Professional Documents

Culture Documents

P 003 Wellhead Control Panel 10K

P 003 Wellhead Control Panel 10K

Uploaded by

HamelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P 003 Wellhead Control Panel 10K

P 003 Wellhead Control Panel 10K

Uploaded by

HamelCopyright:

Available Formats

Hydraulic

Power Units

Wellhead Control Panel 10K

Profile

These type of wellhead control panel have electrically driven • Closed stainless steel cabinet with seven doors for protection

hydraulic pumps to generate hydraulic power source for (IP 65) and maintenance

wellhead valves operational requirements. Hydraulic logic • Four lifting points and two forklift pockets for transport

header pressure is derived from the main hydraulic header by • Outside installed accumulator bank

using hydraulic regulators and the required control & shut- • Stainless steel fluid reservoir with level control

down logics are developed. The panels can be controlled either • Two hydraulic piston pumps for normal operation

locally or remotely. Wellhead control panels are provided with • One hydraulic hand pump for emergency

level gauge, level transmitter for oil storage tank, pressure • One hydraulic pressure filter with gauge for dust indication

transmitters for hydraulic main header, fusible loop header • Two hydraulic control areas

and wellhead valves control line pressure header. Direct acting

high pressure solenoid valves (EEx d) are provided to control Approvals

the wellhead valve open/close operations. • ATEX 94/9/EC – Ex II 3G IIB T3

Electrical control panel is provided with start/stop push but- • Low voltage directive 2006/95/EC

tons, ESD push button, indication lamps and selector switches • Machinery directive 2006/42/EC

for local & remote controls.

Wellsite Equipment P-003

Wellhead Control Panel 10K

Controlled Functions Dimensions

Once Master Valve (MV) Length 2,825 mm

Once Wing Valve (WV) Width 1,185 mm

Once Surface controlled Subsurfave Safety Valve (SCSSV) Height 2,210 mm

Twice High Integrity Pressure System (HIPPS) Gross weight 2,150 kg

Operating Elements Hydraulic System

Hydraulic and electric control panes, on per function Two electic piston pumps 2.7 l/min, MWP 700 bar

Pressure regulators Hydraulic tube system HP Autoclave, LP Swagelok double

Different valves, turn-switches and information lamps per function ferrule

Fuction lines 5 times supply

(MV,WV,SCSSV,HIPPS twice)

Power Sources available Twice return (HIPPS 1+2)

Electrical supply once 400 V, 50 Hz Working fluid Shell Tellus 22 / Transaqua HT

Electrical control voltage once 24 V DC

for the internal junction boxes

Electric System

Once junction box Ex e for supply voltage and motor control

Ambient Conditions and customer connections

Ambient temprature -20 / +40 °C Once junction box Ex e (i) for supply voltage and circuits control

Relative humidity 65 % and customer connections

T: +49 5141 9898-0

F: +49 5141 9898-98

Bruchkampweg 5

29227 Celle/Germany

info@koller-celle.de

www.koller-celle.com scan with your smartphone P-003 Rev.01

You might also like

- VC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesDocument8 pagesVC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesGiovanni Dala PaulaNo ratings yet

- Waiter System (Was1:) Workshop 5 (25) Three-Tier ApplicationDocument6 pagesWaiter System (Was1:) Workshop 5 (25) Three-Tier Applicationhayathmail9375No ratings yet

- Catalogo Heein-Recloser (With R200 Control) 17.07) PDFDocument16 pagesCatalogo Heein-Recloser (With R200 Control) 17.07) PDFLuis Perdomo100% (1)

- P 003 Wellhead Control Panel 10KDocument2 pagesP 003 Wellhead Control Panel 10KDidik PramujiNo ratings yet

- Elektric Clamp EK 24V v11 ENDocument25 pagesElektric Clamp EK 24V v11 ENkarthikeyan1992No ratings yet

- Eries: Electric Control Panels With InvertersDocument1 pageEries: Electric Control Panels With InvertersDang Nguyen VuNo ratings yet

- Capital Controls Series 2000: Chloromatic™ Gas Control ValveDocument4 pagesCapital Controls Series 2000: Chloromatic™ Gas Control ValveLoan NguyênNo ratings yet

- Variotrack: Model Vt-80 Electrical Characteristics PV Array SideDocument1 pageVariotrack: Model Vt-80 Electrical Characteristics PV Array Sideanmn123No ratings yet

- Proportional Directional Valve System Series SC18: Solution For Mobile Hydraulics in Sectional DesignDocument6 pagesProportional Directional Valve System Series SC18: Solution For Mobile Hydraulics in Sectional DesignYulianto JoeNo ratings yet

- The 1,400-MW Kii-Channel HVDC SystemDocument7 pagesThe 1,400-MW Kii-Channel HVDC SystemHashirama SenjuNo ratings yet

- HVDC Kolar Station PDFDocument47 pagesHVDC Kolar Station PDFrajesh100% (1)

- TC 25C e Un 1Document2 pagesTC 25C e Un 1Ali HadiNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPEng.Gihad EladlNo ratings yet

- HVDC 8Document124 pagesHVDC 8Bvijaya krishnaNo ratings yet

- Energy Overview Energy ValveDocument45 pagesEnergy Overview Energy ValveEpsoniaBasraNo ratings yet

- 2.9MVA 3-15kV Transformer SpecificationDocument2 pages2.9MVA 3-15kV Transformer SpecificationMahesh MirajkarNo ratings yet

- H-6745 00 Gma 00 002 Fe ADocument21 pagesH-6745 00 Gma 00 002 Fe Afuad aliNo ratings yet

- Valve Islands GenerationDocument13 pagesValve Islands GenerationNasr Eldin AlyNo ratings yet

- Spec Sheet 3412c 635kva PrimeDocument6 pagesSpec Sheet 3412c 635kva Primehashir zamanNo ratings yet

- 2910Document24 pages2910Messouaf FouadNo ratings yet

- Mod. Ct/Ev Mod. Ctc/Ev: Cooling Tower ApparatusDocument4 pagesMod. Ct/Ev Mod. Ctc/Ev: Cooling Tower Apparatusessam essNo ratings yet

- Mx213 INDUSTRIAL HYDRAULICSDocument89 pagesMx213 INDUSTRIAL HYDRAULICSRuelNo ratings yet

- Solid Pad Mount Switchgear - 150123 V2.0Document8 pagesSolid Pad Mount Switchgear - 150123 V2.0Edwin Quispe50% (2)

- DSSP Systemspowerrange hv20052021Document2 pagesDSSP Systemspowerrange hv20052021Hector Flores HerraizNo ratings yet

- ExtremeServiceBook HardwiredDocument92 pagesExtremeServiceBook HardwiredfrostyfoleyNo ratings yet

- Pole Top sf6 Gas Lbs - Pt. Eei - Rev. 1.3Document4 pagesPole Top sf6 Gas Lbs - Pt. Eei - Rev. 1.3user.haleyorapowerNo ratings yet

- Basic Design RequirementDocument23 pagesBasic Design RequirementAli SialNo ratings yet

- Type VHXM: Under / Over Voltage RelayDocument6 pagesType VHXM: Under / Over Voltage RelayNikki AgarwalNo ratings yet

- VE Transfer Switch-Pdf-EnDocument9 pagesVE Transfer Switch-Pdf-EnAnte MilanovićNo ratings yet

- Tech. Specifications On Power TransformerDocument2 pagesTech. Specifications On Power Transformershine1975No ratings yet

- 00 Datasheet of STS-6000K-H1 For 185KTL 20200706Document2 pages00 Datasheet of STS-6000K-H1 For 185KTL 20200706Lindy PortsuNo ratings yet

- Deh Presentation by MR (1) - Biswas and MR PDFDocument92 pagesDeh Presentation by MR (1) - Biswas and MR PDFKrishna KumarNo ratings yet

- MVL DBL011eDocument2 pagesMVL DBL011eirshad2010No ratings yet

- Xe70 Series VC Series: Balanced Hydronic Valves 2-Way and 3-WayDocument8 pagesXe70 Series VC Series: Balanced Hydronic Valves 2-Way and 3-WayEst ServoNo ratings yet

- Alat UjiDocument4 pagesAlat UjiJesmi RahmatNo ratings yet

- Bomas OBL XL Xla XLB XLCDocument12 pagesBomas OBL XL Xla XLB XLCJ Ferreyra LibanoNo ratings yet

- Type Version / Actuation P (Bar) Q (LPM) : Proportional Directional Spool ValveDocument19 pagesType Version / Actuation P (Bar) Q (LPM) : Proportional Directional Spool ValveY.EbadiNo ratings yet

- High Voltage ContactorsDocument9 pagesHigh Voltage ContactorsFeri RinaldiNo ratings yet

- DS8640 8640 6524 27 Eu enDocument15 pagesDS8640 8640 6524 27 Eu enLucas Vinícius CostaNo ratings yet

- VIC EDH - Catalog - Data Sheet - 01Document38 pagesVIC EDH - Catalog - Data Sheet - 01Zubair KhanNo ratings yet

- Brochure Intellix MO150 English Spec SheetDocument2 pagesBrochure Intellix MO150 English Spec SheetkjkljkljlkjljlkNo ratings yet

- Controllers: For Power, Stirring and Temperature ControlDocument6 pagesControllers: For Power, Stirring and Temperature ControlChing Yee TanNo ratings yet

- AI197986442906en 000501Document25 pagesAI197986442906en 000501Santiago MillánNo ratings yet

- List of MaterialsDocument1 pageList of MaterialsCynthia De VeraNo ratings yet

- Pliz Pnoz8Document3 pagesPliz Pnoz8zyr23No ratings yet

- CETS HIGHVOLT Water TerminationsystemDocument4 pagesCETS HIGHVOLT Water TerminationsystemkmiqdNo ratings yet

- Gen Rating Info 28005Document16 pagesGen Rating Info 28005tableman.test9000No ratings yet

- Data Sheet VEK M2HDocument2 pagesData Sheet VEK M2Hjaaarfi100% (1)

- 14706347-22 Process Control Philosophy - Rev5 - For RFQDocument9 pages14706347-22 Process Control Philosophy - Rev5 - For RFQHawk MrNo ratings yet

- Cn05, Cn10 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating ControlDocument8 pagesCn05, Cn10 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating ControlLindEtjulietcapulet KplesetmontagueNo ratings yet

- Alevo Energy BrochureDocument6 pagesAlevo Energy BrochureMagsNo ratings yet

- D-25BD 3PDT, 100 Amps, 115/200 VAC, 400 HZ: AC RelaysDocument1 pageD-25BD 3PDT, 100 Amps, 115/200 VAC, 400 HZ: AC Relaysruslan futkaradzeNo ratings yet

- Chilleri Rhoss Tcee 105 140Document20 pagesChilleri Rhoss Tcee 105 140Sorin DiaconuNo ratings yet

- 2100 2500 Cummins ENDocument2 pages2100 2500 Cummins ENMinn Thet NaingNo ratings yet

- PIX Catalog 2011-9-10Document2 pagesPIX Catalog 2011-9-106A EntertainmentNo ratings yet

- EV..F BAC Datasheet En-GbDocument12 pagesEV..F BAC Datasheet En-GbTareq JildehNo ratings yet

- Zone1 C GarmaDocument1 pageZone1 C GarmaTzu Huan PengNo ratings yet

- FDTC87 25Document2 pagesFDTC87 25fokou.simplicegmail.com Fokou SimpliceNo ratings yet

- 1ZUA549200-505 VRLTC Technical Guide Rev2Document20 pages1ZUA549200-505 VRLTC Technical Guide Rev2Mạnh Nguyễn VănNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Komatsu Crawler Doozer D37pxi 23 Shop ManualDocument20 pagesKomatsu Crawler Doozer D37pxi 23 Shop Manualrodney100% (40)

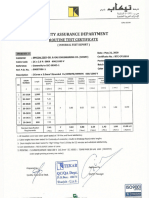

- Test CertificateDocument6 pagesTest CertificateAlaa NayefNo ratings yet

- All PDF Merged Complete TocDocument755 pagesAll PDF Merged Complete TocSHIVAM GARGNo ratings yet

- Topic 3.1 Data Transmission and Networking MediaDocument47 pagesTopic 3.1 Data Transmission and Networking MediaمحمدجوزيايNo ratings yet

- ChE396 Manual Spr11 Ver2bDocument74 pagesChE396 Manual Spr11 Ver2bYousef SailiniNo ratings yet

- 3fak 1998Document47 pages3fak 1998motorciNo ratings yet

- Human or More Generally Articulated Figure Animations Have Been Seen in A Variety of Application Fields Including AdvertisingDocument6 pagesHuman or More Generally Articulated Figure Animations Have Been Seen in A Variety of Application Fields Including AdvertisingYongKang YKNo ratings yet

- ICT Careers and Job TypesDocument4 pagesICT Careers and Job Typesshdfan aseel95100% (1)

- Infinix Zero 2023Document2 pagesInfinix Zero 2023LEVIATHANDAVIDNo ratings yet

- What Is Chat GPT?Document7 pagesWhat Is Chat GPT?BCANo ratings yet

- Computer Networks: Krishna KantDocument27 pagesComputer Networks: Krishna KantAh RifatNo ratings yet

- BiodataLakshmiDocument7 pagesBiodataLakshmiashagolhe742No ratings yet

- Badistea Membership FormDocument2 pagesBadistea Membership FormGiles Palencia BotavaraNo ratings yet

- Essentials of Statistics For The Behavioral Sciences 3rd Edition Nolan Solutions ManualDocument7 pagesEssentials of Statistics For The Behavioral Sciences 3rd Edition Nolan Solutions ManualLaurenThompsontawyq100% (15)

- Cocina 6 Hornillas de TopeDocument2 pagesCocina 6 Hornillas de Topejrangel.cenvihNo ratings yet

- Effetto Pietra: Stone LookDocument23 pagesEffetto Pietra: Stone LookClaudio AllegriNo ratings yet

- Lesson Plan Week 3 NSDocument4 pagesLesson Plan Week 3 NSLewaa HaidarNo ratings yet

- AS Interface - 2005 2006Document356 pagesAS Interface - 2005 2006Zulfiqar ZaidiNo ratings yet

- EcoStruxure Dashboards - Formulas Used To Calculate ValuesDocument11 pagesEcoStruxure Dashboards - Formulas Used To Calculate ValuesGlenn Midel Delos SantosNo ratings yet

- Heart Disease Prediction Using Machine Learning Techniques: AbstractDocument5 pagesHeart Disease Prediction Using Machine Learning Techniques: Abstractshital shermaleNo ratings yet

- Lecture 4 - LAN TechnologiesDocument35 pagesLecture 4 - LAN TechnologiesSamuel SilasNo ratings yet

- Department of Computer Science and EngineeringDocument25 pagesDepartment of Computer Science and EngineeringjesudosssNo ratings yet

- Astm A285 Grade CDocument3 pagesAstm A285 Grade CCastoriadisNo ratings yet

- Veacam Solar Wifi 4G AI Dual-Lens Camera Price List-2402V3Document3 pagesVeacam Solar Wifi 4G AI Dual-Lens Camera Price List-2402V3Juan MartinezNo ratings yet

- Quality Problem Resolution Sheet: Measurement Machine MANDocument1 pageQuality Problem Resolution Sheet: Measurement Machine MANSunilNo ratings yet

- Ads Lab RecordDocument44 pagesAds Lab Recordsandeepabi25No ratings yet

- Manual Screen Changer For Extrusion Processes: Your Benefi TsDocument2 pagesManual Screen Changer For Extrusion Processes: Your Benefi Tsneuro4761No ratings yet

- Deep Learning Based Bitcoin Price Forecasing Using LSTMDocument8 pagesDeep Learning Based Bitcoin Price Forecasing Using LSTMIJRASETPublicationsNo ratings yet