Professional Documents

Culture Documents

POSEIDON SAFETY (M) SDN BHD 2010X01, Poseidon FR 7.7oz Twill Dark Green

POSEIDON SAFETY (M) SDN BHD 2010X01, Poseidon FR 7.7oz Twill Dark Green

Uploaded by

yaya0 ratings0% found this document useful (0 votes)

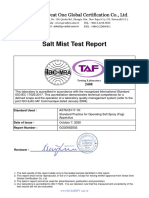

10 views3 pagesThe document is a test report from ArcWear that evaluated a fabric sample from Poseidon Safety against the ASTM F2894 heat resistance standard. The fabric experienced an average of -0.8% length change and -0.5% width change in the initial test. After washing and drying, the fabric experienced an average of -1.3% length change and -0.6% width change when exposed to heat. The fabric showed no signs of ignition, deformation, or damage in either test.

Original Description:

safety

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a test report from ArcWear that evaluated a fabric sample from Poseidon Safety against the ASTM F2894 heat resistance standard. The fabric experienced an average of -0.8% length change and -0.5% width change in the initial test. After washing and drying, the fabric experienced an average of -1.3% length change and -0.6% width change when exposed to heat. The fabric showed no signs of ignition, deformation, or damage in either test.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views3 pagesPOSEIDON SAFETY (M) SDN BHD 2010X01, Poseidon FR 7.7oz Twill Dark Green

POSEIDON SAFETY (M) SDN BHD 2010X01, Poseidon FR 7.7oz Twill Dark Green

Uploaded by

yayaThe document is a test report from ArcWear that evaluated a fabric sample from Poseidon Safety against the ASTM F2894 heat resistance standard. The fabric experienced an average of -0.8% length change and -0.5% width change in the initial test. After washing and drying, the fabric experienced an average of -1.3% length change and -0.6% width change when exposed to heat. The fabric showed no signs of ignition, deformation, or damage in either test.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Page 1 of 3

3018 Eastpoint Parkway, Louisville, KY 40223

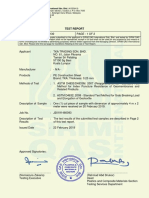

Date: 10/13/2020 Test Report: 2010X01

Client: Poseidon Safety (M) SDN BHD

No. 9, Jalan Juruanalisis U1/35A, Section U1

Hicom Glenmarie Industrial Park

Shah Alam, Selangor, Malaysia 40150

Sample(s) Received: 10/1/2020

Sample Description POSEIDON SAFETY (M) SDN BHD, Mfg. ChiBi Xiang Yuan Special Fabric Co. Ltd, Style Poseidon FR, 7.7

(provided by client): oz/yd² 260 g/m² Twill, 100% Cotton FR, Dark Green, ArcWear# 2010X01

Procedure: Testing was completed in accordance with the method(s) identified below at ArcWear in Louisville, Kentucky.

ASTM F2894-19 Standard Test Method for Evaluation of Materials, Protective Clothing and Equipment for Heat Resistance

Using a Hot Air Circulating Oven

Any modifications to the tests listed above are documented in the data table information

Signed for the Company by:

Jill Kirby Digitally signed by Jill

Kirby

Lab Manager Date: 2020.10.13 12:30:43

ArcWear -04'00'

Any Test Method Modification noted on this Test Report may affect the test results.

When information is noted as having been supplied by the client, this information may affect the validity of reported results.

This test report shall not be reproduced except in full, without written approval of ArcWear. Test results relate only to the item submitted for testing.

Test results of the sample(s) provided by the client apply only to the sample as received.

If verdicts are presented above, they are based upon a direct comparison of the measured value at the time of testing, to a published or customer supplied tolerance for the specification listed. Results determined by ArcWear do

not include measurement uncertainty in making the determinations of conformity to the applicable specification, unless specifically requested. It is the responsibility of the report recipient to determine if the pass / fail tolerances

meet the requirements of the intended end use.

Neither Hugh Hoagland Consulting, Inc. dba/ArcWear, nor its affiliates, nor any person acting on behalf of any of them:

a) makes any warranty, express or implied, with respect to the use of any information, apparatus, method, or process disclosed in this report or that such use may not infringe privately owned rights; or

b) assumes any liabilities with respect to the use of, or for damages resulting from the use of, any information, apparatus, method, or process disclosed in this report

Warranty Disclaimer and Limitation of Liability. The Services and Test Reports provided by ARCWEAR hereunder shall materially conform with the written product and service specifications, descriptions and documentation

delivered by ARCWEAR. ALL SERVICES ARE DELIVERED WITHOUT WARRANTY OF ANY KIND EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF TITLE, MERCHANTABILITY, OR

FITNESS OR A PARTICULAR PURPOSE. CUSTOMER’S SOLE REMEDY FOR ARCWEAR’S BREACH OF ALL WARRANTIES HEREUNDER OR ANY TERM OR CONDITION OF THIS AGREEMENT, IS AS SET FORTH IN

THIS PARAGRAPH. IN NO EVENT SHALL ARCWEAR BE LIABLE TO CUSTOMER OR THIRD PARTIES UNDER THIS AGREEMENT FOR ANY AMOUNT IN EXCESS OF THE FEES ACTUALLY PAID BY CUSTOMER TO

ARCWEAR FOR SERVICES PROVIDED HEREUNDER DURING THE SIX (6) MONTH PERIOD PRIOR TO THE ARISING OF SUCH CLAIMS. ARCWEAR SHALL NOT BE LIABLE FOR ANY INDIRECT, INCIDENTAL, SPECIAL,

CONSEQUENTIAL, PUNITIVE, OR EXEMPLARY DAMAGES INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR PERSONAL INJURY, BODILY INJURY, PROPERTY, LOST PROFITS, GOOD WILL, USE, DATA, OR OTHER

INTANGIBLE LOSSES WHETHER DERIVED FROM THIRD PARTY CLAIMS OR LOSSES OF ANY NATURE WHATSOEVER OR OTHERWISE, REGARDLESS OF WHETHER ARCWEAR WAS ADVISED OF THE POSSIBILITY

OR LIKELIHOOD OF SUCH DAMAGES OR COSTS OCCURRING, AND WHETHER SUCH LIABILITY WAS BASED UPON TORT, WARRANTY, NEGLIGENCE, STRICT LIABILITY, CONTRACT, PRODUCT LIABILITY, OR ANY

OTHER CLAIM AT LAW OR IN EQUITY. THE LIMITATIONS OF LIABILITY AS SET FORTH HEREIN SHALL BE APPLICABLE TO AND SHALL INURE TO THE BENEFIT OF ARCWEAR AND ITS OFFICERS, DIRECTORS,

EMPLOYEES, AGENTS, ATTORNEYS, AFFILIATES, AND PARTNERS. TO THE EXTENT PERMITTED BY APPLICABLE LAW, CUSTOMER IRREVOCABLY WAIVES ANY STATE, FEDERAL, OR LOCAL LAW, REGULATION,

OR STATUTE THAT WOULD OTHERWISE LIMIT OR PROHIBIT LIMITATIONS OF OR GENERAL RELEASES OF LIABILITY. THE LIMITATIONS SET FORTH HEREIN ARE INTENDED TO COMPLY TO THE FULLEST

EXTENT POSSIBLE WITH ANY APPLICABLE LAW REGULATION OR STATUTE PROHIBITING OR LIMITING THE EXCLUSION OR LIMITATION OF DAMAGES OR THE DISCLAIMER OF WARRANTIES AND

Page 2 of 3

ArcWear Number: 2010X01

Client: Poseidon Safety (M) SDN BHD

Product Description: POSEIDON SAFETY (M) SDN BHD, Mfg. ChiBi Xiang Yuan Special Fabric Co. Ltd,

Style Poseidon FR, 7.7 oz/yd² 260 g/m² Twill, 100% Cotton FR, Dark Green, ArcWear#

2010X01

Modifications: None

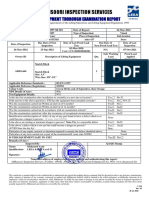

ASTM F2894-19

Standard Test Method for Evaluation of Materials, Protective Clothing and Equipment for Heat Resistance Using a Hot Air

Circulating Oven

Method Of Sampling: Sample provided by client

Preconditioning: None

Conditioning: In accordance with ASTM D1776

Dimensions of test specimens: 15x15in

Testing Temperature (°C): 267

Time of exposure: 5min

Optional Stretching frame used: No

Dimensional Change

Specimens % Change - Length % Change - Width

1 -1.0% -0.5%

2 -0.5% -0.5%

3 -1.0% -0.5%

Average -0.8% -0.5%

Observations

Ignition, deformation, degradation, delamination, melting, dripping, flaking, hole formation, separation, and splitting

Specimens List any observations:

1 None

2 None

3 None

Test Date: 10/7/2020

Page 3 of 3

ArcWear Number: 2010X01

Client: Poseidon Safety (M) SDN BHD

Product Description: POSEIDON SAFETY (M) SDN BHD, Mfg. ChiBi Xiang Yuan Special Fabric Co. Ltd,

Style Poseidon FR, 7.7 oz/yd² 260 g/m² Twill, 100% Cotton FR, Dark Green, ArcWear#

2010X01

Modifications: None

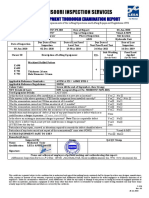

ASTM F2894-19

Standard Test Method for Evaluation of Materials, Protective Clothing and Equipment for Heat Resistance Using a Hot Air

Circulating Oven

Method Of Sampling: Sample provided by client

Preconditioning:

Tested after three cycles of washing and drying as specified in NFPA 2112- 18 sec. 8.1.3

Conditioning: In accordance with ASTM D1776

Dimensions of test specimens: 15x15in

Testing Temperature (°C): 267

Time of exposure: 5min

Optional Stretching frame used: No

Dimensional Change

Specimens % Change - Length % Change - Width

1 -1.3% -0.7%

2 -1.3% -0.5%

3 -1.2% -0.5%

Average -1.3% -0.6%

Observations

Ignition, deformation, degradation, delamination, melting, dripping, flaking, hole formation, separation, and splitting

Specimens List any observations:

1 None

2 None

3 None

Test Date: 10/7/2020

You might also like

- V NSL 2109024078 TXDocument193 pagesV NSL 2109024078 TXHoa NguyenNo ratings yet

- Concept Note For Trade FairDocument5 pagesConcept Note For Trade FairRalph Aldrin F. VallesterosNo ratings yet

- Sunbeam: Instructor ManualDocument88 pagesSunbeam: Instructor ManualWill AsinNo ratings yet

- Uncle CheffyDocument8 pagesUncle CheffyKaly Rie100% (1)

- The Eyes of The Skin - Opinion Piece.Document2 pagesThe Eyes of The Skin - Opinion Piece.Disha RameshNo ratings yet

- RPT-Easi Screed Eco-MEC19-02-ED-202003Document3 pagesRPT-Easi Screed Eco-MEC19-02-ED-202003Phan YhNo ratings yet

- Sgs Astm d638Document6 pagesSgs Astm d638vasilecmirceaNo ratings yet

- KD GOWN PPPE 45gsm AAMI Level 2 Physical Test EUROFINSDocument12 pagesKD GOWN PPPE 45gsm AAMI Level 2 Physical Test EUROFINSTom GewinnNo ratings yet

- 190724005SHF-001 Drum Peel Strength PDFDocument5 pages190724005SHF-001 Drum Peel Strength PDFaziz hNo ratings yet

- Structur A 1Document4 pagesStructur A 1vasilecmirceaNo ratings yet

- SIRIM Eco Label (Dri-Floor EP1550)Document3 pagesSIRIM Eco Label (Dri-Floor EP1550)胡大威No ratings yet

- VNHL2012025672HG Test Mút Kháng CháyDocument3 pagesVNHL2012025672HG Test Mút Kháng CháyHà LêNo ratings yet

- Steel Toe Cap 459 CertificateDocument3 pagesSteel Toe Cap 459 CertificatelufvijpharmaNo ratings yet

- Report No.: MAN:HL:1348003357 DATE: 21 April, 2022: JOE No.:2248801377 4919047 Control No.:1348504335Document9 pagesReport No.: MAN:HL:1348003357 DATE: 21 April, 2022: JOE No.:2248801377 4919047 Control No.:1348504335sumanNo ratings yet

- 羽林GB32610英文检测报告Document5 pages羽林GB32610英文检测报告A ANo ratings yet

- 羽林GB32610英文检测报告Document5 pages羽林GB32610英文检测报告A ANo ratings yet

- PFR800AUSSR1 120508 RoHSDocument5 pagesPFR800AUSSR1 120508 RoHSymabc123No ratings yet

- Docs China Test ReportDocument8 pagesDocs China Test ReportAsistente DT - Droguería CadilloNo ratings yet

- LKNLKNLDocument11 pagesLKNLKNLyusufwahyupratamaNo ratings yet

- DSS - SGS-R20-1517-En00 - 38kV, Pruebas de Rutina (SIGMA - Peru)Document24 pagesDSS - SGS-R20-1517-En00 - 38kV, Pruebas de Rutina (SIGMA - Peru)Martin RodriguezNo ratings yet

- Flex - ULDocument8 pagesFlex - ULFareethAbdullahNo ratings yet

- Sirim Test Report 0.25mm ThicknessDocument3 pagesSirim Test Report 0.25mm ThicknessUMINo ratings yet

- ADX 711 (New) PDFDocument12 pagesADX 711 (New) PDFSusana KhoNo ratings yet

- PN95 Mask Bfe TestDocument3 pagesPN95 Mask Bfe TestAnurag BackupNo ratings yet

- Target Corporation: Report Number: (8221) 098-0360 REVISEDDocument10 pagesTarget Corporation: Report Number: (8221) 098-0360 REVISEDMehedi HasanNo ratings yet

- Test ReportDocument8 pagesTest ReportNishantNo ratings yet

- Bai Yun-2Document8 pagesBai Yun-2Hamada Shoukry MohammedNo ratings yet

- Gridmesh Anchor Test Report ANSI Z359.18Document14 pagesGridmesh Anchor Test Report ANSI Z359.18IMIXCINo ratings yet

- Snatch Block VisualDocument10 pagesSnatch Block VisualRanjithNo ratings yet

- Bell Qualifier - DOTDocument4 pagesBell Qualifier - DOTJumper MenajeNo ratings yet

- - 1. 厂家简介和产品图示 - 2. 营业执照及医疗器械备案证 - 3. 产品使用说明 - 4. 产品检测报告(多项) - 5. ISO 13485认证 - 6. CE 认证 - 7. FDA认证 - 8. 欧么委员会符合性声明书Document45 pages- 1. 厂家简介和产品图示 - 2. 营业执照及医疗器械备案证 - 3. 产品使用说明 - 4. 产品检测报告(多项) - 5. ISO 13485认证 - 6. CE 认证 - 7. FDA认证 - 8. 欧么委员会符合性声明书Jcr AsesoriasNo ratings yet

- Zertifikate Nitril-IntcoDocument63 pagesZertifikate Nitril-IntcoÜmit Sahin KonurNo ratings yet

- Decision RuleDocument6 pagesDecision Ruleabanoub ebaidNo ratings yet

- Test Report: Routine TestsDocument6 pagesTest Report: Routine Testsgrigore mirceaNo ratings yet

- Salt Spray Test Report - SampleDocument8 pagesSalt Spray Test Report - SamplearvindNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Itma Tga PVC & AbsDocument4 pagesItma Tga PVC & AbsSetiausaha JKTN SelangorNo ratings yet

- Spectro Fire Test ReportDocument7 pagesSpectro Fire Test ReportKishoreNo ratings yet

- PVC Waterstop (Sirim)Document3 pagesPVC Waterstop (Sirim)lensa jijiNo ratings yet

- UntitledDocument21 pagesUntitledአንዋርጀማልNo ratings yet

- Sgs Ibr Laboratories: Test ReportDocument4 pagesSgs Ibr Laboratories: Test ReportDaniel KrugNo ratings yet

- EVVO 3-6KW-G2 - IP65 ReportDocument8 pagesEVVO 3-6KW-G2 - IP65 ReportUdara DissanayakeNo ratings yet

- (SS75C LF120X BK T6) 190306135GZU 001 - Security2019 3 18Document29 pages(SS75C LF120X BK T6) 190306135GZU 001 - Security2019 3 18jim kangNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- PH.50.60-24 - 11A0035-Original (FOR ASEAN)Document5 pagesPH.50.60-24 - 11A0035-Original (FOR ASEAN)sirikhwan wonganuntNo ratings yet

- Test ReportDocument5 pagesTest Reportsumonuctc13No ratings yet

- Concrete Cube Test Report: Cast Laboratories Pte LTDDocument1 pageConcrete Cube Test Report: Cast Laboratories Pte LTDsawwahwahNo ratings yet

- Test Report: Terms & ConditionsDocument1 pageTest Report: Terms & Conditionschetan selokarNo ratings yet

- Draft: Test Report For Sieve Analysis-ASTM C-136Document1 pageDraft: Test Report For Sieve Analysis-ASTM C-136civillabNo ratings yet

- Solid Aluminum Sheet-SGS ReportDocument12 pagesSolid Aluminum Sheet-SGS ReportTran The AnhNo ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- Safety Harness-2Document15 pagesSafety Harness-2Shirley Sofia Yancapallo CruzNo ratings yet

- Test Report No.: IC200520W003-3Document62 pagesTest Report No.: IC200520W003-3Heather HarrisNo ratings yet

- Test Report ChamberDocument4 pagesTest Report ChamberaariefmaulanaNo ratings yet

- Determination Risk Level Associated To Decision of ConformityDocument5 pagesDetermination Risk Level Associated To Decision of ConformityAlaa NoureldeenNo ratings yet

- 456, T1 Roof, 10-12Document1 page456, T1 Roof, 10-12linwaileong78No ratings yet

- Supplementary Test Report: SIRIM QAS International Sdn. Bhd. (Company No.: 199601037981 (410334-X) )Document3 pagesSupplementary Test Report: SIRIM QAS International Sdn. Bhd. (Company No.: 199601037981 (410334-X) )Nurul Abdul JalilNo ratings yet

- ASTM D1929 Core Test Report PDFDocument5 pagesASTM D1929 Core Test Report PDFaziz hNo ratings yet

- SDWH M202005367 5 enDocument14 pagesSDWH M202005367 5 en一叶一木一席No ratings yet

- T 375R3Document3 pagesT 375R3조준장No ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- MCL350 - Clause 5Document1 pageMCL350 - Clause 5RizalNo ratings yet

- SKC Compliance Lab Pvt. LTDDocument12 pagesSKC Compliance Lab Pvt. LTDRAVIRAJ DATTATRAYA PADOLNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Backplane Designer's Guide 4Document11 pagesBackplane Designer's Guide 4terryschNo ratings yet

- Ebook Prehistoric Life The Definitive Visual History of Life On Earth Low Quality Version DK Publishing Online PDF All ChapterDocument69 pagesEbook Prehistoric Life The Definitive Visual History of Life On Earth Low Quality Version DK Publishing Online PDF All Chapterjoe.simmons244100% (7)

- Avnet TP Sap Arp PL May14Document77 pagesAvnet TP Sap Arp PL May14Kathak DancerNo ratings yet

- Math ProblemsDocument3 pagesMath Problemsaibajo2004No ratings yet

- Patient NameDocument3 pagesPatient NameSmith91No ratings yet

- Managing Windows Server: With Windows Admin CenterDocument31 pagesManaging Windows Server: With Windows Admin CenterKocsis Csaba ÖrkényNo ratings yet

- Setting and Hardening of ConcreteDocument30 pagesSetting and Hardening of ConcreteManjer123No ratings yet

- Extended Abstract Comparison of Effectiveness of The Various Species of Citrus' Peels As Styrofoam DecomposerDocument3 pagesExtended Abstract Comparison of Effectiveness of The Various Species of Citrus' Peels As Styrofoam DecomposerKen EzekielNo ratings yet

- Hq004 Hq006 Oplusm Manual Rev BDocument7 pagesHq004 Hq006 Oplusm Manual Rev BadrianioantomaNo ratings yet

- Peripheral Blood Smear Pathologist ToolDocument3 pagesPeripheral Blood Smear Pathologist ToolSimon HafeniNo ratings yet

- 2013 Sappia BollatiDocument7 pages2013 Sappia BollatiRakshithNo ratings yet

- Optimisation of Supply Chain of Smart ColoursDocument29 pagesOptimisation of Supply Chain of Smart ColoursPooja ShahNo ratings yet

- PF100/PF150 Manual Postformers: Process For Postforming A Waterfall (90°) EdgeDocument1 pagePF100/PF150 Manual Postformers: Process For Postforming A Waterfall (90°) EdgeAngel CazaresNo ratings yet

- Fce StrategiesDocument19 pagesFce StrategiesTere AguirreNo ratings yet

- Autocad Mep 2009Document132 pagesAutocad Mep 2009haneefaparokot100% (1)

- Vendor: Design Information: Gas BootDocument2 pagesVendor: Design Information: Gas Boot124swadeshiNo ratings yet

- Study SkillsDocument7 pagesStudy SkillsmodarthNo ratings yet

- Basic Customer Service Principles-ImportantDocument39 pagesBasic Customer Service Principles-Importantzoltan2014100% (6)

- 2023 Lupong Tagapamayapa Incentives Awards (Ltia) Assessment FormDocument4 pages2023 Lupong Tagapamayapa Incentives Awards (Ltia) Assessment FormNicole Chupungco100% (1)

- Transportation orDocument5 pagesTransportation orAaditya shahNo ratings yet

- PPT-finalDocument21 pagesPPT-finalRamu KetkarNo ratings yet

- LMP 400-401 430-431 Series: Maximum Working Pressure Up To 6 Mpa (60 Bar) - Flow Rate Up To 740 L/MinDocument12 pagesLMP 400-401 430-431 Series: Maximum Working Pressure Up To 6 Mpa (60 Bar) - Flow Rate Up To 740 L/MinChris BanksNo ratings yet

- Melt Shop Ventilation Upgrade 2Document1 pageMelt Shop Ventilation Upgrade 2mshahNo ratings yet

- MT6227 SchematicsDocument7 pagesMT6227 SchematicsRenan Birck PinheiroNo ratings yet

- Robert Walters Salary SurveyDocument5 pagesRobert Walters Salary SurveySyaiful BahriNo ratings yet

- Human EvolutionDocument10 pagesHuman Evolution11 E Harsh dagarNo ratings yet