Professional Documents

Culture Documents

Experimental Problems in Statistical Concepts: Use Standard Normal Distribution Tables

Experimental Problems in Statistical Concepts: Use Standard Normal Distribution Tables

Uploaded by

Chand Patel0 ratings0% found this document useful (0 votes)

14 views2 pagesThe document contains 4 experimental problems involving statistical concepts and standard normal distribution tables:

1. Frequency distribution data of signal duration measurements from radio transmitting sets is given. The mean and standard deviation must be calculated.

2. Stiffness test data for aluminum alloy channels is distributed. The mean, standard deviation and percentages below a given point must be calculated.

3. Process data is given with a mean of 360 and standard deviation of 40. Percentages meeting specifications must be determined for the original and re-centered processes.

4. Resistance measurement data from electronic components is distributed. The mean, standard deviation and percentages outside specifications must be determined, both assuming normal and uniform distributions. Conclusions about process control

Original Description:

Original Title

1_Exptl_Problems_in_Statistical_concepts_1642829919145

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains 4 experimental problems involving statistical concepts and standard normal distribution tables:

1. Frequency distribution data of signal duration measurements from radio transmitting sets is given. The mean and standard deviation must be calculated.

2. Stiffness test data for aluminum alloy channels is distributed. The mean, standard deviation and percentages below a given point must be calculated.

3. Process data is given with a mean of 360 and standard deviation of 40. Percentages meeting specifications must be determined for the original and re-centered processes.

4. Resistance measurement data from electronic components is distributed. The mean, standard deviation and percentages outside specifications must be determined, both assuming normal and uniform distributions. Conclusions about process control

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

14 views2 pagesExperimental Problems in Statistical Concepts: Use Standard Normal Distribution Tables

Experimental Problems in Statistical Concepts: Use Standard Normal Distribution Tables

Uploaded by

Chand PatelThe document contains 4 experimental problems involving statistical concepts and standard normal distribution tables:

1. Frequency distribution data of signal duration measurements from radio transmitting sets is given. The mean and standard deviation must be calculated.

2. Stiffness test data for aluminum alloy channels is distributed. The mean, standard deviation and percentages below a given point must be calculated.

3. Process data is given with a mean of 360 and standard deviation of 40. Percentages meeting specifications must be determined for the original and re-centered processes.

4. Resistance measurement data from electronic components is distributed. The mean, standard deviation and percentages outside specifications must be determined, both assuming normal and uniform distributions. Conclusions about process control

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 2

Experimental Problems in Statistical Concepts

Use standard normal distribution tables

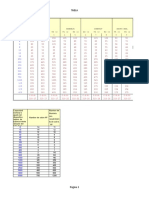

1. A small radio transmitting set is designed so that it can be used to generate

a certain automatic signal. The time duration of this signal is one of the

specified quality characteristics of the set. At regular intervals, five sets from

the production line were tested for this quality characteristic. In the following

table, which shows 125 such measurements, the values in each subgroup of

five have been arranged in order of magnitude.

Subgroup Duration of automatic signal

number (time units unspecified)

A B C D E

1 390 393 395 405 420

2 376 381 381 383 401

3 380 387 395 397 407

4 377 383 387 390 393

5 393 395 403 405 414

6 376 388 395 397 400

7 387 400 400 403 410

8 391 392 394 397 405

9 390 391 395 401 405

10 379 391 393 394 410

11 390 397 400 406 428

12 380 382 389 391 399

13 375 383 392 395 404

14 387 390 398 400 408

15 390 395 395 397 403

16 382 399 401 406 406

17 390 395 395 400 410

18 381 390 394 397 399

19 387 389 398 401 415

20 372 378 396 400 405

21 387 389 391 391 400

22 376 380 391 406 412

23 395 396 397 400 400

24 392 394 397 399 400

25 385 390 390 392 392

Make a tally of these 125 measurements to arrange them in a frequency

distribution. Use cell mid-points of 370,375,380,385……………………430. From

this check sheet, prepare a table showing cell mid-points, cell boundaries, and

observed frequencies. Find the arithmetic mean and standard deviation of the

problem. (May shift origin and scale of data)

2. Tests of the stiffness of a number of aluminum- alloy channels gave the

following frequency distribution.

Stiffness Freq. Stiffness Freq. Stiffness Freq.

2640 1 2440 33 2280 14

2600 2 2400 41 2240 5

2560 7 2360 35 2200 3

2520 11 2320 22 2160 1

2480 25

a) Compute ΄ and

b) If a normal distribution had this ΄ and , what percentage of the

distribution would fall below 2150 ?

c) It is decided to fix lower specification limit for stiffness such that at least 99%

of the channels satisfy it. Determine what would be the specification limit.

3. The results of an analysis yield the following: = 360, = 40. Assume

that the process generates a normal distribution and specifications are 400+

60. a) What proportion of the product meets the specifications ?

b) if the process is re-centered at 400, what proportion would meet the

specifications? (Draw figures)

c) To what extent should the dispersion be reduced if it is required that at

least 99% of the product meets the specifications (if process is centered at

400)?

4. A manufacturer of electrical products purchases many parts from outside

vendors. A lot of 20000 of a certain small component is received from a new

vendor. The receiving inspection department for the manufacturer has taken a

random sample of 200 components from this lot and measured the resistance of

each component. These resistances in ohms have been arranged into the

following frequency distribution:

Cell boundaries, ohms Frequency

88.5-86.5 2

86.5-84.5 5

84.5-82.5 16

82.5-80.5 24

80.5-78.5 40

78.5-76.5 44

76.5-74.5 25

74.5-72.5 22

72.5-70.5 13

70.5-68.5 7

68.5-66.5 2

a) Compute the average and standard deviation of this frequency distribution.

What percentage of a normal distribution having your computed average and

s.d. would fall outside the specification limits 75+10 ohms ?

b) If you make the arbitrary assumption that resistances are distributed uniformly

throughout each cell, what percentage of the actual distribution fell outside these

limits?

c) What conclusion, if any, can you reach on the question of whether or not the

vendor was maintaining good statistical control of this quality characteristic?

Explain your answer.

d) How much would be the percentage reduction in defectives if the process is

re-centered at (U+L)/2 i.e. at 75 ohms, assuming that resistances are normally

distributed?

You might also like

- AS A Level Biology Teacher's Guide PDFDocument49 pagesAS A Level Biology Teacher's Guide PDFEman Yasin100% (5)

- UC PVC CatalogueDocument2 pagesUC PVC CataloguelimNo ratings yet

- DMC Full Thread ChecklistDocument4 pagesDMC Full Thread ChecklistKate ChanningsNo ratings yet

- C06 DataDocument16 pagesC06 DataAndrei MorenoNo ratings yet

- Fractured Fairy Tale Rubric NOT MINE, Just An IdeaDocument1 pageFractured Fairy Tale Rubric NOT MINE, Just An Ideapatty rdz100% (1)

- V6 Auto TransDocument9 pagesV6 Auto Trans08088338No ratings yet

- Math 10 LT PracticeDocument7 pagesMath 10 LT PracticeAlessandraNo ratings yet

- Power Cables & Wires Technical Manual: Table A23. Minimum Wire-Bending Space at TerminalsDocument77 pagesPower Cables & Wires Technical Manual: Table A23. Minimum Wire-Bending Space at Terminalsbharatsehgal00@gmail.comNo ratings yet

- Table 4d4aDocument2 pagesTable 4d4aZunnur ZamzamNo ratings yet

- FDT Excel SampleDocument4 pagesFDT Excel SampleCarlo Lopez CantadaNo ratings yet

- 8 - Tai Lieu Tham KhaoDocument4 pages8 - Tai Lieu Tham KhaoNguyễn Tấn ĐạtNo ratings yet

- Current Rating and Voltage DropDocument11 pagesCurrent Rating and Voltage Dropahmed saberNo ratings yet

- Hammertes Pole 6M-B R2Document12 pagesHammertes Pole 6M-B R2s3mp4ckNo ratings yet

- 4769 10 LedDocument3 pages4769 10 LedAlejandro Paez DiazNo ratings yet

- ( (All Three Data Are Normalised To The Range of (0,1) First) ) - The Data Are Given in Table 1. Input of SVRDocument6 pages( (All Three Data Are Normalised To The Range of (0,1) First) ) - The Data Are Given in Table 1. Input of SVRStenZiL PandeyNo ratings yet

- H-UTM S.no SheetDocument47 pagesH-UTM S.no SheetkesarNo ratings yet

- BS 7671 Table 4E4BDocument2 pagesBS 7671 Table 4E4Bj658503No ratings yet

- 4D2A IEE RegulationDocument1 page4D2A IEE RegulationGoogool Y100% (1)

- Table 4D1A PDFDocument1 pageTable 4D1A PDFMadusanka Weebedda100% (1)

- 2 22 PDFDocument2 pages2 22 PDFpriecs100% (1)

- Acceptance of Concrete Test ResultsDocument5 pagesAcceptance of Concrete Test ResultsMani Raj NNo ratings yet

- TechBuilder - MPPT CALCULATORDocument6 pagesTechBuilder - MPPT CALCULATORBabumani MandiNo ratings yet

- Assignment 3 - Due Date 4 - 1 - 2024 - 1.30 PMDocument2 pagesAssignment 3 - Due Date 4 - 1 - 2024 - 1.30 PMkawnnkawnNo ratings yet

- Financial AnalysisDocument258 pagesFinancial AnalysisKunal SharmaNo ratings yet

- Charts & Tables: Rated Motor Current Conversion TableDocument1 pageCharts & Tables: Rated Motor Current Conversion Tablemuqtar4uNo ratings yet

- Room Name: EMR-G1 EMR-G2 Pabx Room Generator Ats Room LV Room# 3 EMR-G3 EMR-G4 LV Room# 2Document11 pagesRoom Name: EMR-G1 EMR-G2 Pabx Room Generator Ats Room LV Room# 3 EMR-G3 EMR-G4 LV Room# 2JojolasNo ratings yet

- Current Carrying Capacity CABLES - BVDocument3 pagesCurrent Carrying Capacity CABLES - BVStefanita100% (1)

- Crude Gann LvlsDocument44 pagesCrude Gann LvlsCharanjit Singh100% (1)

- Cond AluminioDocument40 pagesCond Aluminiorodolfoordiguez_70No ratings yet

- An OvaDocument1 pageAn OvaChu PecyNo ratings yet

- Exercise # 3Document1 pageExercise # 3Ailyn LabajoNo ratings yet

- BS 1Document12 pagesBS 1ABHISHEK GOYALNo ratings yet

- Short Radius 180 Deg. 20.4.2020Document1 pageShort Radius 180 Deg. 20.4.2020Sunil GurubaxaniNo ratings yet

- Typical Full Laod Amp ChartDocument2 pagesTypical Full Laod Amp Chartdramsree1No ratings yet

- MetroDocument4 pagesMetroMAU XMXNo ratings yet

- Tesca Technologies Pvt. LTD.: Device SupportsDocument1 pageTesca Technologies Pvt. LTD.: Device Supportsreza yousefiNo ratings yet

- Step by Step Guide For Low Voltage Copper Conductor Cable SizingDocument21 pagesStep by Step Guide For Low Voltage Copper Conductor Cable SizingNouman AhmadNo ratings yet

- Figure (3) :KC Value For P Controller Only and ZiglerDocument11 pagesFigure (3) :KC Value For P Controller Only and ZiglerاشرفاللساميNo ratings yet

- ESP Start-Up and OperationDocument46 pagesESP Start-Up and OperationazareiforoushNo ratings yet

- Variables You Can Change: Press F9 Key To Update SimulationDocument1 pageVariables You Can Change: Press F9 Key To Update Simulationapi-19921807No ratings yet

- Strategies of Matebilitics1Document51 pagesStrategies of Matebilitics1紫泰No ratings yet

- Crude Gann LvlsDocument44 pagesCrude Gann LvlskandanNo ratings yet

- Remington Copper Hook-Up Wire Ampacity ChartsDocument1 pageRemington Copper Hook-Up Wire Ampacity ChartsAntonio AdorzaNo ratings yet

- 18 Appendix.ADocument4 pages18 Appendix.AMoe Thant OoNo ratings yet

- Screenshot 2022-07-14 at 12.30.24Document44 pagesScreenshot 2022-07-14 at 12.30.24zakkNo ratings yet

- System Voltage Suggested Arrester RatingDocument26 pagesSystem Voltage Suggested Arrester RatinggilbertomjcNo ratings yet

- Production Table 1 (300,000 Tpa)Document1 pageProduction Table 1 (300,000 Tpa)ravranaNo ratings yet

- Superelevation FinalDocument455 pagesSuperelevation FinalEskinder KebedeNo ratings yet

- Lab 4+rubric-Isometric DrawingDocument8 pagesLab 4+rubric-Isometric DrawingSyahmi AmriNo ratings yet

- Demag AC650Document21 pagesDemag AC650joshuatree20021No ratings yet

- ITLS5050 Data Set 2 v5 Simple RegressionDocument19 pagesITLS5050 Data Set 2 v5 Simple RegressionShamim AlamNo ratings yet

- Category 6 Cable: DescriptionDocument2 pagesCategory 6 Cable: DescriptionkapilNo ratings yet

- Packing List SetiembreDocument519 pagesPacking List SetiembreSteve SaavedraNo ratings yet

- MutuDocument5 pagesMutudhitadhitNo ratings yet

- Indo Pacific Line Transect (Substrate)Document7 pagesIndo Pacific Line Transect (Substrate)RevanNo ratings yet

- L T - R M: AB Esting Esilient OdulusDocument8 pagesL T - R M: AB Esting Esilient Odulusmdusman2010No ratings yet

- ExpediçãoDocument79 pagesExpediçãolucaslimadiogoNo ratings yet

- Responsibility Incre. Weight Factor Prev Progress: Summary Progress 3D ModellingDocument19 pagesResponsibility Incre. Weight Factor Prev Progress: Summary Progress 3D ModellingMichael RobinsonNo ratings yet

- Statistik 2 NursinDocument6 pagesStatistik 2 Nursinhasna alwanNo ratings yet

- ZSMG 0938 Ta FDD TDD 20190212194210Document11 pagesZSMG 0938 Ta FDD TDD 20190212194210Narto MujiatmikoNo ratings yet

- Week3 Lec6Document24 pagesWeek3 Lec6Chand PatelNo ratings yet

- Assignment 3Document2 pagesAssignment 3Chand PatelNo ratings yet

- Week4 Lec7Document31 pagesWeek4 Lec7Chand PatelNo ratings yet

- CVL100:Environmental Science (2-0-0) : Introduction To Water Pollution Lec2: Jan 05,2022Document32 pagesCVL100:Environmental Science (2-0-0) : Introduction To Water Pollution Lec2: Jan 05,2022Chand PatelNo ratings yet

- Week3 Lec5Document38 pagesWeek3 Lec5Chand PatelNo ratings yet

- Week4 Lec9Document25 pagesWeek4 Lec9Chand PatelNo ratings yet

- Week4 Lec8Document21 pagesWeek4 Lec8Chand PatelNo ratings yet

- CVL100:Environmental Science (2-0-0) : Introduction To Water Pollution Lec3: Jan 11,2022Document32 pagesCVL100:Environmental Science (2-0-0) : Introduction To Water Pollution Lec3: Jan 11,2022Chand PatelNo ratings yet

- CVL100:Environmental Science (2-0-0) : Introduction To Water Pollution Lec1: Jan 04,2022Document17 pagesCVL100:Environmental Science (2-0-0) : Introduction To Water Pollution Lec1: Jan 04,2022Chand PatelNo ratings yet

- Extrusion and Wire Drawing 2020 PDFDocument64 pagesExtrusion and Wire Drawing 2020 PDFChand PatelNo ratings yet

- Practice Problems In, R and ChartsDocument2 pagesPractice Problems In, R and ChartsChand Patel100% (1)

- Week2 Lec4Document40 pagesWeek2 Lec4Chand PatelNo ratings yet

- Statistical Quality Control by Eugene L. Grant PDFDocument620 pagesStatistical Quality Control by Eugene L. Grant PDFChand Patel100% (1)

- 1-Introduction To Biology-23July2019 PDFDocument14 pages1-Introduction To Biology-23July2019 PDFChand PatelNo ratings yet

- SSRN Id969950Document34 pagesSSRN Id969950Chand PatelNo ratings yet

- Water Quality ParametersDocument29 pagesWater Quality ParametersChand PatelNo ratings yet

- wp0477 PDFDocument43 pageswp0477 PDFChand PatelNo ratings yet

- Accounting For Growth: Comparing China and India: Barry Bosworth and Susan M. CollinsDocument37 pagesAccounting For Growth: Comparing China and India: Barry Bosworth and Susan M. CollinsChand PatelNo ratings yet

- Water Pollution-IntroductionDocument35 pagesWater Pollution-IntroductionChand PatelNo ratings yet

- Reviewer BoardDocument17 pagesReviewer BoardTerrencio ReodavaNo ratings yet

- 9 Class Holiday HomeworkDocument5 pages9 Class Holiday HomeworksavageitgirlNo ratings yet

- 111 - Presentation-14 LCCDE and Block DiagramsDocument13 pages111 - Presentation-14 LCCDE and Block DiagramsDeniz SummerNo ratings yet

- CFD 06 Kainz ANSYS Instationaere Kopplung Von SchaufelreihenDocument40 pagesCFD 06 Kainz ANSYS Instationaere Kopplung Von SchaufelreihenmohamedezeldinNo ratings yet

- Deque and Its ApplicationsDocument18 pagesDeque and Its ApplicationsTech_MXNo ratings yet

- Word FormationDocument3 pagesWord FormationHoàng BùiNo ratings yet

- Balancing of Redox Reactions - 1Document2 pagesBalancing of Redox Reactions - 1Anonymous vRpzQ2BL0% (1)

- Oracle Tca DQMDocument17 pagesOracle Tca DQManand.g7720No ratings yet

- A Glimpse Into The Technology of 21 Century NanotechnologyDocument24 pagesA Glimpse Into The Technology of 21 Century Nanotechnologyapi-19937584100% (1)

- Gel in SituDocument10 pagesGel in SituNur IslamiaNo ratings yet

- Director IT Vendor Management in Philadelphia PA Resume Mark DiTomasoDocument3 pagesDirector IT Vendor Management in Philadelphia PA Resume Mark DiTomasoMark DiTomasoNo ratings yet

- Option A: The Karate Kid (2010)Document11 pagesOption A: The Karate Kid (2010)Lynn Potts50% (2)

- BITP 2213 Software EngineeringDocument30 pagesBITP 2213 Software EngineeringasyiqinNo ratings yet

- 9608 November 2015 Question Paper 42 PDFDocument16 pages9608 November 2015 Question Paper 42 PDFCrustNo ratings yet

- Part 1 - Indian Cons Tu On Class Notes For Civil Services in Telugu MediumDocument22 pagesPart 1 - Indian Cons Tu On Class Notes For Civil Services in Telugu MediumrameshNo ratings yet

- Devex 2018 Introduction To Reservoir SimulationDocument52 pagesDevex 2018 Introduction To Reservoir SimulationKonul AlizadehNo ratings yet

- Learning Theory by BanduraDocument5 pagesLearning Theory by BanduraOnwuka FrancisNo ratings yet

- Differences Male and FemaleDocument13 pagesDifferences Male and Femalejames.dharmawan100% (1)

- Data Structures and Algorithms For External Storage: External Sorting. Index FilesDocument50 pagesData Structures and Algorithms For External Storage: External Sorting. Index FilesNorbert DeakNo ratings yet

- Steps of CellularDocument15 pagesSteps of CellularerikabeltranNo ratings yet

- Gas Permeability, Diffusivity and Solubility of Nitrogen, Helium, Methane, CO2, CH2O in Dense Polymeric Membranes Using A New On-Line Permeation ApparatusDocument12 pagesGas Permeability, Diffusivity and Solubility of Nitrogen, Helium, Methane, CO2, CH2O in Dense Polymeric Membranes Using A New On-Line Permeation ApparatusCinthiaCevallosNo ratings yet

- Analysis of Trofimov From The Cherry OrchardDocument6 pagesAnalysis of Trofimov From The Cherry OrchardAnkit Yadav100% (1)

- T.018 Certification Process Specific Requirements For Other Types of Audits Transcript V1.0Document8 pagesT.018 Certification Process Specific Requirements For Other Types of Audits Transcript V1.0Myriam MaflaNo ratings yet

- DLP My Father Goes To CourtDocument7 pagesDLP My Father Goes To CourtHAHAHAHA GAMINGNo ratings yet

- Facets of The Past The Challenge of The Balkan Neo Eneolithic 2008Document770 pagesFacets of The Past The Challenge of The Balkan Neo Eneolithic 2008Gaspar LoredanaNo ratings yet

- DHCP Ubuntu 12.04Document6 pagesDHCP Ubuntu 12.04Adiel TriguerosNo ratings yet

- Engelking, Sieklucki - Topology A Geometric ApproachDocument437 pagesEngelking, Sieklucki - Topology A Geometric ApproachAnonymous OZa29Avdw100% (2)