Professional Documents

Culture Documents

Maintenance Manual

Maintenance Manual

Uploaded by

MartinezCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GAT SampleDocument10 pagesGAT SampleMahnoor SajidNo ratings yet

- Can-Bus ControlDocument22 pagesCan-Bus ControlMartinezNo ratings yet

- J1939 Datalink 280509Document26 pagesJ1939 Datalink 280509MartinezNo ratings yet

- Rear Dump TruckDocument4 pagesRear Dump TruckMartinezNo ratings yet

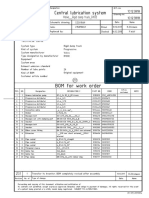

- Central Lubrication System: BOM For Work Order BOM For Work OrderDocument2 pagesCentral Lubrication System: BOM For Work Order BOM For Work OrderMartinezNo ratings yet

- Diesel Particulate Filter System: Johnson MattheyDocument2 pagesDiesel Particulate Filter System: Johnson MattheyMartinezNo ratings yet

- D-1007 Doosan - ADT - Family - LitDocument20 pagesD-1007 Doosan - ADT - Family - LitMartinezNo ratings yet

- Rear Dump TruckDocument4 pagesRear Dump TruckMartinezNo ratings yet

- Integrated Electronic Controller Type EP-tronic: ContentsDocument14 pagesIntegrated Electronic Controller Type EP-tronic: ContentsMartinezNo ratings yet

- Central Lubrication System: BOM For Work Order BOM For Work OrderDocument2 pagesCentral Lubrication System: BOM For Work Order BOM For Work OrderMartinezNo ratings yet

- PU21578000517EN Service Handbuch 0517ENDocument32 pagesPU21578000517EN Service Handbuch 0517ENMartinezNo ratings yet

- Dearborn Protocol Adapter 4 Plus Dpa4Pma - Multi-Application Drivers Installation and User ManualDocument54 pagesDearborn Protocol Adapter 4 Plus Dpa4Pma - Multi-Application Drivers Installation and User ManualMartinezNo ratings yet

- Material DensitiesDocument2 pagesMaterial DensitiesMartinezNo ratings yet

- JM SCR Brochure 012909mDocument4 pagesJM SCR Brochure 012909mMartinezNo ratings yet

- Pre-Cleaners: No Matter What Dust Condition, Pre-Cleaners Extend Air Filter LifeDocument14 pagesPre-Cleaners: No Matter What Dust Condition, Pre-Cleaners Extend Air Filter LifeMartinezNo ratings yet

- 3950 LX-4 Progressive DistributorDocument10 pages3950 LX-4 Progressive DistributorMartinezNo ratings yet

- En Ta Artic Dump Trucks Filters Kit Brochure 0512 72dpiDocument15 pagesEn Ta Artic Dump Trucks Filters Kit Brochure 0512 72dpiMartinezNo ratings yet

- TR70 Off-Highw Ay Truck Maintenance Manual: Click Here For Table ofDocument508 pagesTR70 Off-Highw Ay Truck Maintenance Manual: Click Here For Table ofMartinez100% (1)

- Banlaw Fuel-Track BrochureDocument4 pagesBanlaw Fuel-Track BrochureMartinezNo ratings yet

- Pioneers of Unified Fuel Management: Banlaw Products and Applica:onsDocument36 pagesPioneers of Unified Fuel Management: Banlaw Products and Applica:onsMartinezNo ratings yet

- TR70 Off-Highway Truck Maintenance Manual: Click Here For Table ofDocument508 pagesTR70 Off-Highway Truck Maintenance Manual: Click Here For Table ofMartinez100% (1)

- TR100 MMBook R13 Augl 191Document475 pagesTR100 MMBook R13 Augl 191MartinezNo ratings yet

- TR70 Tier 2 - 913Document476 pagesTR70 Tier 2 - 913MartinezNo ratings yet

- TR70 2004Document510 pagesTR70 2004MartinezNo ratings yet

- Tr70 MM Telr9131 June16.PDF PDocument478 pagesTr70 MM Telr9131 June16.PDF PMartinezNo ratings yet

- Fermi-Level Pinning and Charge Neutrality Level in GermaniumDocument4 pagesFermi-Level Pinning and Charge Neutrality Level in Germaniumbabu aggarwalNo ratings yet

- Ring Design Chapter08Document1 pageRing Design Chapter08ismail güleçNo ratings yet

- Making Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintDocument11 pagesMaking Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintGuian EitoNo ratings yet

- Table of Specification 9.4Document2 pagesTable of Specification 9.4Promise SalvatieraNo ratings yet

- Evaluating The Installation of Vibration and Temperature Monitoring Equipment For PumpsDocument46 pagesEvaluating The Installation of Vibration and Temperature Monitoring Equipment For PumpsAbdullah Sabry Azzam100% (1)

- Procedimiento de Reemplazo de CojinetesDocument32 pagesProcedimiento de Reemplazo de CojinetesJavier Hector CayaNo ratings yet

- Boost Glide and WaveriderDocument24 pagesBoost Glide and Waveriderbring it onNo ratings yet

- WB 40 LC Data SheetDocument8 pagesWB 40 LC Data SheetsandeepkhandarNo ratings yet

- Electric Drives and Control LabDocument6 pagesElectric Drives and Control LabParul ChandnaNo ratings yet

- The Evaluation of Wetting Agents: A Student ExperimentDocument2 pagesThe Evaluation of Wetting Agents: A Student ExperimentKrupali Umeshkumar KapadiyaNo ratings yet

- Astm C78 - Group10Document23 pagesAstm C78 - Group10Miyamura IzumiNo ratings yet

- Angle Construction Upper PrimaryDocument39 pagesAngle Construction Upper Primarybukenya MosesNo ratings yet

- Bab 4 OkeDocument16 pagesBab 4 OkeDwi amandaNo ratings yet

- Untitled NotebookDocument12 pagesUntitled NotebookPuffy KungNo ratings yet

- Lktyr235a01 PH I Adv 1Document28 pagesLktyr235a01 PH I Adv 1Atharva GuptaNo ratings yet

- Soal Uas Tek KoputasiDocument1 pageSoal Uas Tek KoputasiAdhe GedeNo ratings yet

- Quint4 5VDCDocument12 pagesQuint4 5VDCAndy Kong KingNo ratings yet

- Non Wovan PDFDocument16 pagesNon Wovan PDFVamsi SegamNo ratings yet

- Assignment QuestionDocument6 pagesAssignment QuestionChin Tiong LeeNo ratings yet

- RS-LiDAR-32 Brochure EN 20200306Document2 pagesRS-LiDAR-32 Brochure EN 20200306nazi1945No ratings yet

- 2005-Cutting Tool Materials For High Speed MachiningDocument7 pages2005-Cutting Tool Materials For High Speed MachiningSivi Karudijan100% (1)

- Casting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Document7 pagesCasting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Munem ShahriarNo ratings yet

- The Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFDocument116 pagesThe Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFKizuna L. ChanthavongNo ratings yet

- Wolfe WaveDocument3 pagesWolfe Wavemohamed ibrahimNo ratings yet

- Nonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiDocument66 pagesNonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiJorge Luis Garcia ZuñigaNo ratings yet

- Understanding Shaft Voltage and Grounding Currents of Turbine GeneratorsDocument12 pagesUnderstanding Shaft Voltage and Grounding Currents of Turbine GeneratorsArni 2020No ratings yet

- Grade 10 Lesson 3 Earthquake Seismic WaveDocument34 pagesGrade 10 Lesson 3 Earthquake Seismic Wavemae ann perochoNo ratings yet

- Topswitch: Designing Multiple Output Flyback Power Supplies WithDocument24 pagesTopswitch: Designing Multiple Output Flyback Power Supplies WithHải TrầnNo ratings yet

Maintenance Manual

Maintenance Manual

Uploaded by

MartinezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Manual

Maintenance Manual

Uploaded by

MartinezCopyright:

Available Formats

Engine 5

5.13 Centrifugal Oil Filter

(1) Maintenance

NOTICE

• The centrifugal cleaner’s rotor is caused to spin by the oil pressure. Particles of dirt are

forced against the wall. For location refer to Figure 5.1.

• When cleaning the centrifugal oil cleaner there will be some dirt deposits in the rotor cover.

This indicates that the rotor is working. If it is clean and not working, the cause must be

established immediately. If the dirt deposits exceed 28 mm (1.1 in) at the recommended

intervals, the rotor cover should be cleaned more often.

• Clean inside of cover and replace paper filter every 500 hours.

(2) Cleaning

� WARNING

• The oil may be hot. Carefully remove the cover from the centrifugal oil cleaner.

� CAUTION

• Take care not to damage the rotor shaft. The rotor must not be put in a vice. Never strike

the rotor cover. This may cause damage resulting in imbalance.

NOTICE

• When cleaning the centrifugal oil cleaner there will be some dirt deposits in the rotor cover.

If this is the case, this indicates that the rotor is working. If it is clean and not working,

the cause must be established immediately. If the dirt deposit exceeds 28 mm at the

recommended intervals, the rotor cover should be cleaned more often.

PROCEDURE

1. Clean the outside cover and remove the securing nut.

2. Let the oil run out from the rotor.

3. Lift out the rotor. Wipe off the outside. Undo the rotor nut and unscrew it about 1.5 turns to

protect the bearing. Refer to Figure 5.7.

4. If the rotor nut is difficult to get loose, turn the rotor upside down and fasten the rotor nut

in a vice. Turn the rotor counterclockwise 1.5 turns by hand or use an M20 nut. Refer

to Figure 5.8.

Maintenance Manual Revision 1.1 08-Aug-2019

TA300 T4F Gen10 Page 5-31

5 Engine

MOT04562 MOT04563

M20

x 1.5

x 1.5

Figure 5.7 - Figure 5.8 -

Centrifugal Oil Filter Removal Centrifugal Oil Filter Removal

5. Remove the rotor cover by holding the rotor in both hands and tapping the rotor nut

against the table. Never strike the rotor directly as this may damage its bearings. Refer

to Figure 5.9.

6. Remove the strainer from the rotor cover. If the strainer is stuck, insert a screwdriver

between the rotor cover and strainer and carefully pries them apart. Refer to Figure 5.10.

MOT04564 MOT04565

Figure 5.9 - Figure 5.10 -

Centrifugal Oil Filter Rotor - Removal Centrifugal Oil Filter Rotor - Removal

7. Remove the paper insert and scrape away any remaining dirt deposits inside the rotor

cover. If the deposits are thicker than 28 mm, the centrifugal oil cleaner must be cleaned

more often. Refer to Figure 5.11.

8. Wash the parts.

9. Inspect the 2 nozzles on the rotor. Ensure that they are not blocked or damaged. Renew

any damaged nozzles.

10. Check that the bearings are undamaged.

11. Fit a new paper insert on the inside of the rotor cover. Refer to Figure 5.12 and follow

steps 1 to 4.

08-Aug-2019 Revision 1.1 Maintenance Manual

Page 5-32 TA300 T4F Gen10

Engine 5

MOT04566 MOT04567

1

2 3 4

Figure 5.11 - Figure 5.12 -

Centrifugal Oil Filter - Cleaning Centrifugal Paper Filter

12. Fit the strainer onto the rotor.

13. Fit a new O-ring by sliding it over the strainer. Refer to Figure 5.13.

14. Refit the rotor cover. Ensure that the O-ring is not outside the cover.

15. Screw the rotor nut back on by hand.

16. Check that the shaft is not damaged or loose. If the shaft is damaged, it should be replaced.

Secure the shaft with thread-locking fluid if it is loose. First clean thoroughly using a suitable

solvent. Tighten the rotor shaft using a socket wrench. Torque tighten to 27 Nm (20 lbf ft.),

together with a ratchet head that is suitable for use during maintenance.

17. Refit the rotor and rotate it by hand to make sure it rotates easily.

18. Refit the oil cleaner housing. Tighten lock nut to 20 Nm (15 lbf ft.). Refer to Figure 5.14.

MOT04568 20 Nm MOT04569

Figure 5.13 - Figure 5.14 -

Centrifugal Oil Filter Assembly Centrifugal Oil Filter Assembly

(3) Operational Testing

Operational testing need only be carried out if there is a suspicion that the centrifugal oil cleaner

is not working properly. For example, if there is an abnormally small amount of deposit in the

centrifugal oil cleaner in relation to the distance driven.

The rotor rotates very fast and should continue to turn when the engine has stopped.

Maintenance Manual Revision 1.1 08-Aug-2019

TA300 T4F Gen10 Page 5-33

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GAT SampleDocument10 pagesGAT SampleMahnoor SajidNo ratings yet

- Can-Bus ControlDocument22 pagesCan-Bus ControlMartinezNo ratings yet

- J1939 Datalink 280509Document26 pagesJ1939 Datalink 280509MartinezNo ratings yet

- Rear Dump TruckDocument4 pagesRear Dump TruckMartinezNo ratings yet

- Central Lubrication System: BOM For Work Order BOM For Work OrderDocument2 pagesCentral Lubrication System: BOM For Work Order BOM For Work OrderMartinezNo ratings yet

- Diesel Particulate Filter System: Johnson MattheyDocument2 pagesDiesel Particulate Filter System: Johnson MattheyMartinezNo ratings yet

- D-1007 Doosan - ADT - Family - LitDocument20 pagesD-1007 Doosan - ADT - Family - LitMartinezNo ratings yet

- Rear Dump TruckDocument4 pagesRear Dump TruckMartinezNo ratings yet

- Integrated Electronic Controller Type EP-tronic: ContentsDocument14 pagesIntegrated Electronic Controller Type EP-tronic: ContentsMartinezNo ratings yet

- Central Lubrication System: BOM For Work Order BOM For Work OrderDocument2 pagesCentral Lubrication System: BOM For Work Order BOM For Work OrderMartinezNo ratings yet

- PU21578000517EN Service Handbuch 0517ENDocument32 pagesPU21578000517EN Service Handbuch 0517ENMartinezNo ratings yet

- Dearborn Protocol Adapter 4 Plus Dpa4Pma - Multi-Application Drivers Installation and User ManualDocument54 pagesDearborn Protocol Adapter 4 Plus Dpa4Pma - Multi-Application Drivers Installation and User ManualMartinezNo ratings yet

- Material DensitiesDocument2 pagesMaterial DensitiesMartinezNo ratings yet

- JM SCR Brochure 012909mDocument4 pagesJM SCR Brochure 012909mMartinezNo ratings yet

- Pre-Cleaners: No Matter What Dust Condition, Pre-Cleaners Extend Air Filter LifeDocument14 pagesPre-Cleaners: No Matter What Dust Condition, Pre-Cleaners Extend Air Filter LifeMartinezNo ratings yet

- 3950 LX-4 Progressive DistributorDocument10 pages3950 LX-4 Progressive DistributorMartinezNo ratings yet

- En Ta Artic Dump Trucks Filters Kit Brochure 0512 72dpiDocument15 pagesEn Ta Artic Dump Trucks Filters Kit Brochure 0512 72dpiMartinezNo ratings yet

- TR70 Off-Highw Ay Truck Maintenance Manual: Click Here For Table ofDocument508 pagesTR70 Off-Highw Ay Truck Maintenance Manual: Click Here For Table ofMartinez100% (1)

- Banlaw Fuel-Track BrochureDocument4 pagesBanlaw Fuel-Track BrochureMartinezNo ratings yet

- Pioneers of Unified Fuel Management: Banlaw Products and Applica:onsDocument36 pagesPioneers of Unified Fuel Management: Banlaw Products and Applica:onsMartinezNo ratings yet

- TR70 Off-Highway Truck Maintenance Manual: Click Here For Table ofDocument508 pagesTR70 Off-Highway Truck Maintenance Manual: Click Here For Table ofMartinez100% (1)

- TR100 MMBook R13 Augl 191Document475 pagesTR100 MMBook R13 Augl 191MartinezNo ratings yet

- TR70 Tier 2 - 913Document476 pagesTR70 Tier 2 - 913MartinezNo ratings yet

- TR70 2004Document510 pagesTR70 2004MartinezNo ratings yet

- Tr70 MM Telr9131 June16.PDF PDocument478 pagesTr70 MM Telr9131 June16.PDF PMartinezNo ratings yet

- Fermi-Level Pinning and Charge Neutrality Level in GermaniumDocument4 pagesFermi-Level Pinning and Charge Neutrality Level in Germaniumbabu aggarwalNo ratings yet

- Ring Design Chapter08Document1 pageRing Design Chapter08ismail güleçNo ratings yet

- Making Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintDocument11 pagesMaking Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintGuian EitoNo ratings yet

- Table of Specification 9.4Document2 pagesTable of Specification 9.4Promise SalvatieraNo ratings yet

- Evaluating The Installation of Vibration and Temperature Monitoring Equipment For PumpsDocument46 pagesEvaluating The Installation of Vibration and Temperature Monitoring Equipment For PumpsAbdullah Sabry Azzam100% (1)

- Procedimiento de Reemplazo de CojinetesDocument32 pagesProcedimiento de Reemplazo de CojinetesJavier Hector CayaNo ratings yet

- Boost Glide and WaveriderDocument24 pagesBoost Glide and Waveriderbring it onNo ratings yet

- WB 40 LC Data SheetDocument8 pagesWB 40 LC Data SheetsandeepkhandarNo ratings yet

- Electric Drives and Control LabDocument6 pagesElectric Drives and Control LabParul ChandnaNo ratings yet

- The Evaluation of Wetting Agents: A Student ExperimentDocument2 pagesThe Evaluation of Wetting Agents: A Student ExperimentKrupali Umeshkumar KapadiyaNo ratings yet

- Astm C78 - Group10Document23 pagesAstm C78 - Group10Miyamura IzumiNo ratings yet

- Angle Construction Upper PrimaryDocument39 pagesAngle Construction Upper Primarybukenya MosesNo ratings yet

- Bab 4 OkeDocument16 pagesBab 4 OkeDwi amandaNo ratings yet

- Untitled NotebookDocument12 pagesUntitled NotebookPuffy KungNo ratings yet

- Lktyr235a01 PH I Adv 1Document28 pagesLktyr235a01 PH I Adv 1Atharva GuptaNo ratings yet

- Soal Uas Tek KoputasiDocument1 pageSoal Uas Tek KoputasiAdhe GedeNo ratings yet

- Quint4 5VDCDocument12 pagesQuint4 5VDCAndy Kong KingNo ratings yet

- Non Wovan PDFDocument16 pagesNon Wovan PDFVamsi SegamNo ratings yet

- Assignment QuestionDocument6 pagesAssignment QuestionChin Tiong LeeNo ratings yet

- RS-LiDAR-32 Brochure EN 20200306Document2 pagesRS-LiDAR-32 Brochure EN 20200306nazi1945No ratings yet

- 2005-Cutting Tool Materials For High Speed MachiningDocument7 pages2005-Cutting Tool Materials For High Speed MachiningSivi Karudijan100% (1)

- Casting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Document7 pagesCasting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Munem ShahriarNo ratings yet

- The Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFDocument116 pagesThe Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFKizuna L. ChanthavongNo ratings yet

- Wolfe WaveDocument3 pagesWolfe Wavemohamed ibrahimNo ratings yet

- Nonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiDocument66 pagesNonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiJorge Luis Garcia ZuñigaNo ratings yet

- Understanding Shaft Voltage and Grounding Currents of Turbine GeneratorsDocument12 pagesUnderstanding Shaft Voltage and Grounding Currents of Turbine GeneratorsArni 2020No ratings yet

- Grade 10 Lesson 3 Earthquake Seismic WaveDocument34 pagesGrade 10 Lesson 3 Earthquake Seismic Wavemae ann perochoNo ratings yet

- Topswitch: Designing Multiple Output Flyback Power Supplies WithDocument24 pagesTopswitch: Designing Multiple Output Flyback Power Supplies WithHải TrầnNo ratings yet