Professional Documents

Culture Documents

CV Huda - Ats

CV Huda - Ats

Uploaded by

Asep TeweCopyright:

Available Formats

You might also like

- Week 8: Ecotourism in The PhilippinesDocument35 pagesWeek 8: Ecotourism in The Philippinesbea krysleen tulio90% (10)

- Catalog Wasser SanitaryDocument84 pagesCatalog Wasser Sanitarypompa wasser indonesiaNo ratings yet

- Chap 1-6 Mixed ReviewDocument16 pagesChap 1-6 Mixed ReviewanNo ratings yet

- The Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinDocument40 pagesThe Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinMara Rebeka Herzog100% (7)

- 17 Grundfos Submersible Deep Well - SP 215 - Performance Curve - Kurva PerformanceDocument5 pages17 Grundfos Submersible Deep Well - SP 215 - Performance Curve - Kurva PerformancePamikatsih PNo ratings yet

- Royal Haskoningdhv IndonesiaDocument1 pageRoyal Haskoningdhv IndonesiaAnton PermanaNo ratings yet

- Manual For FLue Gas Analyzer E4400Document72 pagesManual For FLue Gas Analyzer E4400Mohit MalikNo ratings yet

- Uraian Analisa Harga SatuanDocument6 pagesUraian Analisa Harga Satuandwi istNo ratings yet

- Penawaran Jasa InstallationDocument1 pagePenawaran Jasa InstallationadihartokoNo ratings yet

- Modul 3 - PLC - Adc and DacDocument6 pagesModul 3 - PLC - Adc and DacAnton IoNo ratings yet

- Vit Series: Inlinecentrifugal Duct FanDocument3 pagesVit Series: Inlinecentrifugal Duct FanTedi A MaulanaNo ratings yet

- Sika Viscocrete 3115Document2 pagesSika Viscocrete 3115Ronald MassoraNo ratings yet

- Pekerjaan Tata Udara Tanpa Fresh Air Ac Casette 3,815,000,000.00Document41 pagesPekerjaan Tata Udara Tanpa Fresh Air Ac Casette 3,815,000,000.00A. muzakiNo ratings yet

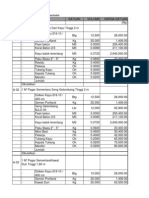

- Analisa Harga Satuan Pekerjaan Persiapan: No. Uraian Satua N Volu ME Harga SatuanDocument116 pagesAnalisa Harga Satuan Pekerjaan Persiapan: No. Uraian Satua N Volu ME Harga SatuanSpidey ArchyNo ratings yet

- HSP SniDocument194 pagesHSP SniSukmana MlqNo ratings yet

- Katalog Luxon & Zeron 2020 + All in One SL - NSSDocument90 pagesKatalog Luxon & Zeron 2020 + All in One SL - NSSBOCAH MAH BEBASNo ratings yet

- Katalog Maspion - Wall Fan - Exhaust Fan - Ceiling FanDocument35 pagesKatalog Maspion - Wall Fan - Exhaust Fan - Ceiling FanKevin ReynaldoNo ratings yet

- Pengaruh Debit Aliran Dan Kemiringan Poros Turbin Ulir Pada Pembangkit Listrik Tenaga Mikro-HidroDocument5 pagesPengaruh Debit Aliran Dan Kemiringan Poros Turbin Ulir Pada Pembangkit Listrik Tenaga Mikro-HidrocomeklNo ratings yet

- Yonex Badminton Catalog 2023 ENDocument116 pagesYonex Badminton Catalog 2023 ENnrhmhealth100% (1)

- Palet Kayu Drawing SolidworksDocument1 pagePalet Kayu Drawing Solidworksanto suliNo ratings yet

- Drafter CVDocument4 pagesDrafter CVachmad ismailNo ratings yet

- Implementasi Reliability Centered Maintenance (RCM) Pada Sistem Plate-Shearing Machine (Studi Kasus: Pt. Ometraco Arya Samanta)Document16 pagesImplementasi Reliability Centered Maintenance (RCM) Pada Sistem Plate-Shearing Machine (Studi Kasus: Pt. Ometraco Arya Samanta)Abdul GofurNo ratings yet

- Laporan Hasil Pengujian (Testing Result Report)Document1 pageLaporan Hasil Pengujian (Testing Result Report)Intan Pratama Putra100% (1)

- Rab PacingDocument1 pageRab PacingRosyadNo ratings yet

- DepanDocument1 pageDepandimasNo ratings yet

- Program Book IConBEM 2020 PDFDocument93 pagesProgram Book IConBEM 2020 PDFYusuf Hartoyo100% (1)

- Tugas 3 MPKDocument10 pagesTugas 3 MPKAmira MaryanaNo ratings yet

- Tabel Diskonto Compound Interest PDFDocument26 pagesTabel Diskonto Compound Interest PDFLintangHzNo ratings yet

- Perhitungan RelDocument30 pagesPerhitungan RelBig ANo ratings yet

- AC Sharp AH-A9UCYDocument2 pagesAC Sharp AH-A9UCYBee NETNo ratings yet

- BVP621 Led1008cw 960W 220-240V NB GM PDFDocument3 pagesBVP621 Led1008cw 960W 220-240V NB GM PDFLauw Tjun NjiNo ratings yet

- Friction - Friction Coefficients and CalculatorDocument3 pagesFriction - Friction Coefficients and CalculatorMaiquel Eduardo ErnNo ratings yet

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanNo ratings yet

- Fair RPLDocument61 pagesFair RPLAliphi Yudhistira AstineNo ratings yet

- Brosur U-Ditch Final PDFDocument2 pagesBrosur U-Ditch Final PDFدينا ديناNo ratings yet

- ADHI Annual ReportDocument448 pagesADHI Annual ReportWawan NesarNo ratings yet

- CV QU Contoh CVDocument2 pagesCV QU Contoh CVroonzNo ratings yet

- 45Mn (China / GB) : Material PropertiesDocument2 pages45Mn (China / GB) : Material PropertiesNguyeentt TntNo ratings yet

- BOQ of Deck Slab 53 MTR Length &9 MTR Width Description Quantity SL No Unit (UOM)Document1 pageBOQ of Deck Slab 53 MTR Length &9 MTR Width Description Quantity SL No Unit (UOM)PrasunNo ratings yet

- SPHC, SPHDDocument2 pagesSPHC, SPHDMihai Condeescu100% (1)

- Brosur Lampu PJU SHT 30WDocument1 pageBrosur Lampu PJU SHT 30WRahmat HidayatNo ratings yet

- Daftar Harga PintuDocument31 pagesDaftar Harga PintuSaut Saragih100% (1)

- Ahsp 2013 Bawah Pebruari 2018Document573 pagesAhsp 2013 Bawah Pebruari 2018Sevtian RNo ratings yet

- CV - Hayy Nur AbdillahDocument1 pageCV - Hayy Nur AbdillahAyy AbdillahNo ratings yet

- Bisnis Plan PdamDocument2 pagesBisnis Plan PdamBundaAyuNo ratings yet

- Tiang Pancang JhsDocument4 pagesTiang Pancang JhsFodki 2019No ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- BQ STP 5 KubikDocument2 pagesBQ STP 5 Kubikbim akadeNo ratings yet

- TUGAS Modul 4Document3 pagesTUGAS Modul 4dheanNo ratings yet

- Tugas Review Jurnal VisualisasiDocument42 pagesTugas Review Jurnal Visualisasiretno budiasihNo ratings yet

- Materi Kuliah Crash ProgramDocument14 pagesMateri Kuliah Crash ProgramImam Syafi'iNo ratings yet

- Bahasa IngrisDocument2 pagesBahasa IngrisHesti Agustina0% (1)

- Aruan EloardoDocument3 pagesAruan Eloardodennyrobertosinurat2023No ratings yet

- Tabel Berat Besi Beton Pu CompressDocument1 pageTabel Berat Besi Beton Pu CompressWelli E SNo ratings yet

- Drill PressDocument1 pageDrill PressBoyke WinterbergNo ratings yet

- Analisa Harga Satuan Pekerjaan: Badan Standarisasi Nasional (BSN) "SNI"Document9 pagesAnalisa Harga Satuan Pekerjaan: Badan Standarisasi Nasional (BSN) "SNI"novitrity4No ratings yet

- Contoh Rab Gorong-GorongDocument24 pagesContoh Rab Gorong-GorongNurdianty MarahenaNo ratings yet

- Compro Atlas Jaya Nusantara.Document14 pagesCompro Atlas Jaya Nusantara.Wachju AtlasNo ratings yet

- Sosialialisasi Sistem Laporan Kerja Sama VERSI 2.0Document15 pagesSosialialisasi Sistem Laporan Kerja Sama VERSI 2.0g4r15No ratings yet

- CV New - Eka SetyaningsihDocument2 pagesCV New - Eka SetyaningsihArmy MahatirNo ratings yet

- Contoh CVDocument2 pagesContoh CVarisNo ratings yet

- 7f31632a-1164-4378-9d1a-16b70220102bDocument1 page7f31632a-1164-4378-9d1a-16b70220102bPrabu JayaNo ratings yet

- Meth QuPPe PO V11 PDFDocument86 pagesMeth QuPPe PO V11 PDFDasharath OulkarNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- SilverCrest SFB 10.1 C3 PDFDocument122 pagesSilverCrest SFB 10.1 C3 PDFvladprajaNo ratings yet

- Taper Grid H Couplings Range - 2013 PDFDocument1 pageTaper Grid H Couplings Range - 2013 PDFAndres GonzalezNo ratings yet

- Module 4: Short Questions: K G X T T TDocument2 pagesModule 4: Short Questions: K G X T T TRohan KulkarniNo ratings yet

- 10 Plant Based Baking RecipesDocument7 pages10 Plant Based Baking RecipesGundesalvusNo ratings yet

- Either Silent or Switched OffDocument67 pagesEither Silent or Switched OffPankaj Kumar Singh100% (1)

- Dolch PhrasesDocument10 pagesDolch PhrasesCharlie Manahan TemonNo ratings yet

- Problems of Iron and Steel Industry in India:: Swot Analysis StrengthDocument4 pagesProblems of Iron and Steel Industry in India:: Swot Analysis StrengthAnonymous hmd3jXd4No ratings yet

- YS VIII Steam ArtbookDocument19 pagesYS VIII Steam ArtbookTuukka MäkinenNo ratings yet

- Method Statement For Water Recticulation (16.12.04)Document8 pagesMethod Statement For Water Recticulation (16.12.04)mochacino6867% (6)

- Axiata Digital Business - Advancing AsiaDocument12 pagesAxiata Digital Business - Advancing AsiaAxiata Group Berhad100% (1)

- "7 Streams of Income For The Average Nigerian": by Oluwatoyin Omotoso ofDocument29 pages"7 Streams of Income For The Average Nigerian": by Oluwatoyin Omotoso ofOliver Dennis100% (1)

- MDSP T18Document100 pagesMDSP T18Arnz BibosoNo ratings yet

- Final Exam Bee4113 Sem 1 201011Document8 pagesFinal Exam Bee4113 Sem 1 201011Kung ChinHan100% (1)

- 4.3 Bone TissueDocument80 pages4.3 Bone TissueManjunathNo ratings yet

- L 10 Boolean AlgebraDocument24 pagesL 10 Boolean AlgebraAlexaNo ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- Ec8252 SyllabusDocument1 pageEc8252 SyllabusSarika AyyathuraiNo ratings yet

- Kenwood Krc-15rg 179ra RG Rya Ryg 25ra RG 279ra RG Rya Ryg 281rgDocument21 pagesKenwood Krc-15rg 179ra RG Rya Ryg 25ra RG 279ra RG Rya Ryg 281rgNenadBlaškovićNo ratings yet

- INFLATIONDocument24 pagesINFLATIONLovely Bordaje dela FuenteNo ratings yet

- Welcoming The VighnahartaDocument2 pagesWelcoming The VighnahartaDeepa HNo ratings yet

- New Process For Production of Trah Ydro UranDocument9 pagesNew Process For Production of Trah Ydro UranGreten TreutelNo ratings yet

- Veeam Top 10 Reasons Choose Veeam 9 5Document2 pagesVeeam Top 10 Reasons Choose Veeam 9 5Anonymous xKgV3e6XLNo ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- Platimagen Customer DatabaseDocument4 pagesPlatimagen Customer DatabaseErik OrtizNo ratings yet

- Presentation Title: RiversDocument9 pagesPresentation Title: RiversninaNo ratings yet

CV Huda - Ats

CV Huda - Ats

Uploaded by

Asep TeweOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CV Huda - Ats

CV Huda - Ats

Uploaded by

Asep TeweCopyright:

Available Formats

Mohammad Khoirul Huda

Karawang, Jawa Barat, 41371 | 085728768365 | khuda@student.uns.ac.id

linkedin.com/in/khuda

About Me

I am a fresh graduate from Sebelas Maret University (UNS ), Bachelor of Mechanical

Engineering Education. I am a person who is firm, committed, thorough, communicative, able to

adapt to new environments , and able to work with a team. I have the ability in manufacturing

planner, I can operate several manufacturing machines, understand technical drawings, create and

analyze mechanical design 2D/3D (Solidworks , AutoCAD , Fusion , Inventor ) and understanding

basic automation work systems . Currently , I have CSWA Certification (Solidworks ) and Welding

Engineer Certification (BNSP).

Ability & Competence

▪ Manufacturing ▪ Project Management

▪ Solidworks ▪ Ms. Office

▪ AutoCAD ▪ Communication And Interpersonal Skills

Work Experience

PT. Dua Kelinci – Internship (Pati, Indonesia)

Maintenance Technician (January 2015 – March 2015)

• Analyze problems and make repairs to production machines.

• Evaluate and take preventive measures so that the same problem doesn't happen.

Kana Photo Studio (Kudus, Indonesia)

Administrative Staff (June 2017 – August 2017)

• Make daily, weekly and monthly financial reports, answering customer requests by telephone

and handling customer requests, and compile a list of purchases of goods / services needed.

PT. Lentera Bumi Nusantara - Internship (Tasikmalaya, Indonesia)

Blade Technician (January 2020 – March 2020)

• Design, manufacture and install turbine blades according to calculations and procedures.

Sebelas Maret University (Surakarta, Indonesia)

Assistant Lecturer (June 2020 – January 2021)

• Prepare study materials. Teach or assist with lectures, assignments, examinations,

evaluations, and assessments.

Education and Organizational Experience

Sebelas Maret University (2017 - 2021)

S1 Mechanical Engineering Education - GPA 3,73

• Member of Studi Ilmiah Mahasiswa (SIM) UNS

• Staff of Kominfo Division - KOMPRESI UNS

• Head of Academic Division - KOMPRESI UNS

• Head of Body Manufacture Division - BENGAWAN FSAE UNS

• Participate in various national scientific writing competitions event.

SMK 2 PATI (2014 - 2017)

Mechanical Engineering – GPA 81,6

Achievement

Sebelas Maret University (July 2017 - June 2021)

• UNS Student Delegation in Formula Society of Automotive Engineers Japan (2019)

• Finalist of National Scientific Writing Competition - Mechanical Engineering Expo UNJ (2020)

• Best Presentation - National Scientific Writing Competition - Hasanudin University (2020)

• 1st Winner of National Scientific Writing Competition - Hasanudin University (2020)

• Grant Recipients by Ministry of Education and Culture – Parabolic Salt Machine – PKM (2020)

• Publishing - Natural Fiber Reinforced Polymer in Automotive Application: A Systematic

Literature Review. (IOP Science - March 2021)

Projects and Research

Bengawan FSAE UNS

Head of Body Manufacture Division (August 2018 – August 2020)

• Bengawan Formula Student car was built for participation in the Formula Student Japan event

which is held every year. This car was made by several UNS students from various scientific

fields. Research and technical and non-technical calculations are carried out so that the

products created have good specifications, have ergonomic and economic values.

Parabolic Salt Machine

Design Coordinator and Manufacturing Planner (January 2020 – November 2020)

• Parabolic Salt Machine is a scientific project carried out in groups in the Student Creativity

Program. This project focuses on a solar energy utilization system with supporting components

such as a parabolic trough concentrator, an atomizer system and a prism housing that is applied

in a salt producing device.

Plastic Injection Machine

Design Coordinator and Manufacturing Planner (December 2020 – March 2021)

• This machine is built for thesis research . Several parameters in considering material and heat

selection are carried out so that this machine is able to process plastic seeds into a plastic

product that has a shape according to the machine's mold.

You might also like

- Week 8: Ecotourism in The PhilippinesDocument35 pagesWeek 8: Ecotourism in The Philippinesbea krysleen tulio90% (10)

- Catalog Wasser SanitaryDocument84 pagesCatalog Wasser Sanitarypompa wasser indonesiaNo ratings yet

- Chap 1-6 Mixed ReviewDocument16 pagesChap 1-6 Mixed ReviewanNo ratings yet

- The Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinDocument40 pagesThe Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinMara Rebeka Herzog100% (7)

- 17 Grundfos Submersible Deep Well - SP 215 - Performance Curve - Kurva PerformanceDocument5 pages17 Grundfos Submersible Deep Well - SP 215 - Performance Curve - Kurva PerformancePamikatsih PNo ratings yet

- Royal Haskoningdhv IndonesiaDocument1 pageRoyal Haskoningdhv IndonesiaAnton PermanaNo ratings yet

- Manual For FLue Gas Analyzer E4400Document72 pagesManual For FLue Gas Analyzer E4400Mohit MalikNo ratings yet

- Uraian Analisa Harga SatuanDocument6 pagesUraian Analisa Harga Satuandwi istNo ratings yet

- Penawaran Jasa InstallationDocument1 pagePenawaran Jasa InstallationadihartokoNo ratings yet

- Modul 3 - PLC - Adc and DacDocument6 pagesModul 3 - PLC - Adc and DacAnton IoNo ratings yet

- Vit Series: Inlinecentrifugal Duct FanDocument3 pagesVit Series: Inlinecentrifugal Duct FanTedi A MaulanaNo ratings yet

- Sika Viscocrete 3115Document2 pagesSika Viscocrete 3115Ronald MassoraNo ratings yet

- Pekerjaan Tata Udara Tanpa Fresh Air Ac Casette 3,815,000,000.00Document41 pagesPekerjaan Tata Udara Tanpa Fresh Air Ac Casette 3,815,000,000.00A. muzakiNo ratings yet

- Analisa Harga Satuan Pekerjaan Persiapan: No. Uraian Satua N Volu ME Harga SatuanDocument116 pagesAnalisa Harga Satuan Pekerjaan Persiapan: No. Uraian Satua N Volu ME Harga SatuanSpidey ArchyNo ratings yet

- HSP SniDocument194 pagesHSP SniSukmana MlqNo ratings yet

- Katalog Luxon & Zeron 2020 + All in One SL - NSSDocument90 pagesKatalog Luxon & Zeron 2020 + All in One SL - NSSBOCAH MAH BEBASNo ratings yet

- Katalog Maspion - Wall Fan - Exhaust Fan - Ceiling FanDocument35 pagesKatalog Maspion - Wall Fan - Exhaust Fan - Ceiling FanKevin ReynaldoNo ratings yet

- Pengaruh Debit Aliran Dan Kemiringan Poros Turbin Ulir Pada Pembangkit Listrik Tenaga Mikro-HidroDocument5 pagesPengaruh Debit Aliran Dan Kemiringan Poros Turbin Ulir Pada Pembangkit Listrik Tenaga Mikro-HidrocomeklNo ratings yet

- Yonex Badminton Catalog 2023 ENDocument116 pagesYonex Badminton Catalog 2023 ENnrhmhealth100% (1)

- Palet Kayu Drawing SolidworksDocument1 pagePalet Kayu Drawing Solidworksanto suliNo ratings yet

- Drafter CVDocument4 pagesDrafter CVachmad ismailNo ratings yet

- Implementasi Reliability Centered Maintenance (RCM) Pada Sistem Plate-Shearing Machine (Studi Kasus: Pt. Ometraco Arya Samanta)Document16 pagesImplementasi Reliability Centered Maintenance (RCM) Pada Sistem Plate-Shearing Machine (Studi Kasus: Pt. Ometraco Arya Samanta)Abdul GofurNo ratings yet

- Laporan Hasil Pengujian (Testing Result Report)Document1 pageLaporan Hasil Pengujian (Testing Result Report)Intan Pratama Putra100% (1)

- Rab PacingDocument1 pageRab PacingRosyadNo ratings yet

- DepanDocument1 pageDepandimasNo ratings yet

- Program Book IConBEM 2020 PDFDocument93 pagesProgram Book IConBEM 2020 PDFYusuf Hartoyo100% (1)

- Tugas 3 MPKDocument10 pagesTugas 3 MPKAmira MaryanaNo ratings yet

- Tabel Diskonto Compound Interest PDFDocument26 pagesTabel Diskonto Compound Interest PDFLintangHzNo ratings yet

- Perhitungan RelDocument30 pagesPerhitungan RelBig ANo ratings yet

- AC Sharp AH-A9UCYDocument2 pagesAC Sharp AH-A9UCYBee NETNo ratings yet

- BVP621 Led1008cw 960W 220-240V NB GM PDFDocument3 pagesBVP621 Led1008cw 960W 220-240V NB GM PDFLauw Tjun NjiNo ratings yet

- Friction - Friction Coefficients and CalculatorDocument3 pagesFriction - Friction Coefficients and CalculatorMaiquel Eduardo ErnNo ratings yet

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanNo ratings yet

- Fair RPLDocument61 pagesFair RPLAliphi Yudhistira AstineNo ratings yet

- Brosur U-Ditch Final PDFDocument2 pagesBrosur U-Ditch Final PDFدينا ديناNo ratings yet

- ADHI Annual ReportDocument448 pagesADHI Annual ReportWawan NesarNo ratings yet

- CV QU Contoh CVDocument2 pagesCV QU Contoh CVroonzNo ratings yet

- 45Mn (China / GB) : Material PropertiesDocument2 pages45Mn (China / GB) : Material PropertiesNguyeentt TntNo ratings yet

- BOQ of Deck Slab 53 MTR Length &9 MTR Width Description Quantity SL No Unit (UOM)Document1 pageBOQ of Deck Slab 53 MTR Length &9 MTR Width Description Quantity SL No Unit (UOM)PrasunNo ratings yet

- SPHC, SPHDDocument2 pagesSPHC, SPHDMihai Condeescu100% (1)

- Brosur Lampu PJU SHT 30WDocument1 pageBrosur Lampu PJU SHT 30WRahmat HidayatNo ratings yet

- Daftar Harga PintuDocument31 pagesDaftar Harga PintuSaut Saragih100% (1)

- Ahsp 2013 Bawah Pebruari 2018Document573 pagesAhsp 2013 Bawah Pebruari 2018Sevtian RNo ratings yet

- CV - Hayy Nur AbdillahDocument1 pageCV - Hayy Nur AbdillahAyy AbdillahNo ratings yet

- Bisnis Plan PdamDocument2 pagesBisnis Plan PdamBundaAyuNo ratings yet

- Tiang Pancang JhsDocument4 pagesTiang Pancang JhsFodki 2019No ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- BQ STP 5 KubikDocument2 pagesBQ STP 5 Kubikbim akadeNo ratings yet

- TUGAS Modul 4Document3 pagesTUGAS Modul 4dheanNo ratings yet

- Tugas Review Jurnal VisualisasiDocument42 pagesTugas Review Jurnal Visualisasiretno budiasihNo ratings yet

- Materi Kuliah Crash ProgramDocument14 pagesMateri Kuliah Crash ProgramImam Syafi'iNo ratings yet

- Bahasa IngrisDocument2 pagesBahasa IngrisHesti Agustina0% (1)

- Aruan EloardoDocument3 pagesAruan Eloardodennyrobertosinurat2023No ratings yet

- Tabel Berat Besi Beton Pu CompressDocument1 pageTabel Berat Besi Beton Pu CompressWelli E SNo ratings yet

- Drill PressDocument1 pageDrill PressBoyke WinterbergNo ratings yet

- Analisa Harga Satuan Pekerjaan: Badan Standarisasi Nasional (BSN) "SNI"Document9 pagesAnalisa Harga Satuan Pekerjaan: Badan Standarisasi Nasional (BSN) "SNI"novitrity4No ratings yet

- Contoh Rab Gorong-GorongDocument24 pagesContoh Rab Gorong-GorongNurdianty MarahenaNo ratings yet

- Compro Atlas Jaya Nusantara.Document14 pagesCompro Atlas Jaya Nusantara.Wachju AtlasNo ratings yet

- Sosialialisasi Sistem Laporan Kerja Sama VERSI 2.0Document15 pagesSosialialisasi Sistem Laporan Kerja Sama VERSI 2.0g4r15No ratings yet

- CV New - Eka SetyaningsihDocument2 pagesCV New - Eka SetyaningsihArmy MahatirNo ratings yet

- Contoh CVDocument2 pagesContoh CVarisNo ratings yet

- 7f31632a-1164-4378-9d1a-16b70220102bDocument1 page7f31632a-1164-4378-9d1a-16b70220102bPrabu JayaNo ratings yet

- Meth QuPPe PO V11 PDFDocument86 pagesMeth QuPPe PO V11 PDFDasharath OulkarNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- SilverCrest SFB 10.1 C3 PDFDocument122 pagesSilverCrest SFB 10.1 C3 PDFvladprajaNo ratings yet

- Taper Grid H Couplings Range - 2013 PDFDocument1 pageTaper Grid H Couplings Range - 2013 PDFAndres GonzalezNo ratings yet

- Module 4: Short Questions: K G X T T TDocument2 pagesModule 4: Short Questions: K G X T T TRohan KulkarniNo ratings yet

- 10 Plant Based Baking RecipesDocument7 pages10 Plant Based Baking RecipesGundesalvusNo ratings yet

- Either Silent or Switched OffDocument67 pagesEither Silent or Switched OffPankaj Kumar Singh100% (1)

- Dolch PhrasesDocument10 pagesDolch PhrasesCharlie Manahan TemonNo ratings yet

- Problems of Iron and Steel Industry in India:: Swot Analysis StrengthDocument4 pagesProblems of Iron and Steel Industry in India:: Swot Analysis StrengthAnonymous hmd3jXd4No ratings yet

- YS VIII Steam ArtbookDocument19 pagesYS VIII Steam ArtbookTuukka MäkinenNo ratings yet

- Method Statement For Water Recticulation (16.12.04)Document8 pagesMethod Statement For Water Recticulation (16.12.04)mochacino6867% (6)

- Axiata Digital Business - Advancing AsiaDocument12 pagesAxiata Digital Business - Advancing AsiaAxiata Group Berhad100% (1)

- "7 Streams of Income For The Average Nigerian": by Oluwatoyin Omotoso ofDocument29 pages"7 Streams of Income For The Average Nigerian": by Oluwatoyin Omotoso ofOliver Dennis100% (1)

- MDSP T18Document100 pagesMDSP T18Arnz BibosoNo ratings yet

- Final Exam Bee4113 Sem 1 201011Document8 pagesFinal Exam Bee4113 Sem 1 201011Kung ChinHan100% (1)

- 4.3 Bone TissueDocument80 pages4.3 Bone TissueManjunathNo ratings yet

- L 10 Boolean AlgebraDocument24 pagesL 10 Boolean AlgebraAlexaNo ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- Ec8252 SyllabusDocument1 pageEc8252 SyllabusSarika AyyathuraiNo ratings yet

- Kenwood Krc-15rg 179ra RG Rya Ryg 25ra RG 279ra RG Rya Ryg 281rgDocument21 pagesKenwood Krc-15rg 179ra RG Rya Ryg 25ra RG 279ra RG Rya Ryg 281rgNenadBlaškovićNo ratings yet

- INFLATIONDocument24 pagesINFLATIONLovely Bordaje dela FuenteNo ratings yet

- Welcoming The VighnahartaDocument2 pagesWelcoming The VighnahartaDeepa HNo ratings yet

- New Process For Production of Trah Ydro UranDocument9 pagesNew Process For Production of Trah Ydro UranGreten TreutelNo ratings yet

- Veeam Top 10 Reasons Choose Veeam 9 5Document2 pagesVeeam Top 10 Reasons Choose Veeam 9 5Anonymous xKgV3e6XLNo ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- Platimagen Customer DatabaseDocument4 pagesPlatimagen Customer DatabaseErik OrtizNo ratings yet

- Presentation Title: RiversDocument9 pagesPresentation Title: RiversninaNo ratings yet