Professional Documents

Culture Documents

FT Series: Float & Thermostatic Steam Trap

FT Series: Float & Thermostatic Steam Trap

Uploaded by

Marcos Mezahuaman LaimeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FT Series: Float & Thermostatic Steam Trap

FT Series: Float & Thermostatic Steam Trap

Uploaded by

Marcos Mezahuaman LaimeCopyright:

Available Formats

STEAM TRAPS

Steam Traps FT Series

Float & Thermostatic Steam Trap Float & Thermostatic

Model FT

Sizes 3/4”, 1”, 11/4”, 11/2”, 2”

Connections NPT

Body Material Cast Iron

PMO Max. Operating Pressure 75 PSIG

TMO Max. Operating Temperature Saturated Steam Temperature

PMA Max. Allowable Pressure 75 PSIG up to 450ºF

TMA Max. Allowable Temperature 450ºF @ 75 PSIG

Typical Applications Features

DRIP, PROCESS: FT Series steam traps are designed for • H-pattern design allows piping from either side of the

operating pressures up to 75 PSIG. These float and thermostatic steam trap (there are two inlet ports at top and two outlet

traps are used for lower pressure HVAC and light industrial process ports at bottom)

applications. They are used on unit heaters, water heaters,

pressing machines, heat exchangers and coils. For drip • F&T traps have excellent air handling capability allows

applications, such as draining steam mains and steam supply air to be discharged rapidly and steam to enter the system

lines, use 3/4” FT-075 (FT73-075-13-N). F&T traps have quickly during start-up

excellent air-handling capability, which make them a better • Welded stainless steel thermostatic air vent resists shock

choice than Inverted Bucket traps for most process applications. from waterhammer

FT Series traps have a dual inlet-outlet H-Pattern connection • In-line repairable (all internals are attached to cover)

allowing for additional flexibility in installation.

Installation and Maintenance

How It Works

The trap must be installed upright and level for the float

Float and thermostatic traps contain a float and seat mechanism mechanism to operate properly. All internal components

with a separate thermostatic element which work together to can be replaced with the trap body piped in-line. Repair

remove both condensate and air from the steam system. The kit includes thermostatic element, valve seat and disc, float

float, which is attached to a valve, rises and opens the valve and sealing gasket.

when condensate enters the trap. This allows the condensate to

discharge. Air is discharged through the thermostatic air vent to

the outlet side of the trap. Steam entering the trap causes the Helpful Selection Information

thermostatic element to expand, closing the air vent and Select a model that can handle the maximum working pressure

trapping the steam. of the steam system. For example, the FT3-015 has a maximum

working pressure of 15 PSI. Consult capacity tables to properly

Sample Specification size unit. Available in 3/4” through 2” NPT connections. Select

these models for steam systems with maximum working pressure

The trap shall be of float and thermostatic design with cast of 75 PSIG.

iron body. Thermostatic element to be welded stainless steel.

Float and seating material to be stainless steel. Trap must

be in-line repairable.

Demonstration of H-Style piping connections:

Plugged Plugged

Inlet Inlet

Outlet

Plugged Plugged

Outlet

Inlet

Plugged Plugged

Inlet

Plugged Plugged

Outlet Outlet

82 www.watsonmcdaniel.com •• Pottstown PA • USA • Tel: 610-495-5131

Steam Traps FT Series

STEAM TRAPS

Float & Thermostatic Steam Trap Float & Thermostatic

C

A

E

inlet inlet

B

D

outlet outlet

DIMENSIONS & WEIGHTS – inches/pounds M AT E R I A L S

Model A B C D E Weight Body & Cover Cast Iron, ASTM A-126 Class B

FT-3, FT-4, FT-33 Nuts & Bolts High-Tensile Steel

FT-34, FT-73, FT-74 4.125 5.00 5.125 3.125 2.75 7.50

Gasket Grafoil/Garlock

FT-6, FT-35, FT-36 5.00 6.81 6.47 4.125 3.43 13.0 Float Stainless Steel

FT-75, FT-76

FT-7, FT-37L, FT-77L 6.375 7.68 8.218 5.25 4.41 21.0

Valve & Seat Stainless Steel

Thermostatic Assembly Stainless Steel Bellows & Valve

FT-8, FT-38, FT-78 6.50 11.0 8.968 7.468 4.531 40.0

FT-S8-15, FT-S8-75

How to Size / Order

The maximum operating pressure (PMO) rating of model selected must meet or exceed the maximum steam pressure or the trap may not open. For

example; the FT-35-030 has a PMO of 30 psi. For drip applications, a 3/4” FT size is sufficient to exceed warm-up loads with a 2X safety factor.

The condensate loads (lbs/hr) for process applications are normally calculated at the maximum steam pressure; then a safety margin is applied in

order to select a trap with sufficient capacity at lower pressures. Reference full explanation of Safety Load Factors in Steam Traps Introduction section.

For Example: Process application has a maximum steam inlet pressure of 50 psi, a maximum condensate load of 1,700 lbs/hr and is

discharging to a condensate return line with a possible back pressure of 10 psig. ΔP = 50-10 = 40 PSI

To select trap: If the Safety Load Factor is chosen to be 2X max capacity at max differential pressure, then Trap should be selected based on

3,400 lbs/hr (1,700 x 2 = 3,400) at 40 PSI differential pressure with a PMO in excess of 50 PSIG

Selection: FT77L-075-16-N, PMO=75 PSIG, 11/2” NPT with a condensate capacity of 3,750 lbs/hr at 40 PSI differential pressure.

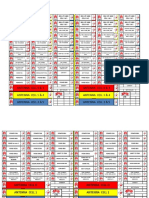

C A PA C I T I E S – Condensate (lbs/hr)

PMO Pipe Orifice ΔP = Differential Pressure (PSI)

Model Code (PSIG) Size Size 1/4 1/2 1 2 3 5 10 15 20 25 30 40 50 60 75

FT3-015-13-N 15 3/4” 9/32” 340 440 600 830 990 1280 1790 2150

FT4-015-14-N 15 1” 9/32” 340 440 600 830 990 1280 1790 2150

FT6-015-15-N 15 11/4” 25/64” 850 1100 1460 2000 2350 2950 4000 4800

FT7-015-16-N 15 11/2” 1/2” 1300 1700 2050 2550 2900 3500 4400 5300

FT8-015-17-N 15 2” 21/32” 2500 3150 4000 5700 6100 6800 8300 9800

FTS8-015-17-N 15 2” 15/16” 4400 5850 7400 9200 10300 12600 15300 18100

FT33-030-13-N 30 3/4” 11/64” 220 300 405 530 650 890 1210 1485 1705 1865 2010

FT34-030-14-N 30 1” 11/64” 220 300 405 530 650 890 1210 1485 1705 1865 2010

FT35-030-14-N 30 1” 1/4” 450 600 880 1205 1420 1845 2560 3230 3715 4100 4405

FT36-030-15-N 30 11/4” 1/4” 450 600 880 1205 1420 1845 2560 3230 3715 4100 4405

FT37L-030-16-N 30 11/2” 7/16” 600 800 1200 1680 2210 2600 3500 4500 5200 5700 6100

FT38-030-17-N 30 2” 13/32” 1550 2045 2625 3560 4260 5660 7890 9440 10500 11360 12095

FT73-075-13-N 75 3/4” 9/64” 140 195 265 360 430 580 770 990 1110 1210 1290 1430 1560 1680 1830

FT74-075-14-N 75 1” 9/64” 140 195 265 360 430 580 710 990 1110 1210 1290 1430 1560 1680 1830

FT75-075-14-N 75 1” #16 270 360 485 660 780 1020 1430 1740 1980 2200 2420 2670 2910 3135 3370

FT76-075-15-N 75 11/4” #16 270 360 485 660 780 1020 1430 1740 1980 2200 2420 2670 2910 3135 3370

FT77L-075-16-N 75 11/2” 5/16” 340 460 690 900 1200 1400 1900 2350 2700 3000 3250 3750 4150 4500 4700

FT78-075-17-N 75 2” 5/16” 800 1075 1300 1700 2000 2600 3750 4350 4700 5050 5400 5960 6500 6950 7550

FTS8-075-17-N 75 2” 13/32” 1360 1800 2100 2800 3300 4300 6300 7300 8000 8500 9000 10000 11000 11600 12500

Tel: 610-495-5131 • Pottstown PA • USA •• www.watsonmcdaniel.com 83

You might also like

- Cat C15Document6 pagesCat C15Y.Ebadi50% (2)

- Send An HTML Email Using CL - BCS ClassDocument6 pagesSend An HTML Email Using CL - BCS Classa3scribd100% (1)

- PRO 1R - Italy PDFDocument2 pagesPRO 1R - Italy PDFShishan AhmadNo ratings yet

- FTT FTTS SteamTrapDocument3 pagesFTT FTTS SteamTrapauxiliar.termicaNo ratings yet

- Trampas de Vapor FFTDocument5 pagesTrampas de Vapor FFTAndrés ChuquillaNo ratings yet

- Trampadevapor Flotador y TermostaticaDocument9 pagesTrampadevapor Flotador y TermostaticaLuis Gutiérrez AlvarezNo ratings yet

- Dae 15 Y764Document4 pagesDae 15 Y764Gerber GarciaNo ratings yet

- Serie WFTDocument3 pagesSerie WFTarmandolea.ventasNo ratings yet

- Steam Control Products: Inverted Bucket Float & Thermostatic Radiator TrapsDocument20 pagesSteam Control Products: Inverted Bucket Float & Thermostatic Radiator TrapssdvitkoNo ratings yet

- Commercial Heavy Duty Water Heater With Surface Mount ThermostatsDocument4 pagesCommercial Heavy Duty Water Heater With Surface Mount Thermostatsfirefightermanta31No ratings yet

- 181-1-2 Water Motor GongDocument2 pages181-1-2 Water Motor GongCkaal74No ratings yet

- WT4000 SteamTrapDocument2 pagesWT4000 SteamTrapdanielaNo ratings yet

- 113 12 - Phe - Brochure PDFDocument6 pages113 12 - Phe - Brochure PDFLe Quang SonNo ratings yet

- AI - Automatic Air Vent (Stainless Steel)Document1 pageAI - Automatic Air Vent (Stainless Steel)Rakhmad sugih hartonoNo ratings yet

- TEV Ammonia SporlanDocument5 pagesTEV Ammonia SporlanDrew CruzNo ratings yet

- IB SERIES Inverted Bucket Steam TrapDocument6 pagesIB SERIES Inverted Bucket Steam TrapThanh ThuNo ratings yet

- Dre 120Document4 pagesDre 120Gesiel SoaresNo ratings yet

- 880 Series Inverted Bucket Steam TrapsDocument2 pages880 Series Inverted Bucket Steam TrapsCherbee FerrerNo ratings yet

- Super Heater SH-series Operation Manual: For PreservationDocument8 pagesSuper Heater SH-series Operation Manual: For PreservationSanjay SharmaNo ratings yet

- Bell & Gossett: Valve KitsDocument2 pagesBell & Gossett: Valve KitsOrson LouNo ratings yet

- TFP725 08 2016Document8 pagesTFP725 08 2016Jun AntonioNo ratings yet

- PDS-3000 LitersDocument1 pagePDS-3000 LitersAslamNo ratings yet

- Float & Thermostatic Steam Traps: For Efficient Condensate Drainage of Industrial Process and HVAC EquipmentDocument12 pagesFloat & Thermostatic Steam Traps: For Efficient Condensate Drainage of Industrial Process and HVAC Equipmentmember1000No ratings yet

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- 3908 SL DatasheetDocument2 pages3908 SL DatasheetspammaniiNo ratings yet

- Issued For Tender - ARCH - 2023.11.06Document4 pagesIssued For Tender - ARCH - 2023.11.06Youngjae YJ Theodore SongNo ratings yet

- Maltec H Air Finned Heater DpstarGroup 1Document4 pagesMaltec H Air Finned Heater DpstarGroup 1Vũ Hoàng BáchNo ratings yet

- FT Pitot Type LDocument4 pagesFT Pitot Type L31011987No ratings yet

- NewT DYNAMODocument22 pagesNewT DYNAMOAbdul KurniadiNo ratings yet

- Válvula de Cuchillo Ac CarbonoDocument2 pagesVálvula de Cuchillo Ac CarbonoEme Eme LorcaNo ratings yet

- Lecture 69 - Hydroelectric Powerplants Construction Operations Failures 12 April 12 Hans Olav Nyland Norconsult PDFDocument50 pagesLecture 69 - Hydroelectric Powerplants Construction Operations Failures 12 April 12 Hans Olav Nyland Norconsult PDFshadow friendNo ratings yet

- Seriestvs 4000Document4 pagesSeriestvs 4000Jimit ShahNo ratings yet

- DS2002 32way EU ENDocument4 pagesDS2002 32way EU ENMuchamad Fajar NugrohoNo ratings yet

- Agitator Cartridge Seals: Applications Operating ConditionsDocument6 pagesAgitator Cartridge Seals: Applications Operating ConditionsHaabin EngineerNo ratings yet

- Boiler For PresentationDocument72 pagesBoiler For PresentationBSP CDCPNo ratings yet

- ENGLISH Presentation TECPESA 2014 PDFDocument50 pagesENGLISH Presentation TECPESA 2014 PDFalexandermattos8513No ratings yet

- Inst. ManualDocument8 pagesInst. ManualHamoud Al khayatiNo ratings yet

- Ficha Tecnica Amstrong.1Document2 pagesFicha Tecnica Amstrong.1ANo ratings yet

- Stamp: Before You ItDocument6 pagesStamp: Before You ItaqhammamNo ratings yet

- Fpe 1 2 Válvula TermostáticaDocument6 pagesFpe 1 2 Válvula TermostáticamarbbanNo ratings yet

- Fte S F & T S T: Eries Loat Hermostatic Team RapsDocument4 pagesFte S F & T S T: Eries Loat Hermostatic Team RapsAlvaro Yaciel Rodríguez LagunesNo ratings yet

- Eaton Fuel HoseDocument6 pagesEaton Fuel HoseKeron TrotzNo ratings yet

- Davey Xp350p8cDocument2 pagesDavey Xp350p8cNum470% (1)

- Moisture ControlDocument34 pagesMoisture ControlYogesh YadavNo ratings yet

- Circulation Heaters: Standard Product RangesDocument3 pagesCirculation Heaters: Standard Product RangesDavid NguyenNo ratings yet

- AV2000 ThermostaticAirVentDocument1 pageAV2000 ThermostaticAirVentauxiliar.termicaNo ratings yet

- 29-New T-DYNAMODocument22 pages29-New T-DYNAMOHeru SACNo ratings yet

- H-1 HoseDocument8 pagesH-1 HoseValentin A.No ratings yet

- WB March 2004Document8 pagesWB March 2004Caterine Jara CeaNo ratings yet

- Float Type Level SwitchDocument8 pagesFloat Type Level SwitchRupesh Kumar SINGHNo ratings yet

- Datasheet E Thermostatic Valve 0612 Rev8Document10 pagesDatasheet E Thermostatic Valve 0612 Rev8Mohamed AhteewishNo ratings yet

- Enercon Blown Ion Quickstart GuideDocument4 pagesEnercon Blown Ion Quickstart GuideAndres Conejo VargasNo ratings yet

- Steam Trap Air TrapDocument52 pagesSteam Trap Air TrapHung Quoc DangNo ratings yet

- Three-Way Thermostatic Valve: SelectionDocument2 pagesThree-Way Thermostatic Valve: SelectionRoshaniNo ratings yet

- Condensing Commercial Gas Water HeatersDocument4 pagesCondensing Commercial Gas Water HeatersAnonymous 7xHNgoKE6eNo ratings yet

- Manguera Calefactora Tempco PDFDocument2 pagesManguera Calefactora Tempco PDFErick MüllerNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- Hot Tapping On Operating LinesDocument20 pagesHot Tapping On Operating LinesCelestine Ozokechi100% (1)

- How Steam Trap WorkDocument40 pagesHow Steam Trap Workdeny prasyamtyo100% (1)

- Yoshitake Steam Trap PDFDocument40 pagesYoshitake Steam Trap PDFDeni SuryaNo ratings yet

- Burkert DS2100-Weldend-EU-ENDocument17 pagesBurkert DS2100-Weldend-EU-ENmike karaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Low Pressure Second Stage Regulators LV5503B Series: Materials ApplicationDocument1 pageLow Pressure Second Stage Regulators LV5503B Series: Materials ApplicationMarcos Mezahuaman LaimeNo ratings yet

- Mindman MUSDocument1 pageMindman MUSMarcos Mezahuaman LaimeNo ratings yet

- V4055A, B, D, E On-Off Fluid Power Gas Valve Actuator: ApplicationDocument8 pagesV4055A, B, D, E On-Off Fluid Power Gas Valve Actuator: ApplicationMarcos Mezahuaman LaimeNo ratings yet

- Ficha Técnica TD600Document2 pagesFicha Técnica TD600Marcos Mezahuaman LaimeNo ratings yet

- Microwave Sensor Technology HFE0407 - PolivkaDocument8 pagesMicrowave Sensor Technology HFE0407 - Polivkatecnolectronica890No ratings yet

- Acer X213H (X223HQ) Service GuideDocument48 pagesAcer X213H (X223HQ) Service GuideCarlos GomesNo ratings yet

- Before You Upgrade: User Manual For Philips/Magnavox DVD Recorder Upgrade DiscsDocument4 pagesBefore You Upgrade: User Manual For Philips/Magnavox DVD Recorder Upgrade DiscseasyyuNo ratings yet

- Open Positions Accross CGIDocument4 pagesOpen Positions Accross CGIejazahmednitNo ratings yet

- Datasheet External Antenna 2000 - Alpha-Con-V7Document4 pagesDatasheet External Antenna 2000 - Alpha-Con-V7Bravemon23No ratings yet

- Nagcarlan Floor PlanDocument11 pagesNagcarlan Floor PlanEngr. Christopher Lennon Dela CruzNo ratings yet

- Co-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Department of Information Technology ApprovalDocument4 pagesCo-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Department of Information Technology ApprovalSenthil RNo ratings yet

- PDFDocument11 pagesPDFIvan JugovicNo ratings yet

- Cit 305Document153 pagesCit 305Temiloluwa Ibrahim100% (1)

- Free YouTube To MP3 Converter 2021 Crack Serial KeygenDocument3 pagesFree YouTube To MP3 Converter 2021 Crack Serial KeygenJohn ShipNo ratings yet

- Revit Paint Tool ParameterDocument4 pagesRevit Paint Tool ParameterI Gede Bayu Chandra NathaNo ratings yet

- Article 2Document6 pagesArticle 2Mugaahed FutaahyNo ratings yet

- Data MiningDocument3 pagesData MiningUdit SinghalNo ratings yet

- Intro ERP Using GBI Slides SD en v2 01 ARISDocument49 pagesIntro ERP Using GBI Slides SD en v2 01 ARISAshisRanjan100% (1)

- Label Multisektor L1800 GabungDocument5 pagesLabel Multisektor L1800 Gabungbiru advertisingNo ratings yet

- ABB-RingCore-przekladniki EN - 13-06Document16 pagesABB-RingCore-przekladniki EN - 13-06TetianaNo ratings yet

- 9608 - s19 - QP - 21 PaperDocument16 pages9608 - s19 - QP - 21 Paperfaizan majidNo ratings yet

- Center of MassDocument27 pagesCenter of Massm 418No ratings yet

- Microsoft SQL Server 2019: Licensing GuideDocument38 pagesMicrosoft SQL Server 2019: Licensing GuidemistersatNo ratings yet

- Technical Data and Dimension Sheets For MOVIMOTDocument107 pagesTechnical Data and Dimension Sheets For MOVIMOTTuk GNo ratings yet

- Farana F-15 Daily and Weekly ChecksDocument7 pagesFarana F-15 Daily and Weekly Checksshakti123456789No ratings yet

- B31.3 Process Piping Course - 06 Flexibility Analysis For IntroDocument10 pagesB31.3 Process Piping Course - 06 Flexibility Analysis For IntroRyan Goh Chuang HongNo ratings yet

- AEMS. Smartsense Advanced Energy Management SystemDocument19 pagesAEMS. Smartsense Advanced Energy Management SystemPankajP.SolankiNo ratings yet

- SLA PresentationDocument48 pagesSLA Presentationandy_klNo ratings yet

- Linux System AdministrationDocument15 pagesLinux System AdministrationdanilaixNo ratings yet

- OFA-CF - Workbook - PreWeek - Day 1Document13 pagesOFA-CF - Workbook - PreWeek - Day 1beanbeanNo ratings yet

- Preventive Maintenance Using Reliability Centred MDocument29 pagesPreventive Maintenance Using Reliability Centred MGiovanni GiudiceNo ratings yet

- Software Ri 1112Document48 pagesSoftware Ri 1112Javier BosigasNo ratings yet