Professional Documents

Culture Documents

20-ME-9 Uzair Akram FM Lab 11

20-ME-9 Uzair Akram FM Lab 11

Uploaded by

uzair akramOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20-ME-9 Uzair Akram FM Lab 11

20-ME-9 Uzair Akram FM Lab 11

Uploaded by

uzair akramCopyright:

Available Formats

Lab Manual Course Title: Fluid Mechanics Lab

FLUID MECHANICS LAB

Experiment No.11

Submitted By: Uzair Akram

Reg. No.: 20-ME-9

Date: 20-12-2021

Section: A1

Submitted To: Engr Abdul Rehman

Mechanical Engineering Department

Faculty of Mechanical & Aeronautical Engineering

University of Engineering & Technology Taxila

Lab Title: Fluid Mechanics 1

Lab Manual Course Title: Fluid Mechanics Lab

EXPERIMENT NO.11

TITLE: -

To study and draw characteristic curves of Francis Turbine

THEORY: -

Turbines:

Turbine is a device that convert the energy in a stream of fluid into mechanical energy.

The conversion is generally accomplished by passing the fluid through a system of stationary

passages or vanes that alternate with passages consisting of finlike blades attached to a rotor.

By arranging the flow so that a tangential force, or torque, is exerted on the rotor blades, the

rotor turns, and work is extracted.

There are two types of turbines.

Impulse Turbine

Reaction Turbine

But here we would just talk about reaction turbine because Francis Turbine is a reaction

turbine,

Reaction Turbine:

If the sum of potential energy and kinetic energy of water which are due to the pressure and

velocity, respectively cause the turbine blades to rotate, the turbine is classified as a reaction

turbine. In these types of turbines, the entire turbine is immersed in water and changes in

water pressure along with the kinetic energy of the water cause power exchange.

Major parts of reaction turbine are as follows:

Spiral Casing

Guide Mechanism

Turbine Runner

Draft Tube

Summary:

Reaction turbines exploit the oncoming flow of water to generate hydrodynamic lift forces to

propel the runner blades. They are distinguished from the impulse type by having a runner

that always functions within a completely water-filled casing. All reaction turbines have a

diffuser known as a ‘draft tube’ below the runner through which the water discharges. The

draft tube slows the discharged water and so creates suction below the runner which

increases the effective head. Propeller-type turbines are similar in principle to the propeller

of a ship, but operating in reversed mode. A set of inlet guide vanes admits the flow to the

propeller and these are often adjustable so as to allow the flow passing through the machine

to be varied. In some cases the blades of the runner can also be adjusted, in which case the

turbine is called a Kaplan. The mechanics for adjusting turbine blades and guide vanes can

be costly and tend to be more affordable for large systems, but can greatly improve

efficiency over a wide range of flows. The Francis turbine is essentially a modified form of

propeller turbine in which water flows radially inwards into the runner and is turned to

emerge axially. For medium-head schemes, the runner is most commonly mounted in a spiral

Lab Title: Fluid Mechanics 2

Lab Manual Course Title: Fluid Mechanics Lab

casing with internal adjustable guide vanes. Since the cross-flow turbine is now a less costly

(though less efficient) alternative to the spiral-case Francis, it is rare for these turbines to be

used on sites of less than 100 kW output.

APPARATUS: -

1. Electric Supply

2. Supply Tank

3. Submersible Tank

4. Supply Line of water

5. Francis Turbine Model (HM-150.20)

6. Stopwatch

7. Measuring Tank

PROCEDURE: -

1. First, take the Francis Turbine Model (HM-150.20) and place it on basic

Hydraulic Bench.

2. The water supply and flow rate measurements are produced via HM-150.

3. Turbine torque is measured using band brake and is read on spring balance.

4. A non-contact speed sensor(tachometer) is used to measure the rotational speed

of turbine.

5. A manometer shows the water pressure at the turbine inlet.

Lab Title: Fluid Mechanics 3

Lab Manual Course Title: Fluid Mechanics Lab

6. Measure the breaking force with help of the scale on the band.

7. Take coordinate reading and plot the graph.

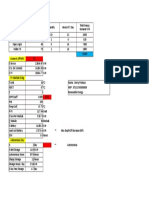

TABLE: -

Sr. Speed Net Force Head Torque Output Power Input Power Efficiency=

No. RPM = F1-F2 Pressur T =FxD 2 πNT =VxPx105 input/Output

=M ×

“N” “Newton” e “Nm” 60 1000x60 “”

P “Bar” “Watt” “Watt”

01 2270 0 0.5 0 0 48.33 0

02 1815 0.5 0.47 0.0125 2.37 45.43 5.22%

03 1435 1 0.42 0.025 3.75 40.6 9.23%

04 1125 1.5 0.40 0.0375 4.41 38.66 11.40%

05 855 2.0 0.38 0.05 4.47 36.73 12.16%

06 551 2.4 0.38 0.06 3.46 36.73 9.42%

07 255 2.7 0.4 0.0675 1.80 38.66 4.65%

Volume V = 58 liters

Time T = 1 min

P ×V ×10 5

P¿ = Watt

1000 ×60

2π × N×T

Pout = Watt

60

For 1:

5

0.5× 58× 10

P¿ = Watt

1000 ×60

P¿ =48.33 Watt

2 π × 2270× 0

Pout = Watt

60

Pout =0 Watt

For 2:

0.47× 58 ×105

P¿ = Watt

1000 ×60

Lab Title: Fluid Mechanics 4

Lab Manual Course Title: Fluid Mechanics Lab

P¿ =45.43 Watt

2 π × 1815× 0.0125

Pout = Watt

60

Pout =2.37 Watt

For 3:

0.42×58 × 105

P¿ = Watt

1000 ×60

P¿ =40.6 Watt

2 π × 1435× 0.025

Pout = Watt

60

Pout =3.75Watt

For 4:

5

0.40× 58× 10

P¿ = Watt

1000 ×60

P¿ =38.66 Watt

2 π × 1125× 0.0375

Pout = Watt

60

Pout =4.41 Watt

For 5:

0.38× 58× 105

P¿ = Watt

1000 ×60

P¿ =36.73 Watt

2 π × 855 ×0.5

Pout = Watt

60

Lab Title: Fluid Mechanics 5

Lab Manual Course Title: Fluid Mechanics Lab

Pout =4.47 Watt

For 6:

5

0.38× 58× 10

P¿ = Watt

1000 ×60

P¿ =36.73 Watt

2 π × 551× 0.06

Pout = Watt

60

Pout =3.46Watt

For 7:

5

0.4 ×58 ×10

P¿ = Watt

1000 ×60

P¿ =38.66 Watt

2 π × 255× 0.0675

Pout = Watt

60

Pout =1.80Watt

GRAPHS: -

Speed VS Output power

Lab Title: Fluid Mechanics 6

Lab Manual Course Title: Fluid Mechanics Lab

Speed VS Output Power

5

4.5

3.5

2.5

1.5

0.5

0

0 500 1000 1500 2000 2500

Speed VS Torque

Speed VS Torque

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

0 500 1000 1500 2000 2500

Speed VS Efficiency

Lab Title: Fluid Mechanics 7

Lab Manual Course Title: Fluid Mechanics Lab

Speed VS Effi ciency

14

12

10

0

0 500 1000 1500 2000 2500

CONCLUSION: -

In this lab, we learned how to find the efficiency of the Francis Turbine. We learned how the

Francis turbine works. We also learned to calculate the input and output powers of the

Francis turbine, From the calculations and the graphical analysis, we come to know that at a

certain speed, the output power is maximum and hence the efficiency of the turbine is

maximum which is given as a hump on the graph. Before this point, efficiency increases and

after this point efficiency decreases.

Taxonomy Contributio Max. Obtained

Knowledge components Domain

level n marks marks

1. Student has conducted the Psychomoto

Precision (P3) 60% 15

experiment by practicing the r

Lab Title: Fluid Mechanics 8

Lab Manual Course Title: Fluid Mechanics Lab

hands on skills.

2. Student has achieved

required accuracy in

performance.

3. Student has contributed or

responded affectively in form Affective Respond (A2) 20% 5

of group or team.

4. Student has knowledge

regarding the experiment and

successfully applied the input Cognitive Apply (C3) 20% 5

values for required

calculations.

Total 25

Experiment Title: To study and draw characteristic curves of Francis Turbine

Course title: Fluid Mechanics Lab Total Marks: ___________

Practical No. 11 Date of experiment performed: 13-12-2021

Course teacher/Lab Instructor: Engr. Abdul Rehman Date of marking: ____________

Student Name: Uzair Akram

Registration no:20-ME-9

Marking Evaluation Sheet

Signed by Course teacher/ Lab Instructor

Lab Title: Fluid Mechanics 9

You might also like

- TME2135-Lab - Manual - (Characteristics of Centrifugal Pump)Document2 pagesTME2135-Lab - Manual - (Characteristics of Centrifugal Pump)Qiao YuNo ratings yet

- Centrifugal Pump Problems Part 1Document16 pagesCentrifugal Pump Problems Part 1Bandaiah GNNo ratings yet

- Pelton Wheel Lab Report Revised SDocument12 pagesPelton Wheel Lab Report Revised STalha100% (1)

- Pelton & Francis TurbinesDocument37 pagesPelton & Francis TurbinesIkhwan Z.100% (11)

- Atkinson Cycle ILPDocument16 pagesAtkinson Cycle ILPDzulkiflee Hj HamdanNo ratings yet

- CH 7 PowerCyclesDocument12 pagesCH 7 PowerCyclescarleston thurgoodNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 12Document10 pages20-ME-9 Uzair Akram FM Lab 12uzair akramNo ratings yet

- Ce411 Ce42s1 Experiment3 PDFDocument12 pagesCe411 Ce42s1 Experiment3 PDFyumi castroNo ratings yet

- Hydraulics Engineering: Technological Institute of The Philippines 1338 Arlegui Street, Quiapo, ManilaDocument12 pagesHydraulics Engineering: Technological Institute of The Philippines 1338 Arlegui Street, Quiapo, ManilaRams GensanNo ratings yet

- Title of ExperimentDocument19 pagesTitle of ExperimentLi Xian YongNo ratings yet

- University of Khartoum Francis Turbine Report: IntroductionDocument5 pagesUniversity of Khartoum Francis Turbine Report: IntroductionAhmed ElnemaNo ratings yet

- Experiment # 3: Objective:: Fig: 3.1 (Pelton Wheel Turbine)Document3 pagesExperiment # 3: Objective:: Fig: 3.1 (Pelton Wheel Turbine)waseemjuttNo ratings yet

- MELAB3 Experiment 2Document18 pagesMELAB3 Experiment 2Russelle GoNo ratings yet

- Chap 4 5 2Document49 pagesChap 4 5 2John Jacob TandangNo ratings yet

- Pelton TurbineDocument13 pagesPelton TurbineHitarth ShahNo ratings yet

- Pelton Turbine: Experiment - 5Document8 pagesPelton Turbine: Experiment - 5gebremariam birkieNo ratings yet

- Micro Hydro Elective III - BEL SEM VIII Tutorial 3Document5 pagesMicro Hydro Elective III - BEL SEM VIII Tutorial 3PRAKASH POKHRELNo ratings yet

- 4 ProblemsDocument17 pages4 ProblemsJairo Fernandez100% (1)

- 20-ME-9 Uzair Akram FM Lab 10Document7 pages20-ME-9 Uzair Akram FM Lab 10uzair akramNo ratings yet

- Performance Test of Series Centrifugal Pumps With Same CharacteristicsDocument7 pagesPerformance Test of Series Centrifugal Pumps With Same CharacteristicsPrecious Gallardo DerainNo ratings yet

- Performance Test of Series Centrifugal Pumps With Same CharacteristicsDocument7 pagesPerformance Test of Series Centrifugal Pumps With Same CharacteristicsPrecious Gallardo DerainNo ratings yet

- Lab (Rankie Cycle)Document15 pagesLab (Rankie Cycle)smisosphamandla30No ratings yet

- ch04 PDFDocument19 pagesch04 PDFAkash Thummar100% (3)

- Lab Report 05: Course Title: Electrical Circuit Lab Course Code: CSE 122Document11 pagesLab Report 05: Course Title: Electrical Circuit Lab Course Code: CSE 122Asis PalNo ratings yet

- Pelton Wheel Lab ReportDocument10 pagesPelton Wheel Lab ReportTalhaNo ratings yet

- PP Lab Reports - Steam Power PlantDocument5 pagesPP Lab Reports - Steam Power PlantMuhammad Waleed TariqNo ratings yet

- Reciprocating PumpDocument4 pagesReciprocating PumpMohamed HassanNo ratings yet

- Per-Unit System of MeasurementDocument9 pagesPer-Unit System of MeasurementAjimNo ratings yet

- Electric Heaters, Reactor and FlashdrumDocument17 pagesElectric Heaters, Reactor and FlashdrumAlnie Albaran DemoralNo ratings yet

- Exp 11 21110006 CL352Document7 pagesExp 11 21110006 CL352Abhinav AnandNo ratings yet

- Lab 5 - Pelton TurbineDocument3 pagesLab 5 - Pelton TurbineChuck CooleyNo ratings yet

- CH 7Document127 pagesCH 7qusayNo ratings yet

- Pelton TurbineDocument5 pagesPelton TurbineWaleed NasirNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 9Document7 pages20-ME-9 Uzair Akram FM Lab 9uzair akramNo ratings yet

- Chain Test RigDocument6 pagesChain Test RigService MMINo ratings yet

- Physics 41 Chapter 22 HW Serway 7 EditionDocument7 pagesPhysics 41 Chapter 22 HW Serway 7 EditionCantalicioNo ratings yet

- Piston Pumps Formulas - enDocument10 pagesPiston Pumps Formulas - ensivakumar subramanianNo ratings yet

- I C Engines NumericalsDocument28 pagesI C Engines NumericalsPrateek ridersNo ratings yet

- Study of Center of Pressure: Etsc 3142 - Fluid MechanicsDocument4 pagesStudy of Center of Pressure: Etsc 3142 - Fluid MechanicsNa Lin AbeyNo ratings yet

- 14 Electrical CircuitsDocument19 pages14 Electrical CircuitsApplicable AppleNo ratings yet

- Experiment 3Document4 pagesExperiment 3Na Lin AbeyNo ratings yet

- Study of Center of Pressure: Etsc 3142 - Fluid MechanicsDocument4 pagesStudy of Center of Pressure: Etsc 3142 - Fluid MechanicsNa Lin AbeyNo ratings yet

- ELEN 30104 Polyphase Induction MotorDocument20 pagesELEN 30104 Polyphase Induction MotorBu DakNo ratings yet

- Magnetic Circuits: 1. (30pts.) The Core Shown Below Has Two Coils of N Turns Each Connected So TheDocument6 pagesMagnetic Circuits: 1. (30pts.) The Core Shown Below Has Two Coils of N Turns Each Connected So TheSaied Aly SalamahNo ratings yet

- Me 142l b39 Reyes Exp 5Document10 pagesMe 142l b39 Reyes Exp 5Cyrus ReyesNo ratings yet

- Chapter 7 Hydro-MechanicalDocument14 pagesChapter 7 Hydro-MechanicalSujan Singh100% (1)

- Applied Electricity 2, Experiment 6Document14 pagesApplied Electricity 2, Experiment 6Tech TucksNo ratings yet

- Exp 11Document8 pagesExp 11Eng TariqNo ratings yet

- Centrifual Pump Group Technical ReportDocument16 pagesCentrifual Pump Group Technical ReportAnele HadebeNo ratings yet

- Autonomous and Sizing PVDocument1 pageAutonomous and Sizing PVIik Nurul IkhsanNo ratings yet

- Unit 6Document30 pagesUnit 6Utkarsh KumarNo ratings yet

- รวมดาวCDocument22 pagesรวมดาวCD 9No ratings yet

- Temperauture.: Prob. Solution: GivenDocument9 pagesTemperauture.: Prob. Solution: Givenharsh patelNo ratings yet

- Monteron Jaji C3Document18 pagesMonteron Jaji C3John Lloyd TulopNo ratings yet

- Verification of Thevenin'S Theorem & Maximum Power Transfer: Eeen 311 Experiment 1Document9 pagesVerification of Thevenin'S Theorem & Maximum Power Transfer: Eeen 311 Experiment 1masateeNo ratings yet

- CSTR FinalDocument5 pagesCSTR FinalHaile S. GebrehiwetNo ratings yet

- Thermal Engg and Fluid Machinery PracticalDocument7 pagesThermal Engg and Fluid Machinery PracticalSwarnaNo ratings yet

- Electrical Machines LabDocument8 pagesElectrical Machines LabrabbystarNo ratings yet

- SOM Lab EXP7Document8 pagesSOM Lab EXP7Amisha SharonNo ratings yet

- Siklus OttoDocument2 pagesSiklus Ottomuhammadalamin131203No ratings yet

- Thermodynamics Manual 9Document7 pagesThermodynamics Manual 9uzair akramNo ratings yet

- Lab 6 ADocument4 pagesLab 6 Auzair akramNo ratings yet

- Driving LicenseDocument1 pageDriving Licenseuzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 13Document12 pages20-ME-9 Uzair Akram FM Lab 13uzair akramNo ratings yet

- Internship Letter 2023 FinalDocument1 pageInternship Letter 2023 Finaluzair akramNo ratings yet

- Uzair AkramDocument2 pagesUzair Akramuzair akramNo ratings yet

- Thermodynamics Manual 7Document4 pagesThermodynamics Manual 7uzair akramNo ratings yet

- Qasim Ali Resume - Mechanical UET LHRDocument1 pageQasim Ali Resume - Mechanical UET LHRuzair akramNo ratings yet

- Experiment No. 6: Title: ObjectiveDocument6 pagesExperiment No. 6: Title: Objectiveuzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 6Document7 pages20-ME-9 Uzair Akram FM Lab 6uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 10Document7 pages20-ME-9 Uzair Akram FM Lab 10uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 7Document8 pages20-ME-9 Uzair Akram FM Lab 7uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 14Document12 pages20-ME-9 Uzair Akram FM Lab 14uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 12Document10 pages20-ME-9 Uzair Akram FM Lab 12uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 4Document8 pages20-ME-9 Uzair Akram FM Lab 4uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 3Document5 pages20-ME-9 Uzair Akram FM Lab 3uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 8Document7 pages20-ME-9 Uzair Akram FM Lab 8uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 2Document5 pages20-ME-9 Uzair Akram FM Lab 2uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 9Document7 pages20-ME-9 Uzair Akram FM Lab 9uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 5Document8 pages20-ME-9 Uzair Akram FM Lab 5uzair akramNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 1Document9 pages20-ME-9 Uzair Akram FM Lab 1uzair akramNo ratings yet

- Heat Balance SheetDocument5 pagesHeat Balance SheetNiteesh Dua0% (1)

- E401 1000 Air Cooled CondensersDocument4 pagesE401 1000 Air Cooled CondensersNguyen Anh TuanNo ratings yet

- Inspection Report RO Plant 17-02-22Document2 pagesInspection Report RO Plant 17-02-22arainzada807No ratings yet

- Calculation Summary - Rev-01.1Document2 pagesCalculation Summary - Rev-01.1RICHARDNo ratings yet

- ME143L - Report 2 - Heat PumpDocument14 pagesME143L - Report 2 - Heat PumpKiel Bernard de Jesus100% (2)

- Midterm Examination Fire Protection and Arson InvestigationDocument2 pagesMidterm Examination Fire Protection and Arson InvestigationRodne Badua RufinoNo ratings yet

- Panasonic 12 V 13 Ah LC R121R3PG BatteryDocument19 pagesPanasonic 12 V 13 Ah LC R121R3PG BatteryGunwant SinghNo ratings yet

- BROCHURE Metel Firepump 2017Document8 pagesBROCHURE Metel Firepump 2017Jakir AhmedNo ratings yet

- 1 Centrifugal TroubleshootingDocument4 pages1 Centrifugal Troubleshootingmohamed elsb3No ratings yet

- String Calculator Morningstar CorporationDocument2 pagesString Calculator Morningstar Corporationrogelio surcoNo ratings yet

- Honeywell 01061GBDocument25 pagesHoneywell 01061GBKyriakos MichalakiNo ratings yet

- Unit-V NcesDocument23 pagesUnit-V NcesMahantesh NyayakarNo ratings yet

- PBD Chapter 6Document17 pagesPBD Chapter 6Aathirah HashimNo ratings yet

- Ramagundam Power PlantDocument38 pagesRamagundam Power PlantMadhu KamshettyNo ratings yet

- Benson BoilerDocument20 pagesBenson BoilerjigsprajapatiNo ratings yet

- Boiler I.B.R. CalculationDocument10 pagesBoiler I.B.R. CalculationGurinder Jit Singh100% (1)

- TNT Equivalence ModelDocument1 pageTNT Equivalence Modelgerri_cumberbatchNo ratings yet

- Highly Rotary Compressor CatalogueDocument16 pagesHighly Rotary Compressor CatalogueMohamed SaidNo ratings yet

- EEI 7FA Supplement r1 2octDocument42 pagesEEI 7FA Supplement r1 2octkshalawi0% (1)

- Stick Hydraulic SystemDocument9 pagesStick Hydraulic SystemWaridi RidiNo ratings yet

- General Introduction To Heat ExchangersDocument11 pagesGeneral Introduction To Heat ExchangersHashem HomadyNo ratings yet

- Calculation For Steam and Hot Water Consumption For: Sun Rise CharmingDocument4 pagesCalculation For Steam and Hot Water Consumption For: Sun Rise CharmingYasser FathiNo ratings yet

- Dual CycleDocument3 pagesDual CycleHazel AdoNo ratings yet

- Screw CompressorDocument2 pagesScrew CompressorsaeidNo ratings yet

- Boilers InfoDocument56 pagesBoilers InfoShafqat AfridiNo ratings yet

- 03 Standard Forms List PDFDocument4 pages03 Standard Forms List PDFShamsul Azhar MohdNo ratings yet

- Boiler Checklist, Unit # 8: Scoop Position/rpmDocument1 pageBoiler Checklist, Unit # 8: Scoop Position/rpmJoydev GangulyNo ratings yet