 117 012064Document8 pagesPikkarainen 2016 IOP Conf. Ser. Mater. Sci. Eng. 117 012064Anonymous 41VNAwiNo ratings yet

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsronaldNo ratings yet

- V 10 P 1068Document5 pagesV 10 P 1068Ruxandra-Elena BratuNo ratings yet

- Utilizing Steel Slag in Environmental Application - An OverviewDocument8 pagesUtilizing Steel Slag in Environmental Application - An OverviewmichaelNo ratings yet

- Corrosion Monitoring of Reinforced Concrete StructDocument29 pagesCorrosion Monitoring of Reinforced Concrete StructAafan ShahidNo ratings yet

- 1 s2.0 S2352179123000959 MainDocument20 pages1 s2.0 S2352179123000959 MainLUIS DAVID RODRIGUEZ NU¥EZNo ratings yet

- Eliades 2007Document10 pagesEliades 2007Beatriz ChilenoNo ratings yet

- Articulo CorrosiónDocument8 pagesArticulo CorrosiónJacqueline Ortiz RNo ratings yet

- 4-Qualitative and Quantitative Observations of Bone Tissue Reactions To Anodised ImplantsDocument9 pages4-Qualitative and Quantitative Observations of Bone Tissue Reactions To Anodised ImplantsNucleo AlgodonesNo ratings yet

- OCP and Cathodic Conditioning 1 PDFDocument11 pagesOCP and Cathodic Conditioning 1 PDFEr Dikshant MalhotraNo ratings yet

- In Vitro Studies Regarding The Corrosion Resistance of Nicr and Cocr Types Dental AlloysDocument5 pagesIn Vitro Studies Regarding The Corrosion Resistance of Nicr and Cocr Types Dental AlloysRuxandra-Elena BratuNo ratings yet

- Biocompatible Zirconia Coated 316 Stainless Steel With Anticorrosive Behavior For Biomedical ApplicationDocument8 pagesBiocompatible Zirconia Coated 316 Stainless Steel With Anticorrosive Behavior For Biomedical ApplicationDiana SantosNo ratings yet

- CS 开发模拟和预测管道腐蚀机械电化学效应的有限元模型Document11 pagesCS 开发模拟和预测管道腐蚀机械电化学效应的有限元模型jraxxus15No ratings yet

- GIORDANI Journal FatigueDocument8 pagesGIORDANI Journal Fatiguekayron limaNo ratings yet

- Dariusz BARTOCHA, Jacek SUCHOŃ, Czesław BARON, Jan SZAJNARDocument7 pagesDariusz BARTOCHA, Jacek SUCHOŃ, Czesław BARON, Jan SZAJNARskNo ratings yet

- Retained Austenite and PittingDocument6 pagesRetained Austenite and PittingSuhaib AshrafNo ratings yet

- The Influence of Porosity On Corrosion Attack of Austenitic Stainless SteelDocument8 pagesThe Influence of Porosity On Corrosion Attack of Austenitic Stainless SteelIka 1521No ratings yet

- Microstructures of BrazingsDocument9 pagesMicrostructures of BrazingsLucas SerenaNo ratings yet

- Hayazi 2020 IOP Conf. Ser. Mater. Sci. Eng. 957 012022Document7 pagesHayazi 2020 IOP Conf. Ser. Mater. Sci. Eng. 957 012022Raza TariqNo ratings yet

- Fayomi 2019 J. Phys. Conf. Ser. 1378 042084Document9 pagesFayomi 2019 J. Phys. Conf. Ser. 1378 042084Herda CahyaningrumNo ratings yet

- Surface Characteristics ImplantsDocument83 pagesSurface Characteristics ImplantsdrpriyamNo ratings yet

- Chen 2013 IOP Conf. Ser.: Mater. Sci. Eng. 52 062006Document9 pagesChen 2013 IOP Conf. Ser.: Mater. Sci. Eng. 52 062006Kin Fatt WongNo ratings yet

- Interpretation of Electrochemical Measurements Made During Micro Scale Abrasion CorrosionDocument10 pagesInterpretation of Electrochemical Measurements Made During Micro Scale Abrasion CorrosionJesus ZilchNo ratings yet

- Piis0109564104000429 PDFDocument8 pagesPiis0109564104000429 PDFMartin AdriazolaNo ratings yet

- Effect of Sintering Atmosphere On Properties of Porous Stainless Steel For Biomedical ApplicationsDocument6 pagesEffect of Sintering Atmosphere On Properties of Porous Stainless Steel For Biomedical ApplicationsDaniela Silva MolinaNo ratings yet

- MIC of Storage Tank Aluminum Oating Roofs During Hydrotest: Materials Performance April 2002Document14 pagesMIC of Storage Tank Aluminum Oating Roofs During Hydrotest: Materials Performance April 2002VidyaParamasivamNo ratings yet

- 2012 Spiking Humping (IEEE) - 1Document13 pages2012 Spiking Humping (IEEE) - 1s_m_taheriNo ratings yet

- An Overview of Orthodontic Material Degradation in Oral CavityDocument10 pagesAn Overview of Orthodontic Material Degradation in Oral CavitySai KrupaNo ratings yet

- 2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelDocument5 pages2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelPedro CunhaNo ratings yet

- Transient Liquid Phase Bonding of AA-6063 To UNS S32304 Using Cu InterlayerDocument8 pagesTransient Liquid Phase Bonding of AA-6063 To UNS S32304 Using Cu InterlayerReza GhavamiNo ratings yet

- Overview of Corrosion and Advanced Corro PDFDocument6 pagesOverview of Corrosion and Advanced Corro PDFStefanos DiamantisNo ratings yet

- Corrosion of Orthodontic AppliancesDocument9 pagesCorrosion of Orthodontic AppliancesNorhan Hossam Ahmed MohamedNo ratings yet

- Study On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeDocument8 pagesStudy On Prevention of Rebar Corrosion Through Cathodic Protection by Using Sacrificial AnodeNew NSskinNo ratings yet

- Weld Discoloration - Pharmaceutical Engineering 2011Document9 pagesWeld Discoloration - Pharmaceutical Engineering 2011Rolando Nuñez MonrroyNo ratings yet

- Besrapub 56Document15 pagesBesrapub 56Laxmidhar BesraNo ratings yet

- Analysis of A Failed Pipe Elbow in Geothermal Production Facility PDFDocument7 pagesAnalysis of A Failed Pipe Elbow in Geothermal Production Facility PDFAz ArNo ratings yet

- 109 AgDocument12 pages109 AgAngel PerezNo ratings yet

- Electropolishing of Medical-Grade Stainless Steel in Preparation For Surface Nano-TexturingDocument27 pagesElectropolishing of Medical-Grade Stainless Steel in Preparation For Surface Nano-TexturingFILM KARTUNNo ratings yet

- Laboratory Simulation of Corrosion Damage in Reinforced ConcreteDocument9 pagesLaboratory Simulation of Corrosion Damage in Reinforced Concretejorge mario martinez gameroNo ratings yet

- DRJ 12 438Document5 pagesDRJ 12 438TiruvalliUttamkumarNo ratings yet

- 2013 - Laguna Camacho - A Study of Cavitation Erosion On Engineering MaterialsDocument10 pages2013 - Laguna Camacho - A Study of Cavitation Erosion On Engineering MaterialsCesar Fernando BenavidesNo ratings yet

- Applied Surface Science: A.W. Tan, R. Ismail, K.H. Chua, R. Ahmad, S.A. Akbar, B. Pingguan-MurphyDocument10 pagesApplied Surface Science: A.W. Tan, R. Ismail, K.H. Chua, R. Ahmad, S.A. Akbar, B. Pingguan-Murphyey_mieNo ratings yet

- 10 1016@j Corsci 2014 07 001Document32 pages10 1016@j Corsci 2014 07 001uocmogiandi_aNo ratings yet

- Accelerated CorrosionDocument8 pagesAccelerated Corrosionjuli_rad100% (2)

- Surface Characterisation and Electrochemical Behaviour of Porous Titanium Dioxide Coated 316L Stainless Steel For Orthopaedic Applications PDFDocument6 pagesSurface Characterisation and Electrochemical Behaviour of Porous Titanium Dioxide Coated 316L Stainless Steel For Orthopaedic Applications PDFRahul MadanNo ratings yet

- Advances in Multifunctional Materials and Systems IIFrom EverandAdvances in Multifunctional Materials and Systems IIJun AkedoNo ratings yet

- Introduction To The Gas LawsDocument5 pagesIntroduction To The Gas LawsMika VaughnNo ratings yet

- Factors Affecting The Rate of Chemical Reactions: Before You ReadDocument9 pagesFactors Affecting The Rate of Chemical Reactions: Before You ReadMika VaughnNo ratings yet

- Balancing Redox Reactions by The Ion-Electron Method AcidDocument3 pagesBalancing Redox Reactions by The Ion-Electron Method AcidMika VaughnNo ratings yet

- Cathodic and Anodic ProtectionDocument2 pagesCathodic and Anodic ProtectionMika VaughnNo ratings yet

- POGIL Activity - Collision TheoryDocument4 pagesPOGIL Activity - Collision TheoryMika VaughnNo ratings yet

- Chapter10-Physical Significance of IntegralDocument66 pagesChapter10-Physical Significance of IntegralMika VaughnNo ratings yet

- NonClinical Labs Inspections List (10-1-2000 Through 9-27-2020)Document78 pagesNonClinical Labs Inspections List (10-1-2000 Through 9-27-2020)Mika VaughnNo ratings yet

- Flame Colors:: Barium Chloride Bacl Pale Green Barium Nitrate Ba (No) Pale GreenDocument1 pageFlame Colors:: Barium Chloride Bacl Pale Green Barium Nitrate Ba (No) Pale GreenMika VaughnNo ratings yet

- Expt #1 - Molecular Modeling of Alkanes Assigned Reading/Viewing - Lab Manual, #1, Expt 18a. Hyperchem InstallationDocument9 pagesExpt #1 - Molecular Modeling of Alkanes Assigned Reading/Viewing - Lab Manual, #1, Expt 18a. Hyperchem InstallationMika VaughnNo ratings yet

- Carib Studies Module 2 NotesDocument96 pagesCarib Studies Module 2 NotesMika Vaughn100% (1)

- BIOL 1263 Living Organisms II Tutorial Questions-Mycology SectionDocument2 pagesBIOL 1263 Living Organisms II Tutorial Questions-Mycology SectionMika VaughnNo ratings yet

- Hyundai Kia VBL InteractiveDocument1 pageHyundai Kia VBL InteractiveMauricio Exequiel Chavez100% (4)

- 3rd Round Wise GATE Cut Off of All Round AY 2024-25 v555 - Copy (1) (1) - RemovedDocument2 pages3rd Round Wise GATE Cut Off of All Round AY 2024-25 v555 - Copy (1) (1) - RemovedAgony SinghNo ratings yet

- (A Guide To Administering Distance Learning) Chapter 5 Theories and Frameworks For Online EducationDocument25 pages(A Guide To Administering Distance Learning) Chapter 5 Theories and Frameworks For Online EducationJohn Patrick Lare Cap-atanNo ratings yet

- RGB LedDocument6 pagesRGB LedEder GómezNo ratings yet

- Course Outline 1. Course Code 2. Course Title 3. Pre - Requisite 4. CO - Requisite 5. Course Credit 6. Contact Hours/Semester 7. Course DescriptionDocument3 pagesCourse Outline 1. Course Code 2. Course Title 3. Pre - Requisite 4. CO - Requisite 5. Course Credit 6. Contact Hours/Semester 7. Course DescriptionFelica Delos ReyesNo ratings yet

- IdeaPad 5 15ALC05 82LN00AKLMDocument2 pagesIdeaPad 5 15ALC05 82LN00AKLMChristian MendozaNo ratings yet

- MIR - LML - Golovina L. I. and Yaglom I. M. - Induction in GeometryDocument134 pagesMIR - LML - Golovina L. I. and Yaglom I. M. - Induction in Geometryavast2008100% (2)

- Kant, Immanuel - Aesthetics - Internet Encyclopedia of PhilosophyDocument7 pagesKant, Immanuel - Aesthetics - Internet Encyclopedia of PhilosophyNazirNo ratings yet

- Lucchini Poly MilanoDocument26 pagesLucchini Poly MilanoAghajaniNo ratings yet

- E25bmhs 2007Document63 pagesE25bmhs 2007Luis GallardoNo ratings yet

- Alternative Wall TechnologiesDocument9 pagesAlternative Wall TechnologiesSACHIDANANDA SNo ratings yet

- Redis Cluster Specification-12Document1 pageRedis Cluster Specification-12Kajaruban SurendranNo ratings yet

- Advent 7109 User ManualDocument73 pagesAdvent 7109 User ManualDaveW1958No ratings yet

- I Pledge Flyer - Ghana@60 CelebrationDocument22 pagesI Pledge Flyer - Ghana@60 CelebrationGhanaWeb100% (1)

- TherbligDocument23 pagesTherbligimrannila910No ratings yet

- Ce 203: Structural Mechanics I: Civil & Environmental Engineering DepartmentDocument2 pagesCe 203: Structural Mechanics I: Civil & Environmental Engineering DepartmentjacobllNo ratings yet

- Module One Wellness PlanDocument10 pagesModule One Wellness PlanMatthew JohnsonNo ratings yet

- MicrosoftDocument20 pagesMicrosoftSagar PatelNo ratings yet

- AmanDocument10 pagesAmanAmanVatsNo ratings yet

- NC101 Module 1Document6 pagesNC101 Module 1Sarah May Nacion MorescoNo ratings yet

- MicropaleontologyDocument20 pagesMicropaleontologyMUHAMMAD FAUZI RODZEENo ratings yet

- IMG Xios XG Supreme USB Operating InstructionsDocument80 pagesIMG Xios XG Supreme USB Operating InstructionsClarity DentalNo ratings yet

- GEC 7 Final Term ModuleDocument131 pagesGEC 7 Final Term ModuleJV PadernaNo ratings yet

- Design Change Request (DCR) : PT - Barata IndonesiaDocument1 pageDesign Change Request (DCR) : PT - Barata IndonesiaRhadityo Shakti BudimanNo ratings yet

- Absurdity Incongruity and LaughterDocument24 pagesAbsurdity Incongruity and LaughterMHardt1No ratings yet

- GTP Strategic Plan Proposal PDFDocument227 pagesGTP Strategic Plan Proposal PDFPak Ngah LebayNo ratings yet