Professional Documents

Culture Documents

Celwel - 60 (Adore Electrodes)

Celwel - 60 (Adore Electrodes)

Uploaded by

Harish KandollaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Celwel - 60 (Adore Electrodes)

Celwel - 60 (Adore Electrodes)

Uploaded by

Harish KandollaCopyright:

Available Formats

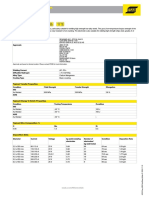

CELWEL 60

CELLULOSIC

Welding Electrode for Pipeline Welding

CLASSIFICATION : EN ISO 2560-A AWS A/SFA 5.1 APPROVALS :

E 38 3 C 21 E 6010 ABS/LRA/IBR

KEY FEATURES :

• High cellulose coated • All position operating characteristics

• Exhibits deep penetration and fast freezing • Ideal for root pass and capping runs

• Radiographic quality weld

WELDING POSITION : DCEP

TYPICAL APPLICATIONS :

• Cross country pipelines subject to dynamic • Suitable for steel grades ASTM A106 Gr.

loading and mechanical restraint A/B, API 5L X42 and for root pass of X56

• Suitable for sour gas pipes

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si S P

Typical 0.15 0.5 0.4 0.01 0.01

Specification 0.10-0.20 0.40-0.70 0.20-0.50 0.015 max. 0.02 max.

MECHANICAL PROPERTIES OF ALL WELD METAL :

YS at 0.2% CVN Impact , J

Condition UTS, MPa EL%

offset, MPa -20°C -30°C

Typical 525 410 26 78 52

As Welded

Specification 490-580 390-460 24-30 70-90 48-70

HARDNESS, 3 LAYER: 235 BHN max

SPECIAL TESTS : HIC & SSCC (NACE)

PARAMETERS - PACKING DATA :

Ø x L, mm Amperage, A Wt./Tin pack, Kg Tin packs/Box Net wt./Box, Kg.

2.5 x 350 50-90 6 3 18

3.15 x 350 80-140 6 3 18

4.0 x 350 120-180 6 3 18

5.0 x 350 160-200 6 3 18

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

41

You might also like

- Watershed Management and Engineering Interventions: Leriza C. Edillo Hazel Joy R. Pontud Alma Mae M. VillarenteDocument21 pagesWatershed Management and Engineering Interventions: Leriza C. Edillo Hazel Joy R. Pontud Alma Mae M. VillarentebaniiknikNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- Electrode Booklet F Web 24Document1 pageElectrode Booklet F Web 24satnamNo ratings yet

- Electrode Booklet F Web 22Document1 pageElectrode Booklet F Web 22satnamNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Electrode Booklet F Web 13Document1 pageElectrode Booklet F Web 13satnamNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Electrode Booklet F Web 9Document1 pageElectrode Booklet F Web 9satnamNo ratings yet

- Electrode Booklet F Web 121Document1 pageElectrode Booklet F Web 121satnamNo ratings yet

- Electrode Booklet F Web 73Document1 pageElectrode Booklet F Web 73satnamNo ratings yet

- Supabase X Plus 2Document1 pageSupabase X Plus 2Michael FortunaNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Electrode Booklet F Web 14Document1 pageElectrode Booklet F Web 14satnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Electrode Booklet F Web 8Document1 pageElectrode Booklet F Web 8satnamNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Ebondm: Mild Steel General Purpose (MSGP)Document1 pageEbondm: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Metalbond: Mild Steel General Purpose (MSGP)Document1 pageMetalbond: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Automig 70S-61Document1 pageAutomig 70S-61tarun kaushalNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnam100% (1)

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Electrode Booklet F Web 120Document1 pageElectrode Booklet F Web 120satnamNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Automig FC 71 T1Document1 pageAutomig FC 71 T1Sushil BhansaliNo ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Electrode Booklet F Web 105Document1 pageElectrode Booklet F Web 105satnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- Electrode Booklet F Web 96Document1 pageElectrode Booklet F Web 96satnamNo ratings yet

- Electrode Booklet F Web 18Document1 pageElectrode Booklet F Web 18satnamNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- Topstar 110: C-MN STEEL (High Efficiency)Document1 pageTopstar 110: C-MN STEEL (High Efficiency)satnamNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Electrode Booklet F Web 90Document1 pageElectrode Booklet F Web 90satnamNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Adobe Scan 08 Dec 2023Document37 pagesAdobe Scan 08 Dec 2023Harish KandollaNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- ధరణ - ﯽﻧرھد - Dharani: Deceased Pattadar Khata DetailsDocument2 pagesధరణ - ﯽﻧرھد - Dharani: Deceased Pattadar Khata DetailsHarish KandollaNo ratings yet

- List-of-Deemed-University 12-B-06-10-2017Document3 pagesList-of-Deemed-University 12-B-06-10-2017Harish KandollaNo ratings yet

- Experience Details: 5Years-2MonthsDocument21 pagesExperience Details: 5Years-2MonthsHarish KandollaNo ratings yet

- Scan Image 001Document4 pagesScan Image 001Harish KandollaNo ratings yet

- Pravin Sharad Dixit (VP) - PowerDocument25 pagesPravin Sharad Dixit (VP) - PowerHarish KandollaNo ratings yet

- CSW CertificationDocument13 pagesCSW CertificationNarendar SaggamNo ratings yet

- Seminar ReportDocument43 pagesSeminar ReportRamaswamy Koodalloor Parasuraman67% (3)

- Construction Project ReportDocument39 pagesConstruction Project ReportVishal Tiwari0% (1)

- Tamilnadu State Board 2nd Standard TextbookDocument60 pagesTamilnadu State Board 2nd Standard TextbookRavi KandasamyNo ratings yet

- Experimental Study On Partial Replacement of Cement With Glass Powder and Egg Shell PowderDocument6 pagesExperimental Study On Partial Replacement of Cement With Glass Powder and Egg Shell PowderArun anandNo ratings yet

- Conductores Copperweld PDFDocument4 pagesConductores Copperweld PDFMiguel Ángel Díaz SepúlvedaNo ratings yet

- C 09Document8 pagesC 09Amal PereraNo ratings yet

- Class 11 CRPDocument2 pagesClass 11 CRPprayag527No ratings yet

- Irvine Etal 2015 Pile Design in Weak RockDocument7 pagesIrvine Etal 2015 Pile Design in Weak RockmikollimNo ratings yet

- MbeDocument6 pagesMbeMarco PlaysNo ratings yet

- DSP Question Paper April 2012Document2 pagesDSP Question Paper April 2012Famida Begam100% (1)

- Rgmo FgmoDocument24 pagesRgmo FgmoPradeep_VashistNo ratings yet

- Analysis of Dither in PWM Control On Electro-HydraDocument7 pagesAnalysis of Dither in PWM Control On Electro-Hydraömer faruk güneyNo ratings yet

- 6 35 11kV Single CoreDocument9 pages6 35 11kV Single CoreKhanSA786No ratings yet

- Arc Welding Arc Welding Electrode Electrode: CCCCC CCCCCDocument36 pagesArc Welding Arc Welding Electrode Electrode: CCCCC CCCCCSantanu SarmahNo ratings yet

- Kabaasha 2018 JHE Incorporating The Modified Orifice Equation Into Pipe Network Solvers For More Realistic Leakage Modeling PDFDocument8 pagesKabaasha 2018 JHE Incorporating The Modified Orifice Equation Into Pipe Network Solvers For More Realistic Leakage Modeling PDFguhmoroNo ratings yet

- 2 - Intro To VectorsDocument3 pages2 - Intro To VectorsMyles QuinteroNo ratings yet

- Establishment of An Aerodynamic Simulation For MotorcycleDocument3 pagesEstablishment of An Aerodynamic Simulation For MotorcycleMarcos SoarNo ratings yet

- Silicon: MOS: Metal Oxide SemiconductorDocument17 pagesSilicon: MOS: Metal Oxide SemiconductorDilanWijerathnaNo ratings yet

- AllProducts CatalogDocument56 pagesAllProducts CatalogOmar ArdilaNo ratings yet

- A Classification of Studies On Properties of Foam ConcreteDocument29 pagesA Classification of Studies On Properties of Foam Concretegonzalez_m_aNo ratings yet

- New Technology - Mod4 - NPTEL Chem EngDocument56 pagesNew Technology - Mod4 - NPTEL Chem EngalkimiaNo ratings yet

- Air To Air Heat Exchanger Performance: Dokuz Eylül University Graduate School of Natural and Applied SciencesDocument78 pagesAir To Air Heat Exchanger Performance: Dokuz Eylül University Graduate School of Natural and Applied SciencesNguyen Son N NguyenNo ratings yet

- Wave GuidesDocument10 pagesWave GuidesCansel ŞahinNo ratings yet

- Good Morning,: Grade 4!Document42 pagesGood Morning,: Grade 4!Tin ManuelNo ratings yet

- Grundfos CR 5 18 A FGJ A e HqqeDocument11 pagesGrundfos CR 5 18 A FGJ A e HqqeEman Adel Shamseldin ElkholyNo ratings yet

- Propiedades de PerfilesDocument10 pagesPropiedades de PerfilesAndy GarciaNo ratings yet

- Kinetics of Condensation Reaction of Crude Glycerol With Acetaldehyde in A Reactive Extraction ProcessDocument10 pagesKinetics of Condensation Reaction of Crude Glycerol With Acetaldehyde in A Reactive Extraction ProcessS Bharadwaj ReddyNo ratings yet

- Topcon Os SeriesDocument4 pagesTopcon Os SeriesRuel Mahinay BacayNo ratings yet