Professional Documents

Culture Documents

4.ASTM A193 B7 Vs A320 L7 Stud Bolts

4.ASTM A193 B7 Vs A320 L7 Stud Bolts

Uploaded by

O'zSamaCopyright:

Available Formats

You might also like

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- ASTM A333 Grade 6 SpecificationDocument9 pagesASTM A333 Grade 6 SpecificationmaldonadohansNo ratings yet

- ASTM Bolts Grade MarkDocument8 pagesASTM Bolts Grade MarkpouyaNo ratings yet

- ASTM A312 Stainless Steel PipesDocument11 pagesASTM A312 Stainless Steel Pipeschua8100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Astm B843 1993 PDFDocument2 pagesAstm B843 1993 PDFAriq FauzanNo ratings yet

- Stainless Steel Socket Head Cap Screws: Standard Specification ForDocument8 pagesStainless Steel Socket Head Cap Screws: Standard Specification ForMarcelo BarretosNo ratings yet

- BS en 10028 7 2016Document58 pagesBS en 10028 7 2016Carlos Benavides75% (4)

- Steel Fasteners: Materials - Carbon & Alloy SteelsDocument1 pageSteel Fasteners: Materials - Carbon & Alloy SteelsNegro PretoNo ratings yet

- What Are The Available Material Grades?Document3 pagesWhat Are The Available Material Grades?elakiyaNo ratings yet

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoNo ratings yet

- Astm Material Summary For BoltsDocument2 pagesAstm Material Summary For BoltsAkshay PoddarNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- ASTM A320: GradesDocument1 pageASTM A320: Gradesmaryam KAHRIZINo ratings yet

- Asme Sa193 Grade b16Document8 pagesAsme Sa193 Grade b16q alexNo ratings yet

- ASTM Specifications - ASTM Specs and Standards For BoltsDocument2 pagesASTM Specifications - ASTM Specs and Standards For BoltsskilachNo ratings yet

- Specification of A193Document2 pagesSpecification of A193Bambang RewanggiNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Bolts GradesDocument9 pagesBolts GradesMachineryengNo ratings yet

- Bolts & Nuts SpecificationDocument7 pagesBolts & Nuts Specificationpattanaik_munaNo ratings yet

- BS Bolt MaterialDocument1 pageBS Bolt MaterialKamlesh LuharNo ratings yet

- Astm A194Document3 pagesAstm A194poerwntiNo ratings yet

- ASTM Bolting Specification Temperature MDocument2 pagesASTM Bolting Specification Temperature Mrazvan65100% (1)

- Buttweld FittingsDocument4 pagesButtweld Fittingskamal_mdNo ratings yet

- Astm A193Document2 pagesAstm A193Saju Thomas AlexanderNo ratings yet

- Astm A194Document1 pageAstm A194Eka Pramudia SantosoNo ratings yet

- Asme Sa193 Grade b5Document8 pagesAsme Sa193 Grade b5q alexNo ratings yet

- AL201LNDocument6 pagesAL201LNCastoriadisNo ratings yet

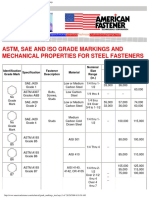

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- 1.6 - Bolting MaterialDocument1 page1.6 - Bolting MaterialchilukamariNo ratings yet

- Standard Steel PlatesDocument39 pagesStandard Steel PlatesCuong TranHung100% (1)

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument4 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsRay CoelloNo ratings yet

- Stainless Steel Pipe To American StandardsDocument7 pagesStainless Steel Pipe To American StandardsAnonymous dziHEjc7YNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDocument8 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858No ratings yet

- ASME Specification For Fastener MaterialsDocument11 pagesASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Astm 193Document2 pagesAstm 193Nilesh TadhaNo ratings yet

- Asme Sa193 Grade b6Document8 pagesAsme Sa193 Grade b6q alexNo ratings yet

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- ASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 pagesASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel Pipesessai expertiseNo ratings yet

- Stainless Steel Pipe SpecsDocument3 pagesStainless Steel Pipe SpecsWahyuTantraFauziNo ratings yet

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- Stainless Steel Pipe SpecificationDocument3 pagesStainless Steel Pipe Specification1trungson1No ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument7 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markingsfujiman35No ratings yet

- A 297 Heat Resistant Casting SteelDocument60 pagesA 297 Heat Resistant Casting SteelIr FankovicNo ratings yet

- ASTM A194 - Portland BoltDocument3 pagesASTM A194 - Portland BoltJonathan DouglasNo ratings yet

- Bolts and Compatible Nuts InformationDocument11 pagesBolts and Compatible Nuts InformationBHARATHNo ratings yet

- Fabory Fasteners ASTM StudboltDocument13 pagesFabory Fasteners ASTM StudboltJohan ConradieNo ratings yet

- Astm A312-A312m-05Document11 pagesAstm A312-A312m-05NadhiraNo ratings yet

- Guide To Selection: Hot Rolled Carbon Steel BarsDocument4 pagesGuide To Selection: Hot Rolled Carbon Steel BarsJess OrtonNo ratings yet

- Asme Sa194 Grade 3Document8 pagesAsme Sa194 Grade 3q alexNo ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersNabil RamehNo ratings yet

- Welded, Unannealed Austenitic Stainless Steel Tubular ProductsDocument4 pagesWelded, Unannealed Austenitic Stainless Steel Tubular ProductsDarwin DarmawanNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsmameeranNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Metal and Non-MetalsDocument20 pagesMetal and Non-Metalsanitaagarwal19891984No ratings yet

- Expander FlangesDocument2 pagesExpander FlangeswillNo ratings yet

- Articulo Cietifico 1Document10 pagesArticulo Cietifico 1KEVIN DANIEL MONTOYA MONTEALEGRENo ratings yet

- Liquid Metal Embrittlement: Larissa Chiesa M. de Souza COT-736 - Téc. Est. Controle de CorrosãoDocument11 pagesLiquid Metal Embrittlement: Larissa Chiesa M. de Souza COT-736 - Téc. Est. Controle de CorrosãoLarissa Chiesa Mendonça De SouzaNo ratings yet

- Repair and Maintenance Weld Overlay Solutions For Steel MillsDocument28 pagesRepair and Maintenance Weld Overlay Solutions For Steel MillsMike CheNo ratings yet

- Uji Komposisi Kimia (Test of Chemical Composition) PDFDocument46 pagesUji Komposisi Kimia (Test of Chemical Composition) PDFRidwan NugrahaNo ratings yet

- UNS N08904, UNS N08925, and UNS N08926 Welded Tube: Standard Specification ForDocument2 pagesUNS N08904, UNS N08925, and UNS N08926 Welded Tube: Standard Specification ForGreg YeeNo ratings yet

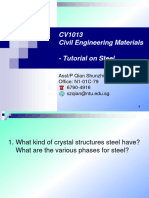

- CV1013 - Tutorial On SteelDocument22 pagesCV1013 - Tutorial On SteelAsh KongNo ratings yet

- ChoiceAnalytical NCSDocument163 pagesChoiceAnalytical NCSQuality Officer GeosKendari (Pandu)No ratings yet

- Sample Location Terraspec Type Hole Id # From To Depth Prefix SpectrumDocument5 pagesSample Location Terraspec Type Hole Id # From To Depth Prefix SpectrumManuelLoliNo ratings yet

- Objectives Objectives: Stabilization of Retained Austenite in The AISI D2 Tool SteelDocument1 pageObjectives Objectives: Stabilization of Retained Austenite in The AISI D2 Tool SteelEdward Giovanni Rodriguez AriasNo ratings yet

- Aluminized t1 TubingDocument4 pagesAluminized t1 TubingshankosiNo ratings yet

- Lecture 10 - Recovery Recrystallication and Grain GrowthDocument22 pagesLecture 10 - Recovery Recrystallication and Grain GrowthsimNo ratings yet

- ZirconiaDocument8 pagesZirconiaSalem GarrabNo ratings yet

- 02 Forms of CorrosionDocument41 pages02 Forms of CorrosionNino AngobNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- Sample Reg From FebDocument31 pagesSample Reg From FebSainath AmudaNo ratings yet

- Steel Guide To SelectionDocument7 pagesSteel Guide To Selectionsinetron88No ratings yet

- Asme SB 381 & Astm B 381Document1 pageAsme SB 381 & Astm B 381jung-57No ratings yet

- Indonesian Picture AgateDocument8 pagesIndonesian Picture AgateAgianto MutiadjajaNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Lihir Fs PDFDocument1 pageLihir Fs PDFKaye ReiesNo ratings yet

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDocument1 pageCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKNo ratings yet

- P20 Tool Steel DescriptionDocument5 pagesP20 Tool Steel DescriptionJAFFERNo ratings yet

- Wire DrawingDocument7 pagesWire DrawingUtkarsh0% (1)

- Igneous Mineral in Thin Section 3Document18 pagesIgneous Mineral in Thin Section 3Michelle MilleniaNo ratings yet

- Guidebook To The Pegmatites of Western Australia: June 2007Document3 pagesGuidebook To The Pegmatites of Western Australia: June 2007WalliseropsNo ratings yet

4.ASTM A193 B7 Vs A320 L7 Stud Bolts

4.ASTM A193 B7 Vs A320 L7 Stud Bolts

Uploaded by

O'zSamaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.ASTM A193 B7 Vs A320 L7 Stud Bolts

4.ASTM A193 B7 Vs A320 L7 Stud Bolts

Uploaded by

O'zSamaCopyright:

Available Formats

ASTM A193 B7 vs A320 L7 Stud Bolts

ASTM A193 B7 is a Bolting specification for medium-high temperature applications. It is a heat

treated Chromium Molybdenum steel and is considered for applications up to 450° Celsius (840°

Fahrenheit).

ASTM A320 L7 has the same chemical and physical properties as B7, with additional Charpy V Notch tests

taken at -101° Celsius (-150° Fahrenheit) for low temperature applications.

Steel is manufactured via Electric Arc Furnace, continuously cast followed by heat treatment and

Bright conversion. It is typically used for the manufacture of Bolts, Fasteners, Studs and

Studbolts in the Petrochemical industry. Available Drawn or Turned depending on the size in

both Metric and Imperial sizes in standard and Thread Rolling Diameters. Typical stock size

range 8mm to 4in Diameter in B7/L7 and 110mm to 130mm Diameter B7 only.

Mechanical Properties B7/L7

Grade Size Tensile ksi, min Yield, ksi, min Elong, %, min RA % min

B7 Up to 2-1/2 125 105 16 50

L7 Up to 2-1/2 125 105 16 50

Chemical Composition B7/L7

Element B7 (AISI 4140) L7 (AISI 4140)

Carbon 0.37 - 0.49% 0.37 - 0.49%

Manganese 0.65 - 1.10% 0.65 - 1.10%

Phosphorus, max 0.035% 0.035%

Sulfur, max 0.040% 0.040%

Silicon 0.15 - 0.35% 0.15 - 0.35%

Chromium 0.75 - 1.20% 0.75 - 1.20%

Nickel

Molybdenum 0.15 - 0.25% 0.15 - 0.25%

Alloy Steel Stud Bolting Materials

ASTM A193

The ASTM A193 is heavily utilized in petroleum and chemical construction applications. The

ASTM standard covers alloy steel and stainless steel bolting materials for high temperature or

high pressure service. This specification includes fasteners intended for use in pressure vessels,

valves, flanges, and fittings. Although, this material is often available in national coarse (UNC)

thread pitches, if being used in traditional applications, threads are specified 8 threads per inch

(tpi) for diameters above one inch.

ASTM 193, Grade B7

Heat treated chromium-molybdenum steel recommended for medium high temperature service.

(Liquid quench -50° to 900° F, Air quench -40° to 900° F)

ASTM A193, Grade B7M

Similar to B7 studs except that the minimum yield and tensile strength requirements are reduced

and the hardness controlled to 235 Brinell maximum. Recommended for use in corrosive

environments. (-50° to 900° F)

ASTM A193, Grade B16

A heat treated chromium-molybdenum-vanadium steel recommended for high pressure, high

temperature service. (-50° to 1100° F)

ASTM A320, Grade L7

This grade is intended for low temperature service down to minus 150° F and has a minimum

Charpy impact value of 20 ft. lbs. at this temperature. (-50° to 1100° F)

ASTM A320, Grade L7M

Similar to L7 studs except that the minimum yield and tensile strength requirements are reduced

and the hardness controlled to 235 Brinell maximum. This stud is recommended for use in low

temperature corrosive environments. (-50° to 1100° F)

ASTM A320, Grade L43

This grade is intended for low temperature service down to minus 150° F and has a minimum

Charpy impact value of 20 ft. lbs. at this temperature. Available in sizes up to a 4 inch diameter.

(-150° to 1100° F)

ASTM A193, Grade B8

These Chromium-Nickel (AISI 304) austenitic steel studs are recommended for use in corrosive

environments. (-325° to 1500° F)

ASTM A193, Grade B8M

These chromium-nickel molybdenum (AISI 316) austenitic steel studs are recommended for use

in corrosive environments. (-325° to 1500° F)

Carbon and Alloy Steel Nuts

ASTM A194

The ASTM A194 specification covers carbon, alloy and stainless steel nuts intended for use in

high-pressure and/or high-temperature service. Unless otherwise specified, the American

National Standard Heavy Hex Series (ANSI B 18.2.2) shall be used. Nuts up to and including 1in

nominal size shall be UNC Series Class 2B fit. Nuts over 1in nominal size shall be either UNC

Series Class 2B fit or 8 UN Series Class 2B fit. High strength ASTM A194 grade 2H nuts are

common in the marketplace.

ASTM A194 Grade 2

Suitable for use in high temperatures and high pressure conditions.

ASTM A194 Grade 2H

Suitable for use in high temperatures and high pressure conditions. Quenched & tempered.

ASTM A194 Grade 2HM

Similar to 2H nuts except this grade is recommended for use in corrosive environments.

ASTM A194 Grade 4

Heat treated molybdenum steel nuts suitable for severe temperature and pressure conditions.

ASTM A194 Grade 7

Heat treated chrome-molybdenum steel nuts suitable for extreme temperature and pressure

conditions. Suitable for sub-zero service conditions and have minimum Charpy impact values in

accordance with ASTM specifications.

ASTM A194 Grade 7L

Heat treated chrome-molybdenum steel nuts suitable for extreme temperature and pressure

conditions. Suitable for sub-zero service conditions and have minimum Charpy impact values in

accordance with ASTM specifications.

ASTM A194 Grade 7M

Similar to grade L7 nuts except this grade is recommended for use in corrosive environments.

ASTM A194 Grade 8/8M

Stainless steel nuts recommended for use in corrosive environments.

You might also like

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- ASTM A333 Grade 6 SpecificationDocument9 pagesASTM A333 Grade 6 SpecificationmaldonadohansNo ratings yet

- ASTM Bolts Grade MarkDocument8 pagesASTM Bolts Grade MarkpouyaNo ratings yet

- ASTM A312 Stainless Steel PipesDocument11 pagesASTM A312 Stainless Steel Pipeschua8100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Astm B843 1993 PDFDocument2 pagesAstm B843 1993 PDFAriq FauzanNo ratings yet

- Stainless Steel Socket Head Cap Screws: Standard Specification ForDocument8 pagesStainless Steel Socket Head Cap Screws: Standard Specification ForMarcelo BarretosNo ratings yet

- BS en 10028 7 2016Document58 pagesBS en 10028 7 2016Carlos Benavides75% (4)

- Steel Fasteners: Materials - Carbon & Alloy SteelsDocument1 pageSteel Fasteners: Materials - Carbon & Alloy SteelsNegro PretoNo ratings yet

- What Are The Available Material Grades?Document3 pagesWhat Are The Available Material Grades?elakiyaNo ratings yet

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoNo ratings yet

- Astm Material Summary For BoltsDocument2 pagesAstm Material Summary For BoltsAkshay PoddarNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- ASTM A320: GradesDocument1 pageASTM A320: Gradesmaryam KAHRIZINo ratings yet

- Asme Sa193 Grade b16Document8 pagesAsme Sa193 Grade b16q alexNo ratings yet

- ASTM Specifications - ASTM Specs and Standards For BoltsDocument2 pagesASTM Specifications - ASTM Specs and Standards For BoltsskilachNo ratings yet

- Specification of A193Document2 pagesSpecification of A193Bambang RewanggiNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Bolts GradesDocument9 pagesBolts GradesMachineryengNo ratings yet

- Bolts & Nuts SpecificationDocument7 pagesBolts & Nuts Specificationpattanaik_munaNo ratings yet

- BS Bolt MaterialDocument1 pageBS Bolt MaterialKamlesh LuharNo ratings yet

- Astm A194Document3 pagesAstm A194poerwntiNo ratings yet

- ASTM Bolting Specification Temperature MDocument2 pagesASTM Bolting Specification Temperature Mrazvan65100% (1)

- Buttweld FittingsDocument4 pagesButtweld Fittingskamal_mdNo ratings yet

- Astm A193Document2 pagesAstm A193Saju Thomas AlexanderNo ratings yet

- Astm A194Document1 pageAstm A194Eka Pramudia SantosoNo ratings yet

- Asme Sa193 Grade b5Document8 pagesAsme Sa193 Grade b5q alexNo ratings yet

- AL201LNDocument6 pagesAL201LNCastoriadisNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- 1.6 - Bolting MaterialDocument1 page1.6 - Bolting MaterialchilukamariNo ratings yet

- Standard Steel PlatesDocument39 pagesStandard Steel PlatesCuong TranHung100% (1)

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument4 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsRay CoelloNo ratings yet

- Stainless Steel Pipe To American StandardsDocument7 pagesStainless Steel Pipe To American StandardsAnonymous dziHEjc7YNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDocument8 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858No ratings yet

- ASME Specification For Fastener MaterialsDocument11 pagesASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Astm 193Document2 pagesAstm 193Nilesh TadhaNo ratings yet

- Asme Sa193 Grade b6Document8 pagesAsme Sa193 Grade b6q alexNo ratings yet

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- ASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel PipesDocument12 pagesASTM A312 A312M Standard Specification For Seamless Welded and Heavily Cold Worked Austenitic Stainless Steel Pipesessai expertiseNo ratings yet

- Stainless Steel Pipe SpecsDocument3 pagesStainless Steel Pipe SpecsWahyuTantraFauziNo ratings yet

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- Stainless Steel Pipe SpecificationDocument3 pagesStainless Steel Pipe Specification1trungson1No ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument7 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markingsfujiman35No ratings yet

- A 297 Heat Resistant Casting SteelDocument60 pagesA 297 Heat Resistant Casting SteelIr FankovicNo ratings yet

- ASTM A194 - Portland BoltDocument3 pagesASTM A194 - Portland BoltJonathan DouglasNo ratings yet

- Bolts and Compatible Nuts InformationDocument11 pagesBolts and Compatible Nuts InformationBHARATHNo ratings yet

- Fabory Fasteners ASTM StudboltDocument13 pagesFabory Fasteners ASTM StudboltJohan ConradieNo ratings yet

- Astm A312-A312m-05Document11 pagesAstm A312-A312m-05NadhiraNo ratings yet

- Guide To Selection: Hot Rolled Carbon Steel BarsDocument4 pagesGuide To Selection: Hot Rolled Carbon Steel BarsJess OrtonNo ratings yet

- Asme Sa194 Grade 3Document8 pagesAsme Sa194 Grade 3q alexNo ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersNabil RamehNo ratings yet

- Welded, Unannealed Austenitic Stainless Steel Tubular ProductsDocument4 pagesWelded, Unannealed Austenitic Stainless Steel Tubular ProductsDarwin DarmawanNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsmameeranNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Metal and Non-MetalsDocument20 pagesMetal and Non-Metalsanitaagarwal19891984No ratings yet

- Expander FlangesDocument2 pagesExpander FlangeswillNo ratings yet

- Articulo Cietifico 1Document10 pagesArticulo Cietifico 1KEVIN DANIEL MONTOYA MONTEALEGRENo ratings yet

- Liquid Metal Embrittlement: Larissa Chiesa M. de Souza COT-736 - Téc. Est. Controle de CorrosãoDocument11 pagesLiquid Metal Embrittlement: Larissa Chiesa M. de Souza COT-736 - Téc. Est. Controle de CorrosãoLarissa Chiesa Mendonça De SouzaNo ratings yet

- Repair and Maintenance Weld Overlay Solutions For Steel MillsDocument28 pagesRepair and Maintenance Weld Overlay Solutions For Steel MillsMike CheNo ratings yet

- Uji Komposisi Kimia (Test of Chemical Composition) PDFDocument46 pagesUji Komposisi Kimia (Test of Chemical Composition) PDFRidwan NugrahaNo ratings yet

- UNS N08904, UNS N08925, and UNS N08926 Welded Tube: Standard Specification ForDocument2 pagesUNS N08904, UNS N08925, and UNS N08926 Welded Tube: Standard Specification ForGreg YeeNo ratings yet

- CV1013 - Tutorial On SteelDocument22 pagesCV1013 - Tutorial On SteelAsh KongNo ratings yet

- ChoiceAnalytical NCSDocument163 pagesChoiceAnalytical NCSQuality Officer GeosKendari (Pandu)No ratings yet

- Sample Location Terraspec Type Hole Id # From To Depth Prefix SpectrumDocument5 pagesSample Location Terraspec Type Hole Id # From To Depth Prefix SpectrumManuelLoliNo ratings yet

- Objectives Objectives: Stabilization of Retained Austenite in The AISI D2 Tool SteelDocument1 pageObjectives Objectives: Stabilization of Retained Austenite in The AISI D2 Tool SteelEdward Giovanni Rodriguez AriasNo ratings yet

- Aluminized t1 TubingDocument4 pagesAluminized t1 TubingshankosiNo ratings yet

- Lecture 10 - Recovery Recrystallication and Grain GrowthDocument22 pagesLecture 10 - Recovery Recrystallication and Grain GrowthsimNo ratings yet

- ZirconiaDocument8 pagesZirconiaSalem GarrabNo ratings yet

- 02 Forms of CorrosionDocument41 pages02 Forms of CorrosionNino AngobNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- Sample Reg From FebDocument31 pagesSample Reg From FebSainath AmudaNo ratings yet

- Steel Guide To SelectionDocument7 pagesSteel Guide To Selectionsinetron88No ratings yet

- Asme SB 381 & Astm B 381Document1 pageAsme SB 381 & Astm B 381jung-57No ratings yet

- Indonesian Picture AgateDocument8 pagesIndonesian Picture AgateAgianto MutiadjajaNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Lihir Fs PDFDocument1 pageLihir Fs PDFKaye ReiesNo ratings yet

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDocument1 pageCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKNo ratings yet

- P20 Tool Steel DescriptionDocument5 pagesP20 Tool Steel DescriptionJAFFERNo ratings yet

- Wire DrawingDocument7 pagesWire DrawingUtkarsh0% (1)

- Igneous Mineral in Thin Section 3Document18 pagesIgneous Mineral in Thin Section 3Michelle MilleniaNo ratings yet

- Guidebook To The Pegmatites of Western Australia: June 2007Document3 pagesGuidebook To The Pegmatites of Western Australia: June 2007WalliseropsNo ratings yet