Professional Documents

Culture Documents

ISEKI TX Operation Manual

ISEKI TX Operation Manual

Uploaded by

Tiago Freire0 ratings0% found this document useful (0 votes)

43 views64 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

43 views64 pagesISEKI TX Operation Manual

ISEKI TX Operation Manual

Uploaded by

Tiago FreireCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 64

SG |

LAWL

Ue ay

STP PLOUBLL ETAL

FOREWORD

Your new ISEKI tractor has been disigned by the ISEKI &

CO., LTD., a manufacturer with long experience in the devel.

opment and production of agricultural machinery and equip.

ment. ISEKI is proud of its engineering skills and manufactur-

ing processes, which place particular emphasis upon strict

quality control, product durability, and safety of operation.

We are confident that your new ISEKI tractor will provide you

with many years of outstanding performance. It » modeen

machine, equipped with the latest devices, and designed for

maximum operatom safety and convenience. This Manual is

intended to provide basic information and instructions con-

cerning the new ISEKI tractor and its operation. By following

the guide lines described in this Manual, you are assured of

achieving top performance from your new ISBKI tractor.

Read this Manual carefully, and understand it throughly

before you attempt to use the tractor or implements, to aseure

safe and productive operation and maintenance.

= wna

a

2

. OUTER VIEW AND NAME OF PART

. OPERATION OF THE NEW MACHINE ..

. CONTROLS AND INDICATORS ....

}. OPERATING THE TRACTOR

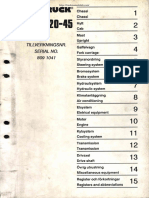

CONTENTS

1. WARNING LAMPS AND SWITCHES

2, CONTROL LEVERS AND PEDALS-

3. OPERATION OF HYDRAULIC SYSTEM-:

1. STARTING THE ENGINE »

2. STOPPING THE ENGINE

3. BASIC OPERATION OF THE TRACTOR

4. OPERATION CHECK DURING WORK

STORAGE «--

1. DAILY STORAGE-

2. LONG-TIME STORAGE ..

3. OPERATION AFTER LONG-TERM STORAGE

OPERATION IN COLD WEATHER

ENGINE OIL -»

ANTI-FREEZE SOLUTION

BATTERY MAINTENANCE «=

OPERATION IN SNOW OR FROZEN ROADS

a

7, MAINTENANCE, INSPECTION AND ADJUSTMENT --- 19

gaena

PROBLEM SOLVING

. SAFETY PRECAUTIONS

. ADDITIONAL INFORMATION

1.

2.

3

4,

MACHINE PRELIMINERY CHECKS

LUBRICATION

LUBRICATION CHART (AND COOLANT)

PERIODICAL SERVICE TABLE

INSPECTION AND ADJUSTMENT

®@ CLUTCH PEDAL ..

© BRAKE PEDAL ..

@ THROTTLE LEVER

@ TOE-IN ADJUSTMENT ..

@ FREE PLAY OF STEERING WHEEL

@ AIR BLEEDING FROM THE FUEL SYSTEM

e

e

e

°

ADJUSTING FRONT AND REAR TREADS ..

ADJUSTING OPERATOR'S SEAT

BATTERY INSPECTION

INSPECTING AND SERVICING THE AIR

CLEANER

@ RADIATOR

RECOMMENDED LUBRICANTS CHART

IMPLEMENTS LIST

SPECIFICATIONS

ELECTRICAL WIRING DIAGRAM ..

{ OUTER VIEW AND NAME.OF PART

1) 4-Wheel Drive Tractor

1.

Engine hood

Light gritt

Head light

. Grill

. Front hitch

|. Front whae!

. Clutch pedal

Step

Rear wheel

PTO speed change lever

|. Lift arm:

. Main speed change lever

|. Instrument panel

|. Turn signal light

. Armrest

}. Fender

. Aux, speed change lever

. Front wheel drive lever

. Brake pedal

). Axle housing

. Bevel case

. Front gear case

. Muffler

. Steering wheel

|. Throttie lever

Operator's seat

Hydraulic control lever

|. Foot accelerator

2) 2-Wheel Drive Tractor

1. Engine hood

2. Light grill

3. Head light

4, Grill

5, Front hitch

6.

7.

8.

9.

|. Front whee!

. Clutch pedal

- Step

. Rear wheel

10. PTO speed change lever

11. Lift arm

12, Main speed change lever

13. Instrument panel

14. Turn signal light

15. Armrest

16. Fender

17. Aux, speed change lever

18. Brake pedal

19. Front axle

20. Muffler

24. Throttle tever

25, Operator's seat

26. Hydraulic control lever

27. Foot accelerator

2 OPERATION OF THE NEW MACHINE

ISEKI continues to modernize and improve its products.

Accordingly, it is possible that some of the specifications and

instructions in this Manual may differ from those applicable to

our latest models. When in doubt, refer to your nearest dealer.

Your new machine should be operated carefully to prolong its

service life, and assure top performance. During the initial 50

hours of operation, the following cautions should be adhered

to:

1, CAUTIONS CONCERNING OPERATION OF THE NEW

MACHINE *

® Read and thoroughly understand the caution plates

attached to the appropriate parts of the machine.

© Warm up the engine at low speed, before starting daily

activities.

© Avoid sudden starts, full acceleraton and sudden braking.

® Change lubrication oil frequently. Always keep oil at the

full level.

3

CONTROLS AND INDICATORS

«

1, WARNING LAMPS AND SWTICHES

Oil lamp

Turn signal switehy

Charging lamp

Heater signal

Horn button

Water temp. lamp.

Parking lamp switch Starter switch

Key switch

Turning-signal pilot lamp

KEY SWITCH

The key switch is separated from the starter switch. The

key can be removed and inserted only at the OFF position.

At the three other positions it functions as follows:

* ON position:

Electrical power is on.

2D position:

Head lights on high beam,

Position

CAUTION:

Never set the key, to OFF position during machine

operation.

Cover the key switch when the machine is not in operation.

© STARTER SWITCH

The starter switch has two operating positions: Start and

Preheat. PREHEAT

“Start”

When turning the starter. switch clockwise, the engine is

started,

By releasing the switch, it returns to its original position.

“Preheat”

When turning the switch counterclockwise, the preheating

circuit is energized to preheat the combustion chamber,

By releasing the switch, it returns to its original position.

© HEATER SIGNAL

Indicates preheating condition of the engine glow plug.

When the combustion chamber is warmed up after turning

the switch to “Preheat”, the signal becomes red. ON Right

@ TURN SIGNAL SWITCH

The turn signal is the flashing indicator type. When the

switch is at horizontal position, the signal is not func- OFF

tioning.

By turning the switch to (C) direction, the left turn signal

flushes, ON Left

By turning it to (R) direction, the right turn signal flashes.

a

© HORN BUTTON

When this button is pushed to “ON, 30) o

the key switch, the warning horn sounds.

" position on

CHARGING LAMP

The red colored oil lamp is ON at key switch positions of

“ON, 3{) and =O)". During engine operation, the lamp

remains off, indicating proper charging of electricity.

OIL Lamp

The red colored oil lamp is ON at key switch positions of

“ON, 3D and “. During engine operation, the lamp

remains off, indicating proper lubrication of the engine.

© WATER TEMPERATURE LAMP °

When the engine is overheated, this lamp is lit for warning.

If this lamp should glow during operation, immediately

stop the machine, and run the engine at low speed to cool it

off. When the water temperature goes down, the lamp goes

off automatically.

2, CONTROL LEVERS AND PEDALS

PTO speed change lever

Auxiliary speed change lever

Throttle lever

Main speed

change lever,

Dif. lock pedat

Front wheel drive lever

(4-wheel drive type only)

Parking brake lever

Lock plate

Foot accelerator LH brake pedal

RH brake pedal

MAIN SPEED CHANGE LEVER

The main speed change lever has

‘three speeds in forward and one

speed in reverse. Combined with

the auxiliary speed change lever,

the machine is capable of six

forward speeds and two reverse

speeds,

AUXILIARY SPEED CHANGE

LEVER

This lever has two speeds. By

pushing the lever forward, ‘High’

speed is selected, By bringing it

to the operator's side, ‘Low’

speed is selected.

25 14 High

3.6 R Low

© PTO SPEED CHANGE LEVER

Three PTO shaft speeds can be selected by using this lever.

If the rotary is mounted on the shaft, this lever changes the

speeds of the tilling blades.

© FRONT WHEEL DRIVE LEVER (4.WHEEL DRIVE TYPE

ONLY)

When driving the machine on inclines, through swamps or

other areas requiring extra tractions, operate this lever to

drive the tractor using all four wheels. By pushing down on

the lever, the front wheels are engaged and put into drive.

By pulling up on the lever, the front wheel drive is

disengaged. *

far

CAUTION: When engaging front wheel drive, the clutch

must be disengaged before operating the lever,

@ THROTTLE LEVER

By pulling the throttle lever to the Operator's side, engine

speed is increased. By pushing the lever forward, the speed

slows down, When the lever is Pushed in as far as the

notched part of the lever guide, the engine becomes idling

speed,

To stop the engine, push the lever forward further from this

notched part.

© CLUTCH PEDAL

The clutch is disengaged when the’ clutch pedalis fully

depressed.

ar

CAUTION:

* When disengaging the clutch, depress the clutch pedal

quickly and fully. When engaging the clutch, gradually

release the pedal,

When changing speeds, disengage the clutch before

Operating the speed change lever,

Never rest your foot on the clutch pedal during

Operation,

ee ee

@ BRAKE PEDALS

Each brake pedal provides separate control over left rear

wheel and right rear wheel braking.

By depressing the LH brake pedal, the left rear wheel brake

is activated.

By depressing the RH pedal, the right rear wheel is stopped

When it is required to turn the machine sharply while

moving at slow speed, use the pedals separately.

When traveling on the road or loading on a truck, however,

interconnect both the pedals with the lock plate provided.

Inspect the brake system to brake equally. If the braking

effect is unequal, dangerous operation may result.

Brake pedal (LH)

Lock plate

Brake pedal (RH)

PARKING LEVER

Interconnect both brake pedals, and keep them depressed.

Pulling up the parking brake lever, engage the round bar at

the left lower part of the brake pedal with the notch on the

parking brake lever. This locks the brake pedal to park the

machine.

When releasing the parking lever, depress the brake pedal

and lower the parking lever until it makes contact with the

stopper.

DIF, LOCK PEDAL

The dif, lock is used to lock the differential, equalizing the

rotational speeds of the left and right tires.

Should the rear tire slip or one tire turn idly, use this device

to drive out of a rough field.

By depressing the pedal, dif. lock is applied. By releasing it,

lock is disengaged.

Ma

CAUTION:

«When traveling on the road, working with heavy load or

working at high speed, never lock the differential, to

avoid accident.

+ When the difference in rotational speeds between both

tires is extreme, operate the pedal after disengaging the

clutch,

0S ee

3. OPERATION OF HYDRAULIC SYSTEM

Neutral

Raise Lower

Hydraulic control lever

Lever set bolt

Liftarm

¢ HYDRAULIC CONTROL LEVER

The hydraulic contro! lever is Moved to the rear “Raise”

Position to elevate the implement by hydraulic power.

The lever should be moved forward to achieve the ‘Lower’?

position.

The implement is then lowered by its own weight.

When the implement is raised to its maximum position, the

lever automatically return to its neutral Position.

If the lever does not return to its neutral position auto-

matically reset the lever by adjusting the lever set bolt,

When it is required to stop the implement at its desired

height, move this lever set bolt to obtain the desired

implement position.

Lowering speed control lever

© LOWERING SPEED ADJUSTMENT LEVER

Adjust the lowering speed to meet conditions and types of

work done,

Rotary work: Slow down the lowering speed.

approx. 2 sec.

Plowing: Quicken the lowering speed

approx. 1 sec.

By turning the adjustment lever clockwise, the lowering

speed accelerates.

By turning it counterclockwise, the speed is reduced.

The implement is not locked ‘even when turning the lever

fully counterclockwise. The lif’ arm may be lowered

gradually.

ee

CAUTION:

* When traveling on the road, set the lowering speed

adjustment lever to its ‘slowest’ position, and apply a

Jock stay on the rotary to fix it in place.

When changing rotary blades, removing entwined straw

or plants and inspecting the implement, the engine must

be turned off with the lowering speed adjustment lever

set at the ‘slowest’ position. Also, lock the implement,

using a lock stay to prevent accidents.

fea

°o

-

eS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Svetruck 28 - 25120-45 Service ManualDocument220 pagesSvetruck 28 - 25120-45 Service ManualTiago FreireNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TC16 0101-0884 5780290002 El 2009-07Document277 pagesTC16 0101-0884 5780290002 El 2009-07Tiago Freire100% (1)

- TC37 0101-0428 5780290007 El-2009-07Document254 pagesTC37 0101-0428 5780290007 El-2009-07Tiago FreireNo ratings yet

- TC16 0885-xxxx 5780400002 EL-5 2015 11Document382 pagesTC16 0885-xxxx 5780400002 EL-5 2015 11Tiago Freire50% (2)

- Folheto TLB850Document15 pagesFolheto TLB850Tiago Freire100% (1)

- Xahs-426-Xahs-536-Xavs-396 Xahs347Document4 pagesXahs-426-Xahs-536-Xavs-396 Xahs347Tiago FreireNo ratings yet

- Manual Instruções Vassoura - CamponesaDocument17 pagesManual Instruções Vassoura - CamponesaTiago FreireNo ratings yet

- 4WG 190Document68 pages4WG 190Tiago FreireNo ratings yet

- Folheto Das TLBDocument21 pagesFolheto Das TLBTiago Freire100% (1)

- TLB 890 Tier3 EspecificaçõesDocument24 pagesTLB 890 Tier3 EspecificaçõesTiago Freire100% (1)

- 6WG 180Document26 pages6WG 180Tiago Freire100% (1)

- Operation & Maintenance Manual Original InstructionDocument100 pagesOperation & Maintenance Manual Original InstructionTiago FreireNo ratings yet

- Kunden-Katalog-TL80 - TL008010385 - 10613747 Motor DeutzDocument87 pagesKunden-Katalog-TL80 - TL008010385 - 10613747 Motor DeutzTiago FreireNo ratings yet

- KS1 - 42pin KS2 - 29pin: CCM (Plug Assignment)Document5 pagesKS1 - 42pin KS2 - 29pin: CCM (Plug Assignment)Tiago FreireNo ratings yet

- Product Information: Valvoline™ Heavy Duty Gear Oil Pro 75W-80 LDDocument2 pagesProduct Information: Valvoline™ Heavy Duty Gear Oil Pro 75W-80 LDTiago FreireNo ratings yet

- 2018 Charger Series Parts Manual PN - 37115 - CHPB - Rev - 1Document118 pages2018 Charger Series Parts Manual PN - 37115 - CHPB - Rev - 1Tiago FreireNo ratings yet

- 2016 Front Discharge Mixer Truck Parts Manual PN 30947 FDPB Rev 6Document189 pages2016 Front Discharge Mixer Truck Parts Manual PN 30947 FDPB Rev 6Tiago FreireNo ratings yet

- 2010 Front Discharge Mixer Truck Parts Manual PN - 30947 - FDPB - Rev - 5Document292 pages2010 Front Discharge Mixer Truck Parts Manual PN - 30947 - FDPB - Rev - 5Tiago FreireNo ratings yet

- 00206bb691e0181106140511 0001Document1 page00206bb691e0181106140511 0001Tiago FreireNo ratings yet

- BB 691 e 0181106135221Document13 pagesBB 691 e 0181106135221Tiago FreireNo ratings yet