Professional Documents

Culture Documents

25 A Lifting Plan

25 A Lifting Plan

Uploaded by

saravanan .b0 ratings0% found this document useful (0 votes)

38 views2 pagesThis lifting plan outlines the steps for lifting a 5 ton office bunk in two sections. It identifies potential hazards, checks for a clear route and laydown area, and lists responsible personnel for each step of the operation. A sketch details the rigging configuration including slings, shackles, and crane information. The lifting authority must review and authorize the plan before work proceeds. A debrief will evaluate if the operation went as planned or if changes are needed.

Original Description:

25 a Lifting Plan

Original Title

25 a Lifting Plan

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis lifting plan outlines the steps for lifting a 5 ton office bunk in two sections. It identifies potential hazards, checks for a clear route and laydown area, and lists responsible personnel for each step of the operation. A sketch details the rigging configuration including slings, shackles, and crane information. The lifting authority must review and authorize the plan before work proceeds. A debrief will evaluate if the operation went as planned or if changes are needed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

38 views2 pages25 A Lifting Plan

25 A Lifting Plan

Uploaded by

saravanan .bThis lifting plan outlines the steps for lifting a 5 ton office bunk in two sections. It identifies potential hazards, checks for a clear route and laydown area, and lists responsible personnel for each step of the operation. A sketch details the rigging configuration including slings, shackles, and crane information. The lifting authority must review and authorize the plan before work proceeds. A debrief will evaluate if the operation went as planned or if changes are needed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

APPEXDIX G – Simple Lifting Plan

Number: RJ/LP/SI/

LIFTING PLAN (Simple) Part 1

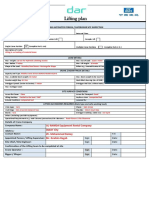

Date: Work Area: Work Permit No:

Task:

Job Safety Analysis No: Diagram, Drawing or Sketches Attached:

Maximum Weight of Load: Actual / Assumed / Calculated:

Description of Lifting Operation:

Check List: Possible considerations (not exhaustive)

Hazards to personnel in the area Weigh of load verified Trial lift required

No lifting points directly above the load Load on pallets requires securing Risk of overturning

Awkward size / Shape /Sharp edges Transport fastenings removed Working under load

Dedicated lifting points on the load Stability of the load an issue Cross Hauling required

Certified suspension points available High Center of gravity Tandem lifts involved

Restricted headroom or confined area Lifting chemicals Tag lines Required

Correctly installed lifting equipment Conflicting tasks in the area Barriers Required

Correctly installed lifting accessories Dynamic factors involved Certification Checked

Engineering Support required Method of communication agreed Safe Access available

Number of people involved identified Adequate lighting and visibility Lifting over live plant

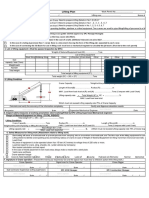

Route to Be Travelled and Laydown Area Yes No

1 Are the route and laydown area clear of obstructions?

2. Is the laydown / landing area adequate

3. Is the laydown /landing area adequate in term of load bearing

4. Is suitable packing avaialble for protecting the load, lifting equipment, slings etc.

5. Have barriers been positioned to prevent access by unauthorised personnel

6. Have you confirmed that the laydown area is within the operating limits / radius of the equipment.

7. Have environmental conditions been considered with regards to the safety of the lifting operation

8. Will the Lifting Equipment operator be able to see the banksman throughout the operation

9. Are there hazardous process plan or materials in the areas.

Step by Step of the Lifting Operation

Person Responsible

1. Identify the loactions for lifting of Office bunk (5 ton) in two section. Ensure area is clear from any

obstruction.

2. Alert other group about the lifting activity.

3. Position the crane for lifting within in detailed working radius

4. Deploy the competent riggers and identify the signal man.

5. Ensure proper communication established between

6. Ensure certified lifting tools & tackles for lifting operations

7. Secure the load properly, ensure correct angle achieved for the lift

8. Use tag lines to the load to prevent the sudden swing.

9. Lift the load slowly, check the load is secured properly

10.Ensure no movement in loading area, no one working under the load

11.Place the load in designated area. Signalman to guide crane operator

12.unsecure the load from pad eye.

SKETCH DETAILING THE RIGGING UP OF THE LIFTING EQUIPMENT AND LIFTING ACCESSORIES

Name of the Plant:

Weight of Load:

Crane Capacity:

(Crane type:

*Crane SWL: ………..Tons

*Working Radius: ……………Max)

*Boom Length: … Meters

(* Refer From Crane Load Chart)

Tools & tackles:

Web Slings:

No. of Web Sling: ………nos.

Sling Details: Length: …. Mts,

Width: ……. inch,

SWL: …... ton

Wire Rope Slings:

No. of Sling: ……nos.

Sling Details: Length: ….. Mts,

Width: ……. inch,

SWL : ……. ton

D- Shackles: ……… Nos.

D-Shackle SWL……………… tons.

(SWL- Safe working load)

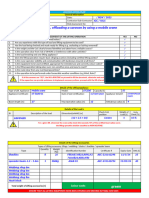

LIFTING EQUIPMENT AND LIFTING ACCESSORIES TO BE USED (SPECIFY TYPE AND SWL)

1

2.

3.

4.

6.

7.

8.

9.

10

AUTHORISATION:

Lifting Authority: I have reviewed the details of the lifting plan and agree the work can proceed

Name: Signature:

DEBRIEF AND LEARNING (Did the lifting opertaion go as planned or are change to plan required)

You might also like

- Lifting Plan FormDocument3 pagesLifting Plan FormFahrul Andi100% (4)

- Lifting Plan Template - Portacamp Container 20'' (East Side 1)Document2 pagesLifting Plan Template - Portacamp Container 20'' (East Side 1)dadang16100% (3)

- Progress Test 2Document7 pagesProgress Test 2alesenan71% (7)

- Booths - Strategic Marketing ManagementDocument25 pagesBooths - Strategic Marketing ManagementSyed Muhammad AhmedNo ratings yet

- Crane Lift Plan: Company Name Project: ClientDocument5 pagesCrane Lift Plan: Company Name Project: Clientscottie Mailau100% (1)

- Lifting PlanDocument2 pagesLifting PlanBHANWARA RAM100% (1)

- Critical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectDocument1 pageCritical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectJianping KeNo ratings yet

- Appendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesDocument32 pagesAppendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesAdebayo M JayeolaNo ratings yet

- Lifting Plan For UnloadingDocument5 pagesLifting Plan For Unloadingkhaled redaNo ratings yet

- Lifting Plan - ExampleDocument5 pagesLifting Plan - Examplejafo_211No ratings yet

- Lifting PlanDocument2 pagesLifting Plansujith s p100% (2)

- Lifting PlanDocument10 pagesLifting PlanEko Kurniawan100% (4)

- Hazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted CraneDocument1 pageHazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted Cranesaravanan .b91% (11)

- Assignment 1 ECN3112Document4 pagesAssignment 1 ECN3112Surenraj SubramaniamNo ratings yet

- Business Case ExampleDocument3 pagesBusiness Case ExampleAlexei TuzikovNo ratings yet

- NRCLP 221Document7 pagesNRCLP 221Ali AlahmaNo ratings yet

- NRCLP 223Document5 pagesNRCLP 223Ali AlahmaNo ratings yet

- Form Rigging PlanDocument2 pagesForm Rigging PlanIin WarlinaNo ratings yet

- Lifting Operations Plan-70 T CraneDocument5 pagesLifting Operations Plan-70 T CraneSvetlanaLiarNo ratings yet

- Lifting PlanDocument1 pageLifting PlansathishkumarNo ratings yet

- NRCLP 224Document5 pagesNRCLP 224Ali AlahmaNo ratings yet

- Lifting Plan of SpoolDocument1 pageLifting Plan of SpoolhazopengineerNo ratings yet

- NRCLP 222Document5 pagesNRCLP 222Ali AlahmaNo ratings yet

- NRCLP 220Document5 pagesNRCLP 220Ali AlahmaNo ratings yet

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- B18 Rigging Plan For Heavy Lifting: Radius 6 MDocument2 pagesB18 Rigging Plan For Heavy Lifting: Radius 6 MAli Ahmed PathanNo ratings yet

- Lifting Plan FormatDocument2 pagesLifting Plan FormatNaveenNo ratings yet

- Lift Plan and Rigging Plan - 1Document40 pagesLift Plan and Rigging Plan - 1daniNo ratings yet

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- 20 Inch - MS - Loading Unloading - ButeneDocument5 pages20 Inch - MS - Loading Unloading - ButeneHSE ENNKAYNo ratings yet

- Rigging Calc. Kato NK550Document9 pagesRigging Calc. Kato NK550ashadiamirNo ratings yet

- Lifting Plan SheetDocument1 pageLifting Plan SheetHoang Dung NguyenNo ratings yet

- Mobile Crane Lifting Plan - Routine Operation1Document2 pagesMobile Crane Lifting Plan - Routine Operation1Becha MouradNo ratings yet

- Routine Lifting Plan - HEINDocument1 pageRoutine Lifting Plan - HEINYunan Edhie100% (1)

- Petroleum Development Oman: Lift Plan For Lifting OperationDocument7 pagesPetroleum Development Oman: Lift Plan For Lifting OperationVuthpalachaitanya KrishnaNo ratings yet

- Lift Study: Project Name Lift No.: Work Area Date Crane Type: Operator(s)Document2 pagesLift Study: Project Name Lift No.: Work Area Date Crane Type: Operator(s)Ikhsan AwanNo ratings yet

- Lifting Plan: Site / Project Site: - Date:-Lift Location: - MSRA References No.: - Load Details / Crane DetailsDocument2 pagesLifting Plan: Site / Project Site: - Date:-Lift Location: - MSRA References No.: - Load Details / Crane DetailsChayank TiwariNo ratings yet

- FM SS 0086Document1 pageFM SS 0086Klaikangwol Anuwarn50% (2)

- Lifting Operation Checlist HASCODocument6 pagesLifting Operation Checlist HASCOArunachu ArunachuNo ratings yet

- Lifting PlanDocument4 pagesLifting PlanMuneeb RehmanNo ratings yet

- Lifting Plan: Name & Signature Name & SignatureDocument1 pageLifting Plan: Name & Signature Name & Signaturenguyễn thuong nghia100% (2)

- LiftingDocument6 pagesLiftinghsem Al EimaraNo ratings yet

- Lifting Plan For Membarane SkidDocument4 pagesLifting Plan For Membarane Skidlike saddamNo ratings yet

- Basic Lifting Plan 5MTDocument1 pageBasic Lifting Plan 5MTshahhussain1031No ratings yet

- 05 Critical Lifting PlanDocument1 page05 Critical Lifting PlanMD AZHER ULLAH BAIGNo ratings yet

- Lift Plan - Routine - Updated-October. 2017 - Rev 01Document1 pageLift Plan - Routine - Updated-October. 2017 - Rev 01sudeesh kumarNo ratings yet

- Lifting PlanDocument2 pagesLifting PlanMidhunRameshThuvasseryNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document4 pages3-Pre-Lift Checklist Rev A 06302015Bruce FerreiraNo ratings yet

- Lifting Plan - Besi Ribar - Kato SL 70 TonDocument2 pagesLifting Plan - Besi Ribar - Kato SL 70 TonJhon SwellyNo ratings yet

- 4.2. Engineered Lift Check ListDocument2 pages4.2. Engineered Lift Check ListJeffrey RamosNo ratings yet

- NRLP - C - 114 Mad Pumps 1 & 2 - 130 T Zb556Document7 pagesNRLP - C - 114 Mad Pumps 1 & 2 - 130 T Zb556MohamedNo ratings yet

- Lifting Plan For CranesDocument9 pagesLifting Plan For CranesBibin JohnNo ratings yet

- Lifting Procedure With AttachmentDocument16 pagesLifting Procedure With AttachmentIshak MalimNo ratings yet

- Lift Plan 1 REV1Document4 pagesLift Plan 1 REV1AkimBiNo ratings yet

- HSE-TP-102-C Lifting Plan Using Mobile CraneDocument13 pagesHSE-TP-102-C Lifting Plan Using Mobile CraneSyed Fawad ShahNo ratings yet

- Introduction To Lifting PlanDocument44 pagesIntroduction To Lifting PlanÐôùxBébê Ðê MãmäñNo ratings yet

- Lifting Plan SheetDocument2 pagesLifting Plan SheetAalam Irshad100% (1)

- Lift Plan Offset Centre of GravityDocument1 pageLift Plan Offset Centre of GravityTasia DiNo ratings yet

- Form 5068A Crane Use Planning Process REV 2015Document4 pagesForm 5068A Crane Use Planning Process REV 2015Samuel LumbanrajaNo ratings yet

- Ordnance Instructions for the United States Navy. 1866. Fourth edition.From EverandOrdnance Instructions for the United States Navy. 1866. Fourth edition.No ratings yet

- Radio Knobs and Scope Dopes: Behind the Scenes in the Air Navigation SystemFrom EverandRadio Knobs and Scope Dopes: Behind the Scenes in the Air Navigation SystemNo ratings yet

- TPI Belt Shackle 190122Document26 pagesTPI Belt Shackle 190122saravanan .bNo ratings yet

- Esec Checklist - Heavy VehcilesDocument2 pagesEsec Checklist - Heavy Vehcilessaravanan .bNo ratings yet

- CGPL Mundra - Contractor Requirements For Safe Operation of Plant and RequirenmentDocument2 pagesCGPL Mundra - Contractor Requirements For Safe Operation of Plant and Requirenmentsaravanan .bNo ratings yet

- Mess Expense PDFDocument1 pageMess Expense PDFsaravanan .bNo ratings yet

- BOQ Supply Installation - Construction PowerDocument1 pageBOQ Supply Installation - Construction Powersaravanan .bNo ratings yet

- 5.1.5 1536734770 1930Document30 pages5.1.5 1536734770 1930swati ganarNo ratings yet

- NIFTY Midcap 50 Apr2020Document2 pagesNIFTY Midcap 50 Apr2020amitNo ratings yet

- Globalization DesglobalizationDocument10 pagesGlobalization DesglobalizationFarhadNo ratings yet

- Non Traditional Threats and Role of Non-State ActorsDocument20 pagesNon Traditional Threats and Role of Non-State ActorsIsmail Hussain100% (2)

- Production Possibility Frontiers, OC, MarginalismDocument4 pagesProduction Possibility Frontiers, OC, Marginalismyai giniNo ratings yet

- XXAR Cash Receipt VoucherDocument1 pageXXAR Cash Receipt Vouchershaikhfaisalx81No ratings yet

- TOS Common Exam 2S1819Document24 pagesTOS Common Exam 2S1819Mary Anne ManaoisNo ratings yet

- Briefing On RA 10963 (TRAIN LAW)Document74 pagesBriefing On RA 10963 (TRAIN LAW)robertoii_suarez50% (2)

- Statute of Limitations For Collecting A DebtDocument2 pagesStatute of Limitations For Collecting A DebtmikotanakaNo ratings yet

- 199A Income Tax FlowchartDocument1 page199A Income Tax FlowchartMichael AuerNo ratings yet

- India's Major and Minor PortsDocument8 pagesIndia's Major and Minor Portsbhatiakshay7433No ratings yet

- Policy Application: Child Care and Labor SupplyDocument9 pagesPolicy Application: Child Care and Labor SupplySiti Nur CholifahNo ratings yet

- ECO111 Microeconomics Class: Handed Out: Submission Due: Format: Submission Mode: Email ToDocument7 pagesECO111 Microeconomics Class: Handed Out: Submission Due: Format: Submission Mode: Email ToHoang AnhNo ratings yet

- A Study On Customer's Attitude and Perception Towards Digital Food App ServicesDocument7 pagesA Study On Customer's Attitude and Perception Towards Digital Food App ServicesAcumen ElthuruthNo ratings yet

- Current List of All Non-U.S. IssuersDocument8 pagesCurrent List of All Non-U.S. IssuerspencilpendekNo ratings yet

- CM Recon - 082014Document377 pagesCM Recon - 082014mleaeraNo ratings yet

- Qatar Airways - Trip SummaryDocument2 pagesQatar Airways - Trip SummaryAnuraag DasuNo ratings yet

- CIRCULAR-For Special Incentive - 15022022Document7 pagesCIRCULAR-For Special Incentive - 15022022Indranil DattaNo ratings yet

- Orrleeflryffiffiffiat-: Wnnnngal FFFFF Lic'SDocument1 pageOrrleeflryffiffiffiat-: Wnnnngal FFFFF Lic'SN Swamy DivitiNo ratings yet

- Calculating GDP DeflatorDocument22 pagesCalculating GDP DeflatornikowawaNo ratings yet

- H 20AM, 25AM, 30AM, 36AM, 41AM JLG Operation EnglishDocument98 pagesH 20AM, 25AM, 30AM, 36AM, 41AM JLG Operation EnglishJaring Prima TeknikNo ratings yet

- QuestionsDocument47 pagesQuestionsTeddy DerNo ratings yet

- Pretest EkonomiDocument18 pagesPretest Ekonomimaikel rudiantoNo ratings yet

- Comprehension - IVDocument49 pagesComprehension - IVNavneet KumarNo ratings yet

- Confluence of The Two SeasDocument11 pagesConfluence of The Two SeasSatchidanandaNo ratings yet

- Pres Kenji AndoDocument35 pagesPres Kenji AndoMikhail BiryukovNo ratings yet