Professional Documents

Culture Documents

Linear Mode Current Sink Led Driver

Linear Mode Current Sink Led Driver

Uploaded by

José Ganga BarbosaCopyright:

Available Formats

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Hyundai Eon Bosch EDC17Document3 pagesHyundai Eon Bosch EDC17Bhanuka Srikantha88% (8)

- Schematic - Pre Balance 1kpro Flaship - 2022!03!29Document1 pageSchematic - Pre Balance 1kpro Flaship - 2022!03!29Komal KesariyaNo ratings yet

- TCS3200 Color SensorColor Detector Schematics PDFDocument1 pageTCS3200 Color SensorColor Detector Schematics PDFsiogNo ratings yet

- Datasheet Ic CE DEDocument15 pagesDatasheet Ic CE DEBersama UkhuwahNo ratings yet

- RC Wireless Car Receiver v1.0Document1 pageRC Wireless Car Receiver v1.0Nishant Khandekar100% (1)

- Mc100e131fn (D Flip Flop) ICDocument8 pagesMc100e131fn (D Flip Flop) ICDwp BhaskaranNo ratings yet

- L298 and L297 Based High Current Stepper Motor Driver With Mach 3 Interface 4Document2 pagesL298 and L297 Based High Current Stepper Motor Driver With Mach 3 Interface 4Ardiansyah Andry100% (1)

- AS179-92 LF - RF SwitchDocument7 pagesAS179-92 LF - RF SwitchsamNo ratings yet

- 1 19115823Document8 pages1 19115823Netaji PatraNo ratings yet

- GPS1.0 SCHDocument1 pageGPS1.0 SCHMukhiturrusda100% (2)

- Schematic - cd4017 Vu - 2024-03-16Document1 pageSchematic - cd4017 Vu - 2024-03-16genesios silvaNo ratings yet

- Tarjeta Reles 4 CanalesDocument2 pagesTarjeta Reles 4 CanalesjbrunobNo ratings yet

- Schematic - B - LM358 BATTERY TESTER - 2022-06-22Document1 pageSchematic - B - LM358 BATTERY TESTER - 2022-06-22usmfusmfNo ratings yet

- Lm358 Battery Voltage TesterDocument1 pageLm358 Battery Voltage TestermukhtarsafarofffNo ratings yet

- Alimentare Sursa Astabil: VCC 9V 9VDocument1 pageAlimentare Sursa Astabil: VCC 9V 9VMares DanielNo ratings yet

- Schematic PrintsDocument1 pageSchematic PrintsDân Kỹ Thuật100% (1)

- Schematic - Termometro Electronico - 2022-04-21Document2 pagesSchematic - Termometro Electronico - 2022-04-21Yuli QuelcaNo ratings yet

- Some Simple Tachometer Input Circuits: SteveDocument3 pagesSome Simple Tachometer Input Circuits: SteveSơn PhạmNo ratings yet

- RGB LED Driver 101D SCHDocument1 pageRGB LED Driver 101D SCHBenni SiswantoNo ratings yet

- Igbt SchematicDocument1 pageIgbt SchematicQuân HàNo ratings yet

- Schematic - LM358 AKÜ ŞARJ DEVRESİ - 2021-10-18Document1 pageSchematic - LM358 AKÜ ŞARJ DEVRESİ - 2021-10-18Med SamiNo ratings yet

- 4.5V To 25V Input, 1ch Synchronous Buck DC/DC Controller: DatasheetDocument24 pages4.5V To 25V Input, 1ch Synchronous Buck DC/DC Controller: DatasheetYnejjamNo ratings yet

- Power Manag 61Document1 pagePower Manag 61azqNo ratings yet

- R1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0Document1 pageR1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0joxNo ratings yet

- 74ALVC74Document16 pages74ALVC74arhangokuNo ratings yet

- Title:: File: AND - SCH SheetDocument1 pageTitle:: File: AND - SCH SheetMochammad PraditiaNo ratings yet

- Mach Dieu Khien Toc Do Dong Co: OUT CV THR DSCHGDocument3 pagesMach Dieu Khien Toc Do Dong Co: OUT CV THR DSCHGthuhaui100% (1)

- Atmega328 Based Circuit Diagram of The ProjectDocument1 pageAtmega328 Based Circuit Diagram of The ProjectKav Mav100% (2)

- AfskDocument1 pageAfskPepe ArgentinaNo ratings yet

- Rt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1Document9 pagesRt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1laptophaianhNo ratings yet

- Schematic - Lampara RGB - 2022-05-02Document1 pageSchematic - Lampara RGB - 2022-05-02Pablo GarciaNo ratings yet

- Levitation LightDocument1 pageLevitation LightHamza_AK100% (1)

- Datasheet - Transceiver CAN - Sgls398aDocument35 pagesDatasheet - Transceiver CAN - Sgls398aAntonio Carlos ACSJRNo ratings yet

- Sgls 398 ADocument31 pagesSgls 398 Aa.escalant.tNo ratings yet

- SURE DB-DP11112 - SCH-розблокованоDocument4 pagesSURE DB-DP11112 - SCH-розблокованоВиталий БеспаловNo ratings yet

- g1 PDFDocument1 pageg1 PDFLourdes Gianella Navas Nuñez100% (1)

- g1 PDFDocument1 pageg1 PDFLourdes Gianella Navas NuñezNo ratings yet

- Multi-Phase PWM Controller For CPU Core Power Supply: Features General DescriptionDocument14 pagesMulti-Phase PWM Controller For CPU Core Power Supply: Features General DescriptionFreddy ArmstrongNo ratings yet

- Diod S A0012994310 1-2543882Document6 pagesDiod S A0012994310 1-2543882Philippe Englert VelhaNo ratings yet

- Elektor BusDocument6 pagesElektor BusFernando VidalNo ratings yet

- Seguidor SolarDocument1 pageSeguidor SolarNestor Daniel Puyen MateoNo ratings yet

- Scania CAN Bus SchematicDocument1 pageScania CAN Bus SchematicMukhitur Rusda100% (1)

- RT9025 25GSP RichtekDocument12 pagesRT9025 25GSP RichtekBengkel Kompu7erNo ratings yet

- Schematic - How To Build LM358 Battery Charge Level Indicator - 2023-11-14Document1 pageSchematic - How To Build LM358 Battery Charge Level Indicator - 2023-11-14usmfusmfNo ratings yet

- VU Meter Technical MrigankaDocument2 pagesVU Meter Technical MrigankaManshi SinghNo ratings yet

- SUBBU DAC Power Supply V3 SchematicsDocument1 pageSUBBU DAC Power Supply V3 Schematicscristi289100% (1)

- Module Description DM15-A-6U 2.01Document7 pagesModule Description DM15-A-6U 2.01felipebdNo ratings yet

- Datasheet 18Document29 pagesDatasheet 18Maicon SouzaNo ratings yet

- Lipo SchematicDocument1 pageLipo SchematicAjithkumar RNo ratings yet

- Topswitch Family: Application Note An-57Document16 pagesTopswitch Family: Application Note An-57Paulo de Amorim CostaNo ratings yet

- Schematic - How To Make MT8870 DTMF Phone Audio Decoder - 2022-08-08Document1 pageSchematic - How To Make MT8870 DTMF Phone Audio Decoder - 2022-08-08Florencio cancheNo ratings yet

- Driver Led - Fairchild SemiconductorDocument13 pagesDriver Led - Fairchild SemiconductorEFranNo ratings yet

- EBM LigaçõesDocument6 pagesEBM LigaçõesruisengoNo ratings yet

- LiPo Charger LS TP4056 SchematicDocument1 pageLiPo Charger LS TP4056 SchematichidalgobNo ratings yet

- 738512Document1 page738512AlexandreNo ratings yet

- Arduino Keypad SCHDocument1 pageArduino Keypad SCHthong lyNo ratings yet

- Schematic - A-RF POWER - 2022-08-22Document1 pageSchematic - A-RF POWER - 2022-08-22VICTOR HUGO PULIDO QUIÑONESNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Gilberto VidalNo ratings yet

- Mod Dimmer 5A 2LDocument1 pageMod Dimmer 5A 2LRazwan ali saeedNo ratings yet

- Instructions For Making The Inflatable Kite PDFDocument15 pagesInstructions For Making The Inflatable Kite PDFJavier Vich BerlangaNo ratings yet

- Retromobile UkDocument27 pagesRetromobile UkVrushadwaj GunjariNo ratings yet

- Válvulas Jamesbury SERIES k815 & 830,860Document16 pagesVálvulas Jamesbury SERIES k815 & 830,860Felipe Ribeiro da CostaNo ratings yet

- Electronic Devices - Lecture Notes, Study Material and Important Questions, AnswersDocument3 pagesElectronic Devices - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- B20se-5 Sb1248e04 PDFDocument703 pagesB20se-5 Sb1248e04 PDFGORDNo ratings yet

- WIDELINE 90 Degree Doors Standard SizeDocument1 pageWIDELINE 90 Degree Doors Standard SizeManasi SatbhaiNo ratings yet

- 10 Introduction To PROFIBUS DP and The HMI Operator PanelDocument31 pages10 Introduction To PROFIBUS DP and The HMI Operator Panelhaftu gideyNo ratings yet

- Temptron 616: Temptron 616 User's ManualDocument21 pagesTemptron 616: Temptron 616 User's ManualAbed ShareefNo ratings yet

- Design Recommendation For Screw Machine ProductsDocument23 pagesDesign Recommendation For Screw Machine Productsashwin josephNo ratings yet

- 110W Flexible Panel Spec SheetDocument1 page110W Flexible Panel Spec Sheetyvj_20006373No ratings yet

- TECON Scaffolding RinglockDocument9 pagesTECON Scaffolding RinglockSergio RebazaNo ratings yet

- 06 Industrial ApplicationDocument45 pages06 Industrial ApplicationshrirangjoshiNo ratings yet

- CJV300 - 150 - CJV300 Plus Mechanical Drawing D501034 Ver.3.60Document96 pagesCJV300 - 150 - CJV300 Plus Mechanical Drawing D501034 Ver.3.60Jim BowenNo ratings yet

- Danfoss H1B Series H1B080 A P1D1NB TADSHS SA10NN 030Z24 NNNDocument143 pagesDanfoss H1B Series H1B080 A P1D1NB TADSHS SA10NN 030Z24 NNNOxmaq SPANo ratings yet

- Series 75: Straight Plastic Valves - 2 WayDocument1 pageSeries 75: Straight Plastic Valves - 2 WayDritan RukaNo ratings yet

- APS-U2001 Manual de ServicioDocument24 pagesAPS-U2001 Manual de ServicioWilmer MaestreNo ratings yet

- Furgo Seastar 3610 User ManualDocument42 pagesFurgo Seastar 3610 User ManualCaroline MariaNo ratings yet

- Makes ListDocument2 pagesMakes ListNagi ReddyNo ratings yet

- User Manual-HJK-R Series-HoltopDocument4 pagesUser Manual-HJK-R Series-Holtopwaynelaw0813No ratings yet

- A PDFDocument1 pageA PDFsarochimNo ratings yet

- LG MDD62 Service Manual PDFDocument69 pagesLG MDD62 Service Manual PDFIvan AsimovNo ratings yet

- PL40 4D95L-1 SN 19790-Or EG40Document52 pagesPL40 4D95L-1 SN 19790-Or EG40yosy prastiyoNo ratings yet

- Gas Installation PDFDocument31 pagesGas Installation PDFNelson VargasNo ratings yet

- Manifold CoplanarDocument5 pagesManifold CoplanarClaudio Salvador Vera AranedaNo ratings yet

- Standard Ac Induction MotorsDocument20 pagesStandard Ac Induction MotorsgalihatmojoNo ratings yet

- Canadian SpecsDocument2 pagesCanadian SpecswendycookconsultingNo ratings yet

- IC Projects For Beginners - RayerDocument58 pagesIC Projects For Beginners - RayerSaurabh singhNo ratings yet

- HT115 Parts ManualDocument151 pagesHT115 Parts ManualSergii wolfNo ratings yet

- Nudi 12345Document3 pagesNudi 12345savitripattanashetti46No ratings yet

Linear Mode Current Sink Led Driver

Linear Mode Current Sink Led Driver

Uploaded by

José Ganga BarbosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linear Mode Current Sink Led Driver

Linear Mode Current Sink Led Driver

Uploaded by

José Ganga BarbosaCopyright:

Available Formats

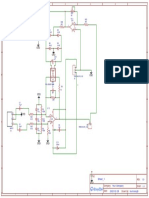

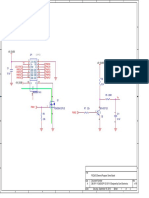

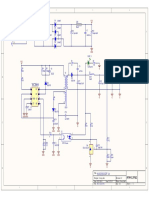

DLD101

LINEAR MODE CURRENT SINK LED DRIVER

Features Mechanical Data

• Primarily Designed for Driving LED/s for Illumination, Signage • Case: DFN3030D-8

and Backlighting Applications • Case Material: Molded Plastic, "Green" Molding Compound.

• Ideally Suited for Linear Mode Constant Current Applications UL Flammability Classification Rating 94V-0

• VBE Referenced Current Sink Circuit • Moisture Sensitivity: Level 1 per J-STD-020

• Includes: • Terminals: Finish — NiPdAu over Copper leadframe. Solderable

• N-Channel Enhancement Mode MOSFET (Q1) per MIL-STD-202, Method 208

• Base Accessible Pre-Biased Transistor (Q2) • Marking Information: See Page 7

• High Voltage Capable (50V) • Ordering Information: See Page 7

• • Weight: 0.0172 grams (approximate)

NEW PRODUCT

Small Form Factor Surface Mount Package

• High Dissipation Capability

• Low Thermal Resistance

• Lead Free By Design/RoHS Compliant (Note 1)

• "Green" Device (Note 2)

• Qualified to AEC-Q101 Standards for High Reliability VCC Supply

LED String

RC

4 3 2 1

S2 B1 B1’ E1 G D

C

8 7 6 5 S2 B1 B1’ E1 VDS

B

8 7 6 5 Q2

R1 R2 R2

Q1

Q1 E R1 S Option 3:

Q2 5 6 7 8 VBE

ILED ≈

RS

Option 3

Options 1 & 2:

Option 2

1.1 VBE

Option 1 ILED ≈

RS

1 2 3 4 1 2 3 4 RS Option 2:

Capacitor is across R2 for

D2 G2 NC C1 D2 G2 NC C1 better noise performance.

Top View Top View

Internal Schematic Package Pin-Out Configuration Typical Application Circuit for Linear

Mode Current Sink LED Driver

Maximum Ratings: (Q1) @TA = 25°C unless otherwise specified

Characteristic Symbol Value Unit

Drain Source Voltage VDSS 100 V

Gate-Source Voltage VGSS ±20 V

Drain Current (Note 3) TA = 25°C 1.0

ID A

TA = 70°C 0.8

Drain Current (Note 3) Pulsed IDM 3.0 A

Body-Diode Continuous Current (Note 3) IS 1.0 A

Maximum Ratings: (Q2) @TA = 25°C unless otherwise specified

Characteristic Symbol Value Unit

Supply Voltage VCC 50 V

Input Voltage VIN -5 to +30 V

Output Current (DC) IO 100 mA

Notes: 1. No purposefully added lead.

2. Diodes Inc.'s "Green" policy can be found on our website at http://www.diodes.com/products/lead_free/index.php.

DLD101 1 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

Thermal Characteristics – Total Device

Characteristic Symbol Value Unit

0.7 (Note 3)

Power Dissipation @TA = 25°C PD 0.9 (Note 4) W

1.4 (Note 5)

See Figure 1

Thermal Resistance Junction to Ambient @TA = 25°C RθJA °C/W

(Notes 3, 4, & 5)

See Figure 2

Thermal Resistance Junction to Case @TA = 25°C RθJC °C/W

(Notes 3, 4, & 5)

Operating and Storage Temperature Range TJ, TSTG -55 to +150 °C

NEW PRODUCT

Notes: 3. Part mounted on FR-4 substrate PC board, with minimum recommended pad layout (see page 6).

4. Part mounted on FR-4 substrate PC board, 2oz Copper with 6 mm2 Cu Area, MOSFET element activated.

5. Part mounted on FR-4 substrate PC board, 2oz Copper with 35 mm2 Cu Area, MOSFET element activated.

Electrical Characteristics: (Q1) @TA = 25°C unless otherwise specified

Characteristic Symbol Min Typ Max Unit Test Condition

OFF CHARACTERISTICS (Note 6)

Drain-Source Breakdown Voltage BVDSS 100 ⎯ ⎯ V VGS = 0V, ID = 250μA

Zero Gate Voltage Drain Current IDSS ⎯ ⎯ 1 μA VDS = 60V, VGS = 0V

Gate-Source Leakage IGSS ⎯ ⎯ ±100 nA VGS = ±20V, VDS = 0V

ON CHARACTERISTICS (Note 6)

Gate Threshold Voltage VGS(th) 2.0 ⎯ 4.1 V VDS = VGS, ID = 250μA

⎯ 0.85 VGS = 10V, ID = 1.5A

Static Drain-Source On-Resistance RDS (ON) ⎯ Ω

⎯ 0.99 VGS = 6V, ID = 1A

Forward Transconductance gfs ⎯ 0.9 ⎯ S VDS = 15V, ID = 1A

Diode Forward Voltage VSD ⎯ 0.89 1.1 V VGS = 0V, IS = 1.5A

DYNAMIC CHARACTERISTICS

Input Capacitance Ciss ⎯ 129 ⎯ pF

VDS = 50V, VGS = 0V

Output Capacitance Coss ⎯ 14 ⎯ pF

f = 1.0MHz

Reverse Transfer Capacitance Crss ⎯ 8 ⎯ pF

SWITCHING CHARACTERISTICS

Total Gate Charge Qg ⎯ 3.4 ⎯

Gate-Source Charge Qgs ⎯ 0.9 ⎯ nC VDS = 50V, VGS = 10V, ID = 1A

Gate-Drain Charge Qgd ⎯ 1 ⎯

Turn-On Delay Time td(on) ⎯ 7.9 ⎯

Rise Time tr ⎯ 11.4 ⎯ VGS = 50V, VDS = 10V,

ns

Turn-Off Delay Time td(off) ⎯ 14.3 ⎯ ID = 1A, RG ≈ 6Ω

Fall Time tf ⎯ 9.6 ⎯

Electrical Characteristics: (Q2) @TA = 25°C unless otherwise specified

Characteristic (Note 6) Symbol Min Typ Max Unit Test Condition

VI(off) 0.4 - - V VCC = 5V, IO = 100μA

Input Voltage

VI(on) - - 1.5 V VCC = 0.3V, IO = 5mA

Output Voltage VO(on) - 0.05 0.3 V IO/II = 5mA/0.25mA

Output Current IO(off) - - 0.5 μA VCC = 50V, VI = 0V

DC Current Gain G1 80 - - - VO = 5V, IO = 10mA

Input Resistance R1 3.2 4.7 6.2 kΩ -

Resistance Ratio R2/R1 8 10 12 - -

VCE = 10V, IE = 5mA,

Transition Frequency fT - 260 - MHz

f = 100MHz

Notes: 6. Short duration pulse test used to minimize self-heating effect.

DLD101 2 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

Thermal Characteristics

180 40

160 T A = 25°C 35 T A = 25°C

JUNCTION TO AMBIENT AIR (°C/W)

JUNCTION TO CASE AIR (°C/W)

RθJA, THERMAL RESISTANCE,

140

RθJC, THERMAL RESISTANCE,

30

120

25

NEW PRODUCT

100

20

80

15

60

10

40

20 5

0 0

0 5 10 15 20 25 30 35 40 0 5 10 15 20 25 30 35 40

2 2

COPPER AREA (mm ) COPPER AREA (mm )

Fig. 1 Thermal Resistance, Junction to Fig. 2 Thermal Resistance, Junction to

Ambient Air Characteristic Case Air Characteristic

1.6

1.4 T A = 25°C

PD, POWER DISSIPATION (W)

1.2

1.0

0.8

0.6

0.4

0.2

0

0 5 10 15 20 25 30 35 40

2

COPPER AREA (mm )

Fig. 3 Power Dissipation Characteristic

DLD101 3 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

Q1 Typical Performance Curves

10 10

RDS(ON), DRAIN-SOURCE ON-RESISTANCE (Ω)

VDS = VGS

9

8

ID, DRAIN CURRENT (A)

6 TA = 150°C

5 1

VGS = 6V

4 TA = 125°C

NEW PRODUCT

VGS = 10V

3

TA = 85°C

2 T A = 25°C

1 T A = -55°C

0 0.1

1.5 2 2.5 3 3.5 4 4.5 0 0.4 0.8 1.2 1.6

VGS, GATE-SOURCE VOLTAGE (V) ID, DRAIN CURRENT (A)

Fig. 4 Typical Transfer Characteristic Fig. 5 Typical On-Resistance

vs. Drain Current and Gate Voltage

1.6 3.0

RDS(ON), DRAIN-SOURCE ON-RESISTANCE (Ω)

1.4 VGS = 10V

ON-RESISTANCE (NORMALIZED)

2.5

1.2

RDSON, DRAIN-SOURCE

TA = 150°C 2.0

1.0

T A = 125°C VGS = 10V

ID = 1.5A

0.8 1.5

T A = 85°C

VGS = 6V

0.6 ID = 1A

TA = 25°C 1.0

0.4

T A = -55°C

0.5

0.2

0 0

0 0.4 0.8 1.2 1.6 -50 -25 0 25 50 75 100 125 150

ID, DRAIN CURRENT (A) TA, AMBIENT TEMPERATURE (°C)

Fig. 6 Typical On-Resistance Fig. 7 On-Resistance Variation with Temperature

vs. Drain Current and Temperature

1.5 4.0

VGS(TH), GATE THRESHOLD VOLTAGE (V)

3.8

1.2 3.6

RDSON, DRAIN-SOURCE

3.4

ON-RESISTANCE (Ω)

0.9 VGS = 6V

3.2

ID = 1A ID = 1mA

3.0

0.6 2.8 ID = 250µA

VGS = 10V

2.6

ID = 1.5A

0.3 2.4

2.2

0 2.0

-50 -25 0 25 50 75 100 125 150 -50 -25 0 25 50 75 100 125 150

TA, AMBIENT TEMPERATURE (°C) TA, AMBIENT TEMPERATURE (°C)

Fig. 8 On-Resistance Variation with Temperature Fig. 9 Gate Threshold Variation vs. Ambient Temperature

DLD101 4 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

Q1 Typical Performance Curves - continued

1.6 1,000

1.4

IDSS, LEAKAGE CURRENT (nA)

TA = 150°C

IS, SOURCE CURRENT (A)

1.2

100

1.0 T A = 25°C

NEW PRODUCT

TA = 125°C

0.8

0.6

10

TA = 85°C

0.4

TA = -55°C

TA = 25°C

0.2

0 1

0.6 0.7 0.8 0.9 1 0 10 20 30 40 50 60

VSD, SOURCE-DRAIN VOLTAGE (V) VDS, DRAIN-SOURCE VOLTAGE (V)

Fig. 10 Source-Drain Diode Forward Voltage vs. Current Fig. 11 Typical Leakage Current vs. Drain-Source Voltage

Q2 Typical Performance Curves

25 1,000

IB = 5mA

IC, COLLECTOR CURRENT (mA)

20

hFE, DC CURRENT GAIN

T A = 150°C

100

IB = 4mA T A = 125°C

15

TA = 85°C

TA = 25°C

IB = 3mA

10 TA = -55°C

10

IB = 2mA

5

IB = 1mA

0 1

0 1 2 3 4 5 0.1 1 10 50

VCE, COLLECTOR-EMITTER VOLTAGE (V) IC, COLLECTOR CURRENT (mA)

Fig. 12 Typical Collector Current Fig. 13 Typical DC Current Gain vs. Collector Current

vs. Collector-Emitter Voltage

DLD101 5 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

Q2 Typical Performance Curves - continued

0.7 1.0

VBE(ON), BASE-EMITTER TURN-ON VOLTAGE (V)

0.9 VCE = 1V

0.6 IC/IB = 10

VCE(SAT), COLLECTOR-EMITTER

0.8

SATURATION VOLTAGE (V)

TA = -55°C

0.5 0.7

0.6 TA = 25°C

0.4

NEW PRODUCT

0.5

TA = 85°C

0.3

0.4 T A = 125°C

TA = 150°C

0.2 0.3

T A = 150°C

TA = 125°C 0.2

0.1

TA = 85°C 0.1

TA = -55°C T A = 25°C

0 0

1 10 100 200 1 0.1

10 100

IC, COLLECTOR CURRENT (mA) IC, COLLECTOR CURRENT (mA)

Fig. 14 Typical Collector-Emitter Saturation Voltage Fig. 15 Base-Emitter Turn-On Voltage vs. Collector Current

vs. Collector Current

1.0

VBE(ON), BASE-EMITTER TURN-ON VOLTAGE (V)

0.9 VCE = 5V

0.8

T A = -55°C

0.7

0.6 TA = 25°C

0.5

T A = 85°C

0.4 TA = 125°C

TA = 150°C

0.3

0.2

0.1

0

1 10 0.1 100

IC, COLLECTOR CURRENT (mA)

Fig. 16 Base-Emitter Turn-On Voltage vs. Collector Current

DLD101 6 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

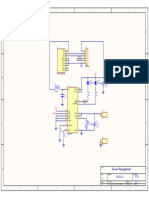

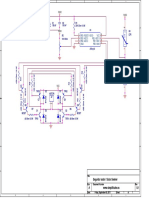

Typical Application Circuit

VCC Supply

The DLD101 has been designed primarily for solid state lighting

applications, to be used as a current sink circuit solution for LEDs. It

LED String features a N-channel MOSFET capable of 1A drive current and a pre-

RC biased NPN transistor (which allows direct connection to the base, or

via a series base resistor).

4 3 2 1

NEW PRODUCT

Figure 12 shows a typical application circuit diagram for driving an

G D LED or string of LEDs. Note that the pre-biased transistor (Q2) has

C the option of bypassing the series base resistor by connecting directly

VDS to pin 7. The N-MOSFET (Q1) is configured as a VBE referenced

B current sink and is biased on by RC. The current passed through the

Q2 LED string, MOSFET and source resistor, develops a voltage across

R2

Q1 RS that provides a bias to the NPN transistor. Consideration of the

E R1 Option 3: expected linear mode power dissipation must be factored into the

S

design, with respect to the DLD101's thermal resistance.

5 6 7 8 VBE

ILED ≈

RS VDS = VCC – VF LED String – VRS

Option 3

Options 1 & 2: PQ1 = VDS * ILED String

Option 2

1.1 VBE

Option 1 ILED ≈ PWM dimming functionality can be effected by either driving the NPN

RS

base via an additional resistor (thereby overriding the feedback from

RS Option 2: RS) or by pulling the gate of the MOSFET down by direct connection.

Capacitor is across R2 for The PWM control pulse stream can be provided by a micro-controller

better noise performance.

or simple 555 based circuitry.

Fig. 12 Typical Application Circuit for

Linear Mode Current Sink LED Driver

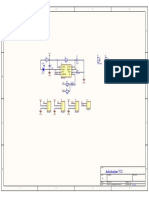

Ordering Information (Note 7)

Part Number Case Packaging

DLD101-7 DFN3030D-8 3000/Tape & Reel

Notes: 7. For packaging details, go to our website at http://www.diodes.com/datasheets/ap02007.pdf.

Marking Information

DFN3030D-8

YYWW

L101 = Product marking code

YYWW = Date code marking

YY = Last digit of year (ex: 10 for 2010)

WW = Week code (01 to 53)

L101

DLD101 7 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

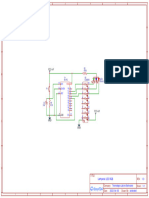

DLD101

Package Outline Dimensions

A

A3 SEATING PLANE

A1 DFN3030D-8

D Dim Min Max Typ Dim Min Max Typ

b D3 A 0.570 0.630 0.600 e - - 0.650

A1 0 0.050 0.020 E 2.950 3.075 3.000

NEW PRODUCT

E3 A3 - - 0.150 E1 1.800 2.000 1.900

b 0.290 0.390 0.340 E2 0.290 0.490 0.390

D1 D 2.950 3.075 3.000 E3 0.175 0.375 0.275

E D1 2.175 2.375 2.275 L 0.300 0.40 0.350

E1 D2 E2

D2 0.980 1.180 1.080 Z - - 0.355

D3 0.105 0.305 0.205

All Dimensions in mm

L

Z e

BOTTOM VIEW

Suggested Pad Layout

X C X3

G6

Value Value

Y5 G Dimensions Dimensions

(in mm) (in mm)

Y2 C 0.650 X2 0.220

X4 G 0.150 X3 0.375

G1 G2

G3 Y3 G1 0.950 X4 1.080

Y1 G2 0.270 X5 0.150

Y

Y4 G3 0.135 Y 2.600

G4 G5 G4 1.350 Y1 1.900

G5 0.925 Y2 0.150

X5 G6 1.350 Y3 0.390

X 0.440 Y4 0.815

X1 X2 X3

X1 0.210 Y5 0.550

DLD101 8 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

DLD101

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

NEW PRODUCT

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2010, Diodes Incorporated

www.diodes.com

DLD101 9 of 9 April 2010

Document number: DS32007 Rev. 8 - 2 www.diodes.com © Diodes Incorporated

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Hyundai Eon Bosch EDC17Document3 pagesHyundai Eon Bosch EDC17Bhanuka Srikantha88% (8)

- Schematic - Pre Balance 1kpro Flaship - 2022!03!29Document1 pageSchematic - Pre Balance 1kpro Flaship - 2022!03!29Komal KesariyaNo ratings yet

- TCS3200 Color SensorColor Detector Schematics PDFDocument1 pageTCS3200 Color SensorColor Detector Schematics PDFsiogNo ratings yet

- Datasheet Ic CE DEDocument15 pagesDatasheet Ic CE DEBersama UkhuwahNo ratings yet

- RC Wireless Car Receiver v1.0Document1 pageRC Wireless Car Receiver v1.0Nishant Khandekar100% (1)

- Mc100e131fn (D Flip Flop) ICDocument8 pagesMc100e131fn (D Flip Flop) ICDwp BhaskaranNo ratings yet

- L298 and L297 Based High Current Stepper Motor Driver With Mach 3 Interface 4Document2 pagesL298 and L297 Based High Current Stepper Motor Driver With Mach 3 Interface 4Ardiansyah Andry100% (1)

- AS179-92 LF - RF SwitchDocument7 pagesAS179-92 LF - RF SwitchsamNo ratings yet

- 1 19115823Document8 pages1 19115823Netaji PatraNo ratings yet

- GPS1.0 SCHDocument1 pageGPS1.0 SCHMukhiturrusda100% (2)

- Schematic - cd4017 Vu - 2024-03-16Document1 pageSchematic - cd4017 Vu - 2024-03-16genesios silvaNo ratings yet

- Tarjeta Reles 4 CanalesDocument2 pagesTarjeta Reles 4 CanalesjbrunobNo ratings yet

- Schematic - B - LM358 BATTERY TESTER - 2022-06-22Document1 pageSchematic - B - LM358 BATTERY TESTER - 2022-06-22usmfusmfNo ratings yet

- Lm358 Battery Voltage TesterDocument1 pageLm358 Battery Voltage TestermukhtarsafarofffNo ratings yet

- Alimentare Sursa Astabil: VCC 9V 9VDocument1 pageAlimentare Sursa Astabil: VCC 9V 9VMares DanielNo ratings yet

- Schematic PrintsDocument1 pageSchematic PrintsDân Kỹ Thuật100% (1)

- Schematic - Termometro Electronico - 2022-04-21Document2 pagesSchematic - Termometro Electronico - 2022-04-21Yuli QuelcaNo ratings yet

- Some Simple Tachometer Input Circuits: SteveDocument3 pagesSome Simple Tachometer Input Circuits: SteveSơn PhạmNo ratings yet

- RGB LED Driver 101D SCHDocument1 pageRGB LED Driver 101D SCHBenni SiswantoNo ratings yet

- Igbt SchematicDocument1 pageIgbt SchematicQuân HàNo ratings yet

- Schematic - LM358 AKÜ ŞARJ DEVRESİ - 2021-10-18Document1 pageSchematic - LM358 AKÜ ŞARJ DEVRESİ - 2021-10-18Med SamiNo ratings yet

- 4.5V To 25V Input, 1ch Synchronous Buck DC/DC Controller: DatasheetDocument24 pages4.5V To 25V Input, 1ch Synchronous Buck DC/DC Controller: DatasheetYnejjamNo ratings yet

- Power Manag 61Document1 pagePower Manag 61azqNo ratings yet

- R1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0Document1 pageR1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0joxNo ratings yet

- 74ALVC74Document16 pages74ALVC74arhangokuNo ratings yet

- Title:: File: AND - SCH SheetDocument1 pageTitle:: File: AND - SCH SheetMochammad PraditiaNo ratings yet

- Mach Dieu Khien Toc Do Dong Co: OUT CV THR DSCHGDocument3 pagesMach Dieu Khien Toc Do Dong Co: OUT CV THR DSCHGthuhaui100% (1)

- Atmega328 Based Circuit Diagram of The ProjectDocument1 pageAtmega328 Based Circuit Diagram of The ProjectKav Mav100% (2)

- AfskDocument1 pageAfskPepe ArgentinaNo ratings yet

- Rt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1Document9 pagesRt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1laptophaianhNo ratings yet

- Schematic - Lampara RGB - 2022-05-02Document1 pageSchematic - Lampara RGB - 2022-05-02Pablo GarciaNo ratings yet

- Levitation LightDocument1 pageLevitation LightHamza_AK100% (1)

- Datasheet - Transceiver CAN - Sgls398aDocument35 pagesDatasheet - Transceiver CAN - Sgls398aAntonio Carlos ACSJRNo ratings yet

- Sgls 398 ADocument31 pagesSgls 398 Aa.escalant.tNo ratings yet

- SURE DB-DP11112 - SCH-розблокованоDocument4 pagesSURE DB-DP11112 - SCH-розблокованоВиталий БеспаловNo ratings yet

- g1 PDFDocument1 pageg1 PDFLourdes Gianella Navas Nuñez100% (1)

- g1 PDFDocument1 pageg1 PDFLourdes Gianella Navas NuñezNo ratings yet

- Multi-Phase PWM Controller For CPU Core Power Supply: Features General DescriptionDocument14 pagesMulti-Phase PWM Controller For CPU Core Power Supply: Features General DescriptionFreddy ArmstrongNo ratings yet

- Diod S A0012994310 1-2543882Document6 pagesDiod S A0012994310 1-2543882Philippe Englert VelhaNo ratings yet

- Elektor BusDocument6 pagesElektor BusFernando VidalNo ratings yet

- Seguidor SolarDocument1 pageSeguidor SolarNestor Daniel Puyen MateoNo ratings yet

- Scania CAN Bus SchematicDocument1 pageScania CAN Bus SchematicMukhitur Rusda100% (1)

- RT9025 25GSP RichtekDocument12 pagesRT9025 25GSP RichtekBengkel Kompu7erNo ratings yet

- Schematic - How To Build LM358 Battery Charge Level Indicator - 2023-11-14Document1 pageSchematic - How To Build LM358 Battery Charge Level Indicator - 2023-11-14usmfusmfNo ratings yet

- VU Meter Technical MrigankaDocument2 pagesVU Meter Technical MrigankaManshi SinghNo ratings yet

- SUBBU DAC Power Supply V3 SchematicsDocument1 pageSUBBU DAC Power Supply V3 Schematicscristi289100% (1)

- Module Description DM15-A-6U 2.01Document7 pagesModule Description DM15-A-6U 2.01felipebdNo ratings yet

- Datasheet 18Document29 pagesDatasheet 18Maicon SouzaNo ratings yet

- Lipo SchematicDocument1 pageLipo SchematicAjithkumar RNo ratings yet

- Topswitch Family: Application Note An-57Document16 pagesTopswitch Family: Application Note An-57Paulo de Amorim CostaNo ratings yet

- Schematic - How To Make MT8870 DTMF Phone Audio Decoder - 2022-08-08Document1 pageSchematic - How To Make MT8870 DTMF Phone Audio Decoder - 2022-08-08Florencio cancheNo ratings yet

- Driver Led - Fairchild SemiconductorDocument13 pagesDriver Led - Fairchild SemiconductorEFranNo ratings yet

- EBM LigaçõesDocument6 pagesEBM LigaçõesruisengoNo ratings yet

- LiPo Charger LS TP4056 SchematicDocument1 pageLiPo Charger LS TP4056 SchematichidalgobNo ratings yet

- 738512Document1 page738512AlexandreNo ratings yet

- Arduino Keypad SCHDocument1 pageArduino Keypad SCHthong lyNo ratings yet

- Schematic - A-RF POWER - 2022-08-22Document1 pageSchematic - A-RF POWER - 2022-08-22VICTOR HUGO PULIDO QUIÑONESNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Gilberto VidalNo ratings yet

- Mod Dimmer 5A 2LDocument1 pageMod Dimmer 5A 2LRazwan ali saeedNo ratings yet

- Instructions For Making The Inflatable Kite PDFDocument15 pagesInstructions For Making The Inflatable Kite PDFJavier Vich BerlangaNo ratings yet

- Retromobile UkDocument27 pagesRetromobile UkVrushadwaj GunjariNo ratings yet

- Válvulas Jamesbury SERIES k815 & 830,860Document16 pagesVálvulas Jamesbury SERIES k815 & 830,860Felipe Ribeiro da CostaNo ratings yet

- Electronic Devices - Lecture Notes, Study Material and Important Questions, AnswersDocument3 pagesElectronic Devices - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- B20se-5 Sb1248e04 PDFDocument703 pagesB20se-5 Sb1248e04 PDFGORDNo ratings yet

- WIDELINE 90 Degree Doors Standard SizeDocument1 pageWIDELINE 90 Degree Doors Standard SizeManasi SatbhaiNo ratings yet

- 10 Introduction To PROFIBUS DP and The HMI Operator PanelDocument31 pages10 Introduction To PROFIBUS DP and The HMI Operator Panelhaftu gideyNo ratings yet

- Temptron 616: Temptron 616 User's ManualDocument21 pagesTemptron 616: Temptron 616 User's ManualAbed ShareefNo ratings yet

- Design Recommendation For Screw Machine ProductsDocument23 pagesDesign Recommendation For Screw Machine Productsashwin josephNo ratings yet

- 110W Flexible Panel Spec SheetDocument1 page110W Flexible Panel Spec Sheetyvj_20006373No ratings yet

- TECON Scaffolding RinglockDocument9 pagesTECON Scaffolding RinglockSergio RebazaNo ratings yet

- 06 Industrial ApplicationDocument45 pages06 Industrial ApplicationshrirangjoshiNo ratings yet

- CJV300 - 150 - CJV300 Plus Mechanical Drawing D501034 Ver.3.60Document96 pagesCJV300 - 150 - CJV300 Plus Mechanical Drawing D501034 Ver.3.60Jim BowenNo ratings yet

- Danfoss H1B Series H1B080 A P1D1NB TADSHS SA10NN 030Z24 NNNDocument143 pagesDanfoss H1B Series H1B080 A P1D1NB TADSHS SA10NN 030Z24 NNNOxmaq SPANo ratings yet

- Series 75: Straight Plastic Valves - 2 WayDocument1 pageSeries 75: Straight Plastic Valves - 2 WayDritan RukaNo ratings yet

- APS-U2001 Manual de ServicioDocument24 pagesAPS-U2001 Manual de ServicioWilmer MaestreNo ratings yet

- Furgo Seastar 3610 User ManualDocument42 pagesFurgo Seastar 3610 User ManualCaroline MariaNo ratings yet

- Makes ListDocument2 pagesMakes ListNagi ReddyNo ratings yet

- User Manual-HJK-R Series-HoltopDocument4 pagesUser Manual-HJK-R Series-Holtopwaynelaw0813No ratings yet

- A PDFDocument1 pageA PDFsarochimNo ratings yet

- LG MDD62 Service Manual PDFDocument69 pagesLG MDD62 Service Manual PDFIvan AsimovNo ratings yet

- PL40 4D95L-1 SN 19790-Or EG40Document52 pagesPL40 4D95L-1 SN 19790-Or EG40yosy prastiyoNo ratings yet

- Gas Installation PDFDocument31 pagesGas Installation PDFNelson VargasNo ratings yet

- Manifold CoplanarDocument5 pagesManifold CoplanarClaudio Salvador Vera AranedaNo ratings yet

- Standard Ac Induction MotorsDocument20 pagesStandard Ac Induction MotorsgalihatmojoNo ratings yet

- Canadian SpecsDocument2 pagesCanadian SpecswendycookconsultingNo ratings yet

- IC Projects For Beginners - RayerDocument58 pagesIC Projects For Beginners - RayerSaurabh singhNo ratings yet

- HT115 Parts ManualDocument151 pagesHT115 Parts ManualSergii wolfNo ratings yet

- Nudi 12345Document3 pagesNudi 12345savitripattanashetti46No ratings yet