Professional Documents

Culture Documents

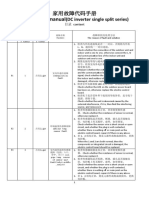

6.3 The Malfunction Oindoor and Outdoor Unit 1 The Common Malfunction Code Analysis and Solutions!

6.3 The Malfunction Oindoor and Outdoor Unit 1 The Common Malfunction Code Analysis and Solutions!

Uploaded by

puc eood0 ratings0% found this document useful (0 votes)

169 views4 pagesThe document provides fault codes, descriptions, and potential causes and solutions for common indoor and outdoor air conditioning unit malfunctions. Some examples include:

F1 - Communication fault caused by a broken wire, damaged control board, unreliable grounding, or external interference.

F2 - Indoor temperature sensor fault due to a faulty sensor, short or open wires, or damaged control board components.

F3 - Indoor coil temperature sensor fault caused by similar issues and requiring control board replacement if sensor and wires check out.

Potential solutions include checking sensor resistances, wire connections, control board contacts and components, power supply, compressor operation, motor voltages, and control chips. Replacing damaged parts can resolve the

Original Description:

Original Title

chigo_2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides fault codes, descriptions, and potential causes and solutions for common indoor and outdoor air conditioning unit malfunctions. Some examples include:

F1 - Communication fault caused by a broken wire, damaged control board, unreliable grounding, or external interference.

F2 - Indoor temperature sensor fault due to a faulty sensor, short or open wires, or damaged control board components.

F3 - Indoor coil temperature sensor fault caused by similar issues and requiring control board replacement if sensor and wires check out.

Potential solutions include checking sensor resistances, wire connections, control board contacts and components, power supply, compressor operation, motor voltages, and control chips. Replacing damaged parts can resolve the

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

169 views4 pages6.3 The Malfunction Oindoor and Outdoor Unit 1 The Common Malfunction Code Analysis and Solutions!

6.3 The Malfunction Oindoor and Outdoor Unit 1 The Common Malfunction Code Analysis and Solutions!

Uploaded by

puc eoodThe document provides fault codes, descriptions, and potential causes and solutions for common indoor and outdoor air conditioning unit malfunctions. Some examples include:

F1 - Communication fault caused by a broken wire, damaged control board, unreliable grounding, or external interference.

F2 - Indoor temperature sensor fault due to a faulty sensor, short or open wires, or damaged control board components.

F3 - Indoor coil temperature sensor fault caused by similar issues and requiring control board replacement if sensor and wires check out.

Potential solutions include checking sensor resistances, wire connections, control board contacts and components, power supply, compressor operation, motor voltages, and control chips. Replacing damaged parts can resolve the

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

6.

3 The malfunction oindoor and outdoor unit

(1)The common malfunction code analysis and solutions!

The fault

The fault content The reason of fault and its solutions

code

1、The communication wire is broken off. Please check

whether the wire is disentwined ;

2、Please check whether the electrical control board is

damaged. It should be replaced when it is damaged;

F1 The communication fault

3、Please check whether the power ground wire is reliable;

4、Please check whether the unit is abnormal caused by the

external interference. If it is, then find the interfering

sources, and remove them.

1、Check whether the resistance of sensor is normal,

otherwise replace it;

2、Check whether the sensor wire is short circuit or open

The indoor temperature circuit, and whether the plug is well contacted, whether

F2 there is welding off or rosin joint on the electric control

sensor fault

board, repair it if there is any above;

3、When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

1、Check whether the resistance of sensor is normal,

otherwise replace it;

2、Check whether the sensor wire is short circuit or open

The indoor coil circuit, and whether the plug is well contacted, whether

F3 there is welding off or rosin joint on the electric control

temperature sensor fault

board ,repair it if there is any above;

3、When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

1、Check whether the contact of the plug of the motor wire

and socket is well. Please make sure it is well contacted;

2、Check whether the indoor motor has damaged, the

motor should be replaced when it is damaged;

Indoor PG motor fault 3 、 Check whether the controllable silicon and other

F4 (tap motor hasn’t so components on the electric control board have damaged,

breakdown ) replace the controllable silicon or electric control board

when they are damaged;

4、Check whether the indoor fan is unobstructed when

running, please fix the indoor fan again when it is

obstructed.

1、Check whether the supply voltage is out of ranging from

150 to 270V(overvoltage and undervoltage protection);

F5 IPM protection Measuring the actual current, if the current is greater than

the rated current of 2A,it is over-temperature protection;

If the above are normal, that is IPM module internal circuit

fault protection, so please replace the IPM module.

1、Check whether the resistance of sensor is normal,

otherwise replace it;

2、Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

F6 The outdoor sensor fault there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3、When the 1 and 2 are both normal ,then the component

or integrated circuit is damaged, the electric control board

should be replaced.

F7 The outdoor coil 1、Check whether the resistance of sensor is normal,

temperature sensor fault otherwise replace it;

(Including the 2、Check whether the sensor wire is short circuit or open

mid-point of tube、 circuit, and whether the plug is well contacted, whether

inspiratory gas) there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3、When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

1、Check whether the resistance of sensor is normal,

otherwise replace it;

2、Check whether the sensor wire is short circuit or open

circuit, and whether the plug is well contacted, whether

F9 Exhaust gas sensor failure there is welding off or rosin joint on the electric control

board, repair it if there is any above;

3、When the 1 and 2 are both normal, then the component

or integrated circuit is damaged, the electric control board

should be replaced.

1、 check whether the wire controller’s connecting wire is

The communication fault short circuit or loose, please make it connect well;

FA between the wire 2、 Check the connecting line、wire controller 、PCB

controller and the indoor whether they are loose or have a bad contact. Please

PCB make them have a good contact.

1、Turn on the power again, and then check whether the

operation of the compressor is normal;

2、Check whether the connection of the compressor is

correct or reliable, otherwise repair it;

outdoor unit driving fault, 3、Check whether the components on the electric control

FC starting compressor board have been damaged, if they are damaged, the

failure components or the electric control board should be

replaced.;

4、Check whether the connecting wires are disentwined

between the Intelligent Power Module board and the main

board, otherwise make the wires connect firmly .

1、Check the resistance value of the DC motor port. If it is

short circuit, please change the DC motor;

2 、 Check the voltage value of the DC motor port

The outdoor DC motor VCC(15Vdc)、Vdm(340Vdc),please change the PCB board

FF fault if the voltage values are abnormal;

3、if all the voltage values of the DC motor port are

normal,the Vsp voltage(0~5v)is also ok ,it shows that the

inner PCB board of the DC motor is damaged, then change

the DC motor.

1、Check whether there are false weld and bad contact etc

between the EEPROM chip block and the electronic

control board ;

2、Check whether the EEPROM chip pin is broken foot

The indoor unit and the direction of installation is in line with the

FH EEPROM error EEPROM block;

3、When the procedure of EEPROM chip and itself have

fault it will appear the code FH. That is the need to replace

the EEPROM chip.

dF Defrosting state The unit is in defrosting state,that is normal.

When the running mode for No.1 indoor unit is different

dI Mode conflict

from No.2 indoor unit, the dF is displayed.

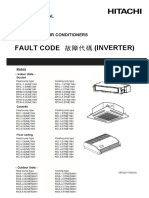

The fault

The fault content The reason of fault and solution

code

1、 Check whether the ambient temperature is over the range

Indoor coil of air-conditioning running temperature ;

temperature 2、 Check whether the indoor coil temperature is higher than

over-temperature or equal to 63 degrees when heating and check whether

protection for heating the outdoor coil temperature is higher than or equal to 65

degrees when cooling, it will appear protection if the

(thermal overload),

P1 value is over the above;

outdoor coil

3、 Check whether the parameters of indoor and outdoor coil

temperature temperature sensors are normal, if abnormal, please

overheating protection replace the sensors;

for cooling (cooling 4、 If the above are normal, check whether the main control

overload) board output parameters are normal, if abnormal, please

replace the main control board.

1、Check whether the connection of the compressor is reliable,

The outdoor unit otherwise connect firmly again;

2、Check whether the fixation between the IPM module and

inverter module

P2 the radiator is firm.;

protection fault 3、Check whether the compressor is well, otherwise replace it;

4、Check whether the IPM module is abnormal, otherwise

replace it.

1 、 Check whether the ambient temperature exceeds the

Over current of operation range for the air conditioner;

P3

outdoor unit 2、Check whether the current detection circuit is abnormal, the

electric control should be replaced when it is abnormal..

discharge temperature of 1、Check whether the pressure is normal when the unit is

compressor is too high, the running, if it is abnormal, you should detect the leakage and

outside ambient then welding and adding refrigerant;

temperature

2、Check whether the ambient temperature is too high or too

P4 over-temperature, switch

low, when the temperature is more than -20 degrees and less

off the compressor shell

55 degrees, it can disappear automatically;

temperature, module

temperature 3 、 Check whether temperature switch of compressor is

over-temperature damage, it should be replaced if it is damaged.

1、Check whether the supply voltage is out of ranging from

The outdoor unit DC 150 to 270V;

P7 generatrix voltage is 2、Check the voltage detection circuit of the IPM base board is

abnormal abnormal, if it is abnormal, the IPM base board or the electric

control board should be replaced.

1、Check whether the high and low pressure valves have been

opened, otherwise open the valves;

2、Check whether the indoor coil pipe temperature sensor is

normal, if it is abnormal, the sensor should be replaced;

3、Check whether the indoor coil temperature sensor hung in

lack refrigerant or reverse the air,please plug it in a correct position if the indoor coil

P8

valve fault temperature sensor hung in the air;

4、Check the system pressure is abnormal, if it is abnormal,

yon should detect leakage and the welding and adding the

refrigerant.;

5、Please change the outdoor PCB board , if all above are

normal.

1、 Check whether the ambient temperature is over the range

of air-conditioning running temperature;

2、 Check the indoor coil temperature is less than or equal to

-1 degrees, if more than this value it will be the protection

protection when indoor of;

pipe temperature is too 3、 Check whether the indoor coil temperature sensor

PA low (Anti-icing) parameters are normal, if abnormal it is the replacement

of the sensor;

4、 If the above are normal, check whether the main control

board output parameters are normal, if abnormal ,please

replace the main control board.

Outdoor ambient 1、 Check whether the outdoor ambient temperature is too

temperature high or too low, when the ambient temperature is lower

PC over-temperature than (T> -20, T <55), this fault automatically discharges;

protection (including high 2、 Check whether the outdoor temperature sensor’s ring

and low) temperature parameters are normal, if abnormal ,please

replace the sensor;

3、 If the above are normal, check whether the main control

board’s output parameters are normal, f abnormal ,please

replace the main control board.

1、Check whether there are false weld and bad contact etc

between the EEPROM chip block and the electronic control

board ;

EEPROM reading error 2、Check whether the EEPROM chip pin is broken foot and

PE

(outdoor unit) the direction of installation is in line with the EEPROM block;

3、When the procedure of EEPROM chip and itself have fault

it will appear the code PE. At this time there is the need to

replace the EEPROM chip.

You might also like

- Esu300 Service ManualDocument15 pagesEsu300 Service ManualMaría Diaz100% (4)

- Kelvinator No Frost Wiring DiagramDocument3 pagesKelvinator No Frost Wiring DiagramLuis Pereira Peña100% (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Swing Gate Opener: Assembling and Operating ManualDocument10 pagesSwing Gate Opener: Assembling and Operating ManualПеђа БекићNo ratings yet

- Failure Code Manual: (DC Inverter Single Split Series)Document5 pagesFailure Code Manual: (DC Inverter Single Split Series)cristian osornoNo ratings yet

- AUX Error Code ListDocument1 pageAUX Error Code ListMuhammad Azeem88% (8)

- Super200 Tig Welder ManualDocument5 pagesSuper200 Tig Welder ManualDermot BrennanNo ratings yet

- Inverter Type (Wall-Mounted) Trouble Shooting Guide: No. Problems Indoor Error Code Outdoor Display SolutionDocument3 pagesInverter Type (Wall-Mounted) Trouble Shooting Guide: No. Problems Indoor Error Code Outdoor Display SolutionMaria StanNo ratings yet

- Electrolux CEW30GF6GSA Service Data SheetDocument4 pagesElectrolux CEW30GF6GSA Service Data SheetTom KakanowskiNo ratings yet

- Of 914Document29 pagesOf 914christianvilcaNo ratings yet

- Apw3 en 221214 190637 PDFDocument5 pagesApw3 en 221214 190637 PDFIndanet TelecomNo ratings yet

- Avr Trouble ShootingDocument2 pagesAvr Trouble ShootingJAYKUMAR SINGH100% (1)

- p15 Dost Bosch Fie Bsiv DTC Codes Trouble Shooting GuidelinesDocument18 pagesp15 Dost Bosch Fie Bsiv DTC Codes Trouble Shooting GuidelinesDinesh MaliNo ratings yet

- Presto 190gc IngDocument18 pagesPresto 190gc Ingandreiion100% (1)

- Chigo Code ErrorDocument1 pageChigo Code ErrorfloriantudorNo ratings yet

- Errores Minisplit CONFORTFRESH Serie Halcon Plus - INPMSGDocument7 pagesErrores Minisplit CONFORTFRESH Serie Halcon Plus - INPMSGedwin gomezNo ratings yet

- Meps4 RAC (R) Trouble ShootingDocument4 pagesMeps4 RAC (R) Trouble Shootinggauris enmanuel javier romeroNo ratings yet

- 316905204Document2 pages316905204John DoeNo ratings yet

- Three Channel Input/Output Unit Installation Guide: Functional Test DataDocument2 pagesThree Channel Input/Output Unit Installation Guide: Functional Test DataRaaft riadNo ratings yet

- B. Appendix B: Motor Control Troubleshooting GuideDocument6 pagesB. Appendix B: Motor Control Troubleshooting GuidebrunoNo ratings yet

- Fault Code InverterDocument11 pagesFault Code InverterHuawei HuaweiNo ratings yet

- IMEE - 7 TroubleDocument5 pagesIMEE - 7 TroubleHirakNo ratings yet

- 63A Series Transfer Switch User ManualDocument1 page63A Series Transfer Switch User ManualOgie SeptiawanNo ratings yet

- ServiceManual OvenDocument4 pagesServiceManual OvenAndreNo ratings yet

- Time Lag SwitchDocument2 pagesTime Lag SwitchSravan SimhadriNo ratings yet

- GenldescDocument3 pagesGenldescjpsingh75No ratings yet

- Philco STC 1500Document50 pagesPhilco STC 1500alvhann_1No ratings yet

- Precaution: 1-1 Safety PrecautionsDocument6 pagesPrecaution: 1-1 Safety PrecautionsFidel ArroyoNo ratings yet

- Samsung Ws32z30hp Ws32z40ht Cw29z308t s63bDocument148 pagesSamsung Ws32z30hp Ws32z40ht Cw29z308t s63bKostas AthanasiadisNo ratings yet

- Chapter 5 Troubleshooting and Maintenance: 5.1. Error Display and RemedyDocument14 pagesChapter 5 Troubleshooting and Maintenance: 5.1. Error Display and RemedyJonathan Castañeda YepesNo ratings yet

- P84 Box Type PSU Common FaultsDocument3 pagesP84 Box Type PSU Common FaultsDominic JamesNo ratings yet

- Manual BookDocument45 pagesManual BookAtaf AmirNo ratings yet

- Trouble ShootingDocument5 pagesTrouble ShootingNehider MunguiaNo ratings yet

- Subaru Impreza 2009 Wiring DiagramsDocument198 pagesSubaru Impreza 2009 Wiring DiagramsPiotr KuchnioNo ratings yet

- F24 60 en (A4) V1.2Document2 pagesF24 60 en (A4) V1.2dozer_kamilNo ratings yet

- Samsung PS42A410 PrecautionDocument6 pagesSamsung PS42A410 PrecautionTiago GonçalvesNo ratings yet

- Samsung L70a Aquamarine Chassis Hl67a750a1fxzc DLP Projectio (ET)Document99 pagesSamsung L70a Aquamarine Chassis Hl67a750a1fxzc DLP Projectio (ET)Dan PrewittNo ratings yet

- Si 10Document42 pagesSi 10Simo SimoNo ratings yet

- Version V1 4 in Year 2015: .: Downloaded From Manuals Search EngineDocument42 pagesVersion V1 4 in Year 2015: .: Downloaded From Manuals Search EngineAbdul Vazeer100% (1)

- Samsung+CS29B850F18XSV+ +KSDB P CB1M RDocument63 pagesSamsung+CS29B850F18XSV+ +KSDB P CB1M Rjose4445100% (1)

- Outdoor LED Troubleshooting GuideDocument7 pagesOutdoor LED Troubleshooting GuideGustavo RodriguezNo ratings yet

- Ignition SystemDocument4 pagesIgnition SystemAbbode HoraniNo ratings yet

- Be PDFDocument127 pagesBe PDFAnaníEscarlethLLocllaVásquezNo ratings yet

- Precaution PDFDocument6 pagesPrecaution PDFgilberto gutierrezNo ratings yet

- Troubleshooting PDFDocument8 pagesTroubleshooting PDFAswanth tkNo ratings yet

- Samsung+CL21Z50MQ3XXAO+Chassis K16C (N) ValiantDocument77 pagesSamsung+CL21Z50MQ3XXAO+Chassis K16C (N) ValiantBLENO TECLASNo ratings yet

- Samsung Pl42d5sx RCLDocument33 pagesSamsung Pl42d5sx RCLOscar RamirezNo ratings yet

- Safety Precautions in Handling Elecrical AppliancesDocument2 pagesSafety Precautions in Handling Elecrical AppliancesKunal MehraNo ratings yet

- CQM1 Operation Manual 02Document10 pagesCQM1 Operation Manual 02วรพงษ์ กอชัชวาลNo ratings yet

- Error Possible Cause ActionDocument2 pagesError Possible Cause ActionChandru RsNo ratings yet

- Electrical System: Routine MaintenanceDocument1 pageElectrical System: Routine MaintenanceStelian CrisanNo ratings yet

- HtutdcDocument5 pagesHtutdcKhả Phúc 2No ratings yet

- VFDDocument5 pagesVFDRanjith KuymarNo ratings yet

- Photoelectric Dual Beam Detector User Manual (V2.0) : 4. Attach Beam To The BaseDocument2 pagesPhotoelectric Dual Beam Detector User Manual (V2.0) : 4. Attach Beam To The BaseCarmen MihaelaNo ratings yet

- Testing A Class I Appliance: Experts in What We DoDocument2 pagesTesting A Class I Appliance: Experts in What We DoKieran RichardsNo ratings yet

- 東元馬達驅動器報警訊息 Servo Motor AlarmDocument10 pages東元馬達驅動器報警訊息 Servo Motor AlarmAndrei IvanovNo ratings yet

- Chassis C7-C8 PDFDocument69 pagesChassis C7-C8 PDFAouadi AbdellazizNo ratings yet

- Operation Manual: Micromotor For Laboratory WorkDocument2 pagesOperation Manual: Micromotor For Laboratory WorkMinaNo ratings yet

- Samsung SP42W4HPX SP43T6HPX SP54T6HPX SP43T7HPX J54aDocument94 pagesSamsung SP42W4HPX SP43T6HPX SP54T6HPX SP43T7HPX J54af1743975% (4)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Versamax Io Guide 0Document36 pagesVersamax Io Guide 0joberhrNo ratings yet

- Economic SectionsDocument13 pagesEconomic SectionsArvin NaborNo ratings yet

- A Formula For Resistance Substation Grounding Grid in Two-Layer SoilDocument8 pagesA Formula For Resistance Substation Grounding Grid in Two-Layer SoilGabriel A. Gabriel MarmolejosNo ratings yet

- AS-B Specification Sheet - SmartStruxure SolutionDocument12 pagesAS-B Specification Sheet - SmartStruxure SolutionOs ShNo ratings yet

- Đánh Giá Phần Mềm Quản Lý Bất Động SảnDocument67 pagesĐánh Giá Phần Mềm Quản Lý Bất Động SảnNguyễn Thế PhongNo ratings yet

- Pure Maths Formula SheetDocument20 pagesPure Maths Formula SheetSaifur Rahman Raffael100% (1)

- Qualitative Research in Management Addresing Complexity Context and PersonaDocument13 pagesQualitative Research in Management Addresing Complexity Context and Personaalbadr20205026No ratings yet

- FINGERPRINT - Price List - SOLUTION - July 2019Document4 pagesFINGERPRINT - Price List - SOLUTION - July 2019Nirmanamedia HRDNo ratings yet

- Core Java NotesDocument56 pagesCore Java Notesraviteja_357No ratings yet

- Social Network Analysis Ii: MTP Ismu Rini Dwi Ari Jurusan Perencanaan Wilayah Dan Kota FtubDocument32 pagesSocial Network Analysis Ii: MTP Ismu Rini Dwi Ari Jurusan Perencanaan Wilayah Dan Kota FtubfikrunnisaNo ratings yet

- Codes TFM Webinar-DSDocument96 pagesCodes TFM Webinar-DSThành TrịnhNo ratings yet

- Benevolence of IslamDocument9 pagesBenevolence of IslamfirdousNo ratings yet

- 3.2.9. Rubber Closures For Containers For Aqueous Parenteral Preparations, For Powders and For Freeze-Dried PowdersDocument2 pages3.2.9. Rubber Closures For Containers For Aqueous Parenteral Preparations, For Powders and For Freeze-Dried PowdersG_RanjithNo ratings yet

- Wide Flange Beam ChartDocument16 pagesWide Flange Beam Chartrtrajan_mech5408No ratings yet

- 1 - Matrix Method of Structural AnalysisDocument5 pages1 - Matrix Method of Structural AnalysistrixiaNo ratings yet

- Problem Solving PDFDocument24 pagesProblem Solving PDFDanny ReyesNo ratings yet

- 2014 ForesterDocument7,222 pages2014 ForesterMykhail KubasovNo ratings yet

- Wwkzii: Jan. 10, 1933. R. H. FarwellDocument3 pagesWwkzii: Jan. 10, 1933. R. H. Farwellmonem2014100% (1)

- Python BasicsDocument39 pagesPython Basicssmartbroad26No ratings yet

- Gnuradio ProgrammingDocument28 pagesGnuradio ProgrammingJavier MelendrezNo ratings yet

- Homeinteriorpaint FractionsdecimalsandpercentsDocument4 pagesHomeinteriorpaint Fractionsdecimalsandpercentsapi-281744400No ratings yet

- Energy Theorems and Structural Analysis PDFDocument88 pagesEnergy Theorems and Structural Analysis PDFjs kalyana rama100% (3)

- Computer Organization and Assembly LanguageDocument31 pagesComputer Organization and Assembly LanguageFahad KareemNo ratings yet

- Dual Fuel EngineDocument14 pagesDual Fuel EngineGUJJARI PREM KUMAR 19981A0344No ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- VRLA - Operating Instruction - Engl (Incluyento S100L, Solo Inglés... )Document7 pagesVRLA - Operating Instruction - Engl (Incluyento S100L, Solo Inglés... )David MonederoNo ratings yet

- BCAoct09 (52-69)Document117 pagesBCAoct09 (52-69)errum_shraddhaNo ratings yet

- Different Types of Loading SchemesDocument14 pagesDifferent Types of Loading SchemesChintan100% (1)

- Coenzyme q10pdfDocument29 pagesCoenzyme q10pdfMyPSA PHCNo ratings yet