Professional Documents

Culture Documents

Baypren New Development With Old Polymer

Baypren New Development With Old Polymer

Uploaded by

Marcos ROSSICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baypren New Development With Old Polymer

Baypren New Development With Old Polymer

Uploaded by

Marcos ROSSICopyright:

Available Formats

New options with Baypren ®

K. Varnhorn

T. Neuner; R. Josten; N. Sary, H. Stange

Sveriges Gummitekniska Förenings vårkonferens

Introduction:

Lanxess offers a broad range of

Polychloroprene rubbers.

Baypren® is a commonly used

elastomer due to it´s multi-purpose

properties.

A new finishing line offers new

options and keep the establish

properties of Baypren ®.

2 Baypren Kay Varnhorn Malmö, 2013-04-11

Agenda

Introduction, Polychloroprene

New products by new technology

New finishing – new possibilities

New products in compound studies

Summary

3 Baypren Kay Varnhorn Malmö, 2013-04-11

What is Polychlorprene - Baypren® ?

a) linear, uniform configuration c) linear, reactive endgroups

variations in MW and MW-distribution

Cl Cl Cl Cl

X

X

n

XD types

Ve

Cl Cl Cl Cl

d) precrosslinked

R R

n R R

R R

determines Mooney viscosity R

R R

R R

R R

b) linear, non-uniform configuration

determines gel content

Cl Cl Cl

n Cl e) sulphur modified

Cl

Cl

comonomer R S S R

Low crystallization tendency S types

4 Baypren Kay Varnhorn Malmö, 2013-04-11

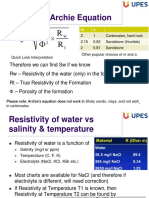

Conventional Lanxess CR products

Pre- Sulphur

General purpose grades Adhesive

crosslinked modified Latex grades

non precrosslinked grades

types grades

120

110

Mooney viscosity * M L 1+4/100 °C

230

100

90

80 126

226

114

70

110

60 214

215 611 711 712

510

210 216

50

112

110

116

40

211

30

5 Baypren Kay Varnhorn Malmö, 2013-04-11

The first new grades:

Nomenclature

Three groups of new Baypren® ‘s

Baypren® 110 A VP

110 crystallization, slow

Baypren® 100 A VP Baypren® 110 A VP Baypren® 126 A VP 210 cryst. medium

Baypren® 200 A VP Baypren® 210 A VP Baypren® 216 A VP

110 Mooney range

Low Mooney Improved Reduced 100 low Mooney

grades, vulcanization marching

better characteristics modus 110 mercaptane

extrusion with MTT

116 xanthogene

performance disulfid

Special Alternative Improved A VP new, trial product

Performance Performance Performance

6 Baypren Kay Varnhorn Malmö, 2013-04-11

Standard and new process

Standard process

Coagulation

Neutralization Washing Drying Roping Chopping

Freeze roll

New (alternative) process

Coagulation Dewatering Drying Chopping

Standard New

Lowest 37 28

Mooney

Resources consumption

„…in that connection, freeze roll isolation of very

low Mooney viscosity polymers or fluid polymers is Ammonia -

difficult or virtually impossible.“ Steam

[Kirk-Othmer Encyclopedia of Chemical Water

Technology]

Natural gas -

Electricity

7 Baypren Kay Varnhorn Malmö, 2013-04-11

Focus of the presentation

Baypren®

Mercaptane Xantogene Disulfide

Low Mooney

ETU MTT

Standard Mooney Standard Mooney

ETU MTT ETU MTT

Fast cure regular cure

8 Baypren Kay Varnhorn Malmö, 2013-04-11

Low Mooney grade

B200A VP - Extrusion

Baypren® 210 Standard 100 50

Baypren® 200A VP 100 50 Mooney viscosity compound

REGAL® SRF / N772 30 30 30

EDENOR® C 18 98-100 0,5 0,5 0,5 45

Mooney-Viscosity [MU]

B210

Scorchguard® O 5,3 5,3 5,3 40

B210-B200 50/50

ZINKWEISS ROTSIEGEL® 5 5 5 35

B200A VP

Edenol® 888 8 8 8

30

MTT based Crosslinking x x x

25

20

15

10

5

0

0 100 200 300 400

Time [s]

9 Baypren Kay Varnhorn Malmö, 2013-04-11

B210 - B200A VP – Extrusion

Die swelling

Lower die swell for low

Mooney B200 compared to

B210

Significant reduced die

swell for blend of

B210: B200 (50:50)

Less nerve

Advantages in calandering

10 Baypren Kay Varnhorn Malmö, 2013-04-11

B210 - B200A VP – Extrusion

Volume output

Higher Volume output for

low Mooney B200

compared to B210

Significant increased

output for blend of

B210: B200 (50:50)

Higher output, higher

production rate

Advantage also for semi-

finished products

11 Baypren Kay Varnhorn Malmö, 2013-04-11

B210 - B200A VP – Extrusion

Energy consumption

Lower Energy consumption

for low Mooney B200

compared to B210

Significant reduced

Energy consumption for

blend of

B210: B200 (50:50)

Safe energy cost

Less compound

temperature

12 Baypren Kay Varnhorn Malmö, 2013-04-11

B210 - B200A VP

Mechanical properties

Stress strain curve for

standard and low Mooney

material comparable

No lack of mechanical

properties if low Mooney

material is used

13 Baypren Kay Varnhorn Malmö, 2013-04-11

B210 - B200A VP

Compression set - hardness

60

Compression set at

CS 70h / 53 53 54 evaluated temperatures for

22°C a blend of low Mooney/

50 CS 70h /

70°C

standard material is

comparable to standard

Compression set (%)

Hardness

40

Hardness (ShA)

(ShA)

Low Mooney material

29 30

30 28 slightly increase

27

24 compression set

22

20

No influence on hardness

10

with low Mooney material

and blend of thereof

0

B210 Standard B200A VP B210-200

14 Baypren Kay Varnhorn Malmö, 2013-04-11

B110 – B100A VP

Injection moulding

Injection moulding formulation

MTT based curing system

Blends of Baypren ® 110 Standard (40 MU) Injection moulding

and Baypren ® 100A VP low Mooney (34 MU) formulation possible

BAYPREN® 110 100 70 50

Investigate the influence of

BAYPREN® 100A VP 30 50 low Mooney CR on flow

SCORCHGUARD® O 5,3 5,3 5,3 behaviour and filling

ZINKWEISS ROTSIEGEL 5 5 5 degree of injection

EDENOR® C 18 98-100 1 1 1 moulding cavity

CORAX® N 330 15 15 15

REGAL® SRF / N772 35 35 35

EDENOL® 888 10 10 10

TUDALEN® 1849-TE 10 10 10

RHENOFIT® DDA-70 1,5 1,5 1,5

RHENOGRAN® MBTS-80 1,25 1,25 1,25

RHENOGRAN® MTT-80 1 1 1

15 Baypren Kay Varnhorn Malmö, 2013-04-11

B110 – B100A VP

Compound Mooney – Filling degree

Compound Mooney

decrease with the addition

of 30 and 50 parts low

Mooney CR

Degree of filling increase

with the addition of 30 and

50 parts low Mooney CR

Better filling of IM cavity

16 Baypren Kay Varnhorn Malmö, 2013-04-11

Summary I: Low Mooney grades

Summary low Mooney grades

Baypren ® A VP low Mooney grades offer low Mooney viscosity about 28 MU

Baypren ® A VP low Mooney grades have comparable mechanical properties to standard grades

despite lower Mooney viscosity

Baypren ® A VP low Mooney grades offer

better flowing

lower die swell

higher out put

lower energy consumption

Baypren ® A VP low Mooney grades offer new compounding option combinations of high and low

Mooney polymers e.g. B230 / B200

Baypren ® A VP low Mooney grades can support to optimize processing

17 Baypren Kay Varnhorn Malmö, 2013-04-11

Curatives ETU and MTT

Most vulcanization systems for CR contain either ETU or MTT as curative.

“US Environmental Protection Agency” (EPA) has classified ethylene thiourea as a group B2,

probable human carcinogen.

Therefore ETU is restricted in many countries. Customers looking for alternatives like MTT.

ETU MTT

Ethylene thiourea N-Methyl-thiazolidin-2-thion

(Imidazolidin-2-thion) Trade names (Rheinchemie)

Trade names (Rheinchemie) Rhenogran® MTT 80,

Rhenogran® ETU 80 Rhenocure® CRV/LG

Rhenocure® NPV/C former

former Vulkacit® CRV

Vulkacit® NPV/V

18 Baypren Kay Varnhorn Malmö, 2013-04-11

B110 - MTT curing - MDR

Variation in temperature and MTT level

Temperature and level of

curative influence the cure

rate (and the maximum

torque)

Baypren® 110 100 100 100

REGAL® SRF / N772 30 30 30

EDENOR® C 18 98-100 0,5 0,5 0,5

Scorchguard® O 5,3 5,3 5,3

ZINKWEISS ROTSIEGEL 5 5 5

RHENOGRAN® MTT 0,5 0,5 1

Rhenofit® DDA 70 1,5 1,5 1,5

19 Baypren Kay Varnhorn Malmö, 2013-04-11

B110 – B110A VP

MTT curing – MDR – Part I

B110 MTT B110 MTT B110 MTT B110 (Ref.) MTT B110 (fast) MTT B110 (regular) MTT

0,5 180°C 0,5 160°C 1,0 160°C 0,5 160°C 0,5 160°C 0,5 160°C

Polymer B110 B110 B110 B110 B110A VP fast B110A VP regular

RHENOGRAN® MTT-80 0,5 0,5 1 0,5 0,5 0,5

Rhenofit® DDA 1,5 1,5 1,5 - - -

20 Temperature and level of

18

curative influence the cure

rate (and the maximum

16 torque)

14 New, fast

New, Cure rate of new B110A VP

12 180°C regular (fast) only be achieved with

S' [dNm]

10 the new material not with

1 phr variation of temperature or

8

curative level

6 B110 MTT 0,5 180°C

B110 MTT 0,5 160°C

4 B110 MTT 1,0 160°C

B110 (ref.) MTT 0,5 160°C

2 B110A VP (fast) MTT 0,5 160°C

B110A VP (regular) MTT 0,5 160°C

0

0 300 600 900 1200 1500 1800 2100 2400

Time [s]

20 Baypren Kay Varnhorn Malmö, 2013-04-11

B110 – B110A VP

MTT curing – MDR - Part II 160°C

Baypren® 110 100

Baypren® 110A VP (fast) 100

Baypren® 110A VP (regular) 100

Scorchguard® O 5,3 5,3 5,3

ZINKWEISS ROTSIEGEL 5 5 5

EDENOR® C 18 98-100 1 1 1

REGAL® SRF / N772 30 30 30

RHENOGRAN® MTT-80 1 1 1

MBTS® 80% 1,25 1,25 1,25

Rhenofit® DDA 1,5 1,5 1,5

21 Baypren Kay Varnhorn Malmö, 2013-04-11

Summary II: Improved MTT curing

Summary Improved MTT curing

Baypren ® A VP grades have improved cure rates for MTT

Curing curve is close to an ideal curing curve

Polymer variations are possible to further adapt the vulcanization rate of MTT curing

22 Baypren Kay Varnhorn Malmö, 2013-04-11

XD grades from alternative finishing

a) linear, uniform configuration c) linear, reactive endgroups

variations in MW and MW-distribution

Cl Cl Cl Cl

X

X

n

XD types

Ve

Cl Cl Cl Cl

d) precrosslinked

R R

n R

R

R R

determines Mooney viscosity R

R R

R R

R R

b) linear, non-uniform configuration

determines gel content

Cl Cl Cl

n Cl e) sulphur modified

Cl

Cl

comonomer R S S R

Low crystallization tendency S types

23 Baypren Kay Varnhorn Malmö, 2013-04-11

B216 – B216A VP

Comparison

Baypren® 216 100

Baypren® 216A VP 100

REGAL® SRF / N772 30 30

EDENOR® C 18 98-100 0,5 0,5

Scorchguard® O 5,3 5,3

ZINKWEISS ROTSIEGEL 5 5

RHENOGRAN® ETU-80 0,5 0,5

24 Baypren Kay Varnhorn Malmö, 2013-04-11

B216 – B216A VP

Scorch (120°C) – MDR 160°C

25 Baypren Kay Varnhorn Malmö, 2013-04-11

B216 – B216A VP

Mechanical properties

Mooney scorch,

comparable to standard

MDR, lower final torque

maximum with ETU,

slightly improved marching

modulus

Stress strain curve

comparable

26 Baypren Kay Varnhorn Malmö, 2013-04-11

B216 – B216A VP

Compression set - Hardness

Compression set and

hardness are on a similar

level for the evaluated

formulation

27 Baypren Kay Varnhorn Malmö, 2013-04-11

Summary III: XD grades

General summary

Summary XD grades

XD grades obtained by new finishing offer a very similar material performance in terms

of vulcanization and mechanical properties

Summary Improved MTT curing

Baypren ® A VP grades have improved cure rates for MTT

Polymer variations are possible to further adapt the vulcanization rate of MTT curing

Summary low Mooney grades

Baypren ® A VP low Mooney grades have comparable mechanical properties to

standard grades despite lower Mooney viscosity

Baypren ® A VP low Mooney grades can support to optimize processing

28 Baypren Kay Varnhorn Malmö, 2013-04-11

Disclaimer

Building K10, 51369 Leverkusen

Internet: www.lanxess.com

http://www.mandatory-information.gmbh.lanxess.com

The manner in which you use and the purpose to which you put and utilize our products, technical

assistance and information (whether verbal, written or by way of production evaluations), including

any suggested formulations and recommendations are beyond our control. Therefore, it is imperative

that you test our products, technical assistance and information to determine to your own satisfaction

whether they are suitable for your intended uses and applications. This application-specific analysis

must at least include testing to determine suitability from a technical as well as health, safety, and

environmental standpoint. Such testing has not necessarily been done by us. Unless we otherwise

agree in writing, all products are sold strictly pursuant to the terms of our standard conditions of sale.

All information and technical assistance is given without warranty or guarantee and is subject to

change without notice. It is expressly understood and agreed that you assume and hereby expressly

release us from all liability, in tort, contract or otherwise, incurred in connection with the use of our

products, technical assistance, and information. Any statement or recommendation not contained

herein is unauthorized and shall not bind us. Nothing herein shall be construed as a recommendation

to use any product in conflict with patents covering any material or its use. No license is implied or in

fact granted under the claims of any patent.

29 Baypren Kay Varnhorn Malmö, 2013-04-11

30 Baypren Kay Varnhorn Malmö, 2013-04-11

You might also like

- Rhein Chemie - Products For Rubber IndustriesDocument36 pagesRhein Chemie - Products For Rubber IndustriesMarcos ROSSINo ratings yet

- Ethico Legal and Moral Considerations in Nursing Leadership ManagementDocument238 pagesEthico Legal and Moral Considerations in Nursing Leadership ManagementEdelrose Lapitan100% (1)

- Denka Evolmer Bro 1Document5 pagesDenka Evolmer Bro 1mouds22100% (1)

- The Validity of Perpetual Alienation of Property Imposed by The Donee or DonorDocument10 pagesThe Validity of Perpetual Alienation of Property Imposed by The Donee or Donoraya5monteroNo ratings yet

- Sample Exam Business LawDocument8 pagesSample Exam Business LawJDR JDRNo ratings yet

- LegalForce v. UpWork & UpWork Attorneys - Fee Sharing and IOLTA Served March 14, 2019Document268 pagesLegalForce v. UpWork & UpWork Attorneys - Fee Sharing and IOLTA Served March 14, 2019Raj Abhyanker0% (2)

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmissaouiNo ratings yet

- 3-Reservoir Engineering For CompletionDocument57 pages3-Reservoir Engineering For CompletionmsvaletNo ratings yet

- Hoek-Brown Critera and GSIDocument112 pagesHoek-Brown Critera and GSIMohit VermaNo ratings yet

- Description: Commercial Level Y XDocument2 pagesDescription: Commercial Level Y Xjonatas priscoNo ratings yet

- Introduction of Well Problems-2Document32 pagesIntroduction of Well Problems-2ROY HANAFI HARAHAPNo ratings yet

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmagedNo ratings yet

- Rio CordDocument2 pagesRio CordCyprien YENo ratings yet

- Basic Reservoir EngineeringDocument74 pagesBasic Reservoir EngineeringRizaldiSaputraNo ratings yet

- 4.3 Lodos Base AceiteDocument52 pages4.3 Lodos Base AceiteJonathan DarioNo ratings yet

- PTEG 323 Well Log Analysis and Well Testing Lec3 16jan2018Document7 pagesPTEG 323 Well Log Analysis and Well Testing Lec3 16jan2018Dennise ShughniNo ratings yet

- GR - SP - CalDocument21 pagesGR - SP - CalsauloeganaNo ratings yet

- 4 - Resistivity LogsDocument34 pages4 - Resistivity LogsAbuzeidNo ratings yet

- Basic Well Logging - CHAPTER 4Document45 pagesBasic Well Logging - CHAPTER 4WSG SARIRNo ratings yet

- D'Series: Submersible PumpDocument8 pagesD'Series: Submersible PumpSenghy MaoNo ratings yet

- Di Cap Data Sheet 022818Document2 pagesDi Cap Data Sheet 022818威爾WNo ratings yet

- Applications of The Reflux Classifier On SA CoalsDocument24 pagesApplications of The Reflux Classifier On SA CoalsSenthilkumar PragasamNo ratings yet

- Physics of Sediment Transport: Lecture/Lab Learning GoalsDocument7 pagesPhysics of Sediment Transport: Lecture/Lab Learning GoalsSaja GhnematNo ratings yet

- 1 - Well Log Evaluation - IntroductionDocument29 pages1 - Well Log Evaluation - IntroductionKyosuke HilmiNo ratings yet

- Lecture - 01 Petrofisica Del ReservorioDocument27 pagesLecture - 01 Petrofisica Del ReservorioJosueGuayuscaSoriaGalvarroNo ratings yet

- MLX90423 Product Flyer MelexiDocument2 pagesMLX90423 Product Flyer MelexiamaeNo ratings yet

- Fluids 3: Real Fluid FlowDocument45 pagesFluids 3: Real Fluid FlowFabio BosioNo ratings yet

- ResistivityDocument25 pagesResistivityZain-Alabdeen Haithem LaftaNo ratings yet

- Rock & Fluid PropertiesDocument24 pagesRock & Fluid PropertiesJosé TimanáNo ratings yet

- 4 - Log ResistivitasDocument45 pages4 - Log ResistivitasYordanNo ratings yet

- Formation Evaluation Based On Logging DataDocument136 pagesFormation Evaluation Based On Logging DataNizar AliNo ratings yet

- LE 01 Formation Evaluation 01Document59 pagesLE 01 Formation Evaluation 01Alhaj MassoudNo ratings yet

- Permeability First DocumentDocument21 pagesPermeability First DocumentMontu PatelNo ratings yet

- Integrated Reservoir ModelingDocument24 pagesIntegrated Reservoir Modelingc_b_umashankarNo ratings yet

- Bangla Basic Character Recognition Using Digital Curvelet TransformDocument10 pagesBangla Basic Character Recognition Using Digital Curvelet Transformapi-26462544No ratings yet

- VELP Scientifica Solutions For Stirring ShaftsDocument1 pageVELP Scientifica Solutions For Stirring ShaftsAbhishek ShrotriyaNo ratings yet

- Fu2018 Article ModelingAndSimulationOfTransitDocument18 pagesFu2018 Article ModelingAndSimulationOfTransitMostafa KorttamNo ratings yet

- Chemical Injection PolymerDocument44 pagesChemical Injection PolymerSyasya Ja’afarNo ratings yet

- DESMODUR LUT+ MocaDocument2 pagesDESMODUR LUT+ MocaSebastian Ordoñez100% (1)

- Dowex Marathon ADocument2 pagesDowex Marathon Ajuan grasselerNo ratings yet

- Reservior Petrophysics - CourseDocument478 pagesReservior Petrophysics - CourseLiliana Plata SarmientoNo ratings yet

- FM - Pete - 663 - Resist ToolsDocument53 pagesFM - Pete - 663 - Resist ToolsKAORU AmaneNo ratings yet

- Brosur Pompa DS Dan DVSDocument4 pagesBrosur Pompa DS Dan DVSBilly Christovel100% (1)

- Sensitivity Studies in Forward AVO ModelingDocument4 pagesSensitivity Studies in Forward AVO ModelingPritesh BhoumickNo ratings yet

- S08 10 - 50 David BulledDocument22 pagesS08 10 - 50 David BulledAndré Cuadros MamaniNo ratings yet

- Typical Textures, Part 2: Thermomechanical Processing (TMP) of BCC MetalsDocument32 pagesTypical Textures, Part 2: Thermomechanical Processing (TMP) of BCC MetalsSally Sedano AmayaNo ratings yet

- Agua Dulce y Reg ElectricosDocument19 pagesAgua Dulce y Reg ElectricosRichard OrtegaNo ratings yet

- Epithermal Vein Textures Lodes & Shoots - Morrison - 2008Document76 pagesEpithermal Vein Textures Lodes & Shoots - Morrison - 2008Andres VillacisNo ratings yet

- PU - TP - Product - Portfolio - For - Footwear HMDocument6 pagesPU - TP - Product - Portfolio - For - Footwear HMManish DobariyaNo ratings yet

- 04 SLF Dumpsite Closure - IldefonsoDocument39 pages04 SLF Dumpsite Closure - IldefonsoElisa Dela FuenteNo ratings yet

- Brosur Pompa Submersible EbaraDocument4 pagesBrosur Pompa Submersible EbaraBudi RahmadiNo ratings yet

- D and F ElementsDocument1 pageD and F ElementsAkshayNo ratings yet

- Chapter 5 - Petro - ViewshaleinterDocument56 pagesChapter 5 - Petro - ViewshaleinterHUY TRẦN ĐÌNHNo ratings yet

- Isolina Weirich. Río de Janeiro, Barra Da Tijuca (2010) - Tel. 3392-3381. Cel. 9154-0171Document92 pagesIsolina Weirich. Río de Janeiro, Barra Da Tijuca (2010) - Tel. 3392-3381. Cel. 9154-0171Raúl BolmaroNo ratings yet

- PGP4204: Enhanced Oil Recovery Processes: Residual Saturations and WettabilityDocument21 pagesPGP4204: Enhanced Oil Recovery Processes: Residual Saturations and WettabilityParth PathakNo ratings yet

- Domino Ip66 - en - 01Document1 pageDomino Ip66 - en - 01rghbfsdfsgsfdNo ratings yet

- 4 - Resistivity - Theory (TP13)Document39 pages4 - Resistivity - Theory (TP13)dewaNo ratings yet

- Performance Studies of Trickle Bed Reactors: Mohan R. KhadilkarDocument25 pagesPerformance Studies of Trickle Bed Reactors: Mohan R. KhadilkaribdudeNo ratings yet

- 13 Water Treatment Training Pretreatment FiltrationDocument32 pages13 Water Treatment Training Pretreatment Filtrationsantoshkumar gurmeNo ratings yet

- PDF Astm d4294 10 - CompressDocument10 pagesPDF Astm d4294 10 - CompressSilvia CarolinaNo ratings yet

- Polymer Flooding IntroductionDocument293 pagesPolymer Flooding IntroductionoreNo ratings yet

- Seg SeminarDocument17 pagesSeg SeminarAdam S KamalNo ratings yet

- Hapjan Paper ReviewedDocument25 pagesHapjan Paper Reviewedaribw5No ratings yet

- Rivers and Floodplains: Forms, Processes, and Sedimentary RecordFrom EverandRivers and Floodplains: Forms, Processes, and Sedimentary RecordNo ratings yet

- Improvement of The Crosslinking of PolychloropreneDocument8 pagesImprovement of The Crosslinking of PolychloropreneMarcos ROSSINo ratings yet

- Antioxidants - MELROB - RubberDocument6 pagesAntioxidants - MELROB - RubberMarcos ROSSINo ratings yet

- Chemicals of High Concern List (Sorted Alphabetically)Document125 pagesChemicals of High Concern List (Sorted Alphabetically)Marcos ROSSINo ratings yet

- How Surface Roughness of Mold CavityDocument8 pagesHow Surface Roughness of Mold CavityMarcos ROSSINo ratings yet

- Santoflex (TM) 77PD: Safety Data SheetDocument13 pagesSantoflex (TM) 77PD: Safety Data SheetMarcos ROSSI100% (1)

- Vulkanox 3100: IdentificationDocument3 pagesVulkanox 3100: IdentificationMarcos ROSSINo ratings yet

- High Production Volume Status of Chemicals On The 2019Document20 pagesHigh Production Volume Status of Chemicals On The 2019Marcos ROSSINo ratings yet

- MSA 4th EditionDocument54 pagesMSA 4th EditionMarcos ROSSINo ratings yet

- Ubber Hemicals: Flexzone 4L Antioxidant / AntiozonantDocument1 pageUbber Hemicals: Flexzone 4L Antioxidant / AntiozonantMarcos ROSSINo ratings yet

- Flexzone 4L Antiozonant: TechnicalDocument2 pagesFlexzone 4L Antiozonant: TechnicalMarcos ROSSINo ratings yet

- Flexsys Santoflex 77PDDocument5 pagesFlexsys Santoflex 77PDMarcos ROSSINo ratings yet

- A2S Phenols AromaticsDocument62 pagesA2S Phenols AromaticsMarcos ROSSINo ratings yet

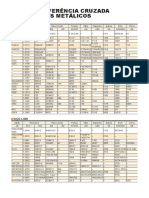

- Lista de Referência Cruzada de Materiais Metálicos: Aço CarbonoDocument4 pagesLista de Referência Cruzada de Materiais Metálicos: Aço CarbonoMarcos ROSSINo ratings yet

- Assignment of Contract Rights PDFDocument29 pagesAssignment of Contract Rights PDFAnonymous oziP2JnNo ratings yet

- We Are Please To Inform You That You Have Been Appointed With RPS HOSPITAL, Ranchi AsDocument6 pagesWe Are Please To Inform You That You Have Been Appointed With RPS HOSPITAL, Ranchi AstanishaNo ratings yet

- Cancellation of Sale DeedDocument11 pagesCancellation of Sale DeedSadiq CheemaNo ratings yet

- BTS3900 Hardware Description (04) (PDF) - ENDocument20 pagesBTS3900 Hardware Description (04) (PDF) - ENMohammed ShakilNo ratings yet

- Please Add Paymaster CompanyDocument10 pagesPlease Add Paymaster CompanyОльга МурзинаNo ratings yet

- Law On Secrecy of Bank DepositsDocument15 pagesLaw On Secrecy of Bank DepositsSj Macky100% (8)

- 2017 08 Philippine ADR ReviewDocument4 pages2017 08 Philippine ADR ReviewCyberR.DomingoNo ratings yet

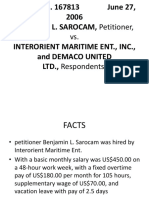

- Labor CaseDocument20 pagesLabor CaseArvin GuevarraNo ratings yet

- Monzon, Jessa Marie M. Law 3E Special ProceedingsDocument9 pagesMonzon, Jessa Marie M. Law 3E Special ProceedingsRonna Faith MonzonNo ratings yet

- Rights of An Unpaid SellerDocument12 pagesRights of An Unpaid SellerJacob Toms NalleparampilNo ratings yet

- User Experience Research Consent and Non Disclosure AgreementDocument2 pagesUser Experience Research Consent and Non Disclosure AgreementMario GuzmanNo ratings yet

- Contract II FinalDocument20 pagesContract II FinalRazor RockNo ratings yet

- Contracts 1Document20 pagesContracts 1masilyn angelesNo ratings yet

- Obligation and Contract - Activity 4 - BSOA-3C - Group 4Document4 pagesObligation and Contract - Activity 4 - BSOA-3C - Group 4Rogelio Olasos BernobaNo ratings yet

- Chapter IV-BLDocument15 pagesChapter IV-BLBantamkak FikaduNo ratings yet

- Securitisation - Luxembourg-Chapter 2023Document25 pagesSecuritisation - Luxembourg-Chapter 2023john pynchonNo ratings yet

- Agency: Loon Karan Sohan Lal Vs Firm John and CoDocument44 pagesAgency: Loon Karan Sohan Lal Vs Firm John and CoBenjamin BallardNo ratings yet

- UiPath Community AgreementDocument10 pagesUiPath Community Agreementfernando.uipath2023No ratings yet

- Caa V Fa and Fifa 301123 Rev 121223 Publication VersionDocument111 pagesCaa V Fa and Fifa 301123 Rev 121223 Publication VersionIkeNo ratings yet

- Philcomsat V Globe Telecom DigestDocument3 pagesPhilcomsat V Globe Telecom DigestGegi F Irong100% (1)

- Transfer of PropertyDocument15 pagesTransfer of PropertyAvinash DangwalNo ratings yet

- Retirement AgreementDocument12 pagesRetirement AgreementckoenisNo ratings yet

- PFR Case-Digest-Art-29-35Document9 pagesPFR Case-Digest-Art-29-35Kristine TarNo ratings yet

- Lecture - 2 Procuremnt, 1Document80 pagesLecture - 2 Procuremnt, 1Riste EyasuNo ratings yet

- C. Breach of ObligationDocument44 pagesC. Breach of ObligationJess EstradaNo ratings yet

- Ch16 CorpVeilDocument29 pagesCh16 CorpVeilSophia LiaoNo ratings yet