Professional Documents

Culture Documents

Glossary

Glossary

Uploaded by

Magin Idelfonso TorreblancaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glossary

Glossary

Uploaded by

Magin Idelfonso TorreblancaCopyright:

Available Formats

Glossary

Glossary

Abbrasion Resistance: Ability to with- compounds of the ethylene and acety-

stand the effects of repeated wearing, lene series.

rubbing, scraping, etc.

Alkyd Resins: A class of resins pro-

ABS: Acrylonitrile-butadiene-styrene duced by condensation of a polybasic

acid or anhydride and a polyhydric

Acceptance Test: An investigation alcohol.

performed on an individual lot of a

previously qualified product, by, or Allyl Resins: A class of resins produced

under the observation of, the purchaser from an ester or other derivative of allyl

to establish conformity with a purchase alcohol by polymerization.

agreement.

Alternate Product: A product whose

Acetal Plastics: Plastics based on use is restricted to incidences where the

resins having a predominance of acetal approved components will not satisfy

linkages in the main chain. the needs of the system.

Acids: One of a class of substances Anneal: To prevent the formation of or

compounded of hydrogen and one or remove stresses in plastic parts by

more other elements, capable of uniting controlled cooling from a suitable

with a base to form a salt, and in temperature.

aqueous solution, turning blue litmus

paper red. Antioxidant: A compounding ingredi-

ent added to a plastic composition to

Acrylate Resins: A class of thermoplas- retard possible degradation from

tic resins produced by polymerization of contact with oxygen (air), particularly in

acrylic and acid derivatives. processing at or exposures to high

temperatures.

Acrylonitrile-Butadiene-Sytrene (ABS)

Pipe and Fitting Plastics: Plastics Approved Product: A product that has

containing polymers and/or blends of been designated for selection, installa-

polymers, in which the minimum butadi- tion and use within an Intel UPW system.

ene content is 6 percent, the minimum

acrylonitrile content is 15 percent, the Aromatic: A large class of cyclic

minimum styrene and/or substituted organic compounds derived from, or

styrene content is 15 percent, and the characterized by the presence of the

maximum content of all other monomers benezene ring and its homologs.

is not more than 5 percent, and lubri-

cants, stabilizers and colorants. Artificial Weathering: The exposure of

plastics to cyclic laboratory conditions

Adhesive: A substance capable of involving changes in temperature,

holding materials together by surface relative humidity, and ultraviolet radiant

attachment. energy, with or without direct water

spray, in an attempt to produce changes

Adhesive, solvent: An adhesive having in the material similar to those observed

a volatile organic liquid as a vehicle. after long-term continuous outdoor

exposure.

Aging: The effect of time on plastics

exposed indoors at ordinary conditions ASTM: American Society for Testing

of temperature and relatively clean air. Materials

Alkalies: Compounds capable of BCF: Bead and Crevice Free, or a

neutralizing acids and usually character- welding technique offered within the

ized by an acrid taste. Can be mild like range of SYGEF® HP products.

baking soda or highly caustic like lye.

Bell End: The enlarged portion of a

Aliphatic: Derived from or related to pipe that resembles the socket portion of

fats and other derivatives of the parrafin a fitting and that is inteded to be used

hydrocarbons, including unsaturated to make a joint by inserting a pieced of 20

www.us.piping.georgefischer.com 20.1

20_ALL 1 6/7/02, 3:27 PM

pipe into it. Joining may be accom- called a catalyst.

plished by solvent cements, adhesives,

or mechanical techniques. Cellulose: Inert substance, chemically a

carbohydrate, which is the chief compo-

Beam Loading: The application of a nent of the solid structure of plants,

load to a pipe between two pints of wood, cotton, linen, etc.

support, usually expressed in pounds

and the distance between the centers of Cellulose Acetate: A class of resins

the supports. made from a cellulose base, either

cotton linters or purified wood pulp, by

Blister: Undesirable rounded elevation the action of acetic anhydride and

of the surface of a plastic, whose acetic acid.

boundaries may be either more or less

sharply defined, somewhat resembling Cement: A dispersion of “solution” of

in shape or blister on the human skin. A unvulcanized rubber or a plastic in a

blister may burst and become flattened. volatile solvent. This meaning is peculiar

to the plastics and rubber industries and

Bond: To attach by means of an may or may not be an adhesive compo-

adhesive. sition.

Burned: Showing evidence of thermal Centipoise: A subunit of the poise, P, the

decomposition through some discolora- unit of viscosity in the cgs system not

tion, distortion, or destruction of the preferred in the International units

surface of the plastic. standard. 1P=0.1 N s/m2 = 0.1Pa s, (or

0.1 pascal-second) 1cP=0.001 N s/m2

Burst Strength: The internal pressure = 0.001 Pa s or m Pa s

required to break a pipe or fitting. This

pressure will vary with the rate of build- Certificate of Analysis: A certification

up of the pressure and the time during from the manufacturer of a product that

which the pressure is held. it has been tested against a specified

standard and meets the requirements.

Butylene Plastics: Plastics based on

resins made by the polymerization of Certificate of Compliance: A certifi-

butene or copolymerization of butene cate from the manufacturer of a product

with one or more unsaturated com- that it meets the requirements based on

pounds, the butene being in in greatest previous testing and manufacturing

amount by weight. process.

CA: Cellulose acetate Chemical Resistance: (1) The effect of

specific chemicals on the properties of

CAB: Cellulose acetate butyrate plastic piping with respect to concentra-

tion, temperature and time of exposure.

CAP: Cellulose acetate propionate (2) The ability of a specific plastic pipe

to render service for a useful period in

Calendering: A process by which a the transport of a specific chemical at a

heated rubber plastic product is specified concentration and tempera-

squeezed between heavy rollers into a ture.

thin sheet or film. The film may be

frictioned into the interstices of cloth, or Class 1000 (example): The level of

it may be coated onto cloth or paper. cleanliness as defined in Federal Stan-

dard 209E equivalent to allowing no

Cast Resin: A resinous product pre- more than 1000 particles of a size

pared by pouring liquid resins into a greater than or equal to 0.5 micron per

mold and heat-treating the mass to cubic foot of air. The smaller the class

harden it. number the cleaner the area. A class

100 area would only be allowed 100 of

Catalysis: The acceleration (or retarda- such particles per cubic foot of air.

tion) of the speed of a chemical reaction

by the presence of a comparatively

small amount of a foreign substance

20.2 ¬ ‡

20_ALL 2 6/7/02, 3:27 PM

Glossary

Clean Room: A particle controlled area cal additives.

which has filtered air being supplied to

maintain a specified level of cleanliness

or class. Deflection Temperature: The tempera-

ture at which a specimen will deflect a

cm: centimeter, or the basic length unit given distance at a given load under

of the International system prescribed conditions of test.

CMC: Carboxymethyl cellulose Degradation: A deleterious change in

the chemical structure of a plastic.

CN: Cellulose nitrate

Delamination: The separation of the

Coalescence: The union or fusing layers of material in a laminate.

together of fluid globules or particles to

form larger drops or a continuous mass. Deterioration: A permanent change in

the physical properties of a plastic

Cold Flow: Change in dimensions or evidenced by impairment of these

shape of some materials when subjected properties.

to external weight or pressure at room

temperature. Dielectric Constant: Specific inductive

capacity. The dielectric constant of a

Compound: A combination of ingredi- material is the ratio of the capacitance

ents before being processed or made of a condenser having that material as

into a finished product. Sometimes used dielectric to the capacity of the same

as a synonym for material, formulation. condenser having a vacuum as dielec-

tric.

Condensation: A chemical reaction in

which two or more molecules combine, Dielectric Strength: This is the force

usually with the separation of water or required to drive an electric current

some other substance. through a definite thickness of the

material; the voltage required to break

Copolymer: The product of simulta- down a specified thickness of insulation.

neous polymerization of two or more

polymerizeable chemicals, commonly Diffusion: The migration or wandering

known as monomers. of the particles or molecules of a body

of fluid matter away from the main body

CP: Cellulose propionate through a medium or into another

medium.

CPVC: Chlorinated polyvinyl chloride

Dimension Ratio: The diameter of a

CR: Chloroprene rubber (Neoprene®) pipe divided by the wall thickness. Each

pipe can have two dimension ratios

Crazing: Fine cracks at or under the depending on whether the outside or

surface of a plastic. inside diameter is used. In practice, the

outside diameter is used if the stan-

Creep: The unit elongation of a particu- dards requirement and manufacturing

lar dimension under load for a specific control are based on this diameter. The

time following the initial elastic elonga- inside diameter is used when this mea-

tion caused by load application. It is surement is the controlling one.

expressed usually in inches per inch per

unit of time. Dimensional Stability: Ability of a

plastic part to maintain its original

CS: Casein proportions under conditions of use.

CSM: Chlorine sulphonyl polyethylene Dry-Blend: A free-flowing dry com-

(Hypalon®) pound prepared without fluxing or

addition of solvent.

Cure: To change the properties of a

polymeric system into a final, more Durometer: Trade name of the Shore

stable, usable condition by the use of Instrument Company for the instrument 20

heat, radiation, or reaction with chemi- that measures hardness. The rubber or

www.us.piping.georgefischer.com 20.3

20_ALL 3 6/7/02, 3:27 PM

plastics durometer determines the ethylene or copolymerization of ethylene

“hardness” of rubber or plastics by with one or more unsaturated com-

measuring the depth of penetration pounds, the ethylene being in greatest

(without puncturing) of blunt needles amount by weight.

compressed on the surface for a short

period of time. Extrusion: Method of processing

plastic in a continuous or extended form

EC: Ethyl cellulose by forcing heat-softened plastic through

an opening shaped like the cross-

ECTFE: Ethylene chlorotrifluoroethylene section of the finished project.

(Halar®)

Extender: A material added to a

Elastic Limit: The load at which a plastic composition to reduce its cost.

material will no longer return to its

original form when the load is released.

Fabricate: Method of forming a plastic

Elastomer: The name applied to into a finished article by machining,

substances having rubberlike properties. drawing and similar operations.

Electrical Properties: Primarily the Failure, adhesive: Rupture of an

resistance of a plastic to the passage of adhesive bond, such that the place of

electricity, e.g. dielectric strength. separation appears to be at the adhe-

sive-adherence interface.

Elevated Temperature Testing: Tests

on plastic pipe above 23°C (73°F). Federal Standard 209E: A US federal

standard which specifies clean rooms

Elongation: The capacity to take and clean room production.

deformation before failure in tension

and is expressed as a percentage of the FEP: Fluorinated ethylene propylene

original length.

Fiber Stress: The unit stress, usually in

Emulsion: A dispersion of one liquid in pounds per square inch (psi), in a piece

another — possibly only when they are of material that is subjected to external

mutually insoluble. load.

Environmental Stress Cracking: Filler: A material added to a plastic

Cracks that develop when the material composition to impart certain qualities in

is subjected to stress in the presence of the finished article.

specific chemicals.

Flexural Strength: The outer fiber stress

EP: Epoxide, epoxy which must be attained in order to

produce a given deformation under a

EPDM: Ethylene propylene rubber beam load.

EPSS: Electropolished stainless steel Fluorocarbon: See Fluoropolymer

Ester: A compound formed by the Fluoropolymer: Also known as fluoro-

elimination of waste during the reaction carbon. Any of a number of organic

between an alcohol and an acid; many compounds analogous to hydrocarbons,

esters are liquids. They are frequently in which the hydrogen atoms have been

used as plasticizers in rubber and plastic replaced by fluorine. However, in the

compounds. context of this documentation they are

limited to the plastic materials used to

Ethyl Cellulose: A thermoplastic create components for piping systems.

material prepared by the ethylation of

cellulose by diethyl sulfate halides and Formulation: A combination of ingredi-

alkali. ents before being processed or made

into a finished product. Sometimes used

Ethylene Plastics: Plastics based on as a synonym for material, compound.

resins made by the polymerization of FPM: Fluorine rubber (Viton®)*

20.4 ¬ ‡

20_ALL 4 6/7/02, 3:27 PM

Glossary

imposed on a cylindrical wall by internal

ft: foot, or the basic length unit of the pressure loading.

English system

HP1: (primary meaning) High purity, or

Fungi Resistance: The ability of plastic the manufacturing and use of a product

pipe to withstand fungi growth and/or in its purest state.

their metabolic products under normal

conditions of service or laboratory tests HP2: (secondary meaning) Laminated

simulating such conditions. paper

Fuse: To join two plastic parts by Hydrostatic Design Stress: The esti-

softening the material by heat or sol- mated maximum tensile stress in the wall

vents. of the pipe in the circumferential orienta-

tion due to internal hydrostatic pressure

that can be applied continuously with a

g: gram, or the basic mass (absolute high degree of certainty that failure of

weight) unit of the International system the pipe will not occur.

Generic: Common names for types of Hydrostatic Strength (quick): The hoop

plastic materials. They may be either stress calculated by means of the ISO

chemical terms or coined names. They equation at which the pipe breaks due

contrast with trademarks which are the to an internal pressure build-up, usually

property of one company. within 60 to 90 seconds.

gf: gram-force, or the conventional Hz: hertz, or 1 cycle per second

gravitational force units used in technol-

ogy and engineering in the cgs system

but not the International system IIR: Isobutene isoprene (butyl) rubber

GPM: U.S. gallons per minute Impact, Izod: A specific type of impact

test made with a pendulum type ma-

chine. The specimens are molded or

Hardness: A comparative gauge of extruded with a machined notch in the

resistance to identation, not of surface center.

hardness or abrasion resistance.

Impact Strength: Resistance or me-

HDPE: High-density polyethylene chanical energy absorbed by a plastic

part to such shocks as dropping and

Heat Joining: Making a pipe joint by hard blows.

heating the edges of the parts to be

joined so that they fuse and become Impact, Tup: A falling weight (tup)

essentially one piece with or without the impact test developed specifically for

use of additional material. pipe and fittings. There are several

variables that can be selected.

Heat Resistance: The ability to with-

stand the effects of exposure to high Impermeability: Permitting no passage

temperature, Care must be exercised in into or through a material.

defining precisely what is meant when

this term is used. Descriptions pertaining Impurity: Any unwanted or potentially

to heat resistance properties include: damaging material or substance which

boilable, washable, cigaretteproof, could be present in an ultrapure water

sterilizable, etc. component or system.

HEPA: High Efficiency Particulate Air, or Injection Molding: A method of repeti-

one method of filtration used to achieve tively producing similar objects by

clean room conditions. means of forcing molten plastic into a

cavity known as a mold. The inside

Hoop Stress: The circumferential stress surface of the component is formed by

the core.

20

www.us.piping.georgefischer.com 20.5

20_ALL 5 6/7/02, 3:27 PM

IR: Infrared, or a welding technique of German technology which uses the

offered within the range of SYGEF® symbol “kp”.

HP products.

kp: see kgf

ISO: International Organization for

Standardization. The scope of ISO KYNAR® A trade name for the raw

9001 is to specify the quality system polyvinylidene fluoride material pro-

requirements for use where a supplier's duced by Elf Atochem.

capability to design and supply con-

forming product must be demonstrated.

These requirements are aimed at achiev- lb.: pound, or the basic mass (absolute

ing customer satisfaction by preventing weight) unit of the English system

nonconformity at all stages from design

through to servicing. ISO 9001 Quality lbf: pound-force, or the conventional

Systems are a model for quality assur- gravitational force units used in technol-

ance in design, development, produc- ogy and engineering in the English

tion, installation and servicing whereas system

ISO 9002 focuses on production,

installation and servicing. Leach Out: The test method of filling a

container or component to be tested

ISO Equation: An equation showing with ultrapure water, waiting a specified

the interrelations between stress, pres- period of time and analyzing the impu-

sure and dimensions of pipe, namely rity content.

Light Stability: Ability of a plastic to

P(ID + t) P(OD - t) retain its original color and physical

S= or properties upon exposure to sun or

2t 2t

where: artificial light.

S = stress

P = pressure Light Transmission: The amount of light

ID = average inside diameter that a plastic will pass.

OD = average outside diameter

t = minimum wall thickness Longitudinal Stress: The stress im-

posed on the long axis of any shape. It

can be either a compressive or tensile

J: The joule of newton-meter is the stress.

International unit of energy or work of

thermal, electrical, mechanical or Long-Term Hydrostatic Strength: The

chemical origin. A force of 1 newton estimated tensile stress in the wall of the

over a distance of 1 meter produces 1 pipe in the circumferential orientation

newton meter or 1 joule of energy. (hoop stress) that when applied continu-

1J=1Nm ously will cause failure of the pipe at

100,000 hours (11 .43 years). These

strengths are usually obtained by

Ketones: Compounds containing the extrapolation of log-log regression

carbonyl group (CO) to which is at- equations or plots.

tached two alkyl groups. Ketones, such

as methyl ethyl ketone, are commonly LPM: Liters per minute

used as solvents for resins and plastics.

Lubricant: A substance used to de-

kg: kilogram, or the basic mass (abso- crease the friction between solid faces

lute weight) unit of the International and sometimes used to improve process-

system ing characteristics of plastic composi-

tions.

kgf: kilogram-force, or the conventional

gravitational force units used in technol-

ogy and engineering in the mks system m: meter, or the basic length unit of the

but not the International system. The International system

kilogram force is equal to the “kilo-pond”

Melt Flow Index: A measure of the

flowing ability of a plastic material at a

20.6 ¬ ‡

20_ALL 6 6/7/02, 3:27 PM

Glossary

specified temperature and pressure.

Nm: see J (or joule)

Melt Point: The temperature at which a

material melts. Non-Flammable: Will not support

combustion.

MF: Melamine formaldehyde

Nonrigid Plastic: A plastic which has a

Modulus: The load in pounds per stiffness or apparent modulus of elastic-

square inch or kilos per square centime- ity of not over 10,000 psi at 23°C which

ter of initial cross-sectional area neces- determined in accordance with the

sary to produce a stated percentage- Standard Method of Test for Stiffness in

elongation which is used in the physical Flexure of Plastics.

testing of plastics.

Non-Toxic: Non-poisonous.

Moisture Resistance: Ability to resist

absorption of water. NR: Natural rubber

Molding, Compression: A method of Nylon Plastics: Plastics based on resins

forming objects from plastics by placing composed principally of a long-chain

the material in a confining mold cavity synthetic polymeric amide which has

and applying pressure and usually heat. recurring amide groups as an integral

part of the main polymer chain.

Molding, Injection: A method of

forming plastics from granular or pow-

dered plastics by the fusing of plastic in Olefin Plastics: Plastics based on resins

a chamber with heat and pressure and made by the polymerization of olefins or

then forcing part of the mass into a copolymerization of olefins with other

cooler chamber where it solidifies. unsaturated compounds, the olefins

being in greatest amount by weight.

Note: This method is commonly used to Polyethylene, polypropylene and

form objects from thermoplastics. polybutylene are the most common

olefin plastics encountered in pipe.

Monomer: A relatively simple chemical

which can react to form a polymer. Orange-Peel: Uneven surface some-

what resembling an orange peel.

N: Newton, or the basic force unit of the Organic Chemical: Originally applied

mks metric system used throughout the to chemicals derived from living organ-

Standard International System. The isms, as distinguished from “inorganic”

newton is the analog of the poundal chemicals found in minerals and inani-

and the dyne, the more “scientific” force mate substances; modern chemists

units of the English and cgs systems define organic chemicals more exactly

which produce unit acceleration of unit as those which contain the element

mass. The force of 1 newton accelerates carbon.

1 kilogram at 1 meter/second2.

1N=1kg x 1 m/s2. Outdoor Exposure: Plastic pipe placed

in service or stored so that it is not

N/m2 (or Pa) - the pascal (Pa) is the protected from the elements of normal

International unit of force/area (stress or weather conditions, i.e., the sun’s rays,

pressure) expressed equivalently as the rain, air and wind. Exposure to indus-

newton per square meter. The choice trial and waste gases, chemicals, engine

was to avoid the use of the pascal as exhausts, etc. are not considered normal

neither particulary useful or informative, “outdoor exposure.”

and stress is expressed as N/cm2 , a

valid submultiple of N/m2,

although it is not a “preferred” form in P: see cP

the International units standard.

1Pa=1N/m21N/cm2=10kN/m2 (where PA: Polyamide

kN = kilonewtons = 1,000 newtons)

Pa: see N/m2 20

NBR: Nitrile (butadiene) rubber

www.us.piping.georgefischer.com 20.7

20_ALL 7 6/7/02, 3:27 PM

PMMA: Polymethyl methacrylate

PB: Polybutylene

Polybutylene: A polymer prepared by

PC: Polycarbonate the polymerization of butene-1 as the

sole monomer.

PCTFE: Polychlorotrifluoroethylene

Polybutylene Plastics: Plastics based

PDAP: Polydiallyl phthalate on polymers made with butene-1 as

essentially the sole monomer.

PEC: Chlorinated polyethylene

Polyethylenes: A class of resins formed

Permanence: The property of a plastic by polymerizing ethylene, a gas ob-

which describes its resistance to appre- tained from petroleum hydrocarbons.

ciable changes in characteristics with

time and environment. Polymer: A product resulting from a

chemical change involving the succes-

PETP: Polyethylene terephthalate sive addition of a large number of

relatively small molecules (monomer) to

PF: Phenol-formaldehyde form the polymer, and whose molecular

weight is usually a multiple of that of the

PFA: Perfluoroalkoxy resin original substance.

PIB: Polyisobutylene Polymerization: Chemical change

resulting in the formation of a new

Phenolic Resins: Resins made by compound whose molecular weight is

reaction of a phenolic compound or tar usually a multiple of that of the original

acid with an aldehyde; more commonly substance.

applied to thermosetting resins made

from pure phenol. Polyolefin: A polymer prepared by the

polymerization of an olefin(s) as the sole

Plasticity: A property of plastics and monomer(s).

resins which allows the material to be

deformed continuously and permanently Polyolefin Plastics: Plastics based on

without rupture upon the application of polymers made with an olefin(s) as

a force that exceeds the yield value of essentially the sole monomer(s).

the material.

Polypropylene: A polymer prepared

Plasticizer: A liquid or solid incorpo- by the polymerization of propylene as

rated in natural and synthetic resins and the sole monomer.

related substances to develop such

properties as resiliency, elasticity and Polypropylene Plastics: Plastics based

flexibility. on polymers made with propylene as the

sole monomer.

Plastics Conduit: Plastic pipe or tubing

used as an enclosure for electrical Polystyrene: A plastic based on a resin

wiring. made by polymerization of styrene as

the sole monomer.

Plastics Pipe: A hollow cylinder of a

plastic material in which the wall thick- Note: Pollystyrene may contain minor

nesses are usually small when compared proportions of lubricants, stabilizers,

to the diameter and in which the inside fillers, pigments and dyes.

and outside walls are essentially con-

centric. Polyvinyl Chloride: Polymerized vinyl

chloride, a synthetic resin, which when

Platics Tubing: A particular size of plasticized or softened with other

plastics pipe in which the outside chemicals has some rubber-like proper-

diameter is essentially the same as that ties. It is derived from acetylene and

of copper tubing.

20.8 ¬ ‡

20_ALL 8 6/7/02, 3:27 PM

Glossary

anhydrous hydrochloric acid. PVDC: Polyvinylidene chloride

Polyvinyl Chloride Plastics: Plastics PVDF: Polyvinylidene fluoride, or the

made by combining polyvinyl chloride fluoropolymer (plastic) material itself

with colorants, fillers, plasticizers, used in either extruding, injection mold-

stabilizers, lubricants, other polymers ing or machining of SYGEF® HP prod-

and other compounding ingredients. ucts.

Not all of these modifiers are used in

pipe compounds. PVF: Polyvinyl fluoride

POM: Polyoxymethylene (Kematal®) PVFM: Polyvinyl formal

Porosity: Presence of numerous visible PVK: Polyvinyl carbazol

voids.

Power Factor: The ratio of the power in Qualification Test: An investigation,

watts delivered in an alternating current independent of a procurement action,

circuit (real power) to the voltampere performed on a product to determine

input (apparent power). The power whether or not the product conforms to

factor of an insulation indicates the all requirements of the applicable

amount of the power input which is specification.

consumed as a result of the impressed

voltage forcing a small leakage current Note: The examination is usually

through the material. conducted by the agency responsible

for the specification, the purchaser, or by

PP: Polypropylene a facility approved by the purchaser, at

the request of the supplier seeking

Pressure: When expressed with refer- inclusion of his product on a qualified

ence to pipe the force per unit area products list.

exerted by the medium in the pipe.

Quick Burst: The internal pressure

Pressure Rating: The estimated maxi- required to burst a pipe or fitting due to

mum pressure that the medium in the an internal pressure build-up, usually

pipe can exert continuously with a high within 60 to 70 seconds.

degree of certainty that failure of the

pipe will not occur.

Resilience: Usually regarded as

Propylene Plastics: Plastics based on another name for elasticity. While both

resins made by the polymerization of terms are fundamentally related, there is

propylene or copolymerization of a distinction in meaning. Elasticity is a

propylene with one or more other general term used to describe the

unsaturated compounds, the propylene property of recovering original shape

being in greatest amount by weight. after a deformation. Resilience refers

more to the energy of recovery; that is, a

PS: Polystyrene body may be elastic but not highly

relient.

PTFE: Polytetrafluoroethylene (Teflon®)

Resin: An organic substance, generally

PUR: Polyurethane synthetic, which is used as a base

material for the manufacture of some

PVAC: Polyvinyl acetate plastics.

PVAL: Polyvinyl alcohol Reworked Material: A plastic material

that has been reprocessed, after having

PVB: Polyvinyl butyral been previously processed by molding,

extrusions, etc., in a fabricator’s plant.

PVC: Polyvinyl chloride

Rigid Plastic: A plastic which has a

PVCA: Polyvinyl chloride acetate stiffness or apparent modulus of elastic-

ity greater than 100,000 psi at 23°C 20

www.us.piping.georgefischer.com 20.9

20_ALL 9 6/7/02, 3:27 PM

when determined in accordance with and low relative humidities and ultravio-

the Standard Method of Test for Stiffness let radiant energy in an attempt to

in Flexure of Plastics. produce changes in their properties

similar to those observed on long-term

Rubber: A material that is capable of continuous exposure outdoors. The

recovering from large deformations laboratory exposure conditions are

quickly and forcibly. usually intensified beyond those encoun-

tered in actual outdoor exposure in an

attempt to achieve an accelerated

Sample: A small part or portion that is effect.

capable of recovering from large

deformations quickly and forcibly. Simulated Aging: The exposure of

plastics to cyclic laboratory conditions

SAN: Styrene-acrylonitrile of high and low temperatures, and high

and low relative humidities in an attempt

Saran Plastics: Plastics based on resins to produce changes in their properties

made by the polymerization of vi- similar to those observed on long-time

nylidene chloride or copolymerization of continuous exposure to conditions of

vinylidene chloride with other unsatur- temperature and relative humidity

ated compounds, the vinylidene chloride commonly encountered indoors or to

being in greatest amount of weight. obtain an acceleration of the effects of

ordinary indoor exposure. The labora-

SB: Styrene-butadiene tory exposure conditions are usually

intensified beyond those actually en-

Schedule: A pipe size system (outside countered in an attempt to achieve an

diameters and wall thicknesses) origi- accelerated effect.

nated by the iron pipe industry.

Softening Range: The range of tem-

Self-Extinguishing: The ability of a perature in which a plastic changes from

plastic to resist burning when the source a rigid to a soft nature.

of heat or flame that ignited it is re-

moved. Note: Actual values will depend on the

method of test. Sometimes referred to as

SEMATECH: Semiconductor Manufac- softening point.

turing Technology Corporation, or a

consortium of member semiconductor SOLEF®: A trade name for the raw

companies joined together to exchange polyvinylidene fluoride material pro-

technology for the advancement of duced by SOLVAY.

semiconductor production. SEMATECH is

located in Austin, Texas. Solvent: The medium within which a

substance is dissolved; most commonly

Service Factor: A factor which is used applied to liquids used to bring particu-

to reduce a strength value to obtain an lar solids into solution, e.g., acetone is a

engineering design stress. The factor solvent for PVC.

may vary depending on the service

conditions, the hazard, the length of Solvent Cement: In the plastic piping

service desired and the properties of the field, a solvent adhesive that contains a

pipe. solvent that dissolves or softens the

surfaces being bonded so that the

Set: To convert an adhesive into a fixed bonded assembly becomes essentially

or hardened state by chemical or one piece of the same type of plastic.

physical action, such as condensation,

polymerization, oxidation, vulcanization, Solvent Cementing: Making a pipe

gelatin, hydration or evaporation of joint with a solvent cement.

volatile constituents.

Specific Gravity: Ratio of the mass of a

SI: Silicone body to the mass of an equal body of

volume of water at 4°C, or some other

Simulated Weathering: The exposure specified temperature.

of plastics to cyclic laboratory condi-

tions of high and low temperatures, high

20.10 ¬ ‡

20_ALL 10 6/7/02, 3:27 PM

Glossary

Specific Heat: Ratio of the thermal Stiffness Factor: A physical property of

capacity of a substance to that of water plastic pipe that indicates the degree of

at 15°C. flexibility of the pipe when subjected to

external loads.

Specimen: An individual piece or

portion of a sample used to make a Strain: The ratio of the amount of

specific test. Specific tests usually deformation to the length being de-

require specimens of specific shape and formed caused by the application of a

dimensions. load on a piece of material.

Stabilizer: A chemical substance which Strength: The mechanical properties of

is frequently added to plastic com- a plastic, such as a load or weight-

pounds to inhibit undesirable changes in carrying ability, and ability to withstand

the material, such as discoloration due sharp blows. Strength properties

to heat or light. include tensile, flexural and tear strength,

toughness, flexibility, etc.

Standard Dimension Ratio: A selected

series of numbers in which the dimension Stress: When expressed with reference

ratios are constants for all sizes of pipe to pipe the force per unit area in the

for each standard dimension, ratio and wall of the pipe in the circumferential

which are the USASI Preferred Number orientation due to internal hydrostatic

Series 10 modified by +1 or -1 . If the pressure.

outside diameter (OD) is used the

modifier is +1 . If the inside diameter (ID) Stress-Crack: External or internal cracks

is used the modifier is -1 . in a plastic caused by tensile stresses

less than that of its short-term mechani-

Standard Thermoplastic Pipe Materi- cal strength.

als Designation Code: A means for

easily identifying a thermoplastic pipe Note: The development of such cracks

material by means of three elements. is frequently accelerated by the environ-

The first element is the abbreviation for ment to which the plastic is exposed.

the chemical type of the plastic in The stresses which cause cracking may

accordance with ASTM D-1600. The be present internally or externally or

second is the type and grade (based on may be combinations of these stresses.

properties in accordance with the ASTM The appearance of a network of fine

materials specification): in the case of cracks is called crazing.

ASTM specifications which have no

types and grades or those in the cell Stress Relaxation: The decrease of

structure system, two digit numbers are stress with respect to time in a piece of

assigned by the PI that are used in plastic that is subject to an external

place of the larger numbers. The third is load.

the recommended hydrostatic design

stress (RHDS) for water at 23°C (73°F) in Styrene Plastics: Plastics based on

pounds per square inch divided by 100 resins made by the polymerization of

and with decimals dropped, e.g., PVC styrene or copolymerization of styrene

1120 indicates that the plastic in polyvi- with other unsaturated compounds, the

nyl chloride, Type I, Grade 1 according styrene being in greatest amount by

to ASTM D-1748 with a RHDS of 2000 weight.

psi for water at 73°F. PE 3306 indicates

that the plastic is polyethylene. Type III Styrene-Rubber (SR) Pipe and Fittings

Grade 3 according to ASTM D-1248 Plastics: Plastics containing at least 50

with a RHDS of 630 psi for water at percent styrene plastics combined with

73°F. PP 1208 is polypropylene. Class I- rubbers and other compounding materi-

19509 in accordance with ASTM D-2146 als, but not more than 15 percent

with a RHDS of 800 psi for water at acrylonitrile.

73°F; the designation of PP 12 for

polypropylene Class I-19509 will be Styrene-Rubber Plastics: Compositions

covered in the ASTM and Product based on rubbers and styrene plastics,

Standards for polypropylene pipe when the styrene plastics being in greatest

they are issued. amount by weight. 20

www.us.piping.georgefischer.com 20.11

20_ALL 11 6/7/02, 3:27 PM

Sustained Pressure Test: A constant Further heating will not soften these

internal pressure test for 1000 hours. materials.

SYGEF® HP: A Georg Fischer trade Translucent: Permitting the passage of

name designating “SYstem GEorg light, but diffusing it so that objects

Fischer - High Purity”, or a group of beyond cannot be clearly distinguished.

components manufactured under strict

cleanliness manufacturing conditions

and provided to the high purity industry. UF: Urea-formaldehyde

SYGEF® HP pipe is made by SYMALIT

exclusively for Georg Fischer. UP: Unsaturated polyester

UPWR: Ultrapure water supply

Tear Strength: Resistance of a material

to tearing (strength). UPWS: Ultrapure water return

Tensile Strength: The capacity of a

material to resist a force tending to Vinyl Chloride Plastics: Plastics based

stretch it. Ordinarily the term is used to on resins made by the polymerization of

denote the force required to stretch a vinyl chloride or copolymerization of

material to rupture, and is known vari- vinyl chloride with minor amounts (not

ously as “breaking load,” “breaking over 50 percent) of other unsaturated

stress,” “ultimate tensile strength,” and compounds.

sometimes erroneously as “breaking

strain.” In plastics testing, it is the load in

pounds per square inch or kilos per Vinyl Plastics: Plastics based on resins

square centimeter of original cross- made from vinyl monomers, except those

sectional area, supported at the moment specifically covered by other classifica-

of rupture by a piece of test sample on tions, such as acrylic and styrene plas-

being elongated. tics. Typical vinyl plastics are polyvinyl

chloride, polyvinyl acetate, polyvinyl

Thermal Conductivity: Capacity of a alcohol, and polyvinyl butyral, and

plastic material to conduct heat. copolymers of vinyl monomers with

unsaturated compounds.

Thermal Expansion: The increase in

length of a dimension under the influ- Virgin Material: A plastic material in

ence of a change in temperature. the form of pellets, granules, powder,

floc or liquid that has not been sub-

Thermoforming: Forming with the aid jected to use or processing other than

of heat. that required for its original manufacture.

Viscosity: Internal friction of a liquid

Thermoplastic Materials: Materials because of its resistance to shear,

which soften when heated to normal agitation or flow.

processing temperatures without the

occurrence of appreciable chemical Volatile: Property of liquids to pass

change, but are quickly hardened by away by evaporation.

cooling. Unlike the thermosetting

materials they can be reheated to Volume Resistivity: The electrical

soften, and recooled to “set,” almost resistance of a 1-centimeter cube of the

indefinitely; they may be formed and material expressed in ohm-centimeters.

reformed many times by heat and

pressure.

W: the watt, or 1 joule per second. This

Thermoset: A plastic which, when is the International unit of power.

cured by application of heat or chemical 1W=1J/s=1Nm/s

means, changes into a substantially

infusible and insoluble product. Water Absorption: The percentage by

weight of water absorbed by a sample

Thermosetting: Plastic materials which immersed in water. Dependent upon

undergo a chemical change and harden area exposed.

permanently when heated in processing.

20.12 ¬ ‡

20_ALL 12 6/7/02, 3:27 PM

Glossary

Water Vapor Transmission: The

penetration of a plastic by moisture in

the air.

Weather Resistance: Ability of a plastic

to retain its original physical properties

and appearance upon prolonged

exposure to outdoor weather.

Weld-or-Knitline: A mark on a molded

plastic formed by the union of two or

more streams of plastic flowing together.

Welding: The joining of two or more

pieces at adjoining or nearby areas

either with or without the addition of

plastic from another source.

Yield Point: The point at which a

material will continue to elongate at no

substantial increase in load during a

short test period.

Yield Stress: The force which must be

applied to a plastic to initiate flow.

20

www.us.piping.georgefischer.com 20.13

20_ALL 13 6/7/02, 3:27 PM

¬ ‡

20_ALL 14 6/7/02, 3:27 PM

You might also like

- Astm D16Document8 pagesAstm D16Danilo FornaroNo ratings yet

- BO105 Maintenance ManualDocument2,532 pagesBO105 Maintenance ManualДенис Мешков100% (6)

- Glossory of CompositeDocument125 pagesGlossory of CompositeIshfaq AhmadNo ratings yet

- Glossary: Pplication UlletinDocument16 pagesGlossary: Pplication UlletinAle VázquezNo ratings yet

- UV Coatings For PlasticsDocument5 pagesUV Coatings For Plasticsrabbit22112No ratings yet

- Lohmann GuideDocument9 pagesLohmann GuideRomulo Mayer FreitasNo ratings yet

- Textile Dictionary by Md. Jakir HossenDocument152 pagesTextile Dictionary by Md. Jakir HossenMd. Jakir HossenNo ratings yet

- Polyester and Vinyl Ester CoatingsDocument14 pagesPolyester and Vinyl Ester Coatingsrasool100% (2)

- PVC: ChemistryDocument55 pagesPVC: ChemistryAnjumol Salim100% (2)

- PSE - Module 5Document13 pagesPSE - Module 5rajesh kothariNo ratings yet

- Polyvinyl Acetate - Polyvinyl AlcoholDocument15 pagesPolyvinyl Acetate - Polyvinyl AlcoholUtkarsh Singh100% (1)

- Final VersionDocument13 pagesFinal VersionmohammedNo ratings yet

- US3463735Document6 pagesUS3463735Sharda RamberanNo ratings yet

- ECJ 0612 OxazolidinesDocument4 pagesECJ 0612 OxazolidinesmajidNo ratings yet

- Search P "Polyether+polyol"&prssweb Search&ei UTF-8&fl 0 PDFDocument15 pagesSearch P "Polyether+polyol"&prssweb Search&ei UTF-8&fl 0 PDFA MahmoodNo ratings yet

- Glossary RubberDocument12 pagesGlossary RubbersabtonluckyNo ratings yet

- Powder Coating Use of Acrylic Resins Grows 1971Document1 pagePowder Coating Use of Acrylic Resins Grows 1971Siriluck NevestNo ratings yet

- Coaker (2003) - Journal - Fire and Flame Retardants For PVC. Journal of Vinyl and Additive TechnologyDocument8 pagesCoaker (2003) - Journal - Fire and Flame Retardants For PVC. Journal of Vinyl and Additive TechnologyBrandon BroNo ratings yet

- Final1 Additive StandardsDocument16 pagesFinal1 Additive StandardsmohammedNo ratings yet

- 20090924_dae676c929736e6d8e11GePs9mDwKXWX.attachDocument5 pages20090924_dae676c929736e6d8e11GePs9mDwKXWX.attachSaheed KalliyadanpoyilNo ratings yet

- Acrylic PolymersDocument25 pagesAcrylic PolymersKaye NicolasNo ratings yet

- Common Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Document4 pagesCommon Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Yashi SrivastavaNo ratings yet

- Specifying and Managing Protective Coatings Projects, Version 8 Glossary G-1Document20 pagesSpecifying and Managing Protective Coatings Projects, Version 8 Glossary G-1Rinush Fedrikdo Bushido OdaNo ratings yet

- Glossy Topcoat Exterior Paint FormulatioDocument7 pagesGlossy Topcoat Exterior Paint FormulatioShahid MirzaNo ratings yet

- Polyvinyl Butyral 2Document42 pagesPolyvinyl Butyral 2sina.javaheryNo ratings yet

- Bonding AgentsDocument137 pagesBonding AgentsHarmeet BajwaNo ratings yet

- ESCR PDFDocument3 pagesESCR PDFGüner GüvençNo ratings yet

- PVC Becoming Even "Hotter": Application StudyDocument3 pagesPVC Becoming Even "Hotter": Application StudySantiago RodriguesNo ratings yet

- Plastics - Manufacturing MethodsDocument2 pagesPlastics - Manufacturing MethodsPassmore DubeNo ratings yet

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDocument8 pagesEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗNo ratings yet

- Anti-Static AgentDocument4 pagesAnti-Static Agentsusheel deoraNo ratings yet

- NCL Report - Chapter 4Document6 pagesNCL Report - Chapter 4Aparna YaduNo ratings yet

- Hamay CL 2839Document5 pagesHamay CL 2839Alejandro MolinariNo ratings yet

- Technical Paper: Waterborne Resins For The Paint Industry - Theory and PracticeDocument28 pagesTechnical Paper: Waterborne Resins For The Paint Industry - Theory and PracticeDantvNo ratings yet

- Polane 700T, Water Reducible EnamelDocument2 pagesPolane 700T, Water Reducible Enamel김도균No ratings yet

- United States Patent (19) : Pre-Mixed Catalyzed WinylacetateDocument6 pagesUnited States Patent (19) : Pre-Mixed Catalyzed WinylacetateSHRINIL DESAINo ratings yet

- Photographic Applications of PolymersDocument12 pagesPhotographic Applications of Polymersvinit singhNo ratings yet

- PDFDocument13 pagesPDFZen AlkaffNo ratings yet

- Waterborne Acrylic-Casein Latexes As Eco-Friendly Binder For CoatingsDocument9 pagesWaterborne Acrylic-Casein Latexes As Eco-Friendly Binder For Coatingsbillyhung860715No ratings yet

- PVC Compounding: Preparation, Physical and Mechanical PropertiesDocument6 pagesPVC Compounding: Preparation, Physical and Mechanical PropertiesPVC XANH QDNo ratings yet

- Flexidone™ - A New Class of Innovative PVC Plasticizers: Martin Bonnet and Hasan KaytanDocument19 pagesFlexidone™ - A New Class of Innovative PVC Plasticizers: Martin Bonnet and Hasan KaytanBenpetro ChaichuaNo ratings yet

- The Use of Paraloid B72 As An AdhesiveDocument9 pagesThe Use of Paraloid B72 As An AdhesivetindaljuNo ratings yet

- 1K Polyurethane Dispersion For Conventional 2K - LubrizolDocument7 pages1K Polyurethane Dispersion For Conventional 2K - Lubrizolphi dinhNo ratings yet

- Consumer Friendly Adhesive - Pressure Sensitive AdhesivesDocument4 pagesConsumer Friendly Adhesive - Pressure Sensitive AdhesivesAnujNo ratings yet

- Understanding Engineering PlasticsDocument46 pagesUnderstanding Engineering PlasticsShubham ChoudhariNo ratings yet

- Acetae Acrylicus3245936Document5 pagesAcetae Acrylicus3245936sinhleprovietNo ratings yet

- Richardson 2000Document14 pagesRichardson 2000ADITYA RAHMANNo ratings yet

- Fiber GrosaryDocument10 pagesFiber GrosaryTiger SahyadriNo ratings yet

- Polyurethane and ABSDocument2 pagesPolyurethane and ABSAlbertNo ratings yet

- Apn 4 05 01Document2 pagesApn 4 05 01fperezbrNo ratings yet

- US4758615Document13 pagesUS4758615Alexander Franco CastrillonNo ratings yet

- Plasticizers 1.1. Historical OverviewDocument6 pagesPlasticizers 1.1. Historical Overviewmuhammad umairNo ratings yet

- Usp37-Nf32 Gc-661 Containers-Plastics (2014)Document6 pagesUsp37-Nf32 Gc-661 Containers-Plastics (2014)Prem PisupatiNo ratings yet

- Polymers For Advanced Techs - 2022 - Yang - Plasticizing and Thermal Stabilizing Effect of Bio Based Epoxidized CardanolDocument14 pagesPolymers For Advanced Techs - 2022 - Yang - Plasticizing and Thermal Stabilizing Effect of Bio Based Epoxidized CardanolVickie HanNo ratings yet

- Guide To Resin SystemsDocument9 pagesGuide To Resin SystemsDaud Simon A100% (1)

- Plasticizer PPT - Global & IndianDocument53 pagesPlasticizer PPT - Global & IndianKaushal KothariNo ratings yet

- BYKDocument4 pagesBYKlqiroxitaNo ratings yet

- MSDS 4020170100Document18 pagesMSDS 4020170100patchar.mayNo ratings yet

- Polyurethane CoatingDocument14 pagesPolyurethane CoatingKhalil Rehman100% (3)

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- British Columbian SBRDocument4 pagesBritish Columbian SBRMagin Idelfonso TorreblancaNo ratings yet

- Chemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionDocument80 pagesChemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionMagin Idelfonso TorreblancaNo ratings yet

- E Series CEDocument2 pagesE Series CEMagin Idelfonso TorreblancaNo ratings yet

- E8 SeriesDocument2 pagesE8 SeriesMagin Idelfonso TorreblancaNo ratings yet

- Corrosion Resistant and Ultra-Pure Rotameters For Accurate Measurement of Liquids and GasesDocument18 pagesCorrosion Resistant and Ultra-Pure Rotameters For Accurate Measurement of Liquids and GasesMagin Idelfonso TorreblancaNo ratings yet

- Effect of Ultrafiltration Permeate Recycling On Deinking Efficiency of Flexo-Printed NewspapersDocument11 pagesEffect of Ultrafiltration Permeate Recycling On Deinking Efficiency of Flexo-Printed NewspapersMagin Idelfonso TorreblancaNo ratings yet

- Ppro-Seal Natural Polypropylene Piping SystemDocument16 pagesPpro-Seal Natural Polypropylene Piping SystemMagin Idelfonso TorreblancaNo ratings yet

- Flange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Document2 pagesFlange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Magin Idelfonso TorreblancaNo ratings yet

- That Is The Question: To Filter or To UltrafilterDocument4 pagesThat Is The Question: To Filter or To UltrafilterMagin Idelfonso TorreblancaNo ratings yet

- Greener, Cleaner, Safer Products For A Better WorldDocument8 pagesGreener, Cleaner, Safer Products For A Better WorldMagin Idelfonso TorreblancaNo ratings yet

- API 12F Steel Tank Data Sheet: Form No. API12FDS1Document2 pagesAPI 12F Steel Tank Data Sheet: Form No. API12FDS1Magin Idelfonso TorreblancaNo ratings yet

- Fiberfrax Blanket and Mat Products: Product Information SheetDocument8 pagesFiberfrax Blanket and Mat Products: Product Information SheetMagin Idelfonso TorreblancaNo ratings yet

- High Temperature Solutions: For Chemical Process IndustriesDocument6 pagesHigh Temperature Solutions: For Chemical Process IndustriesMagin Idelfonso TorreblancaNo ratings yet

- Polymers Aids ScreeningDocument17 pagesPolymers Aids ScreeningMagin Idelfonso TorreblancaNo ratings yet

- Ratros y AlimentosDocument6 pagesRatros y AlimentosMagin Idelfonso TorreblancaNo ratings yet

- Collectors: Water Treatment & Chemical ProcessingDocument7 pagesCollectors: Water Treatment & Chemical ProcessingMagin Idelfonso TorreblancaNo ratings yet

- UniplanxDocument12 pagesUniplanxbiik0076153No ratings yet

- Lab 6 - Compression Testing of WoodDocument5 pagesLab 6 - Compression Testing of WoodManikandan Selvam0% (1)

- Construction Chemicals 17.06.08Document27 pagesConstruction Chemicals 17.06.08Kanupriya JainNo ratings yet

- Microstructures of Iron-Carbon Alloys: Fine Pearlite 3000XDocument9 pagesMicrostructures of Iron-Carbon Alloys: Fine Pearlite 3000XVaishu 07No ratings yet

- Microstructure Degradation of Nickel Base Single Crystal Superalloy Cmsx-4Document8 pagesMicrostructure Degradation of Nickel Base Single Crystal Superalloy Cmsx-4Sriman NarayanaNo ratings yet

- Deutz Fahr AGROTRON 105 MK3 Tractor Service Repair ManualDocument20 pagesDeutz Fahr AGROTRON 105 MK3 Tractor Service Repair ManuallaopaodunNo ratings yet

- AMS4930LDocument8 pagesAMS4930Lremaja1249No ratings yet

- Thermoplastic ElastomerDocument4 pagesThermoplastic ElastomerpepeNo ratings yet

- Definition, Advantages, Disadvantages, ProcedureDocument35 pagesDefinition, Advantages, Disadvantages, ProcedureRica RegisNo ratings yet

- Sigma Plate Heat ExchangersDocument6 pagesSigma Plate Heat ExchangersDirkNo ratings yet

- Ijert1 PDFDocument5 pagesIjert1 PDFSHUBHAMNo ratings yet

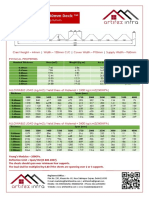

- ARTIFEX INFRA - 44mm Decksheet ProfileDocument1 pageARTIFEX INFRA - 44mm Decksheet ProfileAmit SharmaNo ratings yet

- Ready Mix ConcreteDocument23 pagesReady Mix ConcreteDevesh Sharma100% (1)

- Fabric-Formed Walls: Kenzo UnnoDocument11 pagesFabric-Formed Walls: Kenzo UnnoffigueroaNo ratings yet

- Pretiox: Titanium DioxideDocument11 pagesPretiox: Titanium DioxideAbhinav TayadeNo ratings yet

- Petronas Technical Standards: Design and Construction of Reinforced Concrete Foundations and StructuresDocument26 pagesPetronas Technical Standards: Design and Construction of Reinforced Concrete Foundations and StructuresvinothNo ratings yet

- Pavement DistressesDocument115 pagesPavement DistressesKevin HernandezNo ratings yet

- ClearLite - ImerysDocument4 pagesClearLite - Imerysmiroslav2paunovNo ratings yet

- Schedule of Rates 2018 For Amini W.E.F 01.11.2018: 1Document62 pagesSchedule of Rates 2018 For Amini W.E.F 01.11.2018: 1Sarthak ShuklaNo ratings yet

- Auramix 400Document2 pagesAuramix 400Srinivash 4423No ratings yet

- VT01 Vitalink MC Transit 2 HR FHIT 120 10-27-20Document2 pagesVT01 Vitalink MC Transit 2 HR FHIT 120 10-27-20Samuel C. HernándezNo ratings yet

- Company Profile & Catalogue PT Orindo Eratec 2021Document16 pagesCompany Profile & Catalogue PT Orindo Eratec 2021HSE Wana Dirga NusantaraNo ratings yet

- HST RNFDocument3 pagesHST RNFDeepu ChaturvediNo ratings yet

- Flexural or Bending Test Lab ReportDocument9 pagesFlexural or Bending Test Lab ReportAman NigamNo ratings yet

- Method Statement Fo Reinforcement Works BlogDocument8 pagesMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- DHL Incoterms PDFDocument4 pagesDHL Incoterms PDFАмаль БоранбайNo ratings yet

- Soudal SpecDocument3 pagesSoudal Specthang TranNo ratings yet

- Cutting Tool - 0Document45 pagesCutting Tool - 0Sam SadaNo ratings yet

- Arkema Nano Strength BlockDocument4 pagesArkema Nano Strength BlockGunjan GadodiaNo ratings yet