Professional Documents

Culture Documents

5s-Fe Engine Troubleshooting-1

5s-Fe Engine Troubleshooting-1

Uploaded by

Mark Anthony Fletcher0 ratings0% found this document useful (0 votes)

17 views3 pagesThe document provides steps for troubleshooting issues with the 5S-FE engine control system:

1. Analyze the customer's reported problem and check for diagnostic trouble codes. Clear any codes.

2. Confirm symptoms in test mode and simulate problems if needed. Check codes again in test mode.

3. Perform basic inspections if codes are normal or use the trouble code chart if codes are present.

4. Use a matrix chart or check circuits to diagnose the problem, inspect parts, make adjustments, and test to confirm the issue is resolved.

Original Description:

Original Title

5S–FE ENGINE TROUBLESHOOTING-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides steps for troubleshooting issues with the 5S-FE engine control system:

1. Analyze the customer's reported problem and check for diagnostic trouble codes. Clear any codes.

2. Confirm symptoms in test mode and simulate problems if needed. Check codes again in test mode.

3. Perform basic inspections if codes are normal or use the trouble code chart if codes are present.

4. Use a matrix chart or check circuits to diagnose the problem, inspect parts, make adjustments, and test to confirm the issue is resolved.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views3 pages5s-Fe Engine Troubleshooting-1

5s-Fe Engine Troubleshooting-1

Uploaded by

Mark Anthony FletcherThe document provides steps for troubleshooting issues with the 5S-FE engine control system:

1. Analyze the customer's reported problem and check for diagnostic trouble codes. Clear any codes.

2. Confirm symptoms in test mode and simulate problems if needed. Check codes again in test mode.

3. Perform basic inspections if codes are normal or use the trouble code chart if codes are present.

4. Use a matrix chart or check circuits to diagnose the problem, inspect parts, make adjustments, and test to confirm the issue is resolved.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

EG1–292

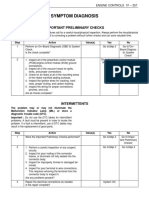

5S–FE ENGINE – HOW TO PROCEED WITH TROUBLESHOOTING

HOW TO PROCEED WITH TROUBLESHOOTING

The Engine Control System broadly consists of the sensors, Engine Control Module (ECM) and actuators.

The ECM receives signals from various sensors, judges the operating conditions and determines the

optimum injection duration, timing, ignition timing and idle speed.

In general, the Engine Control System is considered to be a very intricate system to troubleshoot. But, the

fact is that if you proceed to inspect the circuit one by one following the procedures directed in this manu-

al, troubleshooting of this system is not complex.

This section explains the most ideal method of troubleshooting and tells how to carry out the necessary

repairs.

1. CUSTOMER PROBLEM ANALYSIS

Using the customer problem analysis check sheet for reference, ask the customer in as much details

as possible about the problem.

2. CHECK AND CLEAR DIAGNOSTIC TROUBLE CODE (PRECHECK)

Before confirming the problem symptom, first check the diagnostic trouble code and make a note of

any malfunction code which is output, then clear the code.

HINT: Output of the malfunction code indicates that there is a malfunction in the circuit indicated.

However, it does not indicate whether the malfunction is still occurring or occurred in the past and

returned to normal. In order to determine this, the problem sym toms should be confirmed in step 4

first and the diagnostic trouble code be rechecked in step [6].

Accordingly, if troubleshooting is begun based on the malfunction code only in diagnostic trouble

code check in step [2], it could result in a misdiagnosis, leading to troubleshooting of circuits which

are normal and making it more difficult to locate the cause of the problem.

3. SETTING THE TEST MODE DIAGNOSIS, [4] PROBLEM SYMPTOM CONFIRMATION,

[5] SYMPTOM SIMULATION

In order to find out the trouble more quickly, set the diagnosis check in test mode and with higher

sensing ability of the ECM, confirm the problem symptoms. If the trouble does not reappear, use the

symptom simulation method to make sure the trouble is reproduced.

6. DIAGNOSTIC TROUBLE CODE CHECK IN TEST MODE

Check the diagnostic trouble code in test mode. If the malfunction code is output, proceed to step. If the

normal code is output, proceed to step [7].

7. BASIC INSPECTION

Carry out basic inspection such as the spark check and fuel pressure check, etc.

8. DIAGNOSTIC TROUBLE CODE CHART

If the malfunction code is displayed, proceed to inspect the circuit indicated by the chart for each

code.

9. MATRIX CHART OF PROBLEM SYMPTOMS

If the normal code is displayed in the diagnosis in test mode, perform troubleshooting according to

the inspection order in the Matrix Chart of Problem Symptoms.

10. PARTS INSPECTION

When the Matrix Chart of Problem Symptoms instructs to check the parts, proceed to parts inspection

section included in this manual.

11. CIRCUIT INSPECTION

Determine if the malfunction is the sensor, actuator, wire harness, connector or the ECM.

EG1–293

5S–FE ENGINE – HOW TO PROCEED WITH TROUBLESHOOTING

CHECK FOR MOMENTARY INTERRUPTION

By performing the check for momentary interruption, the place where momentary interruptions or

momentary shorts are occurring due to poor contacts can be isolated.

ADJUSTMENT, REPAIR

After the cause of the problem is located, perform adjustment or repairs by following the inspection

and replacement procedures in this manual.

CONFIRMATION TEST

After completing adjustment or repairs, confirm not only that the malfunction is eliminated, but also

conduct a test drive, etc., to make sure the entire Engine Control System is operating normally.

EG1–294

5S–FE ENGINE – HOW TO PROCEED WITH TROUBLESHOOTING

Titles inside are titles of pages

Vehicle Brought to Workshop

in this manual, with the page number

indicated in the bottom portion.

Customer Problem Analysis See the indicated pages for detailed

P. EG1–295 explanations

Check and clear Diagnostic Trouble Code (Pre-

check.) P. EG1–297, 299

Setting the Test Mode Diagnosis

P. EG1–298

Problem Symptom Confirmation

Malfunction does not occur.

Malfunction Symptom Simulation

occurs: P. IN–24

Diagnostic Trouble Code Check

P. EG1–298

Normal code Malfunction code

Basic Inspection Diagnostic Trouble Code Chart

p. P. EG1–300

EG1–310

Matrix Chart of Problem Symptoms

P. EG1–327

Circuit Inspection

P. EG1–336

Parts Inspection Check for Momentary Interruption

P. EG1–309

Identification of Problem

Adjustment, Repair

Confirmation Test Step : Diagnostic steps per–

mitting the use of the

TOYOTA hand–held

End tester or TOYOTA

break–out–box.

You might also like

- Troubleshooting JLG T350, T500JDocument225 pagesTroubleshooting JLG T350, T500Jgpe GardunoNo ratings yet

- Hino J08E Engine Workshop Manual PDFDocument291 pagesHino J08E Engine Workshop Manual PDFAsril Kdr100% (7)

- Fuse Box Diagram Toyota Noah Voxy and Relay With Assignment andDocument14 pagesFuse Box Diagram Toyota Noah Voxy and Relay With Assignment andMark Anthony Fletcher100% (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Toyota Noah Wiring DiagramDocument6 pagesToyota Noah Wiring DiagramMark Anthony FletcherNo ratings yet

- Vantage Troubleshooting GuideDocument12 pagesVantage Troubleshooting GuideJose G LopezNo ratings yet

- J05e Ta PDFDocument294 pagesJ05e Ta PDFAdi M100% (10)

- Toyota 1AZ-FSE Engine Repair Manual (RM1019E) - PDFs Free OnlineDocument5 pagesToyota 1AZ-FSE Engine Repair Manual (RM1019E) - PDFs Free OnlineMark Anthony Fletcher75% (4)

- Fault Code 287 SAE J1939 Multiplexing Accelerator Pedal or Lever Sensor System Error - Received Network Data ErrorDocument8 pagesFault Code 287 SAE J1939 Multiplexing Accelerator Pedal or Lever Sensor System Error - Received Network Data ErrorAhmedmahNo ratings yet

- Revision de Codigo 1139, 1145Document8 pagesRevision de Codigo 1139, 1145OlivaresM.EmanuelNo ratings yet

- Fault Code InjectorDocument16 pagesFault Code InjectorAgung Ardhana0% (1)

- Transocean Offshore OperationDocument123 pagesTransocean Offshore OperationAkshat Tarate100% (2)

- Aec3414 Philosophy FinalDocument5 pagesAec3414 Philosophy Finalapi-532996380No ratings yet

- Moral Theories and Mental FramesDocument2 pagesMoral Theories and Mental FramesJohn Paul Alfonso Fontanilla75% (12)

- How To Troubleshoot Ecu Controlled Systems: Repair Manual SystemDocument17 pagesHow To Troubleshoot Ecu Controlled Systems: Repair Manual SystemOscar AcevedoNo ratings yet

- p11 5S-FE+ENGINE+REPAIR+MANUALDocument5 pagesp11 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- How To Proceed With Troubleshooting (2001.8 - )Document10 pagesHow To Proceed With Troubleshooting (2001.8 - )Jurol MassambaNo ratings yet

- How To Proceed With Troubleshooting (1998.8 - )Document10 pagesHow To Proceed With Troubleshooting (1998.8 - )Jurol MassambaNo ratings yet

- Troubleshooting: Section 5Document158 pagesTroubleshooting: Section 5Tú Xuân Lương100% (1)

- Troubleshooting: Section 5Document136 pagesTroubleshooting: Section 5Vu HoiNo ratings yet

- Trouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDocument66 pagesTrouble Diagnosis Trouble Diagnosis Trouble Diagnosis IntroductionDavid QuispeNo ratings yet

- How To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDocument10 pagesHow To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopastaorNo ratings yet

- How To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDocument10 pagesHow To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopMohamed HarbNo ratings yet

- Power Steering (Diagnostics)Document52 pagesPower Steering (Diagnostics)rwNo ratings yet

- How To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDocument10 pagesHow To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDaniel Mamani ParedezNo ratings yet

- Rouble Shooting PDFDocument10 pagesRouble Shooting PDFGuillermo UcNo ratings yet

- How To Troubleshoot Ecu Controlled Systems: General InformationDocument10 pagesHow To Troubleshoot Ecu Controlled Systems: General InformationDanilo Jr. MontealegreNo ratings yet

- Engine 12V140E-3 Series: 40 TroubleshootingDocument48 pagesEngine 12V140E-3 Series: 40 TroubleshootingЕгорNo ratings yet

- 6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BDocument303 pages6E-104 4Ja1/4Jh1 Engine Driveability and Emissions Breaker Box Connection Type BVõ Nam PhươngNo ratings yet

- Time SND Speed Circuit TestDocument7 pagesTime SND Speed Circuit TestbejoythomasNo ratings yet

- Sensor Signal (Analog, Active) - Test: TroubleshootingDocument5 pagesSensor Signal (Analog, Active) - Test: TroubleshootingcristianNo ratings yet

- Cummins: Fault Code: 298 PID: P223 SPN: 1084 FMI: 4Document4 pagesCummins: Fault Code: 298 PID: P223 SPN: 1084 FMI: 4Enrrique LaraNo ratings yet

- FAULT CODE 415 - Engine Oil Rifle Pressure - Data Valid But Below Normal Operating Range - Most Severe LevelDocument3 pagesFAULT CODE 415 - Engine Oil Rifle Pressure - Data Valid But Below Normal Operating Range - Most Severe Levelkhaled kamelNo ratings yet

- Automatic Transmission and DifferentialDocument58 pagesAutomatic Transmission and Differentialvadim vadimNo ratings yet

- 297 t05 3236Document5 pages297 t05 3236Himadri Sarkar100% (1)

- How To Proceed With TroubleshootingDocument9 pagesHow To Proceed With TroubleshootingdiemnganNo ratings yet

- 2011 Softail CodesDocument8 pages2011 Softail Codesmah mudinNo ratings yet

- Caterpillar Ep20tDocument66 pagesCaterpillar Ep20tCoque de LunaNo ratings yet

- Pajero Full 2008 13Document1,059 pagesPajero Full 2008 13Antonio GasparNo ratings yet

- 3500 Trouble Afr Rev1Document145 pages3500 Trouble Afr Rev1Esau Jose PabloNo ratings yet

- Tech Sheet - W10607408 - Rev F PDFDocument48 pagesTech Sheet - W10607408 - Rev F PDFNolan HicksNo ratings yet

- TroubleshootingWithCodes-NonTurbo Volvo 850Document18 pagesTroubleshootingWithCodes-NonTurbo Volvo 850azaharNo ratings yet

- Automatic Transmission and DifferentialDocument59 pagesAutomatic Transmission and Differentialvadim vadimNo ratings yet

- En (STI) (Diag) Engine (Diagnostics)Document386 pagesEn (STI) (Diag) Engine (Diagnostics)George Iordache100% (1)

- 303-06 Starting System - Diagnosis and Testing - Starting SystemDocument22 pages303-06 Starting System - Diagnosis and Testing - Starting SystemCARLOS LIMADANo ratings yet

- Cummins: Fault Code: 297 PID: P223 SPN: 1084 FMI: 3Document4 pagesCummins: Fault Code: 297 PID: P223 SPN: 1084 FMI: 3Enrrique LaraNo ratings yet

- 4.2l Engine PerformanceDocument240 pages4.2l Engine Performanceadnmb100% (1)

- Hitachi Zaxis 170w 190w 3 Training Text Performance Test TroubleshootingDocument10 pagesHitachi Zaxis 170w 190w 3 Training Text Performance Test Troubleshootingashley100% (52)

- Symptom TroubleshootingDocument3 pagesSymptom Troubleshootingbenjir shuvoNo ratings yet

- 01-356 ESP DTC Table PDFDocument96 pages01-356 ESP DTC Table PDFmefisto06cNo ratings yet

- RenaultDocument8 pagesRenaultcostinel iordachescuNo ratings yet

- KENR8566 101 Systems Operation Section: Illustration 94Document2 pagesKENR8566 101 Systems Operation Section: Illustration 94kaswade BrianNo ratings yet

- Illustration 1 g03326191 Schematic of The Action AlarmDocument3 pagesIllustration 1 g03326191 Schematic of The Action AlarmJuan LopezNo ratings yet

- Service Training and Publication BulletinDocument9 pagesService Training and Publication BulletingalmetronikNo ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P0562 System Voltage LowDocument3 pagesDiagnostic Trouble Codes (DTC) : DTC P0562 System Voltage Lowluis eduardo corzo enriquezNo ratings yet

- Troubleshooting 320D-2 WBYDocument110 pagesTroubleshooting 320D-2 WBYasyuzwarNo ratings yet

- Engine PerformanceDocument33 pagesEngine PerformanceRuben Cruces LiraNo ratings yet

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- Steering InitializationDocument87 pagesSteering Initializationomanstar120% (2)

- Symptom Diagnosis Secc 1FDocument20 pagesSymptom Diagnosis Secc 1FMiguel Antonio Sanchez ValeraNo ratings yet

- TPM (Diag) Tire Press MonDocument38 pagesTPM (Diag) Tire Press Monj yuNo ratings yet

- Engine Performance Diagnostic RoutineDocument1 pageEngine Performance Diagnostic RoutineRius RiusNo ratings yet

- Overhaul: 1. Remove Valve LifterDocument13 pagesOverhaul: 1. Remove Valve LifterMark Anthony FletcherNo ratings yet

- Latest Statistics On England Mortality Suggest...Document24 pagesLatest Statistics On England Mortality Suggest...David Souto AlcaldeNo ratings yet

- Jay A Stotsky Navier Stokes Equation 2016Document22 pagesJay A Stotsky Navier Stokes Equation 2016dawing david guette tuiranNo ratings yet

- Self Evaluating Hydro BlastingDocument11 pagesSelf Evaluating Hydro Blastingmmd BusinessNo ratings yet

- ClearTax Excelity PresentationDocument7 pagesClearTax Excelity PresentationBalakrishnan RajendranNo ratings yet

- Test Bank For Human Development A Life Span View Third EditionDocument20 pagesTest Bank For Human Development A Life Span View Third Editiondenisedanielsbkgqyzmtr100% (28)

- Methodology For Product Design PDFDocument45 pagesMethodology For Product Design PDFCherun ChesilNo ratings yet

- Roman JakobsonDocument9 pagesRoman Jakobsonfatima zohra khelifiNo ratings yet

- PP Accounting System Analysis & DesignDocument13 pagesPP Accounting System Analysis & DesignCik TeaniNo ratings yet

- Conscience: Mr. Jose A. Procalla JR., MsmeDocument17 pagesConscience: Mr. Jose A. Procalla JR., MsmeStella SalvadorNo ratings yet

- Caietul Cursantului Chestionare 2015Document13 pagesCaietul Cursantului Chestionare 2015John DoesNo ratings yet

- Catalog HYUNDAI HGMP (E)Document33 pagesCatalog HYUNDAI HGMP (E)Kostas TressosNo ratings yet

- Organizational Structures and The Performance of Supply Chain ManagementDocument23 pagesOrganizational Structures and The Performance of Supply Chain ManagementSerp YelmazNo ratings yet

- Dwnload Full Leadership Theory Application and Skill Development 6th Edition Lussier Test Bank PDFDocument36 pagesDwnload Full Leadership Theory Application and Skill Development 6th Edition Lussier Test Bank PDFgallivatmetholhvwz0100% (13)

- Electrical Plan Review: Building Permit ApplicationDocument3 pagesElectrical Plan Review: Building Permit ApplicationalostooraNo ratings yet

- Networks of Touch A Tactile History of Chinese Art 1790 1840 Perspectives On Sensory History 1St Edition Hatch Full ChapterDocument67 pagesNetworks of Touch A Tactile History of Chinese Art 1790 1840 Perspectives On Sensory History 1St Edition Hatch Full Chapterheather.bekis553100% (12)

- IC Auto Invoice 10768 PDFDocument2 pagesIC Auto Invoice 10768 PDFBubba ManlutacNo ratings yet

- RICSDocument4 pagesRICSTony KennedyNo ratings yet

- Cyberoam OS To Sophos Firewall OS Upgrade Guide PDFDocument29 pagesCyberoam OS To Sophos Firewall OS Upgrade Guide PDFJ Miguel Borges CNo ratings yet

- HSE Business Plan: Updated November 2020Document40 pagesHSE Business Plan: Updated November 2020sanjeev thadaniNo ratings yet

- Generadores MarelliMotoriDocument18 pagesGeneradores MarelliMotoriEdú Brizuela100% (1)

- University Department of Chemical Technology, Thesis - CertificatesDocument6 pagesUniversity Department of Chemical Technology, Thesis - CertificatesDulal MahatoNo ratings yet

- Piping Design Professional: Kamalakannan ADocument4 pagesPiping Design Professional: Kamalakannan AKamalakannan AyyaduraiNo ratings yet

- Lesson Plan-Effects of Force On The Size of An ObjectDocument2 pagesLesson Plan-Effects of Force On The Size of An ObjectGlenda Ricafort100% (1)

- Sherif Lawal A.: Software Engineer-AndroidDocument2 pagesSherif Lawal A.: Software Engineer-AndroidLawal SherifNo ratings yet

- Program Schedule & Report - Research Methodology WorkshopDocument13 pagesProgram Schedule & Report - Research Methodology WorkshopDr. Vijaykumar BandalNo ratings yet

- BELL B40C - 872071-01 Section 3-Power TrainDocument106 pagesBELL B40C - 872071-01 Section 3-Power TrainALI AKBAR100% (1)

- Ananta Group Profile Feb 2012Document20 pagesAnanta Group Profile Feb 2012Tareq SarkerNo ratings yet