Professional Documents

Culture Documents

Dealer Process 2-1-2022!2!19-50 Form Order

Dealer Process 2-1-2022!2!19-50 Form Order

Uploaded by

Tnpl Cat0 ratings0% found this document useful (0 votes)

45 views6 pagesThis report summarizes the results of an inspection of a Caterpillar 323D3 excavator with 2773 hours. The inspection checked the engine, undercarriage, hydraulic and electrical systems. Minor issues were found, such as the need to clean the battery vent hole. Routine maintenance was also performed, including changing engine and fuel filters and taking oil samples. The machine was found to be in good working order.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis report summarizes the results of an inspection of a Caterpillar 323D3 excavator with 2773 hours. The inspection checked the engine, undercarriage, hydraulic and electrical systems. Minor issues were found, such as the need to clean the battery vent hole. Routine maintenance was also performed, including changing engine and fuel filters and taking oil samples. The machine was found to be in good working order.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

45 views6 pagesDealer Process 2-1-2022!2!19-50 Form Order

Dealer Process 2-1-2022!2!19-50 Form Order

Uploaded by

Tnpl CatThis report summarizes the results of an inspection of a Caterpillar 323D3 excavator with 2773 hours. The inspection checked the engine, undercarriage, hydraulic and electrical systems. Minor issues were found, such as the need to clean the battery vent hole. Routine maintenance was also performed, including changing engine and fuel filters and taking oil samples. The machine was found to be in good working order.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

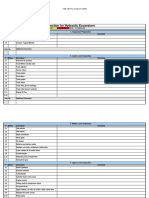

323D PM1 & TA1 COMBINED GCPL REPORT

Dealer Process 0 0 1 4

Inspection Number 7777483

Make CATERPILLAR Customer No 9818131019

Serial Number FEY10213 Customer Name Mangal Roda dhunga

udhyog Pvt.Ltd

Model 323D3 Equipment Family EXCAVATORS

Completed On 1/19/2022 9:48:55 PM SMU 2773 Hours

Inspector Santosh Surkheti Location Chasebesi

Work Order 100452927 Coordinates 0, 0, 0

PDF Generated On 1/27/2022

Operator

Technician

General Info & Comments

General info/Comments NORMAL

Comments: Pm 1 mantinance engine oil and engine oil filter fuel filters change check the machine hydraulic

funtion and electric funtion check found okay

MACHINE PREPARATION FOR INSPECTION

1.1 Check with customer for operator complaints

1.2 Perform machine inspection preparation

1.3 Download Product Status Report

Form Order Report Serial Number : FEY10213 Page 1 of 6

1.4 Is the machine software including Product Link current with what published

in SIS?

1.5 Check Product Link

1.6 Observe engine exhaust colors

1.7 Listen for unusual noises

1.8 Lockout / Tagout Machine

LOWER LEVEL INSPECTION

2.1 Final drive & sprocket N/A

2.2 Inspect travel motors and brake valves N/A

2.3 Inspect track adjusters N/A

2.4 Inspect carrier rollers N/A

2.5 Inspect track rollers

2.6 Inspect front idlers

2.7 Inspect the track guides

2.8 Inspect the track shoes

2.9 Inspect track links, pins, and bushings

2.10 Inspect the track roller frames and carbody

2.11 Inspect engine oil pan

MIDDLE LEVEL INSPECTION

Form Order Report Serial Number : FEY10213 Page 2 of 6

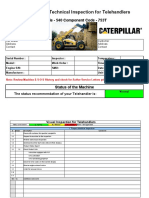

3.1 Inspect the cab exterior

3.2 Inspect the cab interior

3.3 Inspect steps and handrails

3.4 Inspect work lights

3.5 Inspect air cleaner

3.6 Inspect battery and battery cables

3.7 Inspect radiator, oil cooler, condenser, and aftercooler

3.8 Inspect lower radiator and oil cooler hoses

3.9 Inspect counterweight

3.10 Inspect hydraulic pump compartment

3.11 Inspect swing drive gear

3.12 Battery Vent Hole need to be check, whether it is cleaned or not

3.13 Data of the electrolyte/distilled water level should be checked

UPPER LEVEL INSPECTION

4.1 Inspect hood and platform

4.2 Inspect exhaust manifold

4.3 Inspect turbocharger

4.4 Inspect cylinder head and valve cover

Form Order Report Serial Number : FEY10213 Page 3 of 6

4.5 Inspect engine mounts

4.6 Inspect belts, pulleys, and compressor

4.7 Inspect fan guard and fan

4.8 Inspect upper radiator, air inlet, oil cooler, and aftercooler lines

4.9 Inspect radiator/oil cooler screen

4.10 Inspect water pump

4.11 If the radiator cap is cool then check Gaskets for wear or damage

4.12 Inspect fuel priming pump, fuel lines, and fuel injection pump

4.13 Inspect engine harness for Loose or damaged wires

4.14 Inspect swing drive compartment

4.15 Inspect swing drive

4.16 Inspect the main hydraulic control valve

IMPLEMENT/ATTACHMENT INSPECTION

5.1 Inspect area around boom cylinders and swivel

5.2 Inspect lower boom area

5.3 Inspect boom cylinder

5.4 Inspect area where boom attaches to stick

5.5 Inspect stick cylinder

Form Order Report Serial Number : FEY10213 Page 4 of 6

5.6 Inspect bucket cylinder

5.7 Inspect bucket linkage

5.8 Inspect bucket wear plates for Excessive wear

5.9 Inspect side cutters

5.10 Inspect bucket tips and adapters

5.11 INSPECT STICK NOSE PLAY

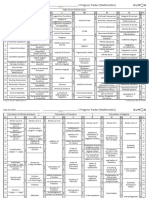

SITE CONDITION

6.1 Ambient Temperature

6.2 Altitude

6.3 Haul Road Grade

6.4 Haul Road Condition

6.5 Humidity

6.6 Air Quality

6.7 Underfoot Condition

6.8 Machine Utilization

6.9 Equipment Role

6.10 Working Material

6.11 Maintenance Practices

Form Order Report Serial Number : FEY10213 Page 5 of 6

PM2 (500 HRS INTERVAL)

7.1 TAKE & ANALYZE S-O-S FROM ENGINE OIL

7.2 REPLACE ENGINE OIL & FILTER

7.3 CLEAN REFRIGERANT CONDENSER

7.4 CHECK SWING DRIVE FLUID LEVEL

7.5 REPLACE WATER SEPARATOR FILTER

7.6 REPLACE FUEL FILTER SECONDARY

7.7 REPLACE FUEL TRANSFER PUMP STRAINER

7.8 INSPECT & MAINTAIN FUEL TANK CAP(S)

7.9 LUBRICATE SWING DRIVE BEARING

7.10 TAKE & ANALYZE S-O-S FROM FINAL DRIVE

7.11 TAKE & ANALYZE S-O-S FROM HYDRAULIC SYSTEM

7.12 TAKE & ANALYZE S-O-S FROM SWING DRIVE

7.13 TAKE & ANALYZE S-O-S FROM ENGINE COOLING SYSTEM LEVEL ONE

7.14 CARRY OUT CTS( ATTACH CTS INSPECTION SHEET IMAGE)

Form Order Report Serial Number : FEY10213 Page 6 of 6

You might also like

- TA2 English - Wheel LoaderDocument22 pagesTA2 English - Wheel Loadercarlos angelNo ratings yet

- Cut and Thread ProcedureDocument4 pagesCut and Thread ProcedurezapspazNo ratings yet

- Classic Car Parts Catalog 2017Document176 pagesClassic Car Parts Catalog 2017Performance Online100% (5)

- TA1 Visual Inspection Form Master - Wheel LoaderDocument12 pagesTA1 Visual Inspection Form Master - Wheel LoaderCarlosNo ratings yet

- 793D Off Higway Truck FDBDocument28 pages793D Off Higway Truck FDBMelissa TorresNo ratings yet

- TA2 English - Track-Type TractorDocument22 pagesTA2 English - Track-Type TractorWilliams ArayaNo ratings yet

- OM&S-R - UpdatedDocument229 pagesOM&S-R - UpdatedTITU V100% (2)

- ITT Mackay Instruction Manual For Model 3030A-3030AR Synthesized Receiver Issue 3 June 1982Document110 pagesITT Mackay Instruction Manual For Model 3030A-3030AR Synthesized Receiver Issue 3 June 1982antoniNo ratings yet

- 966H Wheel Loader A6GDocument22 pages966H Wheel Loader A6GJean Claude EidNo ratings yet

- TA1 English - Wheeled ExcavatorDocument18 pagesTA1 English - Wheeled Excavatorcarlos angelNo ratings yet

- TA2 English - Wheeled ExcavatorDocument24 pagesTA2 English - Wheeled Excavatorcarlos angelNo ratings yet

- TA1 English - Wheeled ExcavatorDocument18 pagesTA1 English - Wheeled Excavatorahmad adelNo ratings yet

- TA1 English ExcavatorDocument13 pagesTA1 English ExcavatorJoel RodríguezNo ratings yet

- Dealer Process 1-23-2022!20!24-51 Form OrderDocument7 pagesDealer Process 1-23-2022!20!24-51 Form OrderTnpl CatNo ratings yet

- TA2 424D Backhoe Loader RXADocument34 pagesTA2 424D Backhoe Loader RXAahmad adelNo ratings yet

- 22E Backhoe Loader HBEDocument29 pages22E Backhoe Loader HBEhebert trujilloNo ratings yet

- TA1 English - Compact Wheel LoadersDocument16 pagesTA1 English - Compact Wheel Loaderscarlos angelNo ratings yet

- TA1 English - Soil CompactorDocument16 pagesTA1 English - Soil CompactorAlex JuárezNo ratings yet

- TA1 English - Mini ExcavatorDocument15 pagesTA1 English - Mini Excavatorcristian chuquicondor torresNo ratings yet

- Manual de CarrileriaDocument20 pagesManual de Carrileriahebert trujilloNo ratings yet

- Dealer Process - 1-2-2022 - 4-4-58 - Form - OrderDocument7 pagesDealer Process - 1-2-2022 - 4-4-58 - Form - OrderTnpl CatNo ratings yet

- TA1 English - KnuckleboomDocument30 pagesTA1 English - Knuckleboomcristian chuquicondor torresNo ratings yet

- TA2 14M Motor Grader B9JDocument21 pagesTA2 14M Motor Grader B9JTony Wilden Angelo Peña100% (1)

- TA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753TDocument22 pagesTA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753Tahmed el sayedNo ratings yet

- TA1 Form For ExcavatorDocument15 pagesTA1 Form For ExcavatorVinod SekharNo ratings yet

- Wheel Dozers TA2 ChecklistDocument22 pagesWheel Dozers TA2 ChecklistVictor Rodrigo Cortes YañezNo ratings yet

- TA1 Report FormDocument23 pagesTA1 Report FormMujtba OsmanNo ratings yet

- TA1 English - Gas Engine Generator SetDocument17 pagesTA1 English - Gas Engine Generator Setcristian chuquicondor torresNo ratings yet

- TA2 English - Motor GraderDocument21 pagesTA2 English - Motor GraderRICHARDNo ratings yet

- TA2 English - Gas Engine Generator SetDocument20 pagesTA2 English - Gas Engine Generator Setcristian chuquicondor torresNo ratings yet

- TA1 English - ForwarderDocument17 pagesTA1 English - Forwardercristian chuquicondor torresNo ratings yet

- TA1 English - Articulated TruckDocument15 pagesTA1 English - Articulated Truckcarlos angel100% (1)

- 304D TYK00743 TA1 - Excavator Inpection ReportDocument11 pages304D TYK00743 TA1 - Excavator Inpection ReportCesar Eduardo Contreras CastilloNo ratings yet

- TA1 English - Wheel LoaderDocument20 pagesTA1 English - Wheel Loadercarlos angel100% (2)

- TA1 English - Backhoe LoaderDocument35 pagesTA1 English - Backhoe Loadercristian chuquicondor torresNo ratings yet

- TA-2 Visual & Technical Inspection For Motor Grader: SMCS - Job Code - 540 Component Code - 753TDocument18 pagesTA-2 Visual & Technical Inspection For Motor Grader: SMCS - Job Code - 540 Component Code - 753THebert TrujilloNo ratings yet

- TA1 English - Track-Type TractorDocument20 pagesTA1 English - Track-Type TractorVictor Rodrigo Cortes YañezNo ratings yet

- Teq - Inspection 1Document14 pagesTeq - Inspection 1ahmed el sayedNo ratings yet

- TA2 English - ExcavatorDocument13 pagesTA2 English - Excavatorcarlos angelNo ratings yet

- 140H Motor Grader XZHDocument18 pages140H Motor Grader XZHHebert Trujillo100% (2)

- TA2 Form ExcavatorDocument13 pagesTA2 Form ExcavatorVinod SekharNo ratings yet

- Inspeccion Ta1 Excavadora Caterpillar 320 DLDocument21 pagesInspeccion Ta1 Excavadora Caterpillar 320 DLRAMON CALDERONNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type TractorDocument11 pagesTA1 Visual Inspection Form Master - Track-Type TractorCarlosNo ratings yet

- TA2 - 740-B1P - Articulated TruckDocument12 pagesTA2 - 740-B1P - Articulated Trucksamsudinnor winataNo ratings yet

- Visual Inspection For Hydraulic Excavators: Cek List Ta 1 ExcavatorDocument3 pagesVisual Inspection For Hydraulic Excavators: Cek List Ta 1 Excavatortab smkn1sgsNo ratings yet

- 962H Wheel Loader SSADocument22 pages962H Wheel Loader SSAPercy Herrera Zeballos100% (1)

- TA1 English - Generator SetDocument13 pagesTA1 English - Generator Setahmad adelNo ratings yet

- TA2 English - ExcavatorDocument41 pagesTA2 English - ExcavatorEfrain DYNo ratings yet

- TA2 950G Wheel Loader AYLDocument21 pagesTA2 950G Wheel Loader AYLMekanik Alat Berat100% (2)

- TA1 English - Marine EngineDocument7 pagesTA1 English - Marine Enginecristian chuquicondor torresNo ratings yet

- TA2 English - Generator SetDocument16 pagesTA2 English - Generator Setahmad adelNo ratings yet

- TA2 Visual & Technical Inspection Form Master - Off-Highway TruckDocument166 pagesTA2 Visual & Technical Inspection Form Master - Off-Highway TruckSandeep Nikhil0% (1)

- 320D3 Pm1 & Ta1 Combined GCPL ReportDocument7 pages320D3 Pm1 & Ta1 Combined GCPL ReportTnpl CatNo ratings yet

- TA1 Report 750Hr For SEM636DDocument7 pagesTA1 Report 750Hr For SEM636DLUC BALOMOCK BIIGANo ratings yet

- 13.diesel Tanker Inspection ChecklistDocument6 pages13.diesel Tanker Inspection Checklistqadeer55afridiNo ratings yet

- 906H Wheel Loader TPEDocument21 pages906H Wheel Loader TPEMahmoud SamerNo ratings yet

- Welcome: Presentation On, Vibratory CompactorDocument75 pagesWelcome: Presentation On, Vibratory CompactorPraful E. PawarNo ratings yet

- Copia de TA1TA2Telehandlers (English)Document18 pagesCopia de TA1TA2Telehandlers (English)hebert trujilloNo ratings yet

- Ta-2 Cargadores de RuedasDocument13 pagesTa-2 Cargadores de RuedasjogremaurNo ratings yet

- At1 - ExcavadoraDocument14 pagesAt1 - ExcavadoraFREDDY NICOLAS ESCOBEDO LOZANONo ratings yet

- Fork LiftDocument4 pagesFork Lifttamer goudaNo ratings yet

- Ta2 English Exc. 320D2 PmodificarDocument14 pagesTa2 English Exc. 320D2 PmodificarJose Cruz Martinez MedinaNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Curriculum Vitae: Mob No: +9779815345327 Address: Mirchaiya-12, Siraha, NepalDocument2 pagesCurriculum Vitae: Mob No: +9779815345327 Address: Mirchaiya-12, Siraha, NepalTnpl CatNo ratings yet

- Dealer Process 12-2-2021!22!10-15 Severity OrderDocument4 pagesDealer Process 12-2-2021!22!10-15 Severity OrderTnpl CatNo ratings yet

- 320D3 Pm1 & Ta1 Combined GCPL ReportDocument7 pages320D3 Pm1 & Ta1 Combined GCPL ReportTnpl CatNo ratings yet

- 950H (J5J, Jad) Pm2 & Ta1 Combined GCPL ReportDocument8 pages950H (J5J, Jad) Pm2 & Ta1 Combined GCPL ReportTnpl CatNo ratings yet

- Dealer Process - 12-2-2021 - 22-14-56 - Severity - OrderDocument4 pagesDealer Process - 12-2-2021 - 22-14-56 - Severity - OrderTnpl CatNo ratings yet

- Hydraulic Excavator (HEX) TA1Document15 pagesHydraulic Excavator (HEX) TA1Tnpl CatNo ratings yet

- Dealer Process - 12-2-2021 - 22-16-9 - Severity - OrderDocument28 pagesDealer Process - 12-2-2021 - 22-16-9 - Severity - OrderTnpl CatNo ratings yet

- PM 1 Perform (250 Hours Interval)Document6 pagesPM 1 Perform (250 Hours Interval)Tnpl CatNo ratings yet

- PM Checklist - 12-2-2021 - 22-16-50 - Severity - OrderDocument4 pagesPM Checklist - 12-2-2021 - 22-16-50 - Severity - OrderTnpl CatNo ratings yet

- PM 1 (250 Hour Interval)Document3 pagesPM 1 (250 Hour Interval)Tnpl CatNo ratings yet

- Dealer Process - 12-2-2021 - 22-13-5 - Severity - OrderDocument4 pagesDealer Process - 12-2-2021 - 22-13-5 - Severity - OrderTnpl CatNo ratings yet

- Dealer Process 1-23-2022!20!24-51 Form OrderDocument7 pagesDealer Process 1-23-2022!20!24-51 Form OrderTnpl CatNo ratings yet

- Dealer Process - 12-2-2021 - 22-10-15 - Severity - OrderDocument4 pagesDealer Process - 12-2-2021 - 22-10-15 - Severity - OrderTnpl CatNo ratings yet

- Dealer Process - 12-2-2021 - 22-11-19 - Severity - OrderDocument4 pagesDealer Process - 12-2-2021 - 22-11-19 - Severity - OrderTnpl CatNo ratings yet

- Fault CodesDocument451 pagesFault CodesTnpl CatNo ratings yet

- Dealer Process - 1-23-2022 - 21-2-8 - Form - OrderDocument4 pagesDealer Process - 1-23-2022 - 21-2-8 - Form - OrderTnpl CatNo ratings yet

- Dealer Process - 12-2-2021 - 22-12-4 - Severity - OrderDocument4 pagesDealer Process - 12-2-2021 - 22-12-4 - Severity - OrderTnpl CatNo ratings yet

- Dealer Process - 1-26-2022 - 21-3-7 - Form - OrderDocument4 pagesDealer Process - 1-26-2022 - 21-3-7 - Form - OrderTnpl CatNo ratings yet

- Master Sheet of TNPL Machine PopulationDocument100 pagesMaster Sheet of TNPL Machine PopulationTnpl CatNo ratings yet

- GP PVT LTD 24.11.2021Document3 pagesGP PVT LTD 24.11.2021Tnpl CatNo ratings yet

- Dealer Process - 1-2-2022 - 4-4-58 - Form - OrderDocument7 pagesDealer Process - 1-2-2022 - 4-4-58 - Form - OrderTnpl CatNo ratings yet

- FAR - Quality Greed & Crusher Pvt. Ltd.Document3 pagesFAR - Quality Greed & Crusher Pvt. Ltd.Tnpl CatNo ratings yet

- The Soaltee KathmanduDocument5 pagesThe Soaltee KathmanduTnpl CatNo ratings yet

- Dealer Process - 1-2-2022 - 4-0-39 - Form - OrderDocument4 pagesDealer Process - 1-2-2022 - 4-0-39 - Form - OrderTnpl CatNo ratings yet

- GCPL Service Report (GCPL/F/ SERV - OPS./SR - R4 - 21/04/19)Document5 pagesGCPL Service Report (GCPL/F/ SERV - OPS./SR - R4 - 21/04/19)Tnpl CatNo ratings yet

- Man Ther 2013 Barra LópezDocument7 pagesMan Ther 2013 Barra LópezRuggiero CannitoNo ratings yet

- 04 MSDS Catalyst (Vandium Penta Oxide)Document6 pages04 MSDS Catalyst (Vandium Penta Oxide)Furqan SiddiquiNo ratings yet

- Gods Jukebox Music ListDocument652 pagesGods Jukebox Music ListaNo ratings yet

- TUT 1 Bending StressDocument8 pagesTUT 1 Bending StressVictoriaNo ratings yet

- ASME Manual Edition 2019Document69 pagesASME Manual Edition 2019hgag selimNo ratings yet

- Kumon Mathematics Progress Tracker Levels C To O PDFDocument2 pagesKumon Mathematics Progress Tracker Levels C To O PDFcharmradeekNo ratings yet

- Epidemiology - Exercises. Gaetano MarroneDocument4 pagesEpidemiology - Exercises. Gaetano Marronemillion assefaNo ratings yet

- Structural Design: 780 CMR 16.00 Is Unique To MassachusettsDocument40 pagesStructural Design: 780 CMR 16.00 Is Unique To MassachusettsDLNo ratings yet

- Lease Contract EnglishDocument7 pagesLease Contract EnglishRajendra T PankhadeNo ratings yet

- ITMO 2017 - Keystage III - Individual PDFDocument6 pagesITMO 2017 - Keystage III - Individual PDFzarifNo ratings yet

- Paradox Alarm - EVO Tech SheetDocument12 pagesParadox Alarm - EVO Tech SheetJulia MagnessNo ratings yet

- CG Lux Lighting Software DownloadDocument2 pagesCG Lux Lighting Software DownloadvenkateshbitraNo ratings yet

- Reddit - PDF For Handbook On PCTDocument43 pagesReddit - PDF For Handbook On PCTGagandeep SinghNo ratings yet

- A Review of The Energy Tax On Electric Power Consumption 8rh054uiDocument31 pagesA Review of The Energy Tax On Electric Power Consumption 8rh054uiSheena Lynne AntalanNo ratings yet

- DAILY REPORT (29/01/2015) Project: BK-TNG Wellhead Platform Item: Fabrication of Pressure VesselDocument20 pagesDAILY REPORT (29/01/2015) Project: BK-TNG Wellhead Platform Item: Fabrication of Pressure VesselVanvien LeNo ratings yet

- Performance Claims by Brian WilliamsonDocument20 pagesPerformance Claims by Brian Williamsonc rkNo ratings yet

- Age Frequency Percentage %Document9 pagesAge Frequency Percentage %Jolly Mae CatabayNo ratings yet

- Lecture For Planning-1 For FBDocument2 pagesLecture For Planning-1 For FBNolieNo ratings yet

- Paragraph Class IX & XDocument20 pagesParagraph Class IX & XPrasun Goswami100% (1)

- Circulatory SystemDocument14 pagesCirculatory Systemsmbdy tbhhhNo ratings yet

- Corrosion Probe TypeDocument26 pagesCorrosion Probe TypeFirman MuttaqinNo ratings yet

- Property, Plant and Equipment (IAS 16.Pptx NEW LATESTDocument47 pagesProperty, Plant and Equipment (IAS 16.Pptx NEW LATESTNick254No ratings yet

- Advance Communication Lab - 2020Document45 pagesAdvance Communication Lab - 2020AdityaNo ratings yet

- Proposed Philippine Games: Title of The Game: Venue/Facility: Plan ADocument2 pagesProposed Philippine Games: Title of The Game: Venue/Facility: Plan AJane DizonNo ratings yet

- Weighted Average MethodDocument16 pagesWeighted Average MethodKevin Estay100% (2)

- Direct and Indirect Tax:: GST IntroductionDocument12 pagesDirect and Indirect Tax:: GST IntroductionDdaksh KumarNo ratings yet

- Data Sheet: Elcometer 415 Paint & Powder Coating Thickness GaugeDocument2 pagesData Sheet: Elcometer 415 Paint & Powder Coating Thickness Gaugemalaya tripathyNo ratings yet