Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 viewsTech 21

Tech 21

Uploaded by

Felipe GustavoThe document discusses small diameter cable designs for medium voltage underground systems as an alternative to traditional PILC cables. It describes how solid dielectric cables use round conductors and EPR insulation to achieve a compact design for tight duct spaces, while maintaining high ampacity. The metallic shield contributes to the small diameter by using shaped copper straps applied in a helical wrap around the cable core. Options for specifying the flat copper strap dimensions to meet conductivity or fault current requirements are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Mistron VaproDocument21 pagesMistron VaproChandrasekar KrishnamurthyNo ratings yet

- Project Report On Abc CableDocument8 pagesProject Report On Abc CableEIRI Board of Consultants and PublishersNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Subsea Umbilical TetherCablesDocument8 pagesSubsea Umbilical TetherCablesDaniel GarciaNo ratings yet

- Technical News: Power Cables - Conductor DesignDocument2 pagesTechnical News: Power Cables - Conductor Designparallax1957No ratings yet

- Product Data: Cubic Accelerometers - Types 4500 and 4501Document2 pagesProduct Data: Cubic Accelerometers - Types 4500 and 4501jhon vargasNo ratings yet

- Bushings COT 24kV To 550kVDocument24 pagesBushings COT 24kV To 550kVtatianaNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Arial Bunch ConductorDocument10 pagesArial Bunch Conductorbbakari2000No ratings yet

- OCC-206-3 Installation-Conduit Guidelines Rev A-1Document6 pagesOCC-206-3 Installation-Conduit Guidelines Rev A-1SAMNo ratings yet

- Gaon - Cables and Wires - CatalogDocument18 pagesGaon - Cables and Wires - Catalogphyo7799100% (2)

- Ijetae 1012 57Document7 pagesIjetae 1012 57Shung Tak ChanNo ratings yet

- Recent Power Transformer Technology PDFDocument8 pagesRecent Power Transformer Technology PDFKhashane Willy MohaleNo ratings yet

- Technical News: The Cable of Choice Between Motor and VFD - CLXDocument2 pagesTechnical News: The Cable of Choice Between Motor and VFD - CLXFelipe GustavoNo ratings yet

- Thin-Film RF/Microwave Capacitor TechnologyDocument25 pagesThin-Film RF/Microwave Capacitor Technologyrudy pumacahuaNo ratings yet

- Unit4 Fiber Joints CouplersDocument22 pagesUnit4 Fiber Joints CouplerspavithraNo ratings yet

- Ashish ShubhDocument96 pagesAshish ShubhShubhendu Singh0% (1)

- Industrial Training Report Finalxx PDFDocument18 pagesIndustrial Training Report Finalxx PDFPiyush Shukla100% (2)

- Lowenberg1952 PDFDocument1 pageLowenberg1952 PDFKundan DuttaNo ratings yet

- Brugg Cables User GuideDocument27 pagesBrugg Cables User GuideMehdi_Mashayekhi_172No ratings yet

- Technical User Guide of High Voltage XLPE Cable SystemsDocument27 pagesTechnical User Guide of High Voltage XLPE Cable SystemsDanielNo ratings yet

- Gemscab HT-XLPEDocument19 pagesGemscab HT-XLPE4usangeetNo ratings yet

- An Introduction To Test CablesDocument5 pagesAn Introduction To Test CablesArun KumarNo ratings yet

- Technical User Guide HV XLPE Cable Systems enDocument21 pagesTechnical User Guide HV XLPE Cable Systems enTaner ErtürkNo ratings yet

- BESCOM Technical-Specification-HT-UG-CablesDocument15 pagesBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿNo ratings yet

- Catalog - Conductor Rail 815 SeriesDocument32 pagesCatalog - Conductor Rail 815 SeriesyongkiNo ratings yet

- Technical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesDocument13 pagesTechnical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesNarendra SinghNo ratings yet

- Cable Tray SystemDocument26 pagesCable Tray SystemAldrien CabinteNo ratings yet

- SECTION 16116 Cable Trunking: Part 1 - General Related DocumentsDocument4 pagesSECTION 16116 Cable Trunking: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- The Fundamentals of Orbital Welding: Material Weldability, Joint Design, Procedures..Document4 pagesThe Fundamentals of Orbital Welding: Material Weldability, Joint Design, Procedures..OnderNo ratings yet

- Bentley 1997Document17 pagesBentley 1997michael arjonaNo ratings yet

- Gemscab LT XlpeDocument16 pagesGemscab LT Xlpevaithy1990No ratings yet

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocument18 pages11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaNo ratings yet

- High Voltage Xlpe Cable Systems Technical User Guide For 127 - 500 KVDocument12 pagesHigh Voltage Xlpe Cable Systems Technical User Guide For 127 - 500 KVmani_208eeNo ratings yet

- Railway 2018 Eng-1Document20 pagesRailway 2018 Eng-1Anand KumarNo ratings yet

- Technical Specification Joint Kits and TerminationsDocument10 pagesTechnical Specification Joint Kits and TerminationsYörükNo ratings yet

- 9-087 9-088 ElectrialShieldDocument2 pages9-087 9-088 ElectrialShieldtwinvbooksNo ratings yet

- Carbon Fibre Composite CableDocument2 pagesCarbon Fibre Composite CableaselahiyeNo ratings yet

- Andrew Fibra OpticaDocument14 pagesAndrew Fibra OpticaVictor Oswaldo GarciaNo ratings yet

- VAC Choke Multivariadores sandCoresDatasheetDocument16 pagesVAC Choke Multivariadores sandCoresDatasheetjavier Z CuapioNo ratings yet

- Powell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BusDocument4 pagesPowell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BuslongnguyenNo ratings yet

- An Introduction To Test CablesDocument5 pagesAn Introduction To Test CablesArun KumarNo ratings yet

- Carc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableDocument9 pagesCarc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableLuca Di ColaNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- WTEC 35KV MV Cable LLDPE Rev S 20160226Document5 pagesWTEC 35KV MV Cable LLDPE Rev S 20160226carloNo ratings yet

- Technical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power SuppliesDocument4 pagesTechnical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power Suppliesatul vijayvergiyaNo ratings yet

- Broch Aerial Trans GBDocument8 pagesBroch Aerial Trans GBsuyambu19No ratings yet

- Recent Advances in NM-OSCILLATOR Design With CMOS Technology: An OverviewDocument6 pagesRecent Advances in NM-OSCILLATOR Design With CMOS Technology: An OverviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Manual de Ferritas y NucleosDocument32 pagesManual de Ferritas y Nucleosjaimeconeo2222No ratings yet

- Practical Guide To Cable SelectionDocument12 pagesPractical Guide To Cable Selectionazitagg100% (1)

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionFrom EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Anixter Csa Flame Tests Wire Wisdom enDocument2 pagesAnixter Csa Flame Tests Wire Wisdom enFelipe GustavoNo ratings yet

- Anixter Wire Wisdom Category Cable Industry StandardsDocument2 pagesAnixter Wire Wisdom Category Cable Industry StandardsFelipe GustavoNo ratings yet

- Technical News: Cable Seals For Type TC/Type TC-ER CablesDocument2 pagesTechnical News: Cable Seals For Type TC/Type TC-ER CablesFelipe GustavoNo ratings yet

- Tech 27Document2 pagesTech 27Felipe GustavoNo ratings yet

- Anixter Thermocouple and RTD Wire Wire Wisdom enDocument2 pagesAnixter Thermocouple and RTD Wire Wire Wisdom enFelipe GustavoNo ratings yet

- Technical News: Epr Semicons A PerspectiveDocument2 pagesTechnical News: Epr Semicons A PerspectiveFelipe GustavoNo ratings yet

- Technical News: Reel AnatomyDocument3 pagesTechnical News: Reel AnatomyFelipe GustavoNo ratings yet

- Technical News: Engineering Information For The Professional EngineerDocument2 pagesTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNo ratings yet

- Technical News: Nuclear Rated Cable QualificationDocument2 pagesTechnical News: Nuclear Rated Cable QualificationFelipe GustavoNo ratings yet

- Technical News: Cables Used in Intrinsically Safe CircuitsDocument1 pageTechnical News: Cables Used in Intrinsically Safe CircuitsFelipe GustavoNo ratings yet

- Technical News: Cables Qualified For Use in Nuclear PlantsDocument1 pageTechnical News: Cables Qualified For Use in Nuclear PlantsFelipe GustavoNo ratings yet

- Technical News: Dupont Exits Global Hypalon BusinessDocument2 pagesTechnical News: Dupont Exits Global Hypalon BusinessFelipe GustavoNo ratings yet

- Technical News: Low Smoke JacketsDocument3 pagesTechnical News: Low Smoke JacketsFelipe GustavoNo ratings yet

- Technical News: NEC 2005 Changes To Medium Voltage Nonshielded CableDocument2 pagesTechnical News: NEC 2005 Changes To Medium Voltage Nonshielded CableFelipe GustavoNo ratings yet

- Chapter 3-Fundamentals of Metal FormingDocument6 pagesChapter 3-Fundamentals of Metal FormingG. Dancer GhNo ratings yet

- Epibear: Technical DatasheetDocument3 pagesEpibear: Technical DatasheetBogdanBNo ratings yet

- Sandwich Design and TheoryDocument46 pagesSandwich Design and Theoryramyasweety1100% (1)

- Fiberfrax Specialties Products: Product Information SheetDocument4 pagesFiberfrax Specialties Products: Product Information SheetHenry Villabona ValbuenaNo ratings yet

- Omnirad 819 - EN PDS 2Document3 pagesOmnirad 819 - EN PDS 2brausenpaulNo ratings yet

- Technical Bulletin: AnsulDocument1 pageTechnical Bulletin: AnsulIvan DNo ratings yet

- Is 8110 2000Document23 pagesIs 8110 2000Sidharth SinghNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Understanding Material Strength, Ductility and ToughnessDocument4 pagesUnderstanding Material Strength, Ductility and ToughnessLiseth SanchezNo ratings yet

- Paper PropertiesDocument34 pagesPaper PropertiesSantha PriyaNo ratings yet

- Han 2016Document20 pagesHan 2016Sourabh GaikwadNo ratings yet

- Tensile - SamujaDocument17 pagesTensile - SamujaNipun DinushaNo ratings yet

- Proton Pca1010Document1 pageProton Pca1010HirenNo ratings yet

- East Coast Fibreglass CATALYST ADDITION CHARTDocument2 pagesEast Coast Fibreglass CATALYST ADDITION CHARTben100% (1)

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Medium Density FiberboardDocument4 pagesMedium Density Fiberboardsabiha naazNo ratings yet

- Wolf - JAC - Designing New QC Compositions in Al Based AlloysDocument6 pagesWolf - JAC - Designing New QC Compositions in Al Based AlloysAlisson WintherNo ratings yet

- Pages From 0000-SP-50-22 - 2 - Thermal - Insulation - SpecificationDocument1 pagePages From 0000-SP-50-22 - 2 - Thermal - Insulation - SpecificationMelih SENTURKNo ratings yet

- Blast Response Simulation of The Alfred Murrah Building Reinforced by Use of HPFRCCDocument16 pagesBlast Response Simulation of The Alfred Murrah Building Reinforced by Use of HPFRCCJhuma DebnathNo ratings yet

- The Complete Conduit Systems Accessories and Cable GlandsDocument164 pagesThe Complete Conduit Systems Accessories and Cable GlandsLidya DewiNo ratings yet

- Technical Data: PR-1428 Class B Access Door SealantDocument2 pagesTechnical Data: PR-1428 Class B Access Door Sealantgano ajiNo ratings yet

- JIS G3101 2004 Chem MechDocument1 pageJIS G3101 2004 Chem Mechtonaoh2009No ratings yet

- Problem Set No.2 - Ultimate Stress Design (USD)Document1 pageProblem Set No.2 - Ultimate Stress Design (USD)Catherine Shaina O. PasionNo ratings yet

- Lesson 5 SculptureDocument37 pagesLesson 5 SculptureAlam AmitNo ratings yet

- 1 s2.0 S254250481830006X MainDocument10 pages1 s2.0 S254250481830006X MainOana MariaNo ratings yet

- Total 211020Document10 pagesTotal 211020Yohanes DitoNo ratings yet

- 946 Mapecoat Ve 825 Ap SGDocument4 pages946 Mapecoat Ve 825 Ap SGmahesh579No ratings yet

- Course Title: Engineering Materials (Cheg) : InformationDocument35 pagesCourse Title: Engineering Materials (Cheg) : Informationkere evaNo ratings yet

- Pyrocrete 239 PDSDocument3 pagesPyrocrete 239 PDSmd shahedNo ratings yet

Tech 21

Tech 21

Uploaded by

Felipe Gustavo0 ratings0% found this document useful (0 votes)

12 views2 pagesThe document discusses small diameter cable designs for medium voltage underground systems as an alternative to traditional PILC cables. It describes how solid dielectric cables use round conductors and EPR insulation to achieve a compact design for tight duct spaces, while maintaining high ampacity. The metallic shield contributes to the small diameter by using shaped copper straps applied in a helical wrap around the cable core. Options for specifying the flat copper strap dimensions to meet conductivity or fault current requirements are also outlined.

Original Description:

Original Title

Tech_21

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses small diameter cable designs for medium voltage underground systems as an alternative to traditional PILC cables. It describes how solid dielectric cables use round conductors and EPR insulation to achieve a compact design for tight duct spaces, while maintaining high ampacity. The metallic shield contributes to the small diameter by using shaped copper straps applied in a helical wrap around the cable core. Options for specifying the flat copper strap dimensions to meet conductivity or fault current requirements are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views2 pagesTech 21

Tech 21

Uploaded by

Felipe GustavoThe document discusses small diameter cable designs for medium voltage underground systems as an alternative to traditional PILC cables. It describes how solid dielectric cables use round conductors and EPR insulation to achieve a compact design for tight duct spaces, while maintaining high ampacity. The metallic shield contributes to the small diameter by using shaped copper straps applied in a helical wrap around the cable core. Options for specifying the flat copper strap dimensions to meet conductivity or fault current requirements are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

g

TECHNICAL NEWS Engineertinion

Informa

from

for the ional

THE OKONITE COMPANY

Profess r

June, 2006 Edition: 0021 Enginee

Small Diameter Cable Designs

Medium voltage cable constructions installed heavy constant ampere loading. PILC

in urban underground raceway systems are cables continue to be manufactured today

predominately the traditional 3/C Compact serving the heavy load applications.

Sector Copper, paper insulated, metallic The option of specifying an equivalent solid

sheath, polyethylene jacketed cable (PILC). dielectric cable construction requires the use

As shown in Figure 1, these cables are diame- of round conductor geometry to accommodate

ter efficient by design and offer the highest the factory extrusion tooling of the basic cable

ampacity (ampere) to duct ratio. core. The EPR (Ethylene Propylene Rubber)

insulation system is the insulation of choice

for these heavy duty high temperature rated

operating systems. EPR offers a stable re-

sponse to heat cycling from ambient to well

over 140°C.

All cable components for the solid dielectric

cable design must be applied to the compact

round conductor with accuracy and preci-

sion needed to meet the application raceway

diameter.

The cable’s metallic shield also contributes to

the small diameter design controls by using

These PILC cable constructions remain the shaped copper. Round copper wires can be

backbone of the urban downtown network processed into rectangular shapes needed to

system having an enviable long term in- maintain the low diameter profile. These flat

service life capable of handling the ag- copper straps are applied in a helical wrap

gressive thermal environment due to the around the basic cable core.

Visit our Website at www.okonite.com

Flat Strap Design Options -

1. The length, width and number of straps

can be selected to match the electrical

conductivity of the PILC cable’s metallic

sheath. This tubular lead sheath has a

conductivity of approximately 7.5%

compared to the 100% conductivity of-

fered by copper. Okonite's Engineering

Handbook (EHB) can be referenced for

the calculation technique required to

equate the conductivity level of each.

2. A different option is to select the flat cop-

per straps based on a system short circuit physical characteristics required for the

requirement specified by fault current project environment. Reference Figure 2

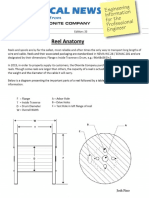

amperes and a time duration of protective for a detail of the completed 3 X 1/C cable

equipment expressed in cycles. Using the assembly.

ampere level and time, an equivalent

amount of copper can be calculated refer- These small diameter cable designs are usu-

encing ICEA P-45-482, Short Circuit ally shipped as a Triplexed configuration.

Characteristics of Metallic Shields and The circular diameter resulting from this fac-

Sheaths on Insulated Cable. tory assembly fits into the existing raceway

with a raceway ID to cable assembly OD of

3. The straps can also be specified as a con- 0.50 inches of clearance.

centric neutral based on a percentage of

the main conductor conductivity. Contact your local Okonite representative by

visiting our website, www.okonite.com, and

Okonite has the in-house processing capabil- ask our Engineering staff to develop a small

ity to mechanically draw down and simulta- diameter cable construction to suit your appli-

neously anneal the copper wire into the cation needs.

required strap dimensions.

The more common individual flat copper strap

sizes are: J. V. Fitzgerald

Vice President

Thickness x Width, mils Circular Mil Area Application Engineering

20 x 150 3819

20 x 175 4456

20 x 225 5729

35 x 200 8911

ISO 9000-1994 CERTIFIED

The cable construction is completed by apply- THE OKONITE COMPANY

ing an overall encapsulating jacket of polyeth- Ramsey, New Jersey 07446

ylene or polypropylene depending on the www.okonite.com

You might also like

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Mistron VaproDocument21 pagesMistron VaproChandrasekar KrishnamurthyNo ratings yet

- Project Report On Abc CableDocument8 pagesProject Report On Abc CableEIRI Board of Consultants and PublishersNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Subsea Umbilical TetherCablesDocument8 pagesSubsea Umbilical TetherCablesDaniel GarciaNo ratings yet

- Technical News: Power Cables - Conductor DesignDocument2 pagesTechnical News: Power Cables - Conductor Designparallax1957No ratings yet

- Product Data: Cubic Accelerometers - Types 4500 and 4501Document2 pagesProduct Data: Cubic Accelerometers - Types 4500 and 4501jhon vargasNo ratings yet

- Bushings COT 24kV To 550kVDocument24 pagesBushings COT 24kV To 550kVtatianaNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Arial Bunch ConductorDocument10 pagesArial Bunch Conductorbbakari2000No ratings yet

- OCC-206-3 Installation-Conduit Guidelines Rev A-1Document6 pagesOCC-206-3 Installation-Conduit Guidelines Rev A-1SAMNo ratings yet

- Gaon - Cables and Wires - CatalogDocument18 pagesGaon - Cables and Wires - Catalogphyo7799100% (2)

- Ijetae 1012 57Document7 pagesIjetae 1012 57Shung Tak ChanNo ratings yet

- Recent Power Transformer Technology PDFDocument8 pagesRecent Power Transformer Technology PDFKhashane Willy MohaleNo ratings yet

- Technical News: The Cable of Choice Between Motor and VFD - CLXDocument2 pagesTechnical News: The Cable of Choice Between Motor and VFD - CLXFelipe GustavoNo ratings yet

- Thin-Film RF/Microwave Capacitor TechnologyDocument25 pagesThin-Film RF/Microwave Capacitor Technologyrudy pumacahuaNo ratings yet

- Unit4 Fiber Joints CouplersDocument22 pagesUnit4 Fiber Joints CouplerspavithraNo ratings yet

- Ashish ShubhDocument96 pagesAshish ShubhShubhendu Singh0% (1)

- Industrial Training Report Finalxx PDFDocument18 pagesIndustrial Training Report Finalxx PDFPiyush Shukla100% (2)

- Lowenberg1952 PDFDocument1 pageLowenberg1952 PDFKundan DuttaNo ratings yet

- Brugg Cables User GuideDocument27 pagesBrugg Cables User GuideMehdi_Mashayekhi_172No ratings yet

- Technical User Guide of High Voltage XLPE Cable SystemsDocument27 pagesTechnical User Guide of High Voltage XLPE Cable SystemsDanielNo ratings yet

- Gemscab HT-XLPEDocument19 pagesGemscab HT-XLPE4usangeetNo ratings yet

- An Introduction To Test CablesDocument5 pagesAn Introduction To Test CablesArun KumarNo ratings yet

- Technical User Guide HV XLPE Cable Systems enDocument21 pagesTechnical User Guide HV XLPE Cable Systems enTaner ErtürkNo ratings yet

- BESCOM Technical-Specification-HT-UG-CablesDocument15 pagesBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿNo ratings yet

- Catalog - Conductor Rail 815 SeriesDocument32 pagesCatalog - Conductor Rail 815 SeriesyongkiNo ratings yet

- Technical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesDocument13 pagesTechnical Specification For Cross Linked Polyethylene Insulated 3 Core 11kv CablesNarendra SinghNo ratings yet

- Cable Tray SystemDocument26 pagesCable Tray SystemAldrien CabinteNo ratings yet

- SECTION 16116 Cable Trunking: Part 1 - General Related DocumentsDocument4 pagesSECTION 16116 Cable Trunking: Part 1 - General Related DocumentsAhmed GamalNo ratings yet

- The Fundamentals of Orbital Welding: Material Weldability, Joint Design, Procedures..Document4 pagesThe Fundamentals of Orbital Welding: Material Weldability, Joint Design, Procedures..OnderNo ratings yet

- Bentley 1997Document17 pagesBentley 1997michael arjonaNo ratings yet

- Gemscab LT XlpeDocument16 pagesGemscab LT Xlpevaithy1990No ratings yet

- 11kV - 3-C - 300 - AL - Cable - Specification Final PDFDocument18 pages11kV - 3-C - 300 - AL - Cable - Specification Final PDFShubham BaderiyaNo ratings yet

- High Voltage Xlpe Cable Systems Technical User Guide For 127 - 500 KVDocument12 pagesHigh Voltage Xlpe Cable Systems Technical User Guide For 127 - 500 KVmani_208eeNo ratings yet

- Railway 2018 Eng-1Document20 pagesRailway 2018 Eng-1Anand KumarNo ratings yet

- Technical Specification Joint Kits and TerminationsDocument10 pagesTechnical Specification Joint Kits and TerminationsYörükNo ratings yet

- 9-087 9-088 ElectrialShieldDocument2 pages9-087 9-088 ElectrialShieldtwinvbooksNo ratings yet

- Carbon Fibre Composite CableDocument2 pagesCarbon Fibre Composite CableaselahiyeNo ratings yet

- Andrew Fibra OpticaDocument14 pagesAndrew Fibra OpticaVictor Oswaldo GarciaNo ratings yet

- VAC Choke Multivariadores sandCoresDatasheetDocument16 pagesVAC Choke Multivariadores sandCoresDatasheetjavier Z CuapioNo ratings yet

- Powell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BusDocument4 pagesPowell Electrical Systems, Inc. Guide Specification: Low and Medium Voltage Metal-Enclosed Cable BuslongnguyenNo ratings yet

- An Introduction To Test CablesDocument5 pagesAn Introduction To Test CablesArun KumarNo ratings yet

- Carc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableDocument9 pagesCarc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableLuca Di ColaNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- WTEC 35KV MV Cable LLDPE Rev S 20160226Document5 pagesWTEC 35KV MV Cable LLDPE Rev S 20160226carloNo ratings yet

- Technical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power SuppliesDocument4 pagesTechnical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power Suppliesatul vijayvergiyaNo ratings yet

- Broch Aerial Trans GBDocument8 pagesBroch Aerial Trans GBsuyambu19No ratings yet

- Recent Advances in NM-OSCILLATOR Design With CMOS Technology: An OverviewDocument6 pagesRecent Advances in NM-OSCILLATOR Design With CMOS Technology: An OverviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Manual de Ferritas y NucleosDocument32 pagesManual de Ferritas y Nucleosjaimeconeo2222No ratings yet

- Practical Guide To Cable SelectionDocument12 pagesPractical Guide To Cable Selectionazitagg100% (1)

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionFrom EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Anixter Csa Flame Tests Wire Wisdom enDocument2 pagesAnixter Csa Flame Tests Wire Wisdom enFelipe GustavoNo ratings yet

- Anixter Wire Wisdom Category Cable Industry StandardsDocument2 pagesAnixter Wire Wisdom Category Cable Industry StandardsFelipe GustavoNo ratings yet

- Technical News: Cable Seals For Type TC/Type TC-ER CablesDocument2 pagesTechnical News: Cable Seals For Type TC/Type TC-ER CablesFelipe GustavoNo ratings yet

- Tech 27Document2 pagesTech 27Felipe GustavoNo ratings yet

- Anixter Thermocouple and RTD Wire Wire Wisdom enDocument2 pagesAnixter Thermocouple and RTD Wire Wire Wisdom enFelipe GustavoNo ratings yet

- Technical News: Epr Semicons A PerspectiveDocument2 pagesTechnical News: Epr Semicons A PerspectiveFelipe GustavoNo ratings yet

- Technical News: Reel AnatomyDocument3 pagesTechnical News: Reel AnatomyFelipe GustavoNo ratings yet

- Technical News: Engineering Information For The Professional EngineerDocument2 pagesTechnical News: Engineering Information For The Professional EngineerFelipe GustavoNo ratings yet

- Technical News: Nuclear Rated Cable QualificationDocument2 pagesTechnical News: Nuclear Rated Cable QualificationFelipe GustavoNo ratings yet

- Technical News: Cables Used in Intrinsically Safe CircuitsDocument1 pageTechnical News: Cables Used in Intrinsically Safe CircuitsFelipe GustavoNo ratings yet

- Technical News: Cables Qualified For Use in Nuclear PlantsDocument1 pageTechnical News: Cables Qualified For Use in Nuclear PlantsFelipe GustavoNo ratings yet

- Technical News: Dupont Exits Global Hypalon BusinessDocument2 pagesTechnical News: Dupont Exits Global Hypalon BusinessFelipe GustavoNo ratings yet

- Technical News: Low Smoke JacketsDocument3 pagesTechnical News: Low Smoke JacketsFelipe GustavoNo ratings yet

- Technical News: NEC 2005 Changes To Medium Voltage Nonshielded CableDocument2 pagesTechnical News: NEC 2005 Changes To Medium Voltage Nonshielded CableFelipe GustavoNo ratings yet

- Chapter 3-Fundamentals of Metal FormingDocument6 pagesChapter 3-Fundamentals of Metal FormingG. Dancer GhNo ratings yet

- Epibear: Technical DatasheetDocument3 pagesEpibear: Technical DatasheetBogdanBNo ratings yet

- Sandwich Design and TheoryDocument46 pagesSandwich Design and Theoryramyasweety1100% (1)

- Fiberfrax Specialties Products: Product Information SheetDocument4 pagesFiberfrax Specialties Products: Product Information SheetHenry Villabona ValbuenaNo ratings yet

- Omnirad 819 - EN PDS 2Document3 pagesOmnirad 819 - EN PDS 2brausenpaulNo ratings yet

- Technical Bulletin: AnsulDocument1 pageTechnical Bulletin: AnsulIvan DNo ratings yet

- Is 8110 2000Document23 pagesIs 8110 2000Sidharth SinghNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Understanding Material Strength, Ductility and ToughnessDocument4 pagesUnderstanding Material Strength, Ductility and ToughnessLiseth SanchezNo ratings yet

- Paper PropertiesDocument34 pagesPaper PropertiesSantha PriyaNo ratings yet

- Han 2016Document20 pagesHan 2016Sourabh GaikwadNo ratings yet

- Tensile - SamujaDocument17 pagesTensile - SamujaNipun DinushaNo ratings yet

- Proton Pca1010Document1 pageProton Pca1010HirenNo ratings yet

- East Coast Fibreglass CATALYST ADDITION CHARTDocument2 pagesEast Coast Fibreglass CATALYST ADDITION CHARTben100% (1)

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Medium Density FiberboardDocument4 pagesMedium Density Fiberboardsabiha naazNo ratings yet

- Wolf - JAC - Designing New QC Compositions in Al Based AlloysDocument6 pagesWolf - JAC - Designing New QC Compositions in Al Based AlloysAlisson WintherNo ratings yet

- Pages From 0000-SP-50-22 - 2 - Thermal - Insulation - SpecificationDocument1 pagePages From 0000-SP-50-22 - 2 - Thermal - Insulation - SpecificationMelih SENTURKNo ratings yet

- Blast Response Simulation of The Alfred Murrah Building Reinforced by Use of HPFRCCDocument16 pagesBlast Response Simulation of The Alfred Murrah Building Reinforced by Use of HPFRCCJhuma DebnathNo ratings yet

- The Complete Conduit Systems Accessories and Cable GlandsDocument164 pagesThe Complete Conduit Systems Accessories and Cable GlandsLidya DewiNo ratings yet

- Technical Data: PR-1428 Class B Access Door SealantDocument2 pagesTechnical Data: PR-1428 Class B Access Door Sealantgano ajiNo ratings yet

- JIS G3101 2004 Chem MechDocument1 pageJIS G3101 2004 Chem Mechtonaoh2009No ratings yet

- Problem Set No.2 - Ultimate Stress Design (USD)Document1 pageProblem Set No.2 - Ultimate Stress Design (USD)Catherine Shaina O. PasionNo ratings yet

- Lesson 5 SculptureDocument37 pagesLesson 5 SculptureAlam AmitNo ratings yet

- 1 s2.0 S254250481830006X MainDocument10 pages1 s2.0 S254250481830006X MainOana MariaNo ratings yet

- Total 211020Document10 pagesTotal 211020Yohanes DitoNo ratings yet

- 946 Mapecoat Ve 825 Ap SGDocument4 pages946 Mapecoat Ve 825 Ap SGmahesh579No ratings yet

- Course Title: Engineering Materials (Cheg) : InformationDocument35 pagesCourse Title: Engineering Materials (Cheg) : Informationkere evaNo ratings yet

- Pyrocrete 239 PDSDocument3 pagesPyrocrete 239 PDSmd shahedNo ratings yet