Professional Documents

Culture Documents

Microencapsulacion de Cafe Verde Con MD y Leche Descremada

Microencapsulacion de Cafe Verde Con MD y Leche Descremada

Uploaded by

Juan Fernando Pineda GutierrezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microencapsulacion de Cafe Verde Con MD y Leche Descremada

Microencapsulacion de Cafe Verde Con MD y Leche Descremada

Uploaded by

Juan Fernando Pineda GutierrezCopyright:

Available Formats

Pelita Perkebunan 36 (1) 2020, 56—67 Perdani et al.

ISSN: 0215-0212 / e-ISSN: 2406-9574

Optimization of Microencapsulation Process of Green Coffee Extract

with Spray Drying Method as A Dietary Supplement

Claudia Gadizza Perdani1*), Tiara Ayu Prihardhini1), and Dodyk Pranowo1)

1)

Department of Agroindustrial Technology, Faculty of Agricultural Technology, Brawijaya University

*)

Corresponding author : cgadizza@ub.ac.id

Received : 31 October 2019 / Accepted : 5 February 2020

Abstract

Green coffee has high content of chlorogenic acid which is potential to

be developed into slimming diet supplement. Microencapsulation was used to

make herbal supplement. Spray drying process with the addition of maltodextrin

as a coating material will protect the extract from high temperatures. The purpose of

this study was to determine the percentage of maltodextrin and optimal skim milk to

produce dietary supplement preparations and find out the quality of dietary supplement

preparations obtained. Robusta coffee beans from Argopuro, Jember, East Java,

was dry processed. This research optimized the microencapsulation process of

green coffee extract using central composite design method. The method was response

surface with two factors namely percentage of maltodextrin and percentage of

skim milk. The response used was total phenolic content and antioxidant activity.

The results showed the optimal percentage of maltodextrin and combined skim

milk were 8.61% and 3.22% respectively with total phenol obtained at 58.75 mg

GAE/g with an accuracy of 93.10% and IC50 65.10 ppm with an accuracy of 95.76%.

Dietary supplement products on the market contain total phenol of 57.52 mg GAE/g

and IC50 87.65 ppm. Comparison with other green coffee supplement products showed

this microencapsulation have higher total phenol content and antioxidant activity.

Keywords: Green coffee bean, maltodextrin, spray drying, dietary supplement,

skimmed milk, polyphenol, antioxidant

INTRODUCTION such as caffeine, phenolic compounds,

chlorogenic acid, and antioxidant compounds

Coffee is widely consumed as refreshing that are able to protect body from free radicals.

drink after mineral water and tea. There are Polyphenols are chemical compounds as anti-

two types of coffee that are populer in Indonesia oxidants those can be found in coffee. In

namely Robusta and Arabica. According to green coffee, the main polyphenol compound

Ministry of Agriculture data in 2017, Robusta is chlorogenic acid. Polyphenol compounds

coffee dominates 72.59% of coffee production are used to reduce body weight so that currently

in Indonesia. Green coffee is dried coffee green coffee can be consumed as supplement

beans that have been peeled off but not yet diets for obese people (Nagao et al., 2009).

roasting. According to Isnindar et al. (2017), According to data of Depkes (2009), the

coffee contains several important substances prevalence of obesity in Indonesia reaches

56 PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition

Optimization of microencapsulation process of green coffee extract with spray drying method

19.1% calculated from population aged of variables on the response formed (Montgomery,

15 years and above. The prevalence of obesity 2001). Therefore, this study aimed to deter-

is expected to increase according to age, mine the percentage of maltodextrin and

increase in population, diet, and lifestyle. optimal skim milk to produce dietary supple-

Obesity will cause several diseases such as ment preparations and to find out the quality

high blood pressure, coronary heart disease, of dietary supplement preparations obtained

diabetes, stroke, and cancer (Husnah, 2012). in form of microencapsulation.

Therefore, it is necessary to do research on

dietary supplements that produce high total

polyphenols and antioxidants with the addition

MATERIALS AND METHODS

of optimal fillers. Microencapsulation is one of The material used in this research is

important process to make bioactive component Robusta coffee beans from Argopuro, Jember,

more stable. East Java. Raw materials were obtained from

Method of microencapsulation can be Jember, harvested in July 2018 and processed

used to make herbal supplement. Spray drying by dry process and no pretreatment was carried

process with the addition of maltodextrin as out. The filling material used were maltodextrin

a coating material that will protect the extract and skim milk, and commercial green coffee

from high temperatures so that important supplement. The research was conducted at the

components in it are not damaged and skim Laboratory of Entrepreneurship and Bioindustry

milk as a protein material. Spray drying is a of Faculty of Agricultural Technology, Brawijaya

method used to convert liquid feed into University and the Laboratory of Pharmacy

powder (Dewi & Loekman, 2015). According Biology, Faculty of Science and Mathematics,

to Heldman et al. (1981), the advantages of Indonesian Islamic University.

the spray drying process are the relatively The research used response surface

fast drying cycles, the retention of the product method (RSM) in two factors that are the

in a short drying chamber, and the finished percentage of maltodextrin and the percentage

product that has been dried ready to be pack- of skim milk so that 13 experimental design

aged. Maltodextrine and skim milk are kind combinations were obtained. The response

of carrier material that will protect bioactive used in this study was total phenolic content

component from high temperature on spray and antioxidant activity. The results of opti-

drying process. mization in the Design Expert 7.1.5 Portable

The optimization method that can be used software were validated by extracting in

is the response surface method (RSM) with accordance with the optimal treatment results

central composite design (CCD). According from the prediction of the response surface

to Aritonang (2014), RSM is used for research then testing the total phenolic content and

that has complex processes and is widely used antioxidant activity.

in food technology research. The RSM method The level used for the percentage of

is able to explore correlations between many maltodextrin was 8.50 as the lower limit and

factors to get the most optimal production 9.50 as the upper limit, while for skim milk

conditions (Chang et al., 2006). In RSM, was 2.20 as the lower limit and 6.60 as the

CCD is used to build a polynomial model of upper limit so that 13 experimental design

a mathematical function of the independent combinations were obtained as in Table 1.

PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition 57

Perdani et al.

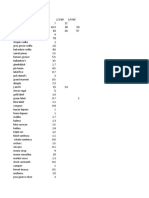

Tabel 1. Experimental design

Fa ctor Fa ctor

X1 X2 Percentage of maltodextrin Percentage of skim milk

(% of total extract) (% of total extract)

-1 -1 8.50 2.20

+1 -1 9.50 2.20

-1 +1 8.50 6.60

+1 +1 9.50 6.60

-1,414 0 8.29 4.40

+1,414 0 9.71 4.40

0 -1,414 9.00 1.29

0 +1,414 9.00 7.51

0 0 9.00 4.40

0 0 9.00 4.40

0 0 9.00 4.40

0 0 9.00 4.40

0 0 9.00 4.40

Coffee Powder Microencapsulation were then analyzed for total phenolic content

and antioxidant activity.

Green coffee beans were aerated at room

temperature for two hours to reduce water

content. Furthermore, the coffee beans were Total Phenolic Content (TPC)

grinded using a disk mill in stages and then

A response to optimization process of

sieved (40 mesh) to produce green coffee powder.

microencapsulation of green coffee was total

The ground coffee obtained were stored in plastic

phenolic content. Every samples was analyzed

containers at room temperature. The green

total phenolic content. The optimum treatment was

coffee powder that did not pass the sieve

analyzed of TPC and compared with commercial

was then grinded again using a blender.

green coffee supplement.

Green coffee powder was taken as much

Standard curves of chlorogenic were set

as 10 g and then macerated in 100 mL of

up by weighing chlorogenic acid powder as

distilled water for 24 hours at room tempera-

much as 0.01 g, then put into 100 mL volu-

ture (± 25OC) without stirring. The extraction

metric flask and added distilled water to mark

results were filtered with a paper filter and

the limit and homogenized to form 100 ppm.

stored in glass bottles in cold temperatures.

The solvent was diluted with concentrations

of 0 ppm, 20 ppm, 40 ppm, 60 ppm, 80 ppm

Coffee Extract Microencapsulation and 100 ppm. Each concentration was taken

0.5 mL and added 2.5 mL of 10% folin

100 mL of green coffee extract was reagent then homogenized and incubated

added with maltodextrin and skim milk using 5 minutes in the dark. After that, 2 mL of

several proportions according to the experi- 7.5% Na 2 CO 3 was added and incubated

mental design. The three ingredients was 30 minutes in the dark. Absorbance measure-

then mixed for 15 minutes for homogeni- ment using 765 nm wavelength was then

zation. The spray drying process was then plotted into a curve where X is the concen-

carried out with an inlet temperature of tration of gallic acid and Y is the absorbance

120OC, an outlet temperature of 60-80OC for so that the regression formula Y = aX + b is

30 minutes. The microcapsules produced obtained.

58 PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition

Optimization of microencapsulation process of green coffee extract with spray drying method

The solvent for analyzed was prepared incubated 30 minutes in the dark. Absor-

by encapsulation powder samples weighed bance measurements used wavelength of 517

as much as 0.01 g and dissolved in 10 mL of nm. DPPH uptake values before and after

distilled water. The solvent was taken 0.5 mL sample addition were calculated as percent

and put in a dark test tube. The solvent was inhibition (% inhibition) by the formula:

mixed with 2.5 mL of Folin C reagent 10% A control - A sample

distilled water and then homogenized and % Inhibition = x 100%

incubated 5 minutes in the dark and at room A sample

temperature. Then it was added with 2 mL

Then the results are entered into the linear

of Na2CO 3 solution, 7.5% distilled water,

regression equation Y = aX + b where Y is

homogeneous, and incubated 30 minutes in

the percent inhibition and X is the concen-

the dark. The blank used was 0.5 mL distilled

tration. The equation was used to determine

water added with 2.5 mL of 10% folin reagent

the LC50 value of each sample. The LC 50

and 2 mL of 7.5% sodium carbonate solution.

value was the half maximal inhibitory

Absorbance measurement used 765 nm

concentration.

wavelength. The amount of phenolic compounds

was measured based on gallic acid standard The chlorogenic acid sample test was

curves and expressed as mg chlorogenic carried out with LC-MS/MS equipment.

acid equivalent (CGAE/g extract). The levels of The column used was the Hypersil Gold

phenolic compounds in extracts were calculated specification (50 mm x 2.1 mm x 1.9 µm).

by the equation: UHPLC brand ACCELLA type 1250 made by

Thermo Scientific which consisted of a vacuum

c x fk x V

C= g degasser, quartener pump, thermostatic auto-

C = concentration of total phenolic content (mg CGAE/g) sampler controlled by a personal computer

c = concentration of chlorogenic acid (µg CGAE/mL) through the x-calibur 2.1 program. Solvent

V = volume of the extract solvent taken for analyzed (mL)

g = extract weights used for analyzed (g) A consisted of 0.1% formic acid in aquabidest,

fk = conversion factor solvent B consisted of 0.1% formic acid in

acetonitrile. A linear gradient with a velocity

Antioxidant Activity of 300 µL/min with the following mobile phase

The second response from optimization adjustments: a) 0–0.6 minutes 95% A; 0.6–

process was antioxidant activity. Analysis 3.0 minutes 75% B; 3.0–3.5 minutes 75% B;

of antioxidant activity was carried out by 3.5–4.0 minutes 75% B and 4.0-5.5 minutes

the DPPH method by means of 0.01 g of 95% A. The injection volume at LC is 2 µL.

microcapsule powder dissolved in 10 mL The column was controlled at 30OC, and the

of methanol to obtain a 1000 ppm solvent. autosampler compartment was set to 16OC.

The solvent was diluted at concentrations

of 60 ppm, 70 ppm, 80 ppm, 90 ppm and RESULTS AND DISCUSSION

100 ppm. Samples at each concentration

were taken 2 mL and put in a dark test tube. Response data of total phenol was in

Each test tube was added with 1 mL DPPH the range of 17.03-61.00 mg GAE/gr while

0.2 mM, homogenized, and incubated in the LC50 value response data was in the range

dark for 30 minutes. The control solvent of 62.69-100.08 ppm. The results of a cen-

was made by 1 mL DPPH 0.2 mM put into tralized composite design analysis can be

2 mL of methanol then homogenized and seen in Table 2.

PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition 59

Perdani et al.

Table 2. Result of central composite design analysis

Fa ctor Response

Percentage of maltodextrin Percentage of skim Total phenolic content IC 50 value (ppm)

(% of total extract) milk (% of total extract) (mg GAE/g)

8.50 2.20 61.00 62.68

9.50 2.20 54.49 86.96

8.50 6.60 32.23 80.36

9.50 6.60 25.25 98.55

8.29 4.40 54.69 81.14

9.71 4.40 31.82 98.86

9.00 1.29 46.07 89.20

9.00 7.51 17.03 100.08

9.00 4.40 37.85 71.85

9.00 4.40 39.63 75.21

9.00 4.40 21.00 66.84

9.00 4.40 26.21 66.83

9.00 4.40 19.63 76.97

Total Phenolic Content In response surface optimization for total

phenols, the most influential factor was the

According to Table 2, it can be seen that percentage of maltodextrin (X1) with a co-

the highest response of total phenol value was efficient value of 11.46 which shows that

61.00 mg GAE/g obtained from the composition the percentage factor of maltodextrin gave

with percentage of maltodextrin was 8.50 an effect of 11.46 for every one point increased.

and percentage of skim milk is 2.20. The lowest Next was the percentage factor of skim milk

total phenol is 17.03 mg GAE/gr obtained (X2) with a coefficient value of 5.630 which

from the treatment with the percentage of shows that the solvent ratio factor gives an

maltodextrin 9.00 and the percentage of skim effect of 5.630 for every one point increase.

milk 7.51. The research data indicate that

the total phenol extract tends to increase with The contour plot of the percentage factor

the smaller percentage of maltodextrin of maltodextrin and skim milk to the total

and the small percentage of skim milk used. phenolic content response can be seen in

The results obtained were in accordance Figure 1. The results of the response are

with Widarta & Hapsari (2014), the higher shown through the contour lines in the picture.

encapsulant’s concentration, the lower total The largest total phenol was shown starting

phenol of the microcapsule product. This from the deepest line and the more out the

was caused by the higher concentration of total phenol value will be lower. The red

encapsulants resulting in a greater ratio of contour indicates that the total phenol was

extracts to encapsulants. higher, while the darker blue the total phenol

content was lower. The surface curve of

Data processing using RSM shows that the percentage response of maltodextrin and

the chosen model was linear with both factors skim milk to the total phenolic content response

significant to the response. The polynomial can be seen in Figure 2.

equation obtained was

Based on the response surface curve

Y1 = 35.92 – 5.73X1 – 12.39X2 ...... (1) it can be seen that the percentage factor of

Y1 = 163.84 – 11.46X1 – 5.630X2 ... (2) maltodextrin and skim milk had a significant

60 PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition

Optimization of microencapsulation process of green coffee extract with spray drying method

effect. The graph also shows a linear model, (Siska & Wahyono, 2013). According to Al

in which total phenols will increased along Fakkar (2018), the combination of skim milk

with low concentrations of maltodextrin and and green coffee extract will produced total

skim milk. Based on these results, maltodextrin phenol, antioxidants, and high chlorogenic

will protect the material from nutrient released acid content which was useful as a dietary

due to high temperatures, but the higher the supplement.

percentage of maltodextrin and skim milk,

the lower the total phenol content. This was

Antioxidant Activity

due to the increasing number of total solids

contained in the material so that it can reduce Antioxidant activity value was carried

the intensity of the blue color in folin reagents out to find out how strong the antioxidant

6.60

Total phenolic content

Design port

61

17.0274

5.50

X1 = A: % maltodextrine

X2 = B: % skim milk

4.40

3.30

2.20

8.50 8.75 9.00 9.25 9.50

Figure 1. Contour plot response percentage of maltodextrin and percentage of skim milk to response

total phenolic content microencapsulation of green coffee extract

Total phenolic content

Design port above predicted value

61

17.0274

X1 = A: % maltodextrine

X2 = B: % skim milk

6.60 9.50

5.50 9.25

4.40 9.00

3.30 8.75

2.20 8.50

Figure 2. Response surface curve percentage of maltodextrin and percentage of skim milk to response

total phenolic content microencapsulation of green coffee extract

PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition 61

Perdani et al.

activity was in the microencapsulation powder LC50 (Y2) which is influenced by the percentage

of green coffee extract produced. Antioxidant factor of maltodextrin (X1) and the percentage

activity can be seen from the LC50 value where of skim milk (X2) is as follows:

the smaller LC50 value, will make antioxidant Y1 = 71.55+8.44X 1+5.58X 2–1.52X 1X 2+6.68 X 12+

activity higher. Based on the data obtained 9 X22 …..................................................... (1)

it can be seen that the response of antioxidant Y1 = 2 0 5 5 . 1 0 - 4 5 8 . 2 4 X 1 - 1 . 3 8 0 6 X 2 -

activity had the lowest LC50 value of 62.68 1.3838X1X2+26.734X12+1.8604X22 ... (2)

at 8.5% maltodextrin percentage and 2.2%

skim milk percentage which means it had high In response surface optimization for LC50

antioxidant activity while the highest LC50 values, the most influential factor is the per-

value was 100.08 at percentage of malto-dex- centage of maltodextrin (X1) with a coefficient

trin 9% and percentage of skim milk 7.51% value of -458.24, which indicates that the

which means it had low antioxidant activity. percentage factor of maltodextrin gives an

The research data obtained indicate that the effect of -458.24 for every one point increase.

antioxidant activity will increase along with Next is the percentage factor of skim milk

the reduction in the composition of additional (X2) with a coefficient value of -1.3806 which

ingredients in green coffee extracts. The more shows that the percentage factor of skim milk

composition of maltodextrin and skim milk gives an effect of -1.3806 every increase of

were added, the lower the antioxidant activity one point. The contour plot of the percentage

as indicated by the higher LC50 value. factor of maltodextrin and percentage of skim

milk to the LC50 value of microencapsulated

These results were linier with the research

green coffee extract can be seen in Figure 3.

of Yuliawaty & Wahono (2015), the addition of

higher concentrations of maltodextrin cause Based on Figure 3, it shows that the

a decrease in levels of antioxidant activity. higher the LC50 value means that antioxidant

This was presumed by the increasing number activity is lower. Conversely, the lower LC50

of total solids contained in the material, namely value means that antioxidant activity is

maltodextrin as a filler so that the measured higher. In addition, in the graph there are

antioxidant activity was reduced, so that with also different colors where the redder the

increasing total solids in an ingredient, the antioxidant activity the smaller and the darker

measured antioxidant activity levels will be blue the color shown, the higher the anti-

smaller. In addition, it was also thought to be oxidant activity.

caused by changes in antioxidant compounds The contour plot of the total phenolic

due to the heating process, namely vitamin content response was different from the plot

C and other oxidized phenol compounds. It contour of the LC50 value response. The dif-

was possible that warming causes the phenol ference was seen from the contour color

compound to decompose so that its ability where the expected total phenolic content

as an antioxidant had decreased. plot response contour was red, the highest

The results of data processing using RSM total phenol content. In contrast, the contour

show that the chosen model was quadratic. color of the expected LC50 response was blue,

The percentage factor of maltodextrin was which is the lowest LC50 value so that it

significant for the response but the percentage has high antioxidant activity. The surface

factor for skim milk was not significant for curve of the maltodextrin percentage response

the response. The polynomial equation for and the percentage of skim milk to the LC50

the quadratic model on the response value of value response is presented in Figure 4.

62 PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition

Optimization of microencapsulation process of green coffee extract with spray drying method

Based on these curves it can be seen that higher causes a decrease in the level of anti-

both factors affect the LC50 value, but the oxidant activity. More total solids are present

percentage of maltodextrin was more dominant in the material, namely maltodextrin as a filler

factor affecting the yield. The graph also and skim milk as a source of protein, which

shows a quadratic model, where it was causes measurably less antioxidant activity.

shown through optimum conditions at the The antioxidant content was also thought

peak then decreased based on the two factors to be affected by the heating process, namely

used. vitamin C and other oxidized phenol com-

The percentage of maltodextrin and the pounds. It was possible that warming causes

percentage of skim milk generally affect the the phenol compound to decompose so that

antioxidant activity produced. Increasing the its ability as an antioxidant had decreased

concentration of maltodextrin which was (Yuliawaty & Wahono, 2015).

6.60

5.50

B = % Skim milk

4.40

3.30

2.20

8.50 8.75 9.00 9.25 9.50

A = % maltodextrine

Figure 3. Contour plot response percentage of maltodextrin and percentage of skim milk to response

LC50 value microencapsulation of green coffee extract

100

90.5

81

71.5

62

6.60 9.50

100 9.25

4.40 9.00

3.30 8.75

B = % Skim milk A = % Maltodextrine

2.20 8.50

Figure 4. Response surface curve percentage of maltodextrin and percentage of skim milk to response

LC50 value microencapsulation of green coffee extract

PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition 63

Perdani et al.

Optimum Solution for the Response desirability value was the value of the objec-

tive optimization function that shows the

The study was conducted to determine

ability of the program to fulfill desires based

the optimal solution results from the opti-

on the final predetermined criteria whose

mization of the percentage of maltodextrin

values range from 0 to 1. The closer to 1

and the percentage of skim milk in the

the value of desirability shows the ability

microencapsulation process of green coffee

of the program to achieve the more perfect

extract by optimizing the total phenol and

optimization goals.

the antioxidant activity. Limitations of opti-

mization for responses and factors can be Based on Figure 5 it was shown that

seen in Table 3. Both responses were selected the value of desirability was 0.926. The

with maximum targets because the aim of more outgoing the smaller the desirability

the study was to obtain the highest total phenol value. The results of optimization carried

yield and antioxidant activity from several out produce desirability values that are in the

treatment variations. Based on the limita- red contour, the highest contour. This shows

tions in Table 3, the optimum solution results that the program can achieve near-perfect

obtained by expert design software 7.1.5 can optimization goals. Besides desirability, it was

be seen in Table 4. In addition to the optimal also shown by the response surface curve

solution results predicted by the program, of the optimization results of total phenolic

there is also an estimate of the lowest to content response and antioxidant activity

highest value of the responses presented in which can be seen in Figure 6.

Table 5. Through the table, the prediction The results of the calculation of green

value can be known for both responses. coffee microencapsulation powder samples

The results of the optimization of total can be seen in Table 6. The chlorogenic acid

phenolic content response and antioxidant content of green coffee extracts was 1.19%.

activity were also presented in the form of Chlorogenic acid percentage increase with

desirability which can be seen in Figure 5. increasing levels of caffeine. In the study

According to Nurmiah et al. (2013), the of Urakova et al. (2008), determination of

Table 3. Optimization limits for responses and factors

Criteria Name (Unit) T a rget Lower limit Upper limit

Factor Percentage of maltodextrin (% of total extract) In range 8.50 9.50

Factor Percentage of skim milk (% of total extract) In range 2.20 6.60

Response Total phenolic content (mg GAE/g) Maximize 17.0274 61.0000

Response Antioxidant activity(LC50 value in ppm) LC50 value Minimize 62.6899 100.0840

Table 4. Optimal solution results from design expert 7.1.5 software

Parameter Prediction standard

Percentage of maltodextrin (%) 8.50

Percentage of skim milk (%) 2.32

Total phenolic content (mg GAE/g) 53.3343

LC50 value (ppm) 71.1029

Desirability 0.800

Information Selected

Table 5. Prediction of the lowest to highest solution

Parameter Prediction SE Pred Lowest prediction Higher prediction

Total phenolic content (mg GAE/g) 53.3343 11.69 27.29 79.38

LC50 value (ppm) 71.1029 8.95 49.95 92.26

64 PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition

Optimization of microencapsulation process of green coffee extract with spray drying method

chlorogenic acid levels was carried out on is different from particles in microcapsules

unroasted coffee bean extracts (0.86%). oleoresin ginger pulp that there is a lot of

Determination of chlorogenic acid levels in adhesion between particles one with the

coffee beans is also done by Belay et al. other particles.

(2008), obtained chlorogenic acid levels of

0.33% and 0.23%.

Comparison with Other Products

The appearance of microencapsulation

of green coffee extract indicates a rift on Microencapsulation products that have

the surface of the microcapsule caused by been produced were then compared with

high temperature. This embezzement can be similar products on the market. It aims to

caused by high temperature spray drying. determine the quality and position of the

This can lead to the loss of volatile compo- products produced with products that were

nents from within the microcapsules already known in the market. The parameters

(Reineccius, 1988). Microcapsule particles compared were total phenolic content, anti-

in the control tend not to stick between the oxidant activity, and solubility. The results

particles one with the others. This condition of the comparison can be seen in Table 7.

Design expert software Desirability

6.60

Desirability

Design ports

1

0 5.50

X1 = A: % maltodextrine

X2 = B: % skim milk

4.40

3.30

2.20

8.50 8.75 9.00 9.25 9.50

Figure 5. Desirability results of optimization of total phenolic content and antioxidant activity response

Design expert software

Desirability

1

0

X1 = A: % maltodextrine

X2 = B: % skim milk

Desirability

6.60 9.50

5.50 9.25

4.40 9.00

3.30 8.75

B = % Skim milk 2.20 8.50 A = % Maltodextrine

Figure 6. Response surface curve rsults optimization response of total phenolic content and antioxidant

activity

PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition 65

Perdani et al.

Table 7. Product comparison of 87.7 and a total phenol of 46.32 mg GAE/g.

Microencapsulation A comparative The quality of the green coffee extract microen-

Parameter of green coffee dietary

extra ct su pplement capsulation product with spray drying method

Total phenol 53.33 mg GAE/g 46.32 mg GAE/g was better than diet supplements exist in the

LC50 value 71.10 ppm 87.65 ppm market.

Solubility Soluble Difficult to dissolve

Based on Table 7, it can be seen that REFERENCES

the quality of the microencapsulated green Al Fakkar, M.A. (2018). Pengembangan Produk

coffee extract powder in this study has better Susu Sereal Gandum dengan Penambahan

quality than diet supplements that were Ekstrak Kopi Hijau. Skripsi. Fakultas

already on the market. The lack of solubility Teknologi Pertanian. Institut Pertanian

in the comparative product is presumed to be Bogor, Bogor.

due to the particle size of the capsule powder Aritonang, A.L.P. (2014). Analisis Metode

being less small or less smooth. The grinding Response Surface Pada Produksi

process aims to reduce the size of the coffee Biodiesel Secara Katalitik dengan Static

making it easier for the coffee powder to Mixing Reactor. Skripsi. Departemen

Teknik Mesin dan Biosistem. Fakultas

dissolve in its solvent. Typically, water-soluble

Teknologi Pertanian. Institut Pertanian

components were chlorogenic acid, caffeine, Bogor. Bogor.

nicotinic acid, melanoidin compounds, and

hydrophilic volatile compounds will be extracted Belay, A.; K. Ture; M. Redi & M. Asfaw (2008).

Measurement of caffein in coffee bean

more highly when using high temperatures

with UV-Vis spectro materi. Food

and pressures. It was also thought to be due Chemistry, 108, 310–315.

to other compositions in Exitox Greenco

Chang, Y.C.; C.L. Lee & T.M. Pan (2006). Statistical

supplement namely Garcinia cambogia,

optimization of media components for

Garcinia mangostana pericarpium, and the production of Anttrodia cinnamomea

Guazuma ulmifolia. The total phenol content AC0623 in submerged cultures. Applied

and antioxidant activity which was lower Microbiology and Biotechnology, 72,

than the microencapsulation product of green 654–661.

coffee extract by spray drying method was Depkes RI (2009). Riset Kesehatan Dasar

thought to be influenced by the type and Laporan Nasional. Balai Penelitian dan

polarity of the solvent at the time of extraction Pengembangan Kesehatan Departemen

where the type and polarity of the solvent Kesehatan Republik Indonesia (RI).

can affect the transfer of a single electron Jakarta.

or transfer of hydrogen atoms which is a key Dewi, A.K. & S. Loekman (2015). Kajian

aspect in testing antioxidant (Meitary, 2017). pengaruh temperatur pengeringan

semprot (Spray dryer) terhadap waktu

pengeringan dan rendemen bubuk

CONCLUSIONS santan kelapa (Coconut milk powder).

The optimum conditions for green coffee Konversi, 4, 25–31.

extract microencapsulation process was Heldman, R.D. & R.P. Singh (1981). Food Process

predicted at 8.5% of maltodextrin and 2.32% Technology. The AVI Publishing Co.,

of skim milk, producing a total phenol of Inc., Westport, Connecticut.

53.33 mg GAE/g and LC50 value of 71.10 ppm. Husnah (2012). Tatalaksana obesitas. Jurnal

The comparative capsule had an LC50 value Kedokteran Syiah Kuala, 12, 99–104.

66 PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition

Optimization of microencapsulation process of green coffee extract with spray drying method

Isnindar; S. Wahyuono & S. Widyarini (2017). Siska, T. & H.S. Wahyono (2013). Pengaruh

Aktivitas antioksidan buah kopi hijau lama pengeringan dan konsentrasi

Merapi. Journal of Pharmaceutical maltodextrin terhadap karakteristik fisik

Science and Clinic Research, 2, 130–136. kimia dan organoleptik. Jurnal Pangan

dan Agroindustri, 3, 41–52.

Meitary, N. (2017). Analisis Total Fenol, Flavonoid,

dan Tanin serta Aktivitas Antioksidan Urakova, L.N.; O.N. Pozharistskaya; A.N. Shikov;

Empat Ekstrak Daun Jati Belanda V.M. Kosman & V.G. Makarov (2008).

(Guazuma ulmifolia). Skripsi. Institut Development and validation of an LC

Pertanian Bogor. Bogor. method for simultaneus determination

Montgomery, D.; K. Vadde & V. Syrotiuk (2001). of ascorbic acid and three phenolic acids

Optimizing Protocol Interaction in sustained released tablet, at a single

Using Response Surface Methodology. wonelength. Chromatographia, 67,

John Willey & Sons. New York. 709–713.

Nagao, T.; R. Ochiai; T. Watanabe; K. Katoka; Widarta, I.W.R. & N.M.I. Hapsari (2014).

M. Komikado; T. Tokimitsu & T. Tsuchida Mikroenkapsulasi ekstrak bekatul beras

(2009). Viceral fat-reducing effect of merah dan aplikasinya sebagai fortifikan

continuous coffee beverage consump- pangan fungsional. Prosiding Seminar

tion in obese subjects. Journal of Japan Sains dan Teknologi. Universitas Udayana,

Denpasar, Bali.

Phamacological Therapy, 37, 33–44.

Yuliawaty, S.T. & H.D. Wahono (2015). Pengaruh

Nurmiah, S.; S. Rizal; Sukarno; P. Rosmawaty

lama pengeringan dan konsentrasi

& Budi (2013). Aplikasi response surface

maltodextrin terhadap karakteristik fisik

methodology pada optimalisasi kondisi

kimia dan organoleptik minuman instan

proses pengolahan Alkali Trated

daun mengkudu (Morinda citrifolia L.).

Cottonii (ATC). Jurnal Kelautan dan

Jurnal Pangan dan Agroindustri, 3, 41.

Ilmu Perikanan, 8, 9–22.

**0**

Reneccius, G.; R. Teranishi & L.C. Ling (1988).

Identification of damascenone in tomato

volatiles. Chemical Industry, 238, 55–66.

PELITA PERKEBUNAN, Volume 36, Number 1, April 2020 Edition 67

You might also like

- Bread and Pastry Production Exam TosDocument6 pagesBread and Pastry Production Exam Tosmoonyeen banagan86% (14)

- Total Surrender by Pargeter Margaret Z-LiborgDocument214 pagesTotal Surrender by Pargeter Margaret Z-Liborganitha100% (5)

- Dietary Fiber and Antioxidant Activity of Gluten-Free Cookies With Coffee Cherry Flour AdditionDocument8 pagesDietary Fiber and Antioxidant Activity of Gluten-Free Cookies With Coffee Cherry Flour AdditionDamatNo ratings yet

- AJGC Volume 4 Issue 3 Pages 327-339Document13 pagesAJGC Volume 4 Issue 3 Pages 327-339Karen HernándezNo ratings yet

- Optimization of Ultrasonic-Assisted Extraction Conditions For Bioactive Components From Coffee Leaves Using The Taguchi Design and Response Surface MethodologyDocument10 pagesOptimization of Ultrasonic-Assisted Extraction Conditions For Bioactive Components From Coffee Leaves Using The Taguchi Design and Response Surface MethodologyHuy Trần Hoài NhậtNo ratings yet

- Nfluence of Pectinase-Assisted Extraction Time On The Antioxidant Capacity ofDocument8 pagesNfluence of Pectinase-Assisted Extraction Time On The Antioxidant Capacity ofThịnh NguyễnNo ratings yet

- Microwave-Assisted Extraction of Pectin From PineaDocument6 pagesMicrowave-Assisted Extraction of Pectin From PineaPatricia Marie FallarNo ratings yet

- Formulation of Solid Soap From Dragon Fruit Skin Waste With Pandan Leaf ExtractDocument12 pagesFormulation of Solid Soap From Dragon Fruit Skin Waste With Pandan Leaf ExtractYuni ArsihNo ratings yet

- The Study of Apple Flour Formulation For Functional CookiesDocument10 pagesThe Study of Apple Flour Formulation For Functional CookiesFRANSISKA DHEASARI KUSUMA PUTRINo ratings yet

- SapotamarmaladeDocument9 pagesSapotamarmaladeBob FloresNo ratings yet

- 6 fr-2021-763 AbdullahDocument5 pages6 fr-2021-763 AbdullahwidyaNo ratings yet

- Program Studi S1 Farmasi Universitas Ngudi Waluyo, Jl. Diponegoro No. 186, Ungaran Timur, Kabupaten Semarang, Jawa Tengah, 50512, IndonesiaDocument10 pagesProgram Studi S1 Farmasi Universitas Ngudi Waluyo, Jl. Diponegoro No. 186, Ungaran Timur, Kabupaten Semarang, Jawa Tengah, 50512, IndonesiaDiah NurlailaNo ratings yet

- Jurnal KakaoDocument11 pagesJurnal KakaoOktavianus BiatoNo ratings yet

- Single Starter Lactobacillus Plantarum For ModifiedDocument7 pagesSingle Starter Lactobacillus Plantarum For ModifiedHellen Puspa NingrumNo ratings yet

- Dyonazkarahman,+3 +437Document11 pagesDyonazkarahman,+3 +437048Auliatur RohmahNo ratings yet

- Maximisation of The Polyphenols Extraction Yield From Green Tea Leaves and Sequential ClarificationDocument8 pagesMaximisation of The Polyphenols Extraction Yield From Green Tea Leaves and Sequential ClarificationrinNo ratings yet

- 736 3478 1 PBDocument13 pages736 3478 1 PBAlya Andien SajidahNo ratings yet

- 12037-Article Text-46933-6-10-20200307Document8 pages12037-Article Text-46933-6-10-20200307Rahmanisa NandaNo ratings yet

- 25-Article Text-264-1-10-20220131Document5 pages25-Article Text-264-1-10-20220131Jamila MotiwalaNo ratings yet

- Optimization of Pectin Extraction From Kepok BananDocument7 pagesOptimization of Pectin Extraction From Kepok BananAdestya S. RamadhanNo ratings yet

- 1 s2.0 S0023643821017230 MainDocument9 pages1 s2.0 S0023643821017230 Mainawanishsingh989No ratings yet

- Formulation & Analysis of Papaya Fortified Biscuits: Rupanjali Pathak, Vandana Thakur and Rajinder Kumar GuptaDocument4 pagesFormulation & Analysis of Papaya Fortified Biscuits: Rupanjali Pathak, Vandana Thakur and Rajinder Kumar GuptaRizki Aulia NuzullinaNo ratings yet

- 36 fr-2021-176 WinarsiDocument9 pages36 fr-2021-176 WinarsiRavoala RakotoarinivoNo ratings yet

- Innovacion Hojas Chocolate 2012Document11 pagesInnovacion Hojas Chocolate 2012Bertinetti YuliNo ratings yet

- 10.1007@s13197 019 03901 8Document10 pages10.1007@s13197 019 03901 8putriiii0811No ratings yet

- Dimas Danar 2017 - Interaction Between Natural Antioxidants Derived From Cinnamon Cocoa - Q1 Food ChemistryDocument9 pagesDimas Danar 2017 - Interaction Between Natural Antioxidants Derived From Cinnamon Cocoa - Q1 Food ChemistrySolo PeduliNo ratings yet

- Valorization of Apple Pomace Powder in Development of Functional CookieDocument6 pagesValorization of Apple Pomace Powder in Development of Functional CookieSujata GhodkeNo ratings yet

- J Basic Appl Sci Res 243588-35922012Document6 pagesJ Basic Appl Sci Res 243588-35922012Beatrice CarliniNo ratings yet

- Characterization of Banana Peel Pectin As Potential Halal Pharmaceutical ExcipientDocument12 pagesCharacterization of Banana Peel Pectin As Potential Halal Pharmaceutical ExcipientRobiatul AwwaliyahNo ratings yet

- Mikroenkapsulasi Minyak Sawit Mentah Dengan Penyalut Maltodekstrin Dan Isolat Protein KedelaiDocument10 pagesMikroenkapsulasi Minyak Sawit Mentah Dengan Penyalut Maltodekstrin Dan Isolat Protein KedelaiAmalia Noviyanti AmelNo ratings yet

- Kartini 2018 IOP Conf. Ser. Earth Environ. Sci. 207 012061Document9 pagesKartini 2018 IOP Conf. Ser. Earth Environ. Sci. 207 012061adityaswaroop143No ratings yet

- ChirimoyaDocument12 pagesChirimoyaNicole LucanoNo ratings yet

- Review SwethaDocument3 pagesReview SwethaJustclick CompNo ratings yet

- 4736 17213 1 PBDocument10 pages4736 17213 1 PBHanifah AyuNo ratings yet

- TEA - FIX Quan V. Vuong Et Al., 2013 Powder Technology - Preparation of Decaffeinated and High Caffeine Powders From Green TeaDocument7 pagesTEA - FIX Quan V. Vuong Et Al., 2013 Powder Technology - Preparation of Decaffeinated and High Caffeine Powders From Green TeaAgung Pambudi UtamaNo ratings yet

- Assignment: Vietnam National University HCMC International UniversityDocument8 pagesAssignment: Vietnam National University HCMC International UniversityHa PhamNo ratings yet

- Optimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeDocument8 pagesOptimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeNancy GonzalezNo ratings yet

- Production of Spray-Dried Honey Jackfruit (Artocarpus Heterophyllus) Powder From Enzymatic Liquefied PureeDocument8 pagesProduction of Spray-Dried Honey Jackfruit (Artocarpus Heterophyllus) Powder From Enzymatic Liquefied PureegraceNo ratings yet

- Qualities of Arabica and Robusta Cascara Kombucha With Different Concentrations of StarterDocument7 pagesQualities of Arabica and Robusta Cascara Kombucha With Different Concentrations of StarterMeysin AnjlianyNo ratings yet

- Optimization of Crude Papaya (Carica Papaya) Protease in Soft-Unripened Cheese PreparationDocument8 pagesOptimization of Crude Papaya (Carica Papaya) Protease in Soft-Unripened Cheese PreparationBriliant GhaustinNo ratings yet

- 69406-Article Text-210174-1-10-20230727Document9 pages69406-Article Text-210174-1-10-20230727Indah Husnul KhatimahNo ratings yet

- 1 OnlineDocument7 pages1 OnlineremyNo ratings yet

- Cankaraca2011 LentilDocument9 pagesCankaraca2011 LentilRadamés RábagoNo ratings yet

- The Effect of Addition Papaya Leaf Extract (Carica Papaya L.) On Reducing Caffeine Levels in Robusta CoffeeDocument13 pagesThe Effect of Addition Papaya Leaf Extract (Carica Papaya L.) On Reducing Caffeine Levels in Robusta CoffeeWa Ode Yulianti Asrar JayaNo ratings yet

- đọc lại phần kết luận tương tự mình làmDocument8 pagesđọc lại phần kết luận tương tự mình làmNo NameNo ratings yet

- Jurnal Mitra Kesehatan (JMK) : Intan Kurnia Putri, Aynna Sufana RaniDocument11 pagesJurnal Mitra Kesehatan (JMK) : Intan Kurnia Putri, Aynna Sufana RaniAqshal AnsariNo ratings yet

- Widyasanti 2020 IOP Conf. Ser. Earth Environ. Sci. 443 012061Document11 pagesWidyasanti 2020 IOP Conf. Ser. Earth Environ. Sci. 443 012061kevinNo ratings yet

- Coffee By-Products As The Source of Antioxidants: A Systematic ReviewDocument12 pagesCoffee By-Products As The Source of Antioxidants: A Systematic ReviewDian RNo ratings yet

- 10.1007@s13197 019 04206 6Document9 pages10.1007@s13197 019 04206 6Ridho DarmawanNo ratings yet

- Shidayat, 94-103 - 332Document10 pagesShidayat, 94-103 - 332anjar_ruspitaNo ratings yet

- Practical Research 2Document10 pagesPractical Research 2Jazzle TanNo ratings yet

- Art Fortification of Mango Peel CookiesDocument4 pagesArt Fortification of Mango Peel CookiesGabrielNo ratings yet

- Analysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFDocument6 pagesAnalysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFTài ColeNo ratings yet

- ADFCA - Enrichment of Date Paste - EDocument4 pagesADFCA - Enrichment of Date Paste - EUsman CheemaNo ratings yet

- Bondesson e 150922Document25 pagesBondesson e 150922Diego Umaña AriasNo ratings yet

- Food Research International 119 (2019) 455-461Document7 pagesFood Research International 119 (2019) 455-461Iris Bustamante PájaroNo ratings yet

- Optimization of Ingredient and Processing ParameteDocument6 pagesOptimization of Ingredient and Processing ParameteJhon NeverNo ratings yet

- Liofilizacion YogurtDocument10 pagesLiofilizacion YogurtDiana FernandaNo ratings yet

- Zhang 2019Document34 pagesZhang 2019ARCILLA, NICO ANDREI SALAVERIANo ratings yet

- 30 fr-2021-723 KhatunDocument7 pages30 fr-2021-723 KhatunHARSHAL NANDURKARNo ratings yet

- Application of Gum Arabic and Maltodextrin For Encapsulation ofDocument10 pagesApplication of Gum Arabic and Maltodextrin For Encapsulation ofNicolas AvendañoNo ratings yet

- Emerging Dairy Processing Technologies: Opportunities for the Dairy IndustryFrom EverandEmerging Dairy Processing Technologies: Opportunities for the Dairy IndustryNo ratings yet

- Exersice We Use Used ToDocument2 pagesExersice We Use Used ToUbaldo VelezNo ratings yet

- Capsule Machine Guide - Graphic Table 2Document1 pageCapsule Machine Guide - Graphic Table 2CL LeeNo ratings yet

- BT Câu Giao Tiếp 2Document15 pagesBT Câu Giao Tiếp 2Nguyễn Lanh AnhNo ratings yet

- 365 Fun Days & ActivitiesDocument65 pages365 Fun Days & ActivitiesFlor y Andre Flor y Andre100% (1)

- Most Common DQ Blizzards RecipesDocument8 pagesMost Common DQ Blizzards RecipesGreatRecipeCollectr29No ratings yet

- Gened 01 IntroDocument117 pagesGened 01 IntroNuch NuchanNo ratings yet

- Coffee Biochemistry and Potential Impact OnDocument23 pagesCoffee Biochemistry and Potential Impact OnNicolás MurilloNo ratings yet

- Minimalist Annual ReportDocument12 pagesMinimalist Annual ReportMannat ShrivastavaNo ratings yet

- 02 Phrases & Clauses - STDocument9 pages02 Phrases & Clauses - STFuck offNo ratings yet

- ResumeDocument3 pagesResumeLoai OshaishNo ratings yet

- Wallstreetjournaleurope 20160307 The Wall Street Journal EuropeDocument22 pagesWallstreetjournaleurope 20160307 The Wall Street Journal EuropestefanoNo ratings yet

- 08 Mock Logic 2Document18 pages08 Mock Logic 2Elixer De Asis VelascoNo ratings yet

- Twice As DeadDocument281 pagesTwice As DeadDaphne SylkNo ratings yet

- Group 8 Concept PaperDocument18 pagesGroup 8 Concept PaperAnime MaxNo ratings yet

- Tiramisu Crepe Cake Recipe - Sally's Baking AddictionDocument3 pagesTiramisu Crepe Cake Recipe - Sally's Baking AddictionDayNo ratings yet

- Moondial (Cresswell, Helen) 2015Document162 pagesMoondial (Cresswell, Helen) 2015Z. K.No ratings yet

- Finalpptorder of AdjectivesDocument34 pagesFinalpptorder of AdjectivesNorodin DalatenNo ratings yet

- History of CoffeeDocument12 pagesHistory of Coffeeapi-726976233No ratings yet

- Gluten Avoidance List V1 UpdatedDocument5 pagesGluten Avoidance List V1 UpdatedJelena MilojevicNo ratings yet

- Contoh Hasil Telaah JurnalDocument2 pagesContoh Hasil Telaah JurnalMade WillyNo ratings yet

- Group: Matsamitsu Mido Kunimoto Marika Valensia Serafim Daniel Daily Report 1 Industrial Study VisitDocument14 pagesGroup: Matsamitsu Mido Kunimoto Marika Valensia Serafim Daniel Daily Report 1 Industrial Study Visitnur oktaviani a.pNo ratings yet

- 7-Eleven CNY E-Catalogue 2021Document13 pages7-Eleven CNY E-Catalogue 2021-No ratings yet

- Essential Grammar in Use 4th Edition by R. MurphyDocument5 pagesEssential Grammar in Use 4th Edition by R. MurphyVinicius VerasNo ratings yet

- HivDocument61 pagesHivcarlos beltranNo ratings yet

- Fill in The Affirmative Form of The VerbDocument4 pagesFill in The Affirmative Form of The VerbAngie La0% (1)

- Book 1Document3 pagesBook 1ayman alsabe3No ratings yet

- AptitudeDocument4 pagesAptitudeKamma VidyaNo ratings yet

- Starbucks Corporation Case Study in Motivation PDFDocument5 pagesStarbucks Corporation Case Study in Motivation PDFNamuunzaya Ganbold0% (1)