Professional Documents

Culture Documents

Goal Zero: Zero Injuries, Zero Fatalities

Goal Zero: Zero Injuries, Zero Fatalities

Uploaded by

vikrant911Copyright:

Available Formats

You might also like

- IHS 613 - Assignment 1Document4 pagesIHS 613 - Assignment 1Nurinsyahirah HamzahNo ratings yet

- MMHE Access Card Application Form - Rev2 30.11.22Document2 pagesMMHE Access Card Application Form - Rev2 30.11.22khairul Anwar100% (1)

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Working at Heights Practical ModuleDocument2 pagesWorking at Heights Practical ModuleMadalina FoteaNo ratings yet

- Competency-Based Learning Material (Common Competency)Document45 pagesCompetency-Based Learning Material (Common Competency)ZOOMTECHVOC TRAINING&ASSESSMENT100% (1)

- 001 MEP - Method Floor&Wall PenetrationDocument7 pages001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- Nma100776 O&m-Section 1 PDFDocument23 pagesNma100776 O&m-Section 1 PDFMichael CaoNo ratings yet

- Tyre SafeDocument75 pagesTyre SafetalabiraNo ratings yet

- Vehicle Hoist: Do NotDocument1 pageVehicle Hoist: Do NotChristian MakandeNo ratings yet

- FA5A Winch Part List ManualDocument72 pagesFA5A Winch Part List ManualMohamed AliNo ratings yet

- GrindingDocument50 pagesGrindinggillawatNo ratings yet

- Service Report: Intervantione On TDS Canrig 1250ACDocument1 pageService Report: Intervantione On TDS Canrig 1250ACAbdelghani ZitouniNo ratings yet

- Milling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURDocument5 pagesMilling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURAshok SureshNo ratings yet

- OG7 V3 Prime Mover Inspection Checklist Jun 2015Document2 pagesOG7 V3 Prime Mover Inspection Checklist Jun 2015Asela Bandara100% (1)

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- Standard Operating ProcedureDocument55 pagesStandard Operating Procedureboy tryadi100% (1)

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts FactsheetJafar KhanNo ratings yet

- MS Working at HeightsDocument15 pagesMS Working at HeightsNauval FadliNo ratings yet

- Safety Alert: Driller Inattention Results in Dropped BlocksDocument1 pageSafety Alert: Driller Inattention Results in Dropped Blockscase013No ratings yet

- KingpinDocument2 pagesKingpinNguyễn Hoài NamNo ratings yet

- Sop Piling WorkDocument2 pagesSop Piling WorkamirNo ratings yet

- Ansi Ppe StandardDocument1 pageAnsi Ppe StandardHerwandi Atmaja0% (1)

- SKPB HsemsDocument67 pagesSKPB Hsemsjihad jamareiNo ratings yet

- Punch Press Safety and Operating ProceduresDocument2 pagesPunch Press Safety and Operating ProceduresRAMESH100% (1)

- Safe Work Practice Dozer OperatorsDocument4 pagesSafe Work Practice Dozer OperatorsMuhammad Ashraf AhmadNo ratings yet

- Common Sense of Tyres User ManualDocument9 pagesCommon Sense of Tyres User ManualJohn SimancaNo ratings yet

- MRF-08 - Top Drive GreasingDocument1 pageMRF-08 - Top Drive GreasingAbdul Hameed OmarNo ratings yet

- Form Inspeksi Bar Cutter Bar Bender - Fix (SfileDocument1 pageForm Inspeksi Bar Cutter Bar Bender - Fix (Sfilerajatua dramaga.projectNo ratings yet

- OMHEC Communication Hoisting OperationsDocument20 pagesOMHEC Communication Hoisting OperationsLasse WelleNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDocument5 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNo ratings yet

- Commander Manual TitanDocument40 pagesCommander Manual TitanjohnfcortesNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- FLT Preventive Maintenance Daily Checklist - UPLDocument2 pagesFLT Preventive Maintenance Daily Checklist - UPLMaham QureshiNo ratings yet

- HIRARC Launching Beam Truss (12561) Contoh ReportDocument3 pagesHIRARC Launching Beam Truss (12561) Contoh ReportfaizalNo ratings yet

- Safety Alert: Tong Incident Results in A FatalityDocument1 pageSafety Alert: Tong Incident Results in A FatalityVimal SinghNo ratings yet

- Posted Swamp Buggy SpecsDocument11 pagesPosted Swamp Buggy SpecsdakidofdaboomNo ratings yet

- Fall Protection Work Plan - Roof CladdingDocument2 pagesFall Protection Work Plan - Roof CladdingGibbs PerNo ratings yet

- SOP GTC 100-02-012 Lower The MastDocument2 pagesSOP GTC 100-02-012 Lower The Mastakv9005No ratings yet

- Tool Box Talk Form: Date - Location - SupervisorDocument2 pagesTool Box Talk Form: Date - Location - SupervisorNeeraj SinghNo ratings yet

- Notice of Implementation of MLC 2006 in MalaysiaDocument39 pagesNotice of Implementation of MLC 2006 in Malaysiamae_blurNo ratings yet

- Stationary Crusher PlantDocument15 pagesStationary Crusher PlantMr. SlabNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- Lull Telehandler 944-E42Document200 pagesLull Telehandler 944-E42Allan DelormeNo ratings yet

- MOEM Company Profile - DOSHDocument7 pagesMOEM Company Profile - DOSHPHH9834No ratings yet

- Corroseal TE 321 Rev 01Document1 pageCorroseal TE 321 Rev 01Ashif AkhtarNo ratings yet

- CylinderCatalog13thEdition HDDocument176 pagesCylinderCatalog13thEdition HDpruebaprueba20No ratings yet

- BX Test Spec TSEL0066Document12 pagesBX Test Spec TSEL0066Jim SharpNo ratings yet

- Auger Boring Safety ManualDocument28 pagesAuger Boring Safety Manualjjrelucio3748No ratings yet

- Part 1Document16 pagesPart 1Bagkermaix Anak ChundiNo ratings yet

- Daily Crane Checklist Naw English and ArabicDocument2 pagesDaily Crane Checklist Naw English and ArabicmejbahNo ratings yet

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- Haws Eye Wash ChecklistDocument2 pagesHaws Eye Wash ChecklistNorman MoralesNo ratings yet

- Mercusys MR70X Router Setting For Maxis FiberDocument5 pagesMercusys MR70X Router Setting For Maxis FiberYovaraj KarunakaranNo ratings yet

- Cameron ValvesDocument44 pagesCameron Valvesadrian villaNo ratings yet

- Forklift Incident - Broken LegDocument1 pageForklift Incident - Broken LegAbdul Hameed OmarNo ratings yet

- BP TD Torque Test ProcudereDocument13 pagesBP TD Torque Test ProcudereHugo MoralesNo ratings yet

- SPP - JSA Bore Pile (Production)Document26 pagesSPP - JSA Bore Pile (Production)BennyNo ratings yet

- Power Generation Cep LoadDocument34 pagesPower Generation Cep LoadHermain Fayyaz KarimNo ratings yet

- DEL DL500 Tail Lift Installation ManualDocument36 pagesDEL DL500 Tail Lift Installation ManualDuncan ReedNo ratings yet

- Original Manual: Type MF3iw - DVDocument37 pagesOriginal Manual: Type MF3iw - DVSuellen Fonseca100% (1)

- 002-Soil Investigation WorkDocument15 pages002-Soil Investigation WorkDon McleanNo ratings yet

- Automotive Diagnostic System GT90 User's Manual v120180622Document84 pagesAutomotive Diagnostic System GT90 User's Manual v120180622CleytonBronoskiNo ratings yet

- Automotive Diagnostic System GT80 MINI User's Manual V2.00Document86 pagesAutomotive Diagnostic System GT80 MINI User's Manual V2.00Felipe LazNo ratings yet

- Worker Welfare in The UAE .CleanedDocument5 pagesWorker Welfare in The UAE .Cleanedvikrant911No ratings yet

- IHS - Day 1 - Session 3 - Michel Theriault - Regulation From An Operators Perspective - CleanedDocument15 pagesIHS - Day 1 - Session 3 - Michel Theriault - Regulation From An Operators Perspective - Cleanedvikrant911No ratings yet

- Hatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic WasteDocument1 pageHatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic Wastevikrant911No ratings yet

- Federal Decree-Law No. 32 of 2021Document70 pagesFederal Decree-Law No. 32 of 2021vikrant911No ratings yet

- 15 Working Hours and Places - CleanedDocument6 pages15 Working Hours and Places - Cleanedvikrant911No ratings yet

- OGUK Health and Safety Report 2021.cleanedDocument40 pagesOGUK Health and Safety Report 2021.cleanedvikrant911No ratings yet

- FR71ODSDocument2 pagesFR71ODSvikrant911No ratings yet

- Hatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic WasteDocument1 pageHatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic Wastevikrant911No ratings yet

- GMSAnnualHSEReport2018 CleanedDocument11 pagesGMSAnnualHSEReport2018 Cleanedvikrant911No ratings yet

- WhyIWorkSafe TemplateDocument1 pageWhyIWorkSafe Templatevikrant911No ratings yet

- SafetyWeek ColoringPageDocument1 pageSafetyWeek ColoringPagevikrant911No ratings yet

- SafetyWeek ColoringPageDocument1 pageSafetyWeek ColoringPagevikrant911No ratings yet

- AtHome ToolboxTalk SafetyWeek2022Document3 pagesAtHome ToolboxTalk SafetyWeek2022vikrant911No ratings yet

- OISD SA 2021 22 POL 11.cleanedDocument2 pagesOISD SA 2021 22 POL 11.cleanedvikrant911No ratings yet

- WhyIWorkSafe TemplateDocument1 pageWhyIWorkSafe Templatevikrant911No ratings yet

- DIL AW 201601 Global FallsDocument3 pagesDIL AW 201601 Global Fallsvikrant911100% (1)

- OISD SA 2021 22 E&P 10.cleanedDocument2 pagesOISD SA 2021 22 E&P 10.cleanedvikrant911No ratings yet

- DOS-AW-201644-SAS-1593571 Mining - Metal To Metal Contact Theme - Incident 2 March 2016Document2 pagesDOS-AW-201644-SAS-1593571 Mining - Metal To Metal Contact Theme - Incident 2 March 2016vikrant911No ratings yet

- DOS-SAS-AW-201620 - 1613088 Turnaround - Worker Fell Asleep While Driving April 2016Document2 pagesDOS-SAS-AW-201620 - 1613088 Turnaround - Worker Fell Asleep While Driving April 2016vikrant911No ratings yet

- Dig LB 201604 q3 GC Lfi BulletinDocument2 pagesDig LB 201604 q3 GC Lfi Bulletinvikrant911No ratings yet

- DOS-AW-201645-SAS-1596185 Mining - Metal To Metal Contact Theme - Incident 3 March 2016Document3 pagesDOS-AW-201645-SAS-1596185 Mining - Metal To Metal Contact Theme - Incident 3 March 2016vikrant911No ratings yet

- Dropped Object - Fatale AccidentDocument9 pagesDropped Object - Fatale Accidentvikrant911No ratings yet

- Crane Hood Dropped ObjectDocument4 pagesCrane Hood Dropped Objectvikrant911No ratings yet

- DOS-AW-201633-SAS-1617347 Turnaround - Fallen Object (Scaffold Tube) April 2016Document2 pagesDOS-AW-201633-SAS-1617347 Turnaround - Fallen Object (Scaffold Tube) April 2016vikrant911No ratings yet

- DOS-AW-201643-SAS-1576371 Mining - Metal To Metal Contact Theme - Incident 1 February 2016Document2 pagesDOS-AW-201643-SAS-1576371 Mining - Metal To Metal Contact Theme - Incident 1 February 2016vikrant911No ratings yet

- Hand Injury - Restricted Work Case: DTS-AW-201627-EU-SA Trading & Supply Operations August 2016Document2 pagesHand Injury - Restricted Work Case: DTS-AW-201627-EU-SA Trading & Supply Operations August 2016vikrant911No ratings yet

- Abb TPS 48 PDFDocument130 pagesAbb TPS 48 PDFVannex MensidorNo ratings yet

- Active Sand SdsDocument4 pagesActive Sand SdsDzulkifli MuhamadNo ratings yet

- Electric Power SteeringDocument11 pagesElectric Power Steeringzul khairiNo ratings yet

- Hand and Power Tool Safety 08Document60 pagesHand and Power Tool Safety 08Adel Ali100% (1)

- Method Statement For Installation of Uv Sterilizer (07!10!19)Document24 pagesMethod Statement For Installation of Uv Sterilizer (07!10!19)Samboy DionisioNo ratings yet

- RAMS Example 1Document11 pagesRAMS Example 1sppNo ratings yet

- Molykote Safety Data SheetDocument15 pagesMolykote Safety Data SheetDevNo ratings yet

- 745 00139 01 Ebam Safe Handling and Storage of Acrylic AcidDocument84 pages745 00139 01 Ebam Safe Handling and Storage of Acrylic AcidMauro MascheroniNo ratings yet

- Chapter 9 HRDocument4 pagesChapter 9 HRSafiaNo ratings yet

- Method Statement of Bored Piles 21Document40 pagesMethod Statement of Bored Piles 21Dharma Pratap LamgadeNo ratings yet

- Schedule 4 HSE Requirements For Contracts Mode 2 PDFDocument11 pagesSchedule 4 HSE Requirements For Contracts Mode 2 PDFbesongNo ratings yet

- Hawk Resurfacing Reference Guide 2020Document51 pagesHawk Resurfacing Reference Guide 2020Bose CatNo ratings yet

- Chemical Safety HandbookDocument39 pagesChemical Safety HandbookZach AdamsonNo ratings yet

- Manual Jet2 PDFDocument192 pagesManual Jet2 PDFGenaro Bessa CeppoNo ratings yet

- Purpose: Scope: Responsibility: Details:: Personal Protective Equipment (PPE)Document5 pagesPurpose: Scope: Responsibility: Details:: Personal Protective Equipment (PPE)prashanthNo ratings yet

- Oli TRAFO Nynas Nytro LibraDocument22 pagesOli TRAFO Nynas Nytro LibraSritoko100% (1)

- Pewaran CI 42090 - Kel 5Document7 pagesPewaran CI 42090 - Kel 5Nur MaulidaNo ratings yet

- Bahan Referat Eria 6Document11 pagesBahan Referat Eria 6Eva Devita SariNo ratings yet

- Emergency and Spill Response Plan - Rev 001Document13 pagesEmergency and Spill Response Plan - Rev 001besongNo ratings yet

- Grinder - Angle-Electric and PneumaticDocument2 pagesGrinder - Angle-Electric and PneumaticjoessterNo ratings yet

- Carbon Dioxide Handling ManualDocument13 pagesCarbon Dioxide Handling Manualrafik1995No ratings yet

- New Guard Group: CoatingsDocument18 pagesNew Guard Group: CoatingsArokiyaNo ratings yet

- 4.method Statement Blinding and Concrete WorksDocument5 pages4.method Statement Blinding and Concrete Worksشاز إياسNo ratings yet

- MSDS DupontDocument8 pagesMSDS DupontEMPATI LUWU TIMURNo ratings yet

- WMS Infineon Project Tower (Piping Installation (Open Cut Trench) )Document5 pagesWMS Infineon Project Tower (Piping Installation (Open Cut Trench) )tanaNo ratings yet

- 025 Health Environment & Safety (HES) PlanDocument76 pages025 Health Environment & Safety (HES) PlanSirajul IslamNo ratings yet

Goal Zero: Zero Injuries, Zero Fatalities

Goal Zero: Zero Injuries, Zero Fatalities

Uploaded by

vikrant911Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Goal Zero: Zero Injuries, Zero Fatalities

Goal Zero: Zero Injuries, Zero Fatalities

Uploaded by

vikrant911Copyright:

Available Formats

Tyre Safety

GRP/AW/201112 All Shell Businesses August 2011

Target audience for this alert

• Managers, Contract Holders, and Supervisors of tyre maintenance facilities

• Road Transport Safety Focal Points

• Workshop personnel

What happened

On 11th February 2011 in a joint venture not under operational control, a tubeless tyre which was placed and

secured in a safety cage for pressurization, burst upon reaching 80 PSI. The incident happened at a workshop

on a site with no injuries as the tyre was contained in the safety cage.

Three additional incidents, releasing the same hazard occurred in 2009 and 2010 (Qatar/Nairobi/Uganda).

Three fatalities and four injured persons resulted.

Goal Zero: Zero injuries, Zero fatalities

Disclaimer: This document is made available for information only and on the condition that (i) it may not be relied upon by anyone, in the conduct of their own operations or otherwise; (ii) neither the

[Shell] company issuing this document nor any other person or company concerned with furnishing information or data used herein (A) is liable for its accuracy or completeness, or for any advice

given in or any omission from this document, or for any consequences whatsoever resulting directly or indirectly from any use made of this document by any person, even if there was a failure to

exercise reasonable care on the part of the issuing company or any other person or company as aforesaid; or (B) make any claim, representation or warranty, express or implied, that acting in

accordance with this document will produce any particular results with regard to the subject matter contained herein or satisfy the requirements of any applicable federal, state or local laws and

regulations; and (iii) nothing in this document constitutes technical advice, if such advice is required it should be sought from a qualified professional adviser.

Why it happened

• In this incident, the structural integrity of the tyre had been compromised for an undetermined reason.

• In the similar Uganda incident, the tyre structural integrity had also been compromised; however, the

technician had not inspected the tyre and the tyre was removed from the safety cage prior to completion of

inflation.

• In the similar Nairobi incident, the tyre rim was compromised. The rim fault was undetected by the

technician and the tyre was inflated outside of the safety cage.

Lessons learned

• Inflated tyres contain stored energy. If tyres are damaged, inflation may cause unexpected rupture resulting

in a destructive air blast and the ejection of high-speed particles. If a wheel is not restrained, it can fly

meters through the air. Failure of split rim wheels can result in explosive ejection of component parts.

• Prior to any work being done, tyres need to be inspected. If there is any evidence of rim or side wall

damage, do not proceed.

Recommendations

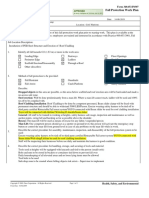

1. Risk Management--Implement the following controls and recovery measures prior to inflating tyres that have

been repaired:

• A competent/trained person should inspect the tyre before inflation. Pay particular attention to

the side walls of the tyre.

• Establish procedures that identify when a tyre repair is not to be attempted. Repairs should not

be made to the side walls of the tyre.

• Inflation of commercial vehicle tyres (i.e. trucks) should be performed inside a restraining

device such as a safety cage /guards of adequate design. This is not necessarily required for

light vehicles (passenger cars) if there is confidence that the replacement tyre has no hidden

damage.

• Demarcate the safety area and enforce no unauthorised personnel in the area during the

inflation.

• Wear appropriate PPE.

• Operator to stand out of line of fire.

• Inflate tyres in 10 psi increments.

• Do not remove the tyre from the cage/guard until after inflation is complete.

• Communicate the hazards and the necessary safety controls via task instructions and regular

tool box talks on tyre inflating precautions.

• Risk assessment (Job Hazards Analysis) to be carried out for all work fitting tyres.

2. Define the Personal Protective Equipment (PPE) to be used and train personnel on the limits of the

PPE.

3. Establish and maintain procedures to inspect the technical integrity of HSSE critical equipment including

hoses, gauges, safety cage, etc. Do not use damaged equipment. Refer to the Operations, Inspection,

and Maintenance section of the Asset Integrity Manual.

.

More information

The UK Health and Safety Executive regulator has published extensive guidance on safety during tyre inflation:

http://www.hse.gov.uk/pubns/indg433.pdf

Two LFI Awareness Alerts have been issued in 2009-2010 on Tyre explosion incidents;

Goal Zero: Zero injuries, Zero fatalities

Disclaimer: This document is made available for information only and on the condition that (i) it may not be relied upon by anyone, in the conduct of their own operations or otherwise; (ii) neither the

[Shell] company issuing this document nor any other person or company concerned with furnishing information or data used herein (A) is liable for its accuracy or completeness, or for any advice

given in or any omission from this document, or for any consequences whatsoever resulting directly or indirectly from any use made of this document by any person, even if there was a failure to

exercise reasonable care on the part of the issuing company or any other person or company as aforesaid; or (B) make any claim, representation or warranty, express or implied, that acting in

accordance with this document will produce any particular results with regard to the subject matter contained herein or satisfy the requirements of any applicable federal, state or local laws and

regulations; and (iii) nothing in this document constitutes technical advice, if such advice is required it should be sought from a qualified professional adviser.

• Third Party injury by tyre burst in Nairobi Service Station – February 2010

• Fatality when a tyre was being inflated – Uganda – December 2009

Goal Zero: Zero injuries, Zero fatalities

Disclaimer: This document is made available for information only and on the condition that (i) it may not be relied upon by anyone, in the conduct of their own operations or otherwise; (ii) neither the

[Shell] company issuing this document nor any other person or company concerned with furnishing information or data used herein (A) is liable for its accuracy or completeness, or for any advice

given in or any omission from this document, or for any consequences whatsoever resulting directly or indirectly from any use made of this document by any person, even if there was a failure to

exercise reasonable care on the part of the issuing company or any other person or company as aforesaid; or (B) make any claim, representation or warranty, express or implied, that acting in

accordance with this document will produce any particular results with regard to the subject matter contained herein or satisfy the requirements of any applicable federal, state or local laws and

regulations; and (iii) nothing in this document constitutes technical advice, if such advice is required it should be sought from a qualified professional adviser.

You might also like

- IHS 613 - Assignment 1Document4 pagesIHS 613 - Assignment 1Nurinsyahirah HamzahNo ratings yet

- MMHE Access Card Application Form - Rev2 30.11.22Document2 pagesMMHE Access Card Application Form - Rev2 30.11.22khairul Anwar100% (1)

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Working at Heights Practical ModuleDocument2 pagesWorking at Heights Practical ModuleMadalina FoteaNo ratings yet

- Competency-Based Learning Material (Common Competency)Document45 pagesCompetency-Based Learning Material (Common Competency)ZOOMTECHVOC TRAINING&ASSESSMENT100% (1)

- 001 MEP - Method Floor&Wall PenetrationDocument7 pages001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- Nma100776 O&m-Section 1 PDFDocument23 pagesNma100776 O&m-Section 1 PDFMichael CaoNo ratings yet

- Tyre SafeDocument75 pagesTyre SafetalabiraNo ratings yet

- Vehicle Hoist: Do NotDocument1 pageVehicle Hoist: Do NotChristian MakandeNo ratings yet

- FA5A Winch Part List ManualDocument72 pagesFA5A Winch Part List ManualMohamed AliNo ratings yet

- GrindingDocument50 pagesGrindinggillawatNo ratings yet

- Service Report: Intervantione On TDS Canrig 1250ACDocument1 pageService Report: Intervantione On TDS Canrig 1250ACAbdelghani ZitouniNo ratings yet

- Milling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURDocument5 pagesMilling Machine - Mill Mate (Bridge Port Style) - JOB PROCEDURAshok SureshNo ratings yet

- OG7 V3 Prime Mover Inspection Checklist Jun 2015Document2 pagesOG7 V3 Prime Mover Inspection Checklist Jun 2015Asela Bandara100% (1)

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- Standard Operating ProcedureDocument55 pagesStandard Operating Procedureboy tryadi100% (1)

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts FactsheetJafar KhanNo ratings yet

- MS Working at HeightsDocument15 pagesMS Working at HeightsNauval FadliNo ratings yet

- Safety Alert: Driller Inattention Results in Dropped BlocksDocument1 pageSafety Alert: Driller Inattention Results in Dropped Blockscase013No ratings yet

- KingpinDocument2 pagesKingpinNguyễn Hoài NamNo ratings yet

- Sop Piling WorkDocument2 pagesSop Piling WorkamirNo ratings yet

- Ansi Ppe StandardDocument1 pageAnsi Ppe StandardHerwandi Atmaja0% (1)

- SKPB HsemsDocument67 pagesSKPB Hsemsjihad jamareiNo ratings yet

- Punch Press Safety and Operating ProceduresDocument2 pagesPunch Press Safety and Operating ProceduresRAMESH100% (1)

- Safe Work Practice Dozer OperatorsDocument4 pagesSafe Work Practice Dozer OperatorsMuhammad Ashraf AhmadNo ratings yet

- Common Sense of Tyres User ManualDocument9 pagesCommon Sense of Tyres User ManualJohn SimancaNo ratings yet

- MRF-08 - Top Drive GreasingDocument1 pageMRF-08 - Top Drive GreasingAbdul Hameed OmarNo ratings yet

- Form Inspeksi Bar Cutter Bar Bender - Fix (SfileDocument1 pageForm Inspeksi Bar Cutter Bar Bender - Fix (Sfilerajatua dramaga.projectNo ratings yet

- OMHEC Communication Hoisting OperationsDocument20 pagesOMHEC Communication Hoisting OperationsLasse WelleNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDocument5 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNo ratings yet

- Commander Manual TitanDocument40 pagesCommander Manual TitanjohnfcortesNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- FLT Preventive Maintenance Daily Checklist - UPLDocument2 pagesFLT Preventive Maintenance Daily Checklist - UPLMaham QureshiNo ratings yet

- HIRARC Launching Beam Truss (12561) Contoh ReportDocument3 pagesHIRARC Launching Beam Truss (12561) Contoh ReportfaizalNo ratings yet

- Safety Alert: Tong Incident Results in A FatalityDocument1 pageSafety Alert: Tong Incident Results in A FatalityVimal SinghNo ratings yet

- Posted Swamp Buggy SpecsDocument11 pagesPosted Swamp Buggy SpecsdakidofdaboomNo ratings yet

- Fall Protection Work Plan - Roof CladdingDocument2 pagesFall Protection Work Plan - Roof CladdingGibbs PerNo ratings yet

- SOP GTC 100-02-012 Lower The MastDocument2 pagesSOP GTC 100-02-012 Lower The Mastakv9005No ratings yet

- Tool Box Talk Form: Date - Location - SupervisorDocument2 pagesTool Box Talk Form: Date - Location - SupervisorNeeraj SinghNo ratings yet

- Notice of Implementation of MLC 2006 in MalaysiaDocument39 pagesNotice of Implementation of MLC 2006 in Malaysiamae_blurNo ratings yet

- Stationary Crusher PlantDocument15 pagesStationary Crusher PlantMr. SlabNo ratings yet

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Document3 pagesStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNo ratings yet

- Lull Telehandler 944-E42Document200 pagesLull Telehandler 944-E42Allan DelormeNo ratings yet

- MOEM Company Profile - DOSHDocument7 pagesMOEM Company Profile - DOSHPHH9834No ratings yet

- Corroseal TE 321 Rev 01Document1 pageCorroseal TE 321 Rev 01Ashif AkhtarNo ratings yet

- CylinderCatalog13thEdition HDDocument176 pagesCylinderCatalog13thEdition HDpruebaprueba20No ratings yet

- BX Test Spec TSEL0066Document12 pagesBX Test Spec TSEL0066Jim SharpNo ratings yet

- Auger Boring Safety ManualDocument28 pagesAuger Boring Safety Manualjjrelucio3748No ratings yet

- Part 1Document16 pagesPart 1Bagkermaix Anak ChundiNo ratings yet

- Daily Crane Checklist Naw English and ArabicDocument2 pagesDaily Crane Checklist Naw English and ArabicmejbahNo ratings yet

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- Haws Eye Wash ChecklistDocument2 pagesHaws Eye Wash ChecklistNorman MoralesNo ratings yet

- Mercusys MR70X Router Setting For Maxis FiberDocument5 pagesMercusys MR70X Router Setting For Maxis FiberYovaraj KarunakaranNo ratings yet

- Cameron ValvesDocument44 pagesCameron Valvesadrian villaNo ratings yet

- Forklift Incident - Broken LegDocument1 pageForklift Incident - Broken LegAbdul Hameed OmarNo ratings yet

- BP TD Torque Test ProcudereDocument13 pagesBP TD Torque Test ProcudereHugo MoralesNo ratings yet

- SPP - JSA Bore Pile (Production)Document26 pagesSPP - JSA Bore Pile (Production)BennyNo ratings yet

- Power Generation Cep LoadDocument34 pagesPower Generation Cep LoadHermain Fayyaz KarimNo ratings yet

- DEL DL500 Tail Lift Installation ManualDocument36 pagesDEL DL500 Tail Lift Installation ManualDuncan ReedNo ratings yet

- Original Manual: Type MF3iw - DVDocument37 pagesOriginal Manual: Type MF3iw - DVSuellen Fonseca100% (1)

- 002-Soil Investigation WorkDocument15 pages002-Soil Investigation WorkDon McleanNo ratings yet

- Automotive Diagnostic System GT90 User's Manual v120180622Document84 pagesAutomotive Diagnostic System GT90 User's Manual v120180622CleytonBronoskiNo ratings yet

- Automotive Diagnostic System GT80 MINI User's Manual V2.00Document86 pagesAutomotive Diagnostic System GT80 MINI User's Manual V2.00Felipe LazNo ratings yet

- Worker Welfare in The UAE .CleanedDocument5 pagesWorker Welfare in The UAE .Cleanedvikrant911No ratings yet

- IHS - Day 1 - Session 3 - Michel Theriault - Regulation From An Operators Perspective - CleanedDocument15 pagesIHS - Day 1 - Session 3 - Michel Theriault - Regulation From An Operators Perspective - Cleanedvikrant911No ratings yet

- Hatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic WasteDocument1 pageHatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic Wastevikrant911No ratings yet

- Federal Decree-Law No. 32 of 2021Document70 pagesFederal Decree-Law No. 32 of 2021vikrant911No ratings yet

- 15 Working Hours and Places - CleanedDocument6 pages15 Working Hours and Places - Cleanedvikrant911No ratings yet

- OGUK Health and Safety Report 2021.cleanedDocument40 pagesOGUK Health and Safety Report 2021.cleanedvikrant911No ratings yet

- FR71ODSDocument2 pagesFR71ODSvikrant911No ratings yet

- Hatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic WasteDocument1 pageHatenboer-Water Infographic Reusable Bottles To Help To Reduce Plastic Wastevikrant911No ratings yet

- GMSAnnualHSEReport2018 CleanedDocument11 pagesGMSAnnualHSEReport2018 Cleanedvikrant911No ratings yet

- WhyIWorkSafe TemplateDocument1 pageWhyIWorkSafe Templatevikrant911No ratings yet

- SafetyWeek ColoringPageDocument1 pageSafetyWeek ColoringPagevikrant911No ratings yet

- SafetyWeek ColoringPageDocument1 pageSafetyWeek ColoringPagevikrant911No ratings yet

- AtHome ToolboxTalk SafetyWeek2022Document3 pagesAtHome ToolboxTalk SafetyWeek2022vikrant911No ratings yet

- OISD SA 2021 22 POL 11.cleanedDocument2 pagesOISD SA 2021 22 POL 11.cleanedvikrant911No ratings yet

- WhyIWorkSafe TemplateDocument1 pageWhyIWorkSafe Templatevikrant911No ratings yet

- DIL AW 201601 Global FallsDocument3 pagesDIL AW 201601 Global Fallsvikrant911100% (1)

- OISD SA 2021 22 E&P 10.cleanedDocument2 pagesOISD SA 2021 22 E&P 10.cleanedvikrant911No ratings yet

- DOS-AW-201644-SAS-1593571 Mining - Metal To Metal Contact Theme - Incident 2 March 2016Document2 pagesDOS-AW-201644-SAS-1593571 Mining - Metal To Metal Contact Theme - Incident 2 March 2016vikrant911No ratings yet

- DOS-SAS-AW-201620 - 1613088 Turnaround - Worker Fell Asleep While Driving April 2016Document2 pagesDOS-SAS-AW-201620 - 1613088 Turnaround - Worker Fell Asleep While Driving April 2016vikrant911No ratings yet

- Dig LB 201604 q3 GC Lfi BulletinDocument2 pagesDig LB 201604 q3 GC Lfi Bulletinvikrant911No ratings yet

- DOS-AW-201645-SAS-1596185 Mining - Metal To Metal Contact Theme - Incident 3 March 2016Document3 pagesDOS-AW-201645-SAS-1596185 Mining - Metal To Metal Contact Theme - Incident 3 March 2016vikrant911No ratings yet

- Dropped Object - Fatale AccidentDocument9 pagesDropped Object - Fatale Accidentvikrant911No ratings yet

- Crane Hood Dropped ObjectDocument4 pagesCrane Hood Dropped Objectvikrant911No ratings yet

- DOS-AW-201633-SAS-1617347 Turnaround - Fallen Object (Scaffold Tube) April 2016Document2 pagesDOS-AW-201633-SAS-1617347 Turnaround - Fallen Object (Scaffold Tube) April 2016vikrant911No ratings yet

- DOS-AW-201643-SAS-1576371 Mining - Metal To Metal Contact Theme - Incident 1 February 2016Document2 pagesDOS-AW-201643-SAS-1576371 Mining - Metal To Metal Contact Theme - Incident 1 February 2016vikrant911No ratings yet

- Hand Injury - Restricted Work Case: DTS-AW-201627-EU-SA Trading & Supply Operations August 2016Document2 pagesHand Injury - Restricted Work Case: DTS-AW-201627-EU-SA Trading & Supply Operations August 2016vikrant911No ratings yet

- Abb TPS 48 PDFDocument130 pagesAbb TPS 48 PDFVannex MensidorNo ratings yet

- Active Sand SdsDocument4 pagesActive Sand SdsDzulkifli MuhamadNo ratings yet

- Electric Power SteeringDocument11 pagesElectric Power Steeringzul khairiNo ratings yet

- Hand and Power Tool Safety 08Document60 pagesHand and Power Tool Safety 08Adel Ali100% (1)

- Method Statement For Installation of Uv Sterilizer (07!10!19)Document24 pagesMethod Statement For Installation of Uv Sterilizer (07!10!19)Samboy DionisioNo ratings yet

- RAMS Example 1Document11 pagesRAMS Example 1sppNo ratings yet

- Molykote Safety Data SheetDocument15 pagesMolykote Safety Data SheetDevNo ratings yet

- 745 00139 01 Ebam Safe Handling and Storage of Acrylic AcidDocument84 pages745 00139 01 Ebam Safe Handling and Storage of Acrylic AcidMauro MascheroniNo ratings yet

- Chapter 9 HRDocument4 pagesChapter 9 HRSafiaNo ratings yet

- Method Statement of Bored Piles 21Document40 pagesMethod Statement of Bored Piles 21Dharma Pratap LamgadeNo ratings yet

- Schedule 4 HSE Requirements For Contracts Mode 2 PDFDocument11 pagesSchedule 4 HSE Requirements For Contracts Mode 2 PDFbesongNo ratings yet

- Hawk Resurfacing Reference Guide 2020Document51 pagesHawk Resurfacing Reference Guide 2020Bose CatNo ratings yet

- Chemical Safety HandbookDocument39 pagesChemical Safety HandbookZach AdamsonNo ratings yet

- Manual Jet2 PDFDocument192 pagesManual Jet2 PDFGenaro Bessa CeppoNo ratings yet

- Purpose: Scope: Responsibility: Details:: Personal Protective Equipment (PPE)Document5 pagesPurpose: Scope: Responsibility: Details:: Personal Protective Equipment (PPE)prashanthNo ratings yet

- Oli TRAFO Nynas Nytro LibraDocument22 pagesOli TRAFO Nynas Nytro LibraSritoko100% (1)

- Pewaran CI 42090 - Kel 5Document7 pagesPewaran CI 42090 - Kel 5Nur MaulidaNo ratings yet

- Bahan Referat Eria 6Document11 pagesBahan Referat Eria 6Eva Devita SariNo ratings yet

- Emergency and Spill Response Plan - Rev 001Document13 pagesEmergency and Spill Response Plan - Rev 001besongNo ratings yet

- Grinder - Angle-Electric and PneumaticDocument2 pagesGrinder - Angle-Electric and PneumaticjoessterNo ratings yet

- Carbon Dioxide Handling ManualDocument13 pagesCarbon Dioxide Handling Manualrafik1995No ratings yet

- New Guard Group: CoatingsDocument18 pagesNew Guard Group: CoatingsArokiyaNo ratings yet

- 4.method Statement Blinding and Concrete WorksDocument5 pages4.method Statement Blinding and Concrete Worksشاز إياسNo ratings yet

- MSDS DupontDocument8 pagesMSDS DupontEMPATI LUWU TIMURNo ratings yet

- WMS Infineon Project Tower (Piping Installation (Open Cut Trench) )Document5 pagesWMS Infineon Project Tower (Piping Installation (Open Cut Trench) )tanaNo ratings yet

- 025 Health Environment & Safety (HES) PlanDocument76 pages025 Health Environment & Safety (HES) PlanSirajul IslamNo ratings yet