Professional Documents

Culture Documents

MD119 - CT TC and Mud Acid - 11sep14

MD119 - CT TC and Mud Acid - 11sep14

Uploaded by

M BOUKHAMLAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD119 - CT TC and Mud Acid - 11sep14

MD119 - CT TC and Mud Acid - 11sep14

Uploaded by

M BOUKHAMLACopyright:

Available Formats

DIVISION PRODUCTION

DIRECTION REGIONALE H.M.D

DIRECTION ENG. & PRODUCTION

DEPARTEMENT TECHNIQUES PUITS

SERVICE TECHNIQUES.NOUVELLES

Hassi-Messaoud, 11 Sep 2014

STIMULATION PROGRAM

CT TC + Mud Acid Treatment

MD119

(Zone 13 – Centrale)

Le CDD Techniques Puits Le Directeur Eng. & Production

Mr. A. BOUMALI

DESTINATAIRES :

DEP/Département CP

DEP/Département OP

Archives

Program Prepared by: DESC/I Nyoman Sutarsana

1. Back Ground

The well MD119 was drilled on 31/12/1969 and completed as vertical LCP. The well then side

tracked on May 2014. The well is located at zone 13-Centrale; below is the detail map of the well

in relation with other offset wells.

After side tracked the well as LCP then perforated on Jul 14, the well didn’t produce. Some study is

needed to find the causes of no productivity and propose solutions.

2. Treatment objective

The main purpose of the intervention is to perform matrix stimulation to get the well on production.

3. Well Data

MD119

Tubing 4-1/2in NV @ 3280.60m TR

OTIS L Nipple “R” 3260m TR, ID 87.78mm

Packer 3281.50m TR

Perforated Interval 06/07/2014

(3395 – 3401)m TR

(3403 – 3411)m TR

TD 3436.00m TR

BHP PFS (01/08/2014)

PG = 208.82kg/cm2

PT = 52.23kg/cm2

4. Geological characteristic

MD119 CT Stimulation Page 2

5. Well Test Data

6. Production Characteristics

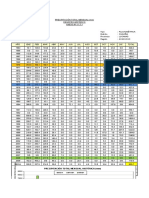

Débit (m³/h) Pression (kg/cm²) Temp. Débit Eau (l/h)

Diam. Huile

Unité

Date Mesure Duse GOR Press. Press. Press. K Psi Observations

Sépar. Huile Gaz Récupérée Injectée

(mm) Tete Pipe Separ.

(°C)

18/01/1970 0 - null -- 239 null null -- -- null 0 0 ------

06/07/1970 0 - 58.87 -- 175 54.4 null 28 -- null 0 0 ------

21/08/1970 0 - 58.73 -- 270 55.6 null 28 -- null 0 0 ------

28/08/1970 0 - null -- 237 null null -- -- null 0 0 ------

08/09/1970 0 - 55.83 -- 270 56.3 null 28 -- null 0 0 ------

23/10/1970 20 - 27.74 -- 320 89.5 null 20 -- null 0 0 ------

26/10/1970 20 - 30.46 -- 267 90.5 null 20.1 -- null 0 0 ------

16/02/1971 0 - 54.58 -- 290 56.7 null 28 -- null 0 0 ------

18/04/1971 17 - 19.45 -- 444 95.6 null 29.5 -- null 0 0 ------

03/08/1971 0 - 50.12 -- 427 60.4 null 28 -- null 0 0 ------

12/09/1971 0 - 49.75 -- 378 59.4 null 28 -- null 0 0 ------

04/12/1973 0 - 15.12 -- 595 80.9 null 30 -- null 0 0 ------

04/04/1977 0 - 23.33 -- 509 59.8 null 30 -- null 0 0 ------

13/10/1978 34 - 34.44 -- 630 58.1 null -- -- null 0 0 ------

02/02/1980 16 - 12.7 -- 508 94 null 13.8 -- null 0 0 ------

08/07/1980 23 - 18.46 -- 678 81 null 26 -- null 0 0 ------

16/07/1983 14 - 9.05 -- 1552 128 null 26.6 -- null 0 0 ------

15/05/1985 13 - 7.62 -- 1290 36.8 null 16.8 -- null 0 0 ------

23/06/1985 15 - 7.08 -- 1321 112.5 null 9.2 -- null 0 0 ------

21/12/1986 23 - 13.64 -- 1004 88.8 null 21.4 -- null 0 0 ------

17/08/1987 13 - 7.39 -- 981 115 null 11.6 -- null 0 0 ------

12/03/1990 13 400 4.84 10348.05 2057 140 34 15 25 2.926 80 0 ------

28/11/1991 13 400 4.64 11322.93 2339 147 33 9.7 14 3.203 250 0 ------

29/11/1991 13 400 4.28 10978.19 2453 146 34 9.5 17 3.451 500 0 ------

18/08/2006 9.5 1440 1.59 6446.52 4051 140 10 8.6 34 5.0609 20 0 ------

20/08/2006 9.5 1440 1.03 6278.15 6087 137 10 8.24 34 7.6417 0 0 ------

28/10/2006 13 655 3.59 5959.97 1660 67.5 10 4.89 18 1.9027 0 0 ------

16/02/2007 13 720 1.8 4078.08 2263 56.7 32.2 3.47 14 3.184 0 0 ------

12/04/2007 13 655 1.59 6443.00 4046 72 35.6 4.28 20 4.5751 0 0 ------

07/09/2007 13 - 1.58 7222.50 4575 82 36.5 6.63 29 5.2554 0 0 ------

07/04/2008 13 655 0.99 7980.05 8050 87.1 36 7.34 24 8.8902 0 0 ------

16/10/2008 13 720 0.99 7615.24 7674 87 38 6.83 23 8.871 0 0 ------

19/03/2009 13 655 1 7746.53 7769 79 35.2 6.02 18 8.0165 0 0 ------

MD119 CT Stimulation Page 3

19/01/2012 12 655 1 8365.89 8358 73 35 6.53 14 6.3887 0 0 ------

25/05/2012 12 655 0.79 7288.62 9214 74 35.8 5.3 27 8.1952 0 0 ------

12/05/2014 9.53 1440 1.01 5802.15 5737 140 12 7.17 33 8.0089 0 0 ------

7. Present Situation

The well is closed due to no production.

8. Well Interventions history

28/02/14 until 31/05/14, the work-over side tracked the well and completed with 4-1/2in

LCP. The PLT and DST performed with condition open hole showing prod (Qo=1.01m3/h,

GOR=5737m3/m3).

17/06/14, Coiled tubing clean out with foam to displace the work-over fluid in the well,

tagged TD@3429m, filled up the well with treated water.

06/07/14, perforated the interval (3395 – 3401)m and (3403 – 3411)m. The well didn’t

flow.

19/07/14, Coiled tubing clean out attempted to start the well production followed by kick

off, tagged TD@3431m. The well didn’t flow after the intervention.

21/08/14, Slickline running gauge size 86mm managed to get down to TD.

9. Discussion and Recommendations

The well was side tracked on May14 then perforated on Jul 14, the well didn’t flow. The

DST performed on May14 during work-over with condition open hole showing skin of

MD119 CT Stimulation Page 4

+17.4 as an indication near wellbore damage. The type of damage might be oil based mud

lost during killed fluid operation and some fine/clay migrations.

CT intervention for clean out and kick off performed on Jul14 was not able to get the well to

flow.

The PFS performed on 01/08/14 confirmed that there was communication between reservoir

and the wellbore.

The well never been treated with acid stimulation after side tracked.

Based on above fact, it’s recommended to perform following intervention:

Wash the perforated intervals with combination of TubeClean and treated water using

high pressure jetting tool follow by unload the spent acid with nitrogen,

Perform stimulation with Mud Acid 6:1.5 as main treatment with foam diverter,

Pump nitrogen at the end of the treatment until all dissolved materials + spent acid

recover back to surface continue with kick off the well,

10. Job Execution

Equipments:

One Coiled Tubing Unit

One (01) High pressure pumping unit

One (01) High pressure N2 convertor

Three (03) tanks for transporting and mixing products

One (01) High pressure jetting tool (JetBlaster/RotoJet/Pulsonix)

One (01) Jetting nozzle

Products:

Day 1 (TubeClean)

31 m3 Treated Water (2%KCl)

04 m3 Tube Clean HCl 7.5%

12 m3 Liquid nitrogen.

Day 2 (Mud Acid)

21 m3 Treated water mixed with 3%NH4Cl

26 m3 Diesel

12 m3 Preflush/Overflush HCl 7.5%

12 m3 Mud Acid 6:1.5

01 m3 Foam Diversion

16 m3 Liquid Nitrogen

11. Job Procedure

Day 1 (Tube Clean)

1. Check well head and surface connections plus the flare line.

2. Spot and R/U CT, high pressure pumping unit, N2 unit and tanks for mixing chemicals.

3. Rigging up the surface lines (pumping line, bleed-off line, and kill line).

4. Rig up CT, nitrogen and liquid pump units, flush lines and CT reel with water and test all

surface lines to 5000 psi, as per Schlumberger and Sonatrach standards.

MD119 CT Stimulation Page 5

5. Open the well to the flare line and start RIH CT with high pressure jetting tool

(JetBlaster/PulSonix/RotoJet), while circulating nitrified treated water at low rate

(0.5bpm + 500 scf/bbl)

Note: Perform pull test whenever necessary to confirm CT can be picked up safely.

6. Once the CT reach depth top of perf interval at 3395m, increase the pump rate to (1.5bpm

+ 500scfm) and running the CT at speed (3-4)m/min.

7. Slow down the CT before tagging TD at 3436m TR.

8. Pick up the CT to the bottom of lower perforated interval at 3411m, start the treatment

with follow below sequences to wash the perf interval (3395 – 3411)m, pump rate at

(1.5bpm + 500 scfm) with slow speed (3-4)m/min.

2.0 m3 Nitrified TubeClean

2.0 m3 Nitrified Treated Water

2.0 m3 Nitrified TubeClean

2.0 m3 Nitrified Treated Water

Note: Adjust the CT speed to get uniform coverage of the perforated intervals.

9. Displace the CT with pumping 1m3 of Nitrogen at high rate.

10. Continue pumping nitrogen while picking up the CT to 2500m to unload the spent acid.

11. Keep circulating nitrogen from depth 2500m to kick off the well. Once all treatment

fluids have been recovered back to the flare line and the well showing a stable flow, pull

the CT to surface.

12. CT on surface. R/D the stack.

Day 2 (Mud Acid Treatment)

1. Perform pressure test CT stack and all lines including the master valve to 5,000 psi for 15

min.

2. Pressure up the annulus between: 4”1/2 x7” to 50bars and 7” x 9”5/8 to 30bars. Confirm

no annulus communication.

3. Open the well to the flare line and start RIH CT with jetting nozzle, while circulating

treated water at low rate 0.5bpm.

Note:

Perform pull test whenever necessary to confirm CT can be picked up safely.

4. Running in hole the CT to TD @ 3436m TR, Start pumping diesel to filling up the

wellbore, wait until clean diesel return on the flare line.

MD119 CT Stimulation Page 6

5. Pick up the CT to desired depth as per below pump schedule. Once the Treated water

with NH4CL exiting the nozzle, Close the well return then follow below sequences to

squeeze to the formation.

o 2 m3 Treated Water with NH4CL

o 3 m3 Preflush HCl (7.5%)

o 6 m3 Mud Acid 6 : 1.5 1st Stage CT@3407m/TR

o 3 m3 Overflush HCl (7.5%)

o 0.5 m3 Spacer (Treated Water)

o 1 m3 Foam Diversion (2000 scf/bbl)

o 0.5 m3 Spacer (Treated Water)

o 3 m3 Preflush HCl (7.5%)

o 6 m3 Mud Acid 6 : 1.5 2nd Stage CT@3398m/TR

o 3 m3 Overflush HCl (7.5%)

o 2 m3 Treated Water with NH4CL

6. Displace the coiled tubing volume with 1m3 of nitrogen at maximum rate. Once all

treatment fluids out of the CT than open the well to the flare line.

7. Reduce nitrogen rate, keep circulating nitrogen while start pulling coiled tubing to 2500m

and observe returns.

8. Continue with the nitrogen kick-off at 2500m; collect samples of return on the flare line

to confirm that all treatment fluids have been recovered back to surface.

9. Pull CT to surface when oil flow is established. Rig down all equipment.

MD119 CT Stimulation Page 7

12.Well Diagram

MD119 CT Stimulation Page 8

13.Job treatment report

sonatrach

Well Name Remarks

Zone Code

Sonatrach Supervisor

Service Company

Completion Slotted Liner Cemented Liner Size

Tubing Size CCE : Yes No Size

Rig Up Equipment Coiled Tubing Unit Yes No

Pump Unit Yes No

Nitrogen Unit Yes No

Others Yes No

Lines Yes No

Pressure Tests 9 5/8" Annulus Yes No

7" Annulus Yes No

TubeClean Date

Stage WHP Before kg/cm2 After kg/cm2

Well Flowing Yes No Yes No

Treatment Reformat Wash Yes No

TubeClean Yes No

Treated Water Yes No

Nitrified Fluids Yes No

Quantities Reformat Wash m3

TubeClean m3

Treated Water m3

Nitrogen m3

Others m3

Flow Back Yes No

Matrix Treatment Date

Stage WHP Before kg/cm2 After kg/cm2

Well Flowing Yes No Yes No

Treatment Preflush 7.5% HCl

Other

Main Treatment Mud Acid

Reformat

Overflush 7.5% HCl

Other

Nitrified Fluids Yes No

Diversion Foam Yes No

Other No

Quantities Preflush m3

Main Treatment m3

Overflush m3

Nitrogen m3

Flow Back All Fluids Yes No

Partial Flow Back Yes No

Kick Off Needed Yes No

Samples Taken Yes No

MD119 CT Stimulation Page 9

You might also like

- Shell Eco-Marathon SOWDocument30 pagesShell Eco-Marathon SOWFirman ErizalNo ratings yet

- Flight PlanDocument7 pagesFlight PlanCristin LeeNo ratings yet

- A.cybulski, J.moulijn - Structured Catalyst and ReactorsDocument645 pagesA.cybulski, J.moulijn - Structured Catalyst and Reactorscaprolactamcl4571No ratings yet

- Datosej OilDocument11 pagesDatosej OilSergioVillagomezNo ratings yet

- Planilha Dados TransmissorasDocument8 pagesPlanilha Dados TransmissorasSandro Jonas NorbertoNo ratings yet

- Eddcedds PDF 1525369528Document29 pagesEddcedds PDF 1525369528bittekeinspam123No ratings yet

- RPL 1Document2 pagesRPL 1Arvind Kumar SinghNo ratings yet

- Otbd OmdbDocument8 pagesOtbd OmdbDoraemonNo ratings yet

- Transformer Oil AnalysisDocument1 pageTransformer Oil Analysisalvin meNo ratings yet

- SIE5178 SBGR-SBPA (12-Jan-2020) #2Document7 pagesSIE5178 SBGR-SBPA (12-Jan-2020) #2Luiz HenriqueNo ratings yet

- Generado: Media Máxima MínimaDocument20 pagesGenerado: Media Máxima MínimaJose AguilarNo ratings yet

- LPG BCRL Updated NOV22 - SennaDocument11 pagesLPG BCRL Updated NOV22 - SennafaizNo ratings yet

- Routine Vertical Load Test-19.07.2023 PDFDocument11 pagesRoutine Vertical Load Test-19.07.2023 PDFBRIDGE ROOF100% (1)

- As Man Engine PartsDocument2 pagesAs Man Engine PartsRAVEENDRA OFFICENo ratings yet

- Flight Briefing Package: Release #1Document7 pagesFlight Briefing Package: Release #1joiko ukukl8kuNo ratings yet

- Liberty Galati S.A. - Romania: Inspection Certificate 20607255 ACCORDING TO: EN 10204/2004/3.1 DATE: 05.11.2019Document1 pageLiberty Galati S.A. - Romania: Inspection Certificate 20607255 ACCORDING TO: EN 10204/2004/3.1 DATE: 05.11.2019Felicia CioabaNo ratings yet

- Thread Pitch ChartDocument1 pageThread Pitch Chartyu7468No ratings yet

- Flight Briefing Package: Release #1Document10 pagesFlight Briefing Package: Release #1Matcha MatchuNo ratings yet

- Egkkojaq PDF 1667872494Document15 pagesEgkkojaq PDF 1667872494xCircusGalleryNo ratings yet

- UDU Site INDEXIM Update Coal (22 Februari 2023)Document2 pagesUDU Site INDEXIM Update Coal (22 Februari 2023)Ovin AvelinusNo ratings yet

- EDDMEIDW PDF 27feb23Document10 pagesEDDMEIDW PDF 27feb23Benoit VoisinNo ratings yet

- 23 - Catenary Final - 230705 - 171820Document15 pages23 - Catenary Final - 230705 - 171820Tao HienNo ratings yet

- Thread Pitch ChartDocument2 pagesThread Pitch ChartGeorgeMtyNo ratings yet

- Eddcedds PDF 1525281029Document29 pagesEddcedds PDF 1525281029bittekeinspam123No ratings yet

- Vehicle Gear RatioDocument2 pagesVehicle Gear Ratioamir sadighiNo ratings yet

- Polycab Cables Pricelist NewDocument8 pagesPolycab Cables Pricelist NewChandan RayNo ratings yet

- BUL 4462 Product Overview Hose Bulletin UK MainDocument4 pagesBUL 4462 Product Overview Hose Bulletin UK MainTuan buivietNo ratings yet

- Retificação Do Resultado Final - Após Recursos: Cargo: Auditor Fiscal de Tributos Municipais - AFTMDocument2 pagesRetificação Do Resultado Final - Após Recursos: Cargo: Auditor Fiscal de Tributos Municipais - AFTMmarcelox2No ratings yet

- SIE5366 SBGR-SBFL (18-Jan-2020) #2Document7 pagesSIE5366 SBGR-SBFL (18-Jan-2020) #2Luiz HenriqueNo ratings yet

- Lab 2Document18 pagesLab 2Dodiya NikunjNo ratings yet

- Budomari Sheet (11) New Second LotDocument12 pagesBudomari Sheet (11) New Second LotRT NafsanNo ratings yet

- SIE5384 SBSV-SBRF (28-Mar-2021) #1Document7 pagesSIE5384 SBSV-SBRF (28-Mar-2021) #1Luiz SantosNo ratings yet

- Bias CorrDocument232 pagesBias CorrivanNo ratings yet

- Dwight ADocument92 pagesDwight Arowell naragNo ratings yet

- Refueling All Unit GSM Site Ke September 2023Document95 pagesRefueling All Unit GSM Site Ke September 2023FachriNo ratings yet

- Data Pengukuran BFPT ADocument3 pagesData Pengukuran BFPT AazisyuswandiNo ratings yet

- Data Pengukuran BFPT ADocument3 pagesData Pengukuran BFPT AazisyuswandiNo ratings yet

- PERFILDocument73 pagesPERFILAngel Dario TobarNo ratings yet

- World Tractor Products PDFDocument12 pagesWorld Tractor Products PDFAshraf MostafaNo ratings yet

- ShipNoon Calc (Engine) Dhop.#12Document51 pagesShipNoon Calc (Engine) Dhop.#12Sasidharan RajendranNo ratings yet

- SIE5230 SBSP-SBUL (24-Dec-2019) #1Document7 pagesSIE5230 SBSP-SBUL (24-Dec-2019) #1Luiz HenriqueNo ratings yet

- Hydrostatic & BonjeanDocument35 pagesHydrostatic & BonjeanNita AviyantiNo ratings yet

- Billing Report - July 2022Document100 pagesBilling Report - July 2022Elaine ALdovinoNo ratings yet

- HDPE Price List LDocument4 pagesHDPE Price List LabhishitewariNo ratings yet

- Final AssignmentDocument11 pagesFinal AssignmentRadwan OhiNo ratings yet

- R.C. Batch: The Following Original Diploma Certificates Were Handed Over On - 2003Document15 pagesR.C. Batch: The Following Original Diploma Certificates Were Handed Over On - 2003PUMANo ratings yet

- Action IiDocument8 pagesAction Iiaditya.prakash35No ratings yet

- BriefingDocument31 pagesBriefingAirbus330 Airbus330No ratings yet

- Wire Ropes Detail - Diepa - Special Wire RopesDocument9 pagesWire Ropes Detail - Diepa - Special Wire RopessebastianvmNo ratings yet

- Number Cable Insert Into The Spiral Conduit - 014646Document1 pageNumber Cable Insert Into The Spiral Conduit - 014646DEATH WISHNo ratings yet

- CorporatedgrDocument7 pagesCorporatedgrelectricalNo ratings yet

- Microfeap PortalDocument10 pagesMicrofeap PortalFredrikus BerkhmansNo ratings yet

- DT50U PartsDocument74 pagesDT50U PartshuckinnzNo ratings yet

- Lgkreddk PDF 1525527274Document62 pagesLgkreddk PDF 1525527274bittekeinspam123No ratings yet

- Injector UDocument3 pagesInjector Umecanik.veracruzNo ratings yet

- SIE5290 SBVT-SBSV (27-Mar-2021) #1Document8 pagesSIE5290 SBVT-SBSV (27-Mar-2021) #1Luiz SantosNo ratings yet

- Steel Pipes - Pipe Schedule Chart: NPS Inches N.D. O.D. MMDocument1 pageSteel Pipes - Pipe Schedule Chart: NPS Inches N.D. O.D. MMJoydev GangulyNo ratings yet

- Mynnkmia PDF 1610002582 PDFDocument15 pagesMynnkmia PDF 1610002582 PDFMartinNo ratings yet

- Eddwedds PDF 1525516763Document32 pagesEddwedds PDF 1525516763bittekeinspam123No ratings yet

- 1 ResDocument91 pages1 ResOli PortalNo ratings yet

- 780321Document3 pages780321Miguel RojasNo ratings yet

- Catalogo-Completo GIMA 2011Document257 pagesCatalogo-Completo GIMA 2011Andreea HoliciuNo ratings yet

- The Antibacterial Mechanism of Silver Nanoparticles and Its Application in DentistryDocument8 pagesThe Antibacterial Mechanism of Silver Nanoparticles and Its Application in DentistryabdulrazaqNo ratings yet

- The Hunger Level Scale: 3. Think About Other Reasons You May Want To EatDocument3 pagesThe Hunger Level Scale: 3. Think About Other Reasons You May Want To EatA Puffin LekvárNo ratings yet

- Chapter 6 Hexavalent ChromiumDocument56 pagesChapter 6 Hexavalent Chromiumgabriel100% (1)

- Exhibition Calendar 20-21Document2 pagesExhibition Calendar 20-21AwaisNo ratings yet

- Types of TaxesDocument15 pagesTypes of TaxesNischal KumarNo ratings yet

- Product Price ReferenceDocument153 pagesProduct Price ReferenceWR2 ASMNo ratings yet

- The Legend of Rawa PeningDocument2 pagesThe Legend of Rawa PeningIbnu AqilNo ratings yet

- Unit ConversionsDocument2 pagesUnit Conversionsangry_granNo ratings yet

- Quarantine Clearance Quarantine Clearance: Barangay Cato Barangay CatoDocument2 pagesQuarantine Clearance Quarantine Clearance: Barangay Cato Barangay CatoBarangay CatoNo ratings yet

- Zuku Visual Flashnotes Distemper ExtendedDocument4 pagesZuku Visual Flashnotes Distemper ExtendedShubham HarishNo ratings yet

- Manejo de Suelos Salinos y SodicoDocument189 pagesManejo de Suelos Salinos y SodicoJean Marco Gozme AcostaNo ratings yet

- Kheerganga TrekDocument15 pagesKheerganga TrekMahesh RautNo ratings yet

- Case Study3-FitbitDocument11 pagesCase Study3-FitbitKwai Fong PANGNo ratings yet

- Auxiliary PowerDocument29 pagesAuxiliary PowerManoj UpadhyayNo ratings yet

- August 2012Document19 pagesAugust 2012TheUnknown LyssNo ratings yet

- User Manual, Maintenance Guide & Log Book: One or Two Loop Analogue Addressable Fire Alarm Control PanelDocument29 pagesUser Manual, Maintenance Guide & Log Book: One or Two Loop Analogue Addressable Fire Alarm Control PanelathNo ratings yet

- DEF Diesel Exhaust Fluid Flowmeter Systems: Application Brochure 200-80Document12 pagesDEF Diesel Exhaust Fluid Flowmeter Systems: Application Brochure 200-80Ricardo NapitupuluNo ratings yet

- Director Risk Management Investment Accountant in NYC Resume James DwyerDocument2 pagesDirector Risk Management Investment Accountant in NYC Resume James DwyerJamesDwyerNo ratings yet

- CHL v4 - U3 Task 8 Additional Parity Pricing FiguresDocument6 pagesCHL v4 - U3 Task 8 Additional Parity Pricing FiguresProdip Debnath Nayan100% (2)

- FAQs - For - Listing - of - Commercial - Paper-BSE (26 Nov 2019)Document2 pagesFAQs - For - Listing - of - Commercial - Paper-BSE (26 Nov 2019)HimanshiNo ratings yet

- Heart, Nerve and Mucsle, Membrane Transport Mcqs With KeyDocument8 pagesHeart, Nerve and Mucsle, Membrane Transport Mcqs With KeyMudassar Roomi100% (7)

- Elecrolysis Cell DrawingDocument2 pagesElecrolysis Cell DrawingRimaNo ratings yet

- STPM Biology 964/1 4 Oktober 2017 1 Hour 30 Minutes: SulitDocument14 pagesSTPM Biology 964/1 4 Oktober 2017 1 Hour 30 Minutes: Sulitrevathy varatharajahNo ratings yet

- Bir Form 1600Document9 pagesBir Form 1600Vincent De GuzmanNo ratings yet

- 2.3.5 Practice - Atomic Structure (Practice)Document11 pages2.3.5 Practice - Atomic Structure (Practice)damarionbryant46No ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- MRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDocument12 pagesMRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDan RotariNo ratings yet