Professional Documents

Culture Documents

MD+PRO Series STD WC 10w

MD+PRO Series STD WC 10w

Uploaded by

ag cnc & wedm machining shopOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD+PRO Series STD WC 10w

MD+PRO Series STD WC 10w

Uploaded by

ag cnc & wedm machining shopCopyright:

Available Formats

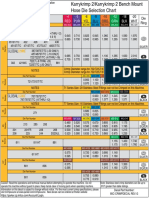

MD+PRO Series Wire Dia.

and Type Material Type Class

Digest .010 hard brass Tungsten Carbide Standard

Thickness 0.25 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 951 HP 0.080

1 2811 HP 0.130 0.00570 0.00690 0.00720 Nozzle Gap

2 2812 HL 0.260 - 0.00510 0.00540 Upper .008"

3 2813 LC 0.260 - - 0.00510 Lower .004"

4 - - -

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 60 23

Thickness 0.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 951 HP 0.080

1 2821 HP 0.160 0.00590 0.00705 0.00745 Nozzle Gap

2 2822 HL 0.230 - 0.00510 0.00550 Upper .008"

3 2823 LC 0.260 - - 0.00510 Lower .004"

4 - - -

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 76 23

Thickness 0.75 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 951 HP 0.080

1 2831 HP 0.120 0.00620 0.00705 0.00745 Nozzle Gap

2 2832 HL 0.160 - 0.00510 0.00550 Upper .008"

3 2833 LC 0.240 - - 0.00510 Lower .004"

4 - - -

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 76 23

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .010 hard brass Tungsten Carbide Standard

Thickness 1 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 952 HP 0.040

1 2841 HP 0.060 0.00650 0.00725 0.00785 0.00815 Nozzle Gap

2 2842 MP 0.250 - 0.00510 0.00570 0.00600 Upper .008"

3 2843 HL 0.100 - - 0.00510 0.00540 Lower .004"

4 2844 LC 0.250 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 1.25 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 952 HP 0.040

1 2851 HP 0.050 0.00660 0.00725 0.00785 0.00815 Nozzle Gap

2 2852 MP 0.250 - 0.00510 0.00570 0.00600 Upper .008"

3 2853 HL 0.100 - - 0.00510 0.00540 Lower .004"

4 2854 LC 0.240 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 1.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 952 HP 0.040

1 2861 HP 0.040 0.00650 0.00725 0.00785 0.00815 Nozzle Gap

2 2862 MP 0.240 - 0.00510 0.00570 0.00600 Upper .008"

3 2863 HL 0.090 - - 0.00510 0.00540 Lower .004"

4 2864 LC 0.240 - - - 0.00510

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .010 hard brass Tungsten Carbide Standard

Thickness 1.75 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 952 HP 0.040

1 2871 HP 0.045 0.00660 0.00725 0.00785 0.00815 Nozzle Gap

2 2872 MP 0.220 - 0.00510 0.00570 0.00600 Upper .008"

3 2873 HL 0.080 - - 0.00510 0.00540 Lower .004"

4 2874 LC 0.230 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 2 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 952 HP 0.040

1 2881 HP 0.040 0.00660 0.00725 0.00785 0.00815 Nozzle Gap

2 2882 MP 0.210 - 0.00510 0.00570 0.00600 Upper .008"

3 2883 HL 0.080 - - 0.00510 0.00540 Lower .004"

4 2884 LC 0.230 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 2.25 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 953 HP 0.020

1 2891 HP 0.035 0.00660 0.00735 0.00795 0.00815 Nozzle Gap

2 2892 MP 0.180 - 0.00520 0.00580 0.00600 Upper .008"

3 2893 HL 0.070 - - 0.00520 0.00540 Lower .004"

4 2894 LC 0.200 - - - 0.00510

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .010 hard brass Tungsten Carbide Standard

Thickness 2.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 953 HP 0.020

1 2901 HP 0.030 0.00660 0.00740 0.00800 0.00825 Nozzle Gap

2 2902 MP 0.170 - 0.00520 0.00580 0.00605 Upper .008"

3 2903 HL 0.070 - - 0.00520 0.00545 Lower .004"

4 2904 LC 0.180 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 2.75 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 953 HP 0.020

1 2911 HP 0.025 0.00670 0.00750 0.00810 0.00840 Nozzle Gap

2 2912 MP 0.160 - 0.00520 0.00580 0.00610 Upper .008"

3 2913 HL 0.070 - - 0.00520 0.00550 Lower .004"

4 2914 LC 0.150 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 3 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 953 HP 0.020

1 2921 HP 0.025 0.00680 0.00755 0.00815 0.00855 Nozzle Gap

2 2922 MP 0.160 - 0.00520 0.00580 0.00620 Upper .008"

3 2923 HL 0.070 - - 0.00520 0.00560 Lower .004"

4 2924 LC 0.130 - - - 0.00510

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Version 1.0 (09-05)

MD+PRO Series Wire Dia. and Type Material Type Class

Digest .010 hard brass Tungsten Carbide Standard

Thickness 3.5 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 953 HP 0.020

1 2931 HP 0.020 0.00680 0.00770 0.00820 0.00850 Nozzle Gap

2 2932 MP 0.150 - 0.00520 0.00570 0.00600 Upper .008"

3 2933 HL 0.070 - - 0.00520 0.00550 Lower .004"

4 2934 LC 0.150 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness 4 inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A 954 HP 0.010

1 2941 HP 0.015 0.00690 0.00775 0.00825 0.00845 Nozzle Gap

2 2942 MP 0.140 - 0.00520 0.00570 0.00590 Upper .008"

3 2943 HL 0.070 - - 0.00520 0.00540 Lower .004"

4 2944 LC 0.140 - - - 0.00510

5 - - - -

6 - - - - -

7 - - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra 90 80 76 23

Thickness inch

Cutting process Offset Step

No, E PS FA 1st 2nd 3rd 4th 5th 6th 7th 8th 9th Increment

A

1 Nozzle Gap

2 - Upper

3 - - Lower

4 - - -

5 - - - -

6 - - - - -

8 - - - - - - -

9 - - - - - - - -

Surface roughness Ra

Version 1.0 (09-05)

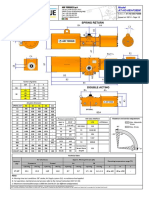

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 0.250 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 951 2811 2812 2813

Power Supply PS HP HP HL LC

Servo SV NM NM SL SL

Voltage Open Vo 12 16 3 3

Power Setting IP 5 6 6 3

Off Time OFF 1 1 8 11

Stabilizer A SA 3 4 2 2

Stabilizer B SB 12 12 8 9

Stabilizer C SC 1 1 1 1

Stabilizer E SE 4 3 1 1

Voltage Gap VG 50 42 57 65

Fine Machining FM OFF OFF OFF OFF

Wire Speed WS 8 12 12 12

Wire Tension WT 10 11 13 13

Pre-Tension PT 14 14 14 14

Flow Balance FB NM NM NM NM

Liquid Quantity LQ 12 14 4 4

Liquid Resistivity LR 7 7 7 7

Feedrate Address FA 0.080 0.130 0.260 0.260

Offset Value(s) H -------- 1 2 3

Rough Cut -------- 0.00570 -------- --------

Rough & 1 Skim -------- 0.00690 0.00510 --------

Rough & 2 Skims -------- 0.00720 0.00540 0.00510

Rough & 3 Skims -------- 0.00730 0.00550 0.00520

Rough & 4 Skims -------- 0.00735 0.00555 0.00525

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .190 ~ .210 .260 ~ .340 .240 ~ .320

Average Voltage Gap VG ~ 40 ~ 44 56 ~ 64 58 ~ 68

Avg. Linear Feedrate ALF 11.97 7.13 4.91

Surface Finish(µ in) Ra ~ 85 ~ 95 55 ~ 65 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 0.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 951 2821 2822 2823

Power Supply PS HP HP HL LC

Servo SV NM NM SL SL

Voltage Open Vo 12 16 4 3

Power Setting IP 5 7 8 3

Off Time OFF 1 1 12 11

Stabilizer A SA 3 5 2 2

Stabilizer B SB 12 12 12 9

Stabilizer C SC 1 1 1 1

Stabilizer E SE 4 4 1 1

Voltage Gap VG 50 42 53 68

Fine Machining FM OFF OFF OFF OFF

Wire Speed WS 8 12 12 12

Wire Tension WT 10 11 13 13

Pre-Tension PT 14 14 14 14

Flow Balance FB NM NM NM NM

Liquid Quantity LQ 12 14 4 4

Liquid Resistivity LR 7 7 7 7

Feedrate Address FA 0.080 0.160 0.230 0.260

Offset Value(s) H -------- 1 2 3

Rough Cut -------- 0.00590 -------- --------

Rough & 1 Skim -------- 0.00705 0.00510 --------

Rough & 2 Skims -------- 0.00745 0.00550 0.00510

Rough & 3 Skims -------- 0.00755 0.00560 0.00520

Rough & 4 Skims -------- 0.00760 0.00565 0.00525

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .120 ~ .140 .200 ~ .280 .180 ~ .280

Average Voltage Gap VG ~ 40 ~ 44 55 ~ 70 60 ~ 70

Avg. Linear Feedrate ALF 8.06 4.78 3.55

Surface Finish(µ in) Ra ~ 85 ~ 95 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 0.750 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 951 2831 2832 2833

Power Supply PS HP HP HL LC

Servo SV NM NM SL SL

Voltage Open Vo 12 16 5 3

Power Setting IP 5 8 10 3

Off Time OFF 1 1 12 10

Stabilizer A SA 3 5 2 2

Stabilizer B SB 12 12 12 8

Stabilizer C SC 1 1 1 1

Stabilizer E SE 4 5 1 1

Voltage Gap VG 50 40 60 73

Fine Machining FM OFF OFF OFF OFF

Wire Speed WS 8 12 12 12

Wire Tension WT 10 11 13 13

Pre-Tension PT 14 14 14 14

Flow Balance FB NM NM NM NM

Liquid Quantity LQ 12 14 4 4

Liquid Resistivity LR 7 7 7 7

Feedrate Address FA 0.080 0.120 0.160 0.240

Offset Value(s) H -------- 1 2 3

Rough Cut -------- 0.00620 -------- --------

Rough & 1 Skim -------- 0.00705 0.00510 --------

Rough & 2 Skims -------- 0.00745 0.00550 0.00510

Rough & 3 Skims -------- 0.00760 0.00565 0.00525

Rough & 4 Skims -------- 0.00765 0.00570 0.00530

Rough & 5 Skims --------

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .090 ~ .120 .140 ~ .220 .200 ~ .280

Average Voltage Gap VG ~ 38 ~ 42 65 ~ 75 70 ~ 80

Avg. Linear Feedrate ALF 6.48 3.85 3.04

Surface Finish(µ in) Ra ~ 85 ~ 95 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 1.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 952 2841 2842 2843 2844

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 4

Power Setting IP 7 9 11 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 57 54 60

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.040 0.060 0.250 0.100 0.250

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00650 -------- -------- --------

Rough & 1 Skim -------- 0.00725 0.00510 -------- --------

Rough & 2 Skims -------- 0.00785 0.00570 0.00510 --------

Rough & 3 Skims -------- 0.00815 0.00600 0.00540 0.00510

Rough & 4 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 5 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .080 ~ .100 .200 ~ .280 .100 ~ .180 .300 ~ .380

Average Voltage Gap VG ~ 38 ~ 42 52 ~ 62 64 ~ 74 65 ~ 80

Avg. Linear Feedrate ALF 4.92 3.62 2.52 2.23

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 1.250 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 952 2851 2852 2853 2854

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 56 53 59

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.040 0.050 0.250 0.100 0.240

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00660 -------- -------- --------

Rough & 1 Skim -------- 0.00725 0.00510 -------- --------

Rough & 2 Skims -------- 0.00785 0.00570 0.00510 --------

Rough & 3 Skims -------- 0.00815 0.00600 0.00540 0.00510

Rough & 4 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 5 Skims -------- 0.00840 0.00625 0.00565 0.00535

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .060 ~ .080 .200 ~ .280 .070 ~ .150 .280 ~ .360

Average Voltage Gap VG ~ 40 ~ 44 50 ~ 60 52 ~ 62 65 ~ 80

Avg. Linear Feedrate ALF 4.24 3.20 2.18 1.95

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 1.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 952 2861 2862 2863 2864

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 55 52 58

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.040 0.040 0.240 0.090 0.240

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00650 -------- -------- --------

Rough & 1 Skim -------- 0.00725 0.00510 -------- --------

Rough & 2 Skims -------- 0.00785 0.00570 0.00510 --------

Rough & 3 Skims -------- 0.00815 0.00600 0.00540 0.00510

Rough & 4 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 5 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .050 ~ .070 .200 ~ .280 .060 ~ .140 .280 ~ .360

Average Voltage Gap VG ~ 40 ~ 44 50 ~ 60 50 ~ 60 65 ~ 80

Avg. Linear Feedrate ALF 3.57 2.79 1.85 1.68

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 1.750 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 952 2871 2872 2873 2874

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 54 51 57

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.040 0.045 0.220 0.080 0.230

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00660 -------- -------- --------

Rough & 1 Skim -------- 0.00725 0.00510 -------- --------

Rough & 2 Skims -------- 0.00785 0.00570 0.00510 --------

Rough & 3 Skims -------- 0.00815 0.00600 0.00540 0.00510

Rough & 4 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 5 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .040 ~ .060 .180 ~ .260 .060 ~ .140 .260 ~ .340

Average Voltage Gap VG ~ 40 ~ 44 50 ~ 60 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 3.07 2.43 1.63 1.49

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 2.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 952 2881 2882 2883 2884

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 4

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 54 50 55

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.040 0.040 0.210 0.080 0.230

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00660 -------- -------- --------

Rough & 1 Skim -------- 0.00725 0.00510 -------- --------

Rough & 2 Skims -------- 0.00785 0.00570 0.00510 --------

Rough & 3 Skims -------- 0.00815 0.00600 0.00540 0.00510

Rough & 4 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 5 Skims -------- 0.00840 0.00625 0.00565 0.00535

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .030 ~ .050 .180 ~ .260 .060 ~ .140 .260 ~ .340

Average Voltage Gap VG ~ 40 ~ 44 50 ~ 60 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 2.57 2.08 1.42 1.31

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 2.250 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 953 2891 2892 2893 2894

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 5

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 53 49 56

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 12 12 12

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.020 0.035 0.180 0.070 0.200

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00660 -------- -------- --------

Rough & 1 Skim -------- 0.00735 0.00520 -------- --------

Rough & 2 Skims -------- 0.00795 0.00580 0.00520 --------

Rough & 3 Skims -------- 0.00815 0.00600 0.00540 0.00510

Rough & 4 Skims -------- 0.00835 0.00620 0.00560 0.00530

Rough & 5 Skims -------- 0.00840 0.00625 0.00565 0.00535

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .025 ~ .045 .170 ~ .250 .050 ~ .130 .180 ~ .260

Average Voltage Gap VG ~ 38 ~ 42 48 ~ 58 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 2.30 1.87 1.28 1.17

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 2.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 953 2901 2902 2903 2904

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 12 5 5

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 12 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 12 8

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 53 48 56

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 14 14 14

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.020 0.030 0.170 0.070 0.180

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00660 -------- -------- --------

Rough & 1 Skim -------- 0.00740 0.00520 -------- --------

Rough & 2 Skims -------- 0.00800 0.00580 0.00520 --------

Rough & 3 Skims -------- 0.00825 0.00605 0.00545 0.00510

Rough & 4 Skims -------- 0.00840 0.00620 0.00560 0.00525

Rough & 5 Skims -------- 0.00845 0.00625 0.00565 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .025 ~ .045 .160 ~ .240 .050 ~ .130 .160 ~ .240

Average Voltage Gap VG ~ 38 ~ 42 48 ~ 58 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 2.04 1.66 1.15 1.04

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 2.750 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 953 2911 2912 2913 2914

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 13 6 6

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 11 10

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 11 7

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 52 48 56

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 14 14 14

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.020 0.025 0.160 0.070 0.150

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00670 -------- -------- --------

Rough & 1 Skim -------- 0.00750 0.00520 -------- --------

Rough & 2 Skims -------- 0.00810 0.00580 0.00520 --------

Rough & 3 Skims -------- 0.00840 0.00610 0.00550 0.00510

Rough & 4 Skims -------- 0.00850 0.00620 0.00560 0.00520

Rough & 5 Skims -------- 0.00860 0.00630 0.00570 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .020 ~ .040 .140 ~ .240 .050 ~ .130 .120 ~ .200

Average Voltage Gap VG ~ 38 ~ 42 48 ~ 58 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 1.88 1.54 1.11 0.99

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 3.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 953 2921 2922 2923 2924

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 14 7 7

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 10 9

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 10 7

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 51 48 58

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 14 14 14

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.020 0.025 0.160 0.070 0.130

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00680 -------- -------- --------

Rough & 1 Skim -------- 0.00755 0.00520 -------- --------

Rough & 2 Skims -------- 0.00815 0.00580 0.00520 --------

Rough & 3 Skims -------- 0.00855 0.00620 0.00560 0.00510

Rough & 4 Skims -------- 0.00860 0.00630 0.00570 0.00520

Rough & 5 Skims -------- 0.00865 0.00635 0.00575 0.00525

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .015 ~ .035 .120 ~ .200 .060 ~ .140 .100 ~ .180

Average Voltage Gap VG ~ 38 ~ 42 48 ~ 58 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 1.72 1.42 1.07 0.95

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 3.500 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 953 2931 2932 2933 2934

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 14 7 7

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 10 9

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 10 7

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 40 48 48 57

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 14 14 14

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.020 0.020 0.150 0.070 0.150

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00680 -------- -------- --------

Rough & 1 Skim -------- 0.00770 0.00520 -------- --------

Rough & 2 Skims -------- 0.00820 0.00570 0.00520 --------

Rough & 3 Skims -------- 0.00850 0.00600 0.00550 0.00510

Rough & 4 Skims -------- 0.00860 0.00610 0.00560 0.00520

Rough & 5 Skims -------- 0.00870 0.00620 0.00570 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .010 ~ .030 .120 ~ .200 .040 ~ .120 .140 ~ .220

Average Voltage Gap VG ~ 38 ~ 42 44 ~ 54 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 1.43 1.19 0.91 0.83

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

M.C.MACHINERY SYSTEMS

MD+PRO EXTENDED VIEW DATA SHEET

Flush cup clearance

Wire Dia. and Type Material Type Process Material Thickness

Upper Lower

.010 hard brass Tungsten Carbide Standard 4.000 .008" .004"

Cutting Process Start Up Rough Cut Skim1 Skim2 Skim3 Skim4 Skim5 Skim6

E-pack Number Eno 954 2941 2942 2943 2944

Power Supply PS HP HP MP HL LC

Servo SV NM NM SL SL SL

Voltage Open Vo 12 16 14 7 7

Power Setting IP 7 9 12 8 3

Off Time OFF 1 1 1 10 9

Stabilizer A SA 3 5 2 2 2

Stabilizer B SB 12 12 8 10 7

Stabilizer C SC 1 1 1 1 1

Stabilizer E SE 4 5 1 1 1

Voltage Gap VG 50 42 45 50 60

Fine Machining FM OFF OFF OFF OFF OFF

Wire Speed WS 8 12 14 14 16

Wire Tension WT 10 11 13 13 13

Pre-Tension PT 14 14 14 14 14

Flow Balance FB NM NM NM NM NM

Liquid Quantity LQ 12 14 4 4 4

Liquid Resistivity LR 7 7 7 7 7

Feedrate Address FA 0.010 0.015 0.140 0.070 0.140

Offset Value(s) H -------- 1 2 3 4

Rough Cut -------- 0.00690 -------- -------- --------

Rough & 1 Skim -------- 0.00775 0.00520 -------- --------

Rough & 2 Skims -------- 0.00825 0.00570 0.00520 --------

Rough & 3 Skims -------- 0.00845 0.00590 0.00540 0.00510

Rough & 4 Skims -------- 0.00860 0.00605 0.00555 0.00525

Rough & 5 Skims -------- 0.00865 0.00610 0.00560 0.00530

Rough & 6 Skims --------

Stepping Increment -------- -------- -------- -------- --------

Upper Flow Rate 6.0 8.0 1.5 1.5 1.5

Lower Flow Rate 5.0 6.0 1.0 1.0 1.0

RESULTS

Feedrate Cutting FC ~ .005 ~ .025 .100 ~ .180 .040 ~ .120 .110 ~ .190

Average Voltage Gap VG ~ 40 ~ 44 44 ~ 54 50 ~ 60 55 ~ 70

Avg. Linear Feedrate ALF 1.23 1.03 0.77 0.71

Surface Finish(µ in) Ra ~ 85 ~ 95 75 ~ 85 72 ~ 80 20 ~ 26

Version 1.0 (09-05)

Note: Set flush cup clearance as shown as Top chart.

(If wire breakage occurs, set FA Adjust to -1 or -2 on monitor screen.)

You might also like

- Tool Estimation SheetDocument2 pagesTool Estimation Sheetsaravananpg247196% (54)

- Crimp DecalDocument1 pageCrimp DecalFernando Padilla0% (1)

- EFI ResistanceDocument3 pagesEFI ResistanceMuni Muniyappan33% (3)

- VM1 PLWD r02x2-304Document241 pagesVM1 PLWD r02x2-304ag cnc & wedm machining shopNo ratings yet

- ECG-Calculation Sheets: Design of Concrete StructuresDocument5 pagesECG-Calculation Sheets: Design of Concrete StructuresBahaa Gaber100% (1)

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- Thermodynamics Sample ProblemDocument14 pagesThermodynamics Sample ProblemEdgardo Emperoso II.100% (1)

- MD+PRO Series Land Steel 8wDocument19 pagesMD+PRO Series Land Steel 8wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series SPD Steel 10wDocument19 pagesMD+PRO Series SPD Steel 10wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series STD Cu 12wDocument20 pagesMD+PRO Series STD Cu 12wag cnc & wedm machining shopNo ratings yet

- Detail Q Detail R: SC 1:2 SC 1:2 5-200Document1 pageDetail Q Detail R: SC 1:2 SC 1:2 5-200Patrick Tripusaka SoloNo ratings yet

- 5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeDocument2 pages5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeMemona FayyazNo ratings yet

- Copper Bussman FusesDocument9 pagesCopper Bussman FusesKhaled BellegdyNo ratings yet

- K-511-V, FLW SWTDocument2 pagesK-511-V, FLW SWTamir shokrNo ratings yet

- Base Slab - BBS TramaniDocument16 pagesBase Slab - BBS TramaniDevesh GuptaNo ratings yet

- NC Specs 3 18 21Document2 pagesNC Specs 3 18 21ai007.rusmanaNo ratings yet

- BBS For FoundationDocument39 pagesBBS For Foundationranjitsaha9593No ratings yet

- Material For Stair at Uth Gas Plant - Rpo # 6510200305: SL# Description Length Bredth Qty Unit Total Grant Total 26.70Document1 pageMaterial For Stair at Uth Gas Plant - Rpo # 6510200305: SL# Description Length Bredth Qty Unit Total Grant Total 26.70Madhan KannanNo ratings yet

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- SET X Y DA Center of Gravity: ISO 5211 Interface Pressure ConnectionDocument2 pagesSET X Y DA Center of Gravity: ISO 5211 Interface Pressure Connectionhamr01No ratings yet

- Renew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiDocument4 pagesRenew Woltman Flange DN50-300-KATALOG CALIBRATE (2) (1) - DikompresiIrwan PangaribuanNo ratings yet

- Woltman Flange DN50-300-KATALOG CALIBRATEDocument4 pagesWoltman Flange DN50-300-KATALOG CALIBRATENurdin FahimNo ratings yet

- 30 ACE AIR - Return Exhaust Fresh Air Grille (Model FL FB EG)Document2 pages30 ACE AIR - Return Exhaust Fresh Air Grille (Model FL FB EG)rndjafNo ratings yet

- Pipe Thickness Sizes PDFDocument1 pagePipe Thickness Sizes PDFSualp EsenliNo ratings yet

- TMP - 20393 Barmex Ruland Oldham 07101550358290Document8 pagesTMP - 20393 Barmex Ruland Oldham 07101550358290Ramsay BoltNo ratings yet

- Relay Test Report: (Click On Fault Tests) RYB Impedance Characteristic (Shot Test)Document4 pagesRelay Test Report: (Click On Fault Tests) RYB Impedance Characteristic (Shot Test)ShahzadmbhattiNo ratings yet

- B5B15102 - PC Finalized 30.08.13Document2 pagesB5B15102 - PC Finalized 30.08.13quality.rudrapurNo ratings yet

- 7-12-0038 Rev 0 PDFDocument4 pages7-12-0038 Rev 0 PDFsuresh_vikiNo ratings yet

- RCC Ladder Qty1Document25 pagesRCC Ladder Qty1Kannan GnanaprakasamNo ratings yet

- Bina-Katni 3Rd Line Projecct: SectionDocument1 pageBina-Katni 3Rd Line Projecct: Sectionnikhil dhoteNo ratings yet

- N2XSRYDocument1 pageN2XSRYYulian Dea ZollaNo ratings yet

- N2XSRYDocument1 pageN2XSRYKrisnandha RahardianNo ratings yet

- Info EN755 9Document19 pagesInfo EN755 9Don JonesNo ratings yet

- Acoples Lovejoy CS-LS (Jaw)Document1 pageAcoples Lovejoy CS-LS (Jaw)marcelo castilloNo ratings yet

- Return Air Grilles: RM LouverDocument2 pagesReturn Air Grilles: RM LouverMinhNo ratings yet

- Cable Selection (Multi-Core)Document1 pageCable Selection (Multi-Core)Hùng Trần XuânNo ratings yet

- L0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023Document25 pagesL0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023quality assuranceNo ratings yet

- Return Air Grilles: RM LouverDocument2 pagesReturn Air Grilles: RM LouverYe Wunna TunNo ratings yet

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Document2 pages5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCNo ratings yet

- Apex Dynamics, Inc.: AB / ABR SeriesDocument14 pagesApex Dynamics, Inc.: AB / ABR SeriesIqtidar GulNo ratings yet

- Air Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesDocument4 pagesAir Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesBiswanath LenkaNo ratings yet

- Drive Shaft CalculationDocument106 pagesDrive Shaft CalculationMustu AkolawalaNo ratings yet

- Finolex Price List Dt. 1-04-2021Document15 pagesFinolex Price List Dt. 1-04-2021p.s.edits96No ratings yet

- A55 A56 CylinderDocument1 pageA55 A56 CylinderBiswanath LenkaNo ratings yet

- Mat 1140 For SuppliersDocument3 pagesMat 1140 For SupplierskarthimeenaNo ratings yet

- Tantalum Alloy Rev3 Tds en 3 v1Document1 pageTantalum Alloy Rev3 Tds en 3 v1Симеон АрабовNo ratings yet

- ST-06 Machine Room Bottom Plan Reinforcement Details of "MERCADO" Sec-80 GGNDocument46 pagesST-06 Machine Room Bottom Plan Reinforcement Details of "MERCADO" Sec-80 GGNRAKESH KUMARNo ratings yet

- Ejot Data Sheet jt2 5.50x 25Document2 pagesEjot Data Sheet jt2 5.50x 25Vengatesh HariNo ratings yet

- Adani Road Job Ra 11Document4 pagesAdani Road Job Ra 11Sasanka SekharNo ratings yet

- Weldedmesh Adets B500a b500bDocument4 pagesWeldedmesh Adets B500a b500bFiraz Kaot'zNo ratings yet

- CS Bridge ApproachesDocument20 pagesCS Bridge ApproachesvenkyNo ratings yet

- Spinning Mill Ukg CalculationDocument9 pagesSpinning Mill Ukg CalculationanandmaliNo ratings yet

- Dorman HandbookDocument4 pagesDorman HandbooksharathkammarNo ratings yet

- Hydroleduc Msi Series MotorDocument7 pagesHydroleduc Msi Series MotorMarusya KlimovaNo ratings yet

- Anchor Bolt: S. No. Bolt Description Qty. AB Dia. (D) Verticle Length (H) Thread (T)Document31 pagesAnchor Bolt: S. No. Bolt Description Qty. AB Dia. (D) Verticle Length (H) Thread (T)Sudhanshu PalNo ratings yet

- Roughness Conversion Chart RampinelliDocument1 pageRoughness Conversion Chart RampinelliServesh KumarNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- Staircase Boq Sr. No. Perticulars Designations Nos. L (M) B (M) T (M)Document2 pagesStaircase Boq Sr. No. Perticulars Designations Nos. L (M) B (M) T (M)Mahadev D. BhandareNo ratings yet

- Part Design Specification: Spring 2011 Dr. R. A. WyskDocument52 pagesPart Design Specification: Spring 2011 Dr. R. A. Wyskag cnc & wedm machining shopNo ratings yet

- From Design To Inspection: The Use of GDT For Predictable AssemblyDocument19 pagesFrom Design To Inspection: The Use of GDT For Predictable Assemblyag cnc & wedm machining shopNo ratings yet

- Understanding The Operation Process in Wire EdmDocument1 pageUnderstanding The Operation Process in Wire Edmag cnc & wedm machining shopNo ratings yet

- A Series Software Loading Instruction ManualDocument12 pagesA Series Software Loading Instruction Manualag cnc & wedm machining shopNo ratings yet

- MD+PRO Series STD Cu 12wDocument20 pagesMD+PRO Series STD Cu 12wag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 12 - ApplicationsDocument33 pagesRa Qa Fa Series Training - Chap 12 - Applicationsag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 4 - MaintenanceDocument53 pagesRa Qa Fa Series Training - Chap 4 - Maintenanceag cnc & wedm machining shopNo ratings yet

- The Best Time You'Ve Ever SpentDocument41 pagesThe Best Time You'Ve Ever Spentag cnc & wedm machining shopNo ratings yet

- MD+PRO Series Land Steel 8wDocument19 pagesMD+PRO Series Land Steel 8wag cnc & wedm machining shopNo ratings yet

- MD+PRO Series SPD Steel 10wDocument19 pagesMD+PRO Series SPD Steel 10wag cnc & wedm machining shopNo ratings yet

- MD+PRO SeriesDocument3 pagesMD+PRO Seriesag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 1 - ScreensDocument33 pagesRa Qa Fa Series Training - Chap 1 - Screensag cnc & wedm machining shopNo ratings yet

- Ra Qa Fa Series Training - Chap 7 - ProgramDocument15 pagesRa Qa Fa Series Training - Chap 7 - Programag cnc & wedm machining shopNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home WorkshopDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home Workshopag cnc & wedm machining shopNo ratings yet

- Digital Flow Meter (G2S10N09GMA) Manual 2Document20 pagesDigital Flow Meter (G2S10N09GMA) Manual 2VladimirNo ratings yet

- Väderstad Parts News April 2019Document32 pagesVäderstad Parts News April 2019martynjoyceNo ratings yet

- Diamond & CBN Powders For Grinding Wheel: ILJIN Micron PowderDocument2 pagesDiamond & CBN Powders For Grinding Wheel: ILJIN Micron PowderXavierNo ratings yet

- 1-6 ST Nomenclature-FeaturesDocument25 pages1-6 ST Nomenclature-FeaturesMahmoud NassarNo ratings yet

- ECIL - Vendor List-ISDDocument99 pagesECIL - Vendor List-ISDJN Choudhuri100% (1)

- Precision Engineering 1Document18 pagesPrecision Engineering 1Pratik KothariNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2010/0326336A1Document8 pagesPatent Application Publication (10) Pub. No.: US 2010/0326336A1ibrahim sugarNo ratings yet

- Table of MetalsDocument26 pagesTable of MetalsAkramNo ratings yet

- Nova BookDocument208 pagesNova BookShailesh ShirguppikarNo ratings yet

- Gta Analytical Methods 0848Document226 pagesGta Analytical Methods 0848milossmile100% (1)

- Erdemir Product Catalogue 2017Document334 pagesErdemir Product Catalogue 2017Burak Kececi0% (1)

- Hardness Vs RuptureDocument9 pagesHardness Vs RuptureVignesh VenkatesanNo ratings yet

- Periodic Table of Elements Trivia A-ZDocument2 pagesPeriodic Table of Elements Trivia A-ZPaolo Miguel NaragdaoNo ratings yet

- L4. Material and Geometry of ToolsDocument77 pagesL4. Material and Geometry of ToolsFasil GetachewNo ratings yet

- TC Color Codes Omega Tech RefDocument5 pagesTC Color Codes Omega Tech Refagha shuaibNo ratings yet

- RV-RVR: Technical CatalogueDocument24 pagesRV-RVR: Technical CatalogueBruno ReisNo ratings yet

- Metal Cutting PDFDocument92 pagesMetal Cutting PDFJagadishchandrabose KondamudiNo ratings yet

- Mickel 2Document6 pagesMickel 2Morgana BagshotNo ratings yet

- UNIT 1 NotesDocument44 pagesUNIT 1 NotesArun KumarNo ratings yet

- Untitled 1 PDFDocument35 pagesUntitled 1 PDFRAVI KANT BARANWALNo ratings yet

- 1 Lecture Metallogenic Zones in PakistanDocument74 pages1 Lecture Metallogenic Zones in PakistanFawad AhmedNo ratings yet

- 3/15/03 NIOSH Manual of Analytical MethodsDocument12 pages3/15/03 NIOSH Manual of Analytical MethodsWeare1_busyNo ratings yet

- X RayDocument18 pagesX RaySyed AshmadNo ratings yet

- Earth Science OutputsDocument7 pagesEarth Science OutputsRangerbackNo ratings yet

- General Chemistry 2017 Notes Stud.Document44 pagesGeneral Chemistry 2017 Notes Stud.victorNo ratings yet

- Reco-Dent International Co., LTD: Proforma InvoiceDocument2 pagesReco-Dent International Co., LTD: Proforma Invoicetrimurni TBANo ratings yet

- Plansee Seminar Technical Programm1Document21 pagesPlansee Seminar Technical Programm1Michelle HarrisNo ratings yet

- Gas Absorption in Wet ScrubbersDocument52 pagesGas Absorption in Wet ScrubbersJohan ConradieNo ratings yet