Professional Documents

Culture Documents

Standard: Renault Automobiles Standardisation DPMI / Service 67210 Section Normes Et Cahiers Des Charges

Standard: Renault Automobiles Standardisation DPMI / Service 67210 Section Normes Et Cahiers Des Charges

Uploaded by

SILLAA BUSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard: Renault Automobiles Standardisation DPMI / Service 67210 Section Normes Et Cahiers Des Charges

Standard: Renault Automobiles Standardisation DPMI / Service 67210 Section Normes Et Cahiers Des Charges

Uploaded by

SILLAA BUSCopyright:

Available Formats

STANDARD

00 - 10 - 039 / - - A

ISO GPS STANDARDS OF TOLERANCING

IN FORCE AT RENAULT

Renault Automobiles Standardisation

DPMI / Service 67210

Section Normes et Cahiers des Charges

RENAULT 00 - 10 - 039 / - - A

This document is to be considered as a whole, the parts of which must not be separated.

© RENAULT 2013.

No duplication permitted without the consent of the issuing department.

No circulation permitted without the consent of RENAULT.

FIRST ISSUE

May 2013 --- This issue originates from the project NC 2013 0139 / - - -.

REVISION

May 2013 - - A Updating label

This issue originates from the Draft NC 2013 0379 / - - -.

REFERENCE DOCUMENTS

Standards : ISO GPS Standards

Renault Standard 00 - 10 - 415 / - - Q

© RENAULT 2013 Page 2/11

RENAULT 00 - 10 - 039 / - - A

CONTENTS

Page

1. SCOPE 4

2. FIELD OF APPLICATION 4

3. STANDARDS APPLICABLE AT RENAULT IN THE FIELD OF DIMENSONAL AND

GEOMETRICAL TOLERANCING AS WELL AS THEIR INDEX ON THE PUBLICATION DATE OF

STANDARD PRESENT 4

3.1. TABLE 1: ISO GPS STANDARDS OF TOLERANCING IN FORCE AT RENAULT AS

WELL AS THEIR INDEX ON THE PUBLICATION DATE OF THE STANDARD PRESENT 5

3.2. TABLE 2: ISO GPS STANDARDS NOT TO BE USED AT RENAULT 6

3.3. TABLE 3: RENAULT STANDARDS IN FORCE AT THE INDEX CORRESPONDING TO

THE DATE OF PUBLICATION OF THE STANDARD PRESENT 6

3.4. SPECIFIC REQUIREMENTS 6

3.4.1. Rule to apply for the tolerancing of location of group of features between them

and/or regarding references 6

3.4.2. Default specification operator for size 9

4. LABEL 10

5. REVISION OF THE STANDARD PRESENT 10

ANNEX 1: WHY IS THERE A CONFLICT BETWEEN THE ISO 5458-1998 AND THE ISO 1101-

2012? 11

© RENAULT 2013 Page 3/11

RENAULT 00 - 10 - 039 / - - A

1. SCOPE

The purpose of this standard is to define the ISO GPS standards (Geometrical Product Specifications)

of dimensional and geometrical tolerance currently effective in RENAULT.

The indications in this standard prevail over the Renault standard 00 - 10 - 415 / - - Q until the next

revision of this last one.

2. FIELD OF APPLICATION

The ISO GPS standards are international standards for specifying the dimensional and geometrical

tolerancing of the parts in the drawings (2D tolerancing), or directly on the 3D representation of the

digitalized part (3D tolerancing), or under another equivalent form.

The new versions ISO GPS standards which are referenced in the present standard RENAULT must

be used in the following case:

- New drawings, drawings of standard parts, module definition drawings, profession drawings…:

systematic use

- Existing drawings requiring an important tolerancing modification (example: solving of proven

failures on the mass production products): Usage recommended.

On the existing plans, it is not mandatory to modify the reference to the standards used for the

tolerancing, in the following cases:

- Already existing drawings which doesn’t require change.

- Already existing drawings which requires a minor change; for example:

o The modification doesn’t require the use of Tolerancing principles defined in the new

standards

o A tolerance value modification without toleranced characteristic modification,

o Nominal size modification...

The indication of the ISO GPS standards used and their index for the interpretation of tolerancing is

made by affixing a label making reference to the current standard: No. of norms + index (refer to §4).

By default (lack of indication, ambiguity...), the version of ISO GPS standards which is in force on the

date of creation of the drawing must to be taken into account to understand the meaning of the

tolerancing.

3. STANDARDS APPLICABLE AT RENAULT IN THE FIELD OF DIMENSIONAL, GEOMETRIC AND

SURFACE STATE TOLERANCING, AS WELL AS THEIR INDEX ON THE DATE OF PUBLICATION

OF THE CURRENT STANDARD

The ISO 8015: 2011 standard (geometrical specification of products - basic principles - Concepts,

principles and rules) introduce 13 principles including one called 'Principle of Invocation'

This principle states: extract from the ISO 8015: 2011 standard:

The ISO GPS standards apply at Renault, and to this title, this principle applies.

© RENAULT 2013 Page 4/11

RENAULT 00 - 10 - 039 / - - A

In accordance with the invocation principle, the current standard:

- shows the list of the main ISO GPS standards to be known and that are likely to be used in

tolerancing (which doesn’t exclude those which are not listed): refer to § 3.1

- defines the ISO GPS standards that must not be applied at RENAULT: refer to § 3.2

- defines the standards to be applied at RENAULT in addition to the ISO GPS standards: refer to §

3.3

- defines the specific requirements that applies by default in the dimensioning, unless otherwise

indicated on the drawings or in the technical documentation: refer to § 3.4

3.1. TABLE 1: ISO GPS STANDARDS IN FORCE AT RENAULT AND THEIR INDEX ON

THE DATE OF PUBLICATION OF THE CURRENT STANDARD

Standard Description

Basic standards:

ISO/TS 17450-1:2011 GPS- General concepts - Part 1: Model for geometrical specification and verification

ISO/TS 17450-2:2012 GPS- General concepts - Part 2: Basic tenets, specifications, operators, uncertainties and ambiguities

ISO 1:2002 GPS- Standard reference temperature for geometrical product specification and verification

ISO 129-1:2004 Technical drawings - Indication of dimensions and tolerances - Part 1: General principles

ISO TR 14638:1995 GPS - Masterplan

Applications:

ISO 8015:2011 GPS – Fundamentals – Concepts, principles and rules

ISO 14253-1:1998 GPS - Inspection by measurement of workpieces and measuring equipment - Part 1: Decision

rules for proving conformity or nonconformity with specifications

ISO 14405-1:2010* GPS- Dimensional tolerancing - Part 1: Linear sizes

ISO 14405-2:2011* GPS- Dimensional tolerancing - Part 2: Dimensions other than linear sizes

ISO 1101:2012* GPS – geometrical tolerancing - Tolerances of form, orientation, location and run-out

ISO 1101/AC1:2013

ISO 12180-1:2011 GPS- General concept-Part 1: vocabulary and parameters of cylindrical form

ISO 12180-2:2011 GPS- Cylindricity-Part 2: specification operators

ISO 12181-1:2011 GPS- Roundness - Part 1: Vocabulary and parameters of roundness

ISO 12181-2:2011 GPS- Roundness - Part 2: specification operators

ISO 12780-1:2011 GPS- Straightness-Part 1: vocabulary and parameters of straightness

ISO 12780-2:2011 GPS- Straightness-Part 2: specification operators

ISO 12781-1:2011 GPS- Flatness-Part 1: vocabulary and parameters of flatness

ISO 12781-2:2011 GPS- Flatness-Part 2: specification operators

ISO 1302:2002 GPS - Indication of surface texture in technical product documentation

ISO 5459:2011* GPS - Geometrical tolerancing - Datums and datum-systems

ISO 2692:2006* GPS - Geometrical tolerancing - Maximum material requirement (MMR), Least material

requirement (LMR) and reciprocity requirement (RPR)

ISO 10579:2010* GPS - Dimensioning and tolerancing - Non-rigid parts

ISO 10579/AC1:2011

ISO 1660:1987* Technical drawings-Dimensioning and tolerancing of profiles

ISO 3040:2009* GPS - Dimensioning and tolerancing - Cones

ISO 13715:2000 Technical drawings – Edges of undefined shape - Vocabulary and indication on drawings

ISO 10135:2007 GPS - Drawing indications for moulded parts in technical product documentation (TPD)

ISO 8062-1:2007 GPS – Dimensional and geometrical tolerances for moulded parts - Part 1: Vocabulary

ISO 8062-3:2007 GPS – Dimensional and geometrical tolerances for moulded parts - Part 3: General dimensional

and geometrical tolerances and machining allowances for castings

ISO 8062-3/AC1:2009 Technical rectification 1 to the ISO 8062-3 of June 2007 standard

ISO 2768-1:1989 General tolerances - Part 1 : Tolerances for linear and angular dimensions without individual

tolerance indications

ISO 2768-2:1989 General tolerances - Part 2 : Geometricaltolerances for features without individual tolerance

indications

ISO 14660-2:1999 Geometrical Product Specifications (GPS) - Geometric features - Part 2: Extracted median line of

a cylinder and a cone, extracted median surface, local size of an extracted feature

*The most commonly used Standards

© RENAULT 2013 Page 5/11

RENAULT 00 - 10 - 039 / - - A

3.2. TABLE 2: ISO GPS STANDARDS TO NOT USE IN RENAULT

Standard Description Comments

ISO 5458:1998 Geometrical A conflict between ISO 1101:2012 and ISO 5458:1998 exists.

product As a result, to reduce the risk of dispute, the use of ISO 5458 standard

specifications is prohibited at RENAULT, and the principles of the ISO 1101:2012 apply

(GPS) — to the positional tolerancing of group of features between them with or

Geometrical without system of references, with the use of the CZ (refer § 3.4.1).

tolerancing — Also refer annex 1 for information.

Positional

tolerancing

3.3. TABLE 3: RENAULT STANDARDS IN FORCE WITH THE CORRESPONDING

INDEX ON THE DATE OF PUBLICATION OF THE CURRENT STANDARD

Standard Description

01 - 00 - 528 - - A Technical drawings : Nominal offset and aligned geometrical tolerance area

3.4. SPECIFIC REQUIREMENTS

This paragraph defines the specific layouts and the default layouts that apply to the dimensioning,

unless otherwise indicated on the plans or in the technical documentation.

3.4.1. Rule to apply for the location tolerancing of group of elements between them

and/or regarding references

Complying with ISO GPS standards in force:

- Complying with the ISO 1101:2012,

- Complying with the rules and definitions defined elsewhere in the ISO GPS standards,

- Complying with the clause 189 of WG18,

The following specific layout is taken:

- the use of the CZ symbol is mandatory with the tolerancing of location:

o When several elements with a same functional role are toleranced between them, and when

all degrees of freedom of the toleranced elements are not removed referred to the reference

or the reference system.

o When several elements with a same functional role are toleranced between them and

without reference.

This indication allows to define a combined zone applicable to a group of toleranced elements

(collection), in compliance with §8.5 of the ISO 1101 (cf extract below):

© RENAULT 2013 Page 6/11

RENAULT 00 - 10 - 039 / - - A

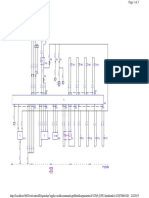

Example 1:

Fig. 1a Indication

Fig. 1b Signification

The specification mentioned in the fig. 1a defines a tolerance zone as mentioned in fig. 1b:

o the combined zone is composed of 8 individual cylindrical tolerance zones of 0, 1.

o the position of the 8 individual tolerance zones is fixed by the implicit or explicit theoretical

dimensions.

o the individual tolerance zones are positioned only between them.

At the same time, the 8 extracted axes must be inside their individual tolerance zone.

Note: the specification being without reference, the combined zone thus defined is free in regard to the

part in the 6 degrees of freedom.

© RENAULT 2013 Page 7/11

RENAULT 00 - 10 - 039 / - - A

Example 2:

Fig. 2 Indication

The specification shown in the fig.2 defines a combined zone:

o the combined zone is composed of 8 individual cylindrical tolerance zones of 0, 1.

o the position of the 8 individual tolerance zones is fixed by the implicit or explicit theoretical

dimensions.

o the position of the 8 individual tolerance zones is also fixed by the exact theoretical implicit

or explicit dimensions in regards to the C and A references.

At the same time, the 8 extracted axes must be inside their individual tolerance zone.

Note: the reference B is not used in the specification, so the distance between the combined zone and

the reference B is not fixed (the combined zone can translate regarding B).

© RENAULT 2013 Page 8/11

RENAULT 00 - 10 - 039 / - - A

Example 3:

Fig. 3 Indication

The specification shown in the fig.2 defines a combined zone:

o the combined zone is composed of 8 individual cylindrical tolerance zones of 0, 1.

o the position of the 8 individual tolerance zones is fixed by the implicit or explicit theoretical

dimensions.

o the position of the 8 individual tolerance zones is also fixed by the exact theoretical implicit

or explicit dimensions in regards to the C and A references.

At the same time, the 8 extracted axes must be inside their individual tolerance zone.

Note: In the specific case of the example in figure 3, the use of the CZ symbol may be omitted

because of the reference system A/C/B, the 6 degrees of freedom of the combined zone are removed,

and it is the same for each individual tolerance zone.

3.4.2. Default specification operator for size

Size ISO 14405 E: the default specification operator for sizes is the envelope requirement, unless

otherwise indicated on the plan, or reference to a document indicating other dispositions.

© RENAULT 2013 Page 9/11

RENAULT 00 - 10 - 039 / - - A

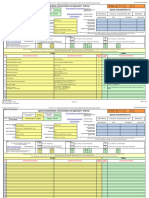

4. LABEL

The dimensional and geometrical tolerancing indicated on the drawings, in the 3D…, done following

the current standard must contain the below label below affixed near the cartridge.

This label is created in compliance with the rules of the norm 00-10-202.

Fig. 4 Label to attach on the plans nearby cartridge.

5. REVISION OF THE EXISTING STANDARD

The existing standard is revised for each major update of the ISO GPS standards and gets a new

index. It is therefore the design engineer to ensure that the label affixed on the drawing corresponds to

the current version of this standard.

© RENAULT 2013 Page 10/11

RENAULT 00 - 10 - 039 / - - A

ANNEX 1: WHY IS THERE A CONFLICT BETWEEN THE ISO 5458-1998 AND THE ISO 1101-2012?

In the ISO 1101:2012, the following indications are found:

Extract of the ISO 1101:2012:

Extract of the ISO 1101:2012:

But this indication (without the CZ modifier) does not imply a relation of position or an exact orientation

between each of the tolerance zones related to the toleranced elements.

For example, in the following reference figure 138 of §18.12.2:

Extract of the ISO 1101:2012:

- The ISO 1101-2012 considers that the location tolerance of 0.2 regarding the reference system

C/A applies to the 8 toleranced elements, each independent from the others

Whereas

- The ISO 5458 (without the CZ modifier) considers the 8 toleranced elements as a group of items

(collection) and that, the toleranced zones are positioned between them and in regard of the

theoretically exact references: cf §.4.2 – Basic requirements:

Extract of the ISO 5458:1998:

The tolerances of location are associated with the exact theoretical dimensions, and define

the limits of position of real (extracted) features, such as points, axes, median surfaces,

nominally straight lines and nominally plane surfaces, with reference to each other, or in

regard to the one or several specified references. The tolerance zone is distributed

symmetrically in regard with the exact theoretical position.

In order to avoid any issue, Renault chooses not to apply the ISO 5458.

There is no reason to write additional rules to those already defined in ISO. The application of the ISO

1101 and especially the CZ modifier are enough. This layout is in agreement with the resolution 189 of

the WG18.

© RENAULT 2013 Page 11/11

You might also like

- ManualnglêsDocument55 pagesManualnglêsMario RobertoNo ratings yet

- D45 1727 en PDFDocument38 pagesD45 1727 en PDFJose ValenciaNo ratings yet

- Hyde.r Motor Works: Installation Guide BMW Supercharger Setup M5XSC14Document35 pagesHyde.r Motor Works: Installation Guide BMW Supercharger Setup M5XSC14Jan KowalskiNo ratings yet

- JDM A22 - Rev 06-1987Document8 pagesJDM A22 - Rev 06-1987Reginaldo SantosNo ratings yet

- Test Method: Renault Automobiles Standardisation DPMI / Service 67250 Section Normes Et Cahiers Des ChargesDocument13 pagesTest Method: Renault Automobiles Standardisation DPMI / Service 67250 Section Normes Et Cahiers Des ChargesJose ValenciaNo ratings yet

- 32-04-033-F Vehicle Cockpit General RequirementsDocument32 pages32-04-033-F Vehicle Cockpit General RequirementsFreddy Tituaña Cadena50% (2)

- Volvo Navigation RTI 1022 Europe MMM2 PDFDocument4 pagesVolvo Navigation RTI 1022 Europe MMM2 PDFRavenNo ratings yet

- enDocument50 pagesenIonelMiocNo ratings yet

- Standard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesDocument7 pagesStandard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesRicardo VitorianoNo ratings yet

- 103XS0200 05Document46 pages103XS0200 05Mihai EnacheNo ratings yet

- Steel WheelsDocument84 pagesSteel WheelsclopogaNo ratings yet

- Ford We 910 - 2001Document6 pagesFord We 910 - 2001Jason-chungNo ratings yet

- B815 PDFDocument3 pagesB815 PDFROHITNo ratings yet

- ANPQP Category 11 Environmental RequirementDocument5 pagesANPQP Category 11 Environmental Requirementjefry sitorusNo ratings yet

- Kenwood 13 PinDocument7 pagesKenwood 13 Pingabr3lNo ratings yet

- Renault+can Clip+manual: Read/DownloadDocument2 pagesRenault+can Clip+manual: Read/DownloadEu BubuNo ratings yet

- VW 10514 enDocument14 pagesVW 10514 enAlexandre UrquizaNo ratings yet

- CS 00018Document13 pagesCS 00018Diego FerreiraNo ratings yet

- Engine 601Document4 pagesEngine 601SlobodanNo ratings yet

- Daewoo Nubira 1997-2004 General InformationDocument29 pagesDaewoo Nubira 1997-2004 General InformationHenry SilvaNo ratings yet

- General Information: Section 0BDocument3,772 pagesGeneral Information: Section 0BLeandro Lcar AutomotivoNo ratings yet

- Iso 14405-1Document15 pagesIso 14405-1RICARDONo ratings yet

- ANPQP 2.1 - ChangesDocument25 pagesANPQP 2.1 - ChangeskoalaboiNo ratings yet

- Rexton W 201206Document1,138 pagesRexton W 201206SebastianoNo ratings yet

- 2.engine Fuel SystemDocument16 pages2.engine Fuel SystemSoeAyeNo ratings yet

- EDC16 Wiring DiagrammDocument3 pagesEDC16 Wiring Diagrammjavier ayllonNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Renault Sport PDFDocument32 pagesRenault Sport PDFCaroline PuckettNo ratings yet

- Norma Fiat-Geometric Dimensioning and Tolerancing Practices-Cs.00019Document25 pagesNorma Fiat-Geometric Dimensioning and Tolerancing Practices-Cs.00019Helder VieiraNo ratings yet

- SVM AgfaLine 30 44 OLPDocument148 pagesSVM AgfaLine 30 44 OLPMarcos SamsoniukNo ratings yet

- Characteristics Accountability and VerificationDocument2 pagesCharacteristics Accountability and Verificationsajithv78No ratings yet

- MG Rover Group: Model/Derivative: N°: DateDocument2 pagesMG Rover Group: Model/Derivative: N°: Dateanon_941221142No ratings yet

- A Complete Guide To Spiratec™ Rotor (Cs41018/Cs41019/Cs41011) & Remote Centrifuge Product Benefits Installation InstructionsDocument7 pagesA Complete Guide To Spiratec™ Rotor (Cs41018/Cs41019/Cs41011) & Remote Centrifuge Product Benefits Installation InstructionsCarlos MeztNo ratings yet

- Ford Fusion 2008Document6 pagesFord Fusion 2008Rogelio ArenasNo ratings yet

- Ford Focus Zetec PDFDocument36 pagesFord Focus Zetec PDFolearydc9447100% (1)

- RenaultDocument46 pagesRenaultcostinel iordachescuNo ratings yet

- Sae J121M-2013Document5 pagesSae J121M-2013phan hoai nam PhanNo ratings yet

- 9 PDFDocument1 page9 PDFEko SulistyoNo ratings yet

- 6HP19A CatalogDocument41 pages6HP19A CatalogRoberto Riva RighettiNo ratings yet

- E-Mail:: Autocom Cars CDP+ - Release 2020 (2020.23) - VCI: 100251Document3 pagesE-Mail:: Autocom Cars CDP+ - Release 2020 (2020.23) - VCI: 100251Вячеслав ГлушакNo ratings yet

- Q151 WML 502Document6 pagesQ151 WML 502Riahi RezegNo ratings yet

- ANPQP Category 8 Non Conforming Product ManagementDocument8 pagesANPQP Category 8 Non Conforming Product Managementjefry sitorusNo ratings yet

- ANPQP Category 6 Product ConfirmationDocument7 pagesANPQP Category 6 Product Confirmationjefry sitorusNo ratings yet

- Standard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesDocument16 pagesStandard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesRicardo VitorianoNo ratings yet

- Mercedes Benz AG IATF 16949 CSR February 2022Document7 pagesMercedes Benz AG IATF 16949 CSR February 2022Naci BolcaNo ratings yet

- Semikron BasicDocument269 pagesSemikron Basic서원범No ratings yet

- JLR - Jaguar and Land Rover - 45b7bDocument27 pagesJLR - Jaguar and Land Rover - 45b7belevendot100% (1)

- MR419X6116A000Document21 pagesMR419X6116A000Ties van Raak100% (1)

- Logan Sandero I, BS11, Manual, 21 Manual Gearbox - Manual Gearbox - Catcar - InfoDocument2 pagesLogan Sandero I, BS11, Manual, 21 Manual Gearbox - Manual Gearbox - Catcar - InfotoufikNo ratings yet

- 2015 Creta G 1.6 Mpi A-T-DiagramDocument1 page2015 Creta G 1.6 Mpi A-T-DiagramJimmy Durand LunaNo ratings yet

- 60 627 - MascottDocument22 pages60 627 - MascottMax SamNo ratings yet

- ANPQP - 3.0 - Category 9Document10 pagesANPQP - 3.0 - Category 9jefry sitorusNo ratings yet

- Weldable Steel Flat Products Extra-Mild Hot Rolled Steels For Cold StampingDocument5 pagesWeldable Steel Flat Products Extra-Mild Hot Rolled Steels For Cold StampingLucasNo ratings yet

- Title: Cover-Fr Under No. 75892 NDS01Document7 pagesTitle: Cover-Fr Under No. 75892 NDS01Diego Camargo100% (1)

- VW 10550 enDocument3 pagesVW 10550 enIsabel SierraNo ratings yet

- 112 0003Document41 pages112 0003judithvelasquezNo ratings yet

- B65 4251 (Rev. D 2016.03) EN - SOUNDPROOFING ACOUSTIC ABSORBENTS SPECIFICATIONDocument25 pagesB65 4251 (Rev. D 2016.03) EN - SOUNDPROOFING ACOUSTIC ABSORBENTS SPECIFICATIONDiego CamargoNo ratings yet

- FAF03-111-2-Externally Supplied ContentDocument6 pagesFAF03-111-2-Externally Supplied ContentKinga EnNo ratings yet

- Customer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012Document4 pagesCustomer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012befoaNo ratings yet

- Rubber and Plastic Parts Behaviour To Impact (Falling Weight Method)Document16 pagesRubber and Plastic Parts Behaviour To Impact (Falling Weight Method)patborNo ratings yet

- Anexo - 19 - ING - FPW - IFN053 - Junx14 KDCS - FCADocument20 pagesAnexo - 19 - ING - FPW - IFN053 - Junx14 KDCS - FCAValdinei OliveiraNo ratings yet

- Q1 2nd EditionDocument20 pagesQ1 2nd EditionAndres Vargas RoldanNo ratings yet

- Renault Truck - KDocument16 pagesRenault Truck - KPaul FisherNo ratings yet

- ITTF Racket Control ProcedureDocument15 pagesITTF Racket Control ProcedureAsep MuhamadNo ratings yet

- Material and Equipment Standard For General Use HosesDocument30 pagesMaterial and Equipment Standard For General Use HosesRezaNo ratings yet

- Geometric Dimension IngDocument106 pagesGeometric Dimension IngjamesliouNo ratings yet

- 6000 - EN - 02 - ACBB - Indd 404 06-10-02 14.21.53Document64 pages6000 - EN - 02 - ACBB - Indd 404 06-10-02 14.21.53Raja NarenderNo ratings yet

- HF-525Plus Service Manual (Rev. 2.2 Latest)Document149 pagesHF-525Plus Service Manual (Rev. 2.2 Latest)Franklyn Acevedo100% (1)

- Reaffirmed February 6, 2020.: ISBN: 1-61481-089-6 Pages: 81Document1 pageReaffirmed February 6, 2020.: ISBN: 1-61481-089-6 Pages: 81gioNo ratings yet

- BS en 10095-1999Document29 pagesBS en 10095-1999Jithu Kareem0% (1)

- Steel Door Institute Fact File PDFDocument355 pagesSteel Door Institute Fact File PDFSwapnil JagtapNo ratings yet

- Raptor Slim Kenter Shackle R5Document1 pageRaptor Slim Kenter Shackle R5mayankdixit2No ratings yet

- Tol Geometrica PDFDocument31 pagesTol Geometrica PDFHaroldo Hübner NetoNo ratings yet

- KAN Pd-02.05 (Jan 2019) Guide On Measurement AssuranceDocument22 pagesKAN Pd-02.05 (Jan 2019) Guide On Measurement AssurancekalibrasibbkkpNo ratings yet

- Maximum Material ConditionDocument15 pagesMaximum Material ConditionKumar ChowdaryNo ratings yet

- 54 Design Specification For Gauges EnglishDocument17 pages54 Design Specification For Gauges EnglishSandip PatilNo ratings yet

- ASTM A781A781M - pdqv6897Document13 pagesASTM A781A781M - pdqv6897Nayth Andres GalazNo ratings yet

- (PIPE Catalogue) MechanicPipesDocument28 pages(PIPE Catalogue) MechanicPipesairsnowNo ratings yet

- Chapter 1 - Introduction To Project: 1.1 AbstractDocument11 pagesChapter 1 - Introduction To Project: 1.1 AbstractbasilNo ratings yet

- IS 1852 - 1985 - Reff2022Document28 pagesIS 1852 - 1985 - Reff2022singaravelan narayanasamy100% (1)

- M&M Unit I LM R20 PDFDocument34 pagesM&M Unit I LM R20 PDFkk11091079No ratings yet

- Bis 12894 - 2002Document7 pagesBis 12894 - 2002rabindora6588100% (1)

- SNC - Paliers A Semelle en PDFDocument88 pagesSNC - Paliers A Semelle en PDFDejanNo ratings yet

- Potenciômetro Burns 10K T15% L3% 1V Sem LimiteDocument4 pagesPotenciômetro Burns 10K T15% L3% 1V Sem Limiteitamar BarbosaNo ratings yet

- Fixturing Guidelines: Keysight I3070 Series 5i Inline In-Circuit Test SystemDocument27 pagesFixturing Guidelines: Keysight I3070 Series 5i Inline In-Circuit Test SystemDanielNo ratings yet

- Rolamentos Vedados SKFDocument28 pagesRolamentos Vedados SKFJose GomesNo ratings yet

- Fundamentals of GD&TDocument75 pagesFundamentals of GD&TAvanish Patel100% (2)

- IS 16014 - 2012 GabionDocument13 pagesIS 16014 - 2012 GabionOM BIHARI SINGHNo ratings yet

- Rubric Satay Stick BridgeDocument2 pagesRubric Satay Stick BridgeFaynie NeaxNo ratings yet

- Notes - Proe Drawing & SketcherDocument474 pagesNotes - Proe Drawing & SketcherChakrapani MiriyalaNo ratings yet