Professional Documents

Culture Documents

CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)

CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)

Uploaded by

PeterWayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)

CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)

Uploaded by

PeterWayCopyright:

Available Formats

CLC 18-10Ti

A Ti stabilized 18Cr-10Ni austenitic stainless steel (321 grade)

CLC 18-10Ti is a 18Cr-9Ni austenitic stainless steel stabilized with some Titanium

additions.

This kind of steel is one of the basic grades of the stainless steels range. Titanium

bearing (carbide forming element) avoids intergranular corrosion, even on welded

pieces without ulterior water quenching.

Alloys CLC 18-10Ti exhibit austenitic microstructures free of deleterious carbide

precipitations but with CNTi precipitations at the grainboundaries. The grade

contains some residual ferrite (≈ 4%) after solution annealing (1000-1100°C –

1832-2012°F) and water quenching.

The main properties are :

- Basic corrosion resistance

- Resistance against intergranular corrosion

- Heat resistant alloy (medium temperature)

- High ductility

STANDARDS EURONORM............................. 1.4541 X6CrNiTi 18-10

AFNOR ..................................... Z6 CNT 18-10

DIN............................................ W1.4541

ASTM........................................ A 240 – TP 321

UNS S32100

CHEMICAL Typical values (Weight %)

ANALYSIS C Cr Ni Mo N Ti

0.050 17.5 9.2 - - 5x%C ; up to 0.70

PREN (=%Cr+3.3%Mo+16%N) ≥ 18

Tensile properties after water quenching

MECHANICAL Minimum guaranteed values * Typical values (10mm plates)

PROPERTIES °C °F Y.S. 0.2% Y.S. 1% UTS Y.S. 0.2% Y.S. 1% UTS El

%

MPa Ksi MPa Ksi MPa Ksi MPa Ksi MPa Ksi MPa Ksi

20 68 200 29 240 35 500 73 280 40 310 45 600 89 45

/ 700 / 102

100 212 176 25 208 30 460 67 236 34 260 38 550 82 40

200 392 157 23 186 27 410 60 200 29 230 33 450 66 35

300 572 136 20 167 24 390 57 186 26 210 30 435 64 35

400 752 125 18 156 23 390 57 175 25 200 29 420 61 30

500 932 119 17 149 22 310 45 168 24 195 28 340 50 30

*Following EN 10088 hot rolled plates

The EN guaranteed values are valid for a thickness from 5 up to 75mm

CLC – 18-10 Ti – Ed 28/10/1999– Page 1

Impact values 1000 H

400

Fracture load (MPa)

10000 H

°C -269 -196 +20 300 100000H

°F -452 -320 68

200

KCV (J/cm²)

100

Minimum 62 100 150

0

KCV (J/cm²) 500 600 700 800

932 1112 1292 1472

Typical 138 160 225

Temperature °C (°F )

Typical creep strength values

PHYSICAL

Density : 7950 kg/m3

PROPERTIES

Young Shear

Interval Thermal °C °F Resistivity Thermal Specific modulus modulus

Temper expansion conductivity heat E G

°C αx10-6K-1 Ω cm)

(µΩ (W.m-1.K-1) (J.kg-1.K-1) (GPa) (GPa)

20-100 16 20 68 73 15 500 200 77

20-200 16.5 100 212 77 16 500 194 75

20-300 17 200 392 84 17.5 520 186 71

20-400 17.5 300 572 91 19 530 179 68

20-500 18 400 752 97 20.5 540 172 65

500 932 102 22 540 165 62

CORROSION Quality corrosion tests guaranteed (special request may be discussed)

RESISTANCE TEST Other name Corrosion (1) Results

ASTM A 262 A Intergranular Step or dual structure

ASTM A 262 B STREICHER Intergranular Not recommended

ASTM A 262 C HUEY Intergranular Not recommended

ASTM A 262 E

DIN 50914 STRAUSS Intergranular No cracking after bending

RCCM

ASTM G48 A Pitting Not recommended

(typical CPT < 5°C-41°F)

ASTM G48B ASTM G78 Crevice Not recommended

(typical CCT ≤ 0°C-32°F)

(1) kind of corrosion mechanism investigated

PROCESSING Hot forming

Hot forming should be carried out in a temperature range of 1150-800°C (2102-

1472°F).

Due to the low thermal conductivity, the holding time of temperature may be longer

(≈ 50%) than for C.Mn steels. The quenching may be faster after forming.

The cleanliness of the surface is very important (avoid oil contamination). A neutral

or slightly oxidizing atmosphere is required.

Cold forming

The alloy can be cold formed without any problem. The cold hardening behaviour of

the steel explains why it may require more powerfull equipments than for a

structural steel.

CLC – 18-10 Ti – Ed 28/10/1999– Page 2

Pickling

A nitro-hydrofluoric acid bath (10-20% HNO3 – 1,5-5% HF) at 20-60°C (68-140°F) is

used for the picking treatment.

A 10-20% H2S04 – 1,5-5% HF pickling bath may also be used. Passivation-

decontamination treatments may be performed with a 10-20% weight nitric acid

solution.

Cutting

Thermal cutting (plasma, thermal sawing…). After cutting pickling or grinding are

necessary to eliminate the oxide formed layer.

Mechanical cutting (shearing, stamping, cold sawing…)

Welding

The alloy, satbilized by Titanium addition, can be very easy welded without hot

cracking phenomenon, using an adequate filler metal (from 5 to 15% δ ferrite).

The alloy is not sensitive to cold cracking phenomenon. All welding processes can

be used including filler processes.

Filler material

Electrode E308L-15 or E308L-16 (ASME Sect II - Part C SFA5-4)

Wire ER 308L (ASME Sect II. - Part C SFA 5-9)

Filler material stabilized with Niobium may be used when specific properties of alloy

CLC 18-10Ti are required.

- Electrode E347-15 or E347-16

- Wire ER347

A post-weld heat treatment is not necessary.

Preheating and post heating are not necessary.

200°C (392°F) is the maximum interpass temperature. Post-weld pickling and

passivation treatment are necessary.

MACHINING Due to its cold work hardening, the alloy is less machinable than structural steel or

than a 13% Cr martensitic stainless steel.

! "# %&

! "$ ' &%

! "% % &% '

( ! "# ) &)

! "$ ' &*!

! "% **& ! '

+

"# ! "! &! "! # &%

! "! $ &! "! ) &% %

! "! # &! "! ) ' &%

,

"# ! "! % &! "! *&

! "! # &! "! & #

! "! ' &! "! * & #

% ! "! *&! " ! & #

- ! "! # &! " ! &%

+

CLC – 18-10 Ti – Ed 28/10/1999– Page 3

APPLICATIONS

The alloy is corrosion resistant in :

- Urban media

- Most of diluted organic acids at moderate temperatures

- Most of food and pharmaceutical products

- Pure phosphoric . Whatever concentration in cold solution

. Up to 10% diluted hot solution

- Caustic solutions free of chlorides or fluorides at medium temperatures.

The alloys is not corrosion resistant in chloride containing solutions, even diluted,

and in sulphuric acid media.

So, the main applications are

- food processing and storage

- chemical industry

- high temperature

Plates

SIZE RANGE Quarto plates Cut to length Cold rolled plates Clad plates

5 to 150 mm 2 to 12 mm 2 to 14 mm 6 to 150 mm

Thickness 3/16" to 6" 5/64" to 1/2" 5/64" to 5/8" 1/4" to 6"

Up to 3800 mm* Up to 2000 mm* Up to 2300 mm Up to 3900 mm

Width Up to 150" Up to 79" Up to 90.5" Up to 154"

Up to 16000 mm Up to 12000 mm Up to 8000 mm Up to 16000 mm

Length Up to 52' Up to 39" Up to 315" Up to 551"

Indicative dimensional programme – *Width related to thickness ; please consult for specific

request.

NOTE

This technical data and information represents our best knowledge at the time of printing. However, it

may be subject to some slight variations due to our ongoing research programme on corrosion resistant

grades.

We therefore suggest that information be verified at time of enquiry or order.

Furthermore, in service, real conditions are specific for each application. The data presented here is

only for the purpose of description, and may only be considered as guarantees when our company has

given written formal approval.

Further information may be obtained from the following address.

For all information :

INDUSTEEL Creusot INDUSTEEL Belgium

56 Rue Clemenceau 266, rue de Châtelet

71201 LE CREUSOT CEDEX - FRANCE B- 6030 MARCHIENNE AU PONT

Sales Tel +33 3 85 80 55 31 Tel +32 71 44 16 99

Fax +33 3 85 80 51 77 Fax +32 71 44 19 56

CLC – 18-10 Ti – Ed 28/10/1999– Page 4

You might also like

- Technical Card Ck45 Mechanical PropertiesDocument3 pagesTechnical Card Ck45 Mechanical PropertiesNuno Miguel TorcatoNo ratings yet

- UC Davis ENG 103 Midterm 2010 SolDocument4 pagesUC Davis ENG 103 Midterm 2010 SolgambitNo ratings yet

- Practice Test CH 4Document4 pagesPractice Test CH 4Umair Nadeem100% (1)

- CLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)Document4 pagesCLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)MichaelNo ratings yet

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Document4 pagesCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayNo ratings yet

- CLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)Document4 pagesCLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)PeterWayNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- CLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)Document4 pagesCLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)PeterWayNo ratings yet

- CLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)Document4 pagesCLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)PeterWayNo ratings yet

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Document4 pagesCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayNo ratings yet

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Document4 pagesCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayNo ratings yet

- CLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)Document4 pagesCLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)PeterWayNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- Industeel: A 22Cr DuplexDocument8 pagesIndusteel: A 22Cr DuplexJoaoNo ratings yet

- AISI416Document2 pagesAISI416shamsi862620No ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- 1.4466 (310L Ug)Document4 pages1.4466 (310L Ug)ramramjeyNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- 310 Data SheetDocument10 pages310 Data SheetAbdullrahman AlzahraniNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- Physical Properties of SteelDocument1 pagePhysical Properties of SteelBigfoot2018No ratings yet

- Material IDocument30 pagesMaterial IgabrieleNo ratings yet

- CLC4003 HardnessDocument5 pagesCLC4003 Hardnessarif.haddieNo ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- 316 TiDocument3 pages316 TiRajeev ChandelNo ratings yet

- Sanicro® 41 Tube and Pipe, Seamless: DatasheetDocument7 pagesSanicro® 41 Tube and Pipe, Seamless: DatasheetyckimNo ratings yet

- Ampcoloy 972: Technical Data SheetDocument1 pageAmpcoloy 972: Technical Data SheetmazaherramazaniNo ratings yet

- Alcoa Specialty Alloys:: Evercast™Document2 pagesAlcoa Specialty Alloys:: Evercast™ShivNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- 34 CR Ni Mo 6Document2 pages34 CR Ni Mo 6hp_vijaykNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Stainless Steel 321 Technical DataDocument2 pagesStainless Steel 321 Technical Datasmith willNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- SUPERDUPLEXDocument7 pagesSUPERDUPLEXM RNo ratings yet

- Stainless Steels 410: MartensiticDocument2 pagesStainless Steels 410: MartensiticKiranNo ratings yet

- Material ZirconiaDocument1 pageMaterial ZirconiaCpc Comercializadora CubillosNo ratings yet

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- Ceramic Fiber Blanket CatalogDocument7 pagesCeramic Fiber Blanket Catalogevelyn reksaNo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Quality 1.4021 Chemical Composition: Lucefin GroupDocument2 pagesQuality 1.4021 Chemical Composition: Lucefin GroupSonNguyenNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Ferrite Free 316lDocument4 pagesFerrite Free 316lnitin kaithwasNo ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4Stefan GhNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- DEMAG GruasDocument36 pagesDEMAG GruasPeterWayNo ratings yet

- Fora 400Document4 pagesFora 400PeterWayNo ratings yet

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 pagesCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNo ratings yet

- Appendix D - EDocument8 pagesAppendix D - EPeterWayNo ratings yet

- Guideline 3Document17 pagesGuideline 3PeterWayNo ratings yet

- SU-ExponentialLeadersGuide 10xgrowth053017Document12 pagesSU-ExponentialLeadersGuide 10xgrowth053017PeterWayNo ratings yet

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Document4 pagesCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayNo ratings yet

- A High Performance Wear Resistant Steel: Creusabro 8000Document8 pagesA High Performance Wear Resistant Steel: Creusabro 8000PeterWayNo ratings yet

- CLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)Document4 pagesCLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)PeterWayNo ratings yet

- ConsumableDocument8 pagesConsumablePeterWayNo ratings yet

- CLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)Document4 pagesCLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)PeterWayNo ratings yet

- Carelso 60/65: Steel For Pressure Equipment in Mild Sour ServiceDocument3 pagesCarelso 60/65: Steel For Pressure Equipment in Mild Sour ServicePeterWayNo ratings yet

- CLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)Document4 pagesCLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)PeterWayNo ratings yet

- CLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)Document4 pagesCLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)PeterWayNo ratings yet

- WWR 500-R-10 - Manual of Standard PracticeDocument38 pagesWWR 500-R-10 - Manual of Standard PracticePeterWayNo ratings yet

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Document4 pagesCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayNo ratings yet

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsPeterWayNo ratings yet

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Document4 pagesCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayNo ratings yet

- Din 17205Document1 pageDin 17205PeterWayNo ratings yet

- Durelloy: Heat Treated Hot Roll AlloyDocument7 pagesDurelloy: Heat Treated Hot Roll AlloyPeterWayNo ratings yet

- Techtron PPS HPV & Ketron PEEK HPV SpecificationsDocument3 pagesTechtron PPS HPV & Ketron PEEK HPV SpecificationsPeterWayNo ratings yet

- En ASME ComparisonDocument18 pagesEn ASME ComparisonPeterWay100% (1)

- Spiralift Catalog 2004-2007Document26 pagesSpiralift Catalog 2004-2007PeterWayNo ratings yet

- Honeywell 01061GBDocument25 pagesHoneywell 01061GBKyriakos MichalakiNo ratings yet

- Separating Mixtures Answer KeyDocument1 pageSeparating Mixtures Answer KeyNtando Nkunzimanikina XimbaNo ratings yet

- Segura 2017 Seismic Performance Limitation of Slender Reinforced Concrete Structural WallsDocument268 pagesSegura 2017 Seismic Performance Limitation of Slender Reinforced Concrete Structural WallsDavid VallejoNo ratings yet

- Caie As Level Chemistry 9701 Theory v1Document30 pagesCaie As Level Chemistry 9701 Theory v1Noora MubarakNo ratings yet

- Nissin Di866 Flash User ManualDocument11 pagesNissin Di866 Flash User ManualJulienBarratNo ratings yet

- Radiographic Testing Report: EGB-S-RT-0002Document4 pagesRadiographic Testing Report: EGB-S-RT-0002Tuấn ĐậuNo ratings yet

- 2023 VCAA Physics Exam SolutionsDocument2 pages2023 VCAA Physics Exam SolutionsRobin MowlaNo ratings yet

- A. Introduction To Archl AcousticsDocument25 pagesA. Introduction To Archl AcousticsDan MarbellaNo ratings yet

- StereolithographyDocument13 pagesStereolithographyElstonD'cruzNo ratings yet

- 03 KinematicsHertzFlexures SullivanDocument50 pages03 KinematicsHertzFlexures SullivanSubhash AhujaNo ratings yet

- Design Simulation Construction of SwimmingDocument26 pagesDesign Simulation Construction of Swimmingmohamed algharbiNo ratings yet

- Impact Toughness of Metallic Materials Lab ReportDocument5 pagesImpact Toughness of Metallic Materials Lab ReportEmıły WınıfredNo ratings yet

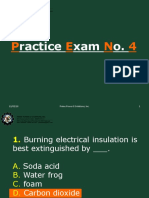

- Practice Exam No. 4 2018 PDFDocument43 pagesPractice Exam No. 4 2018 PDFJevan CalaqueNo ratings yet

- Mysterious OceanDocument202 pagesMysterious OceanPedro Carlos PicapiedraNo ratings yet

- Major Losses: Due To Friction, Significant Head Loss Is Associated With The StraightDocument2 pagesMajor Losses: Due To Friction, Significant Head Loss Is Associated With The StraightVarun ShastryNo ratings yet

- Hitachi Anisotropic Conductive Film AnisolmDocument9 pagesHitachi Anisotropic Conductive Film AnisolmAyanNo ratings yet

- Tailormade: Individual Solutions, High-Quality Products, and Comprehensive ServiceDocument24 pagesTailormade: Individual Solutions, High-Quality Products, and Comprehensive ServiceGustavo Adolfo Soto G.No ratings yet

- General Formula For Bi-Aspheric Singlet Lens Design Free of Spherical AberrationDocument5 pagesGeneral Formula For Bi-Aspheric Singlet Lens Design Free of Spherical AberrationSç-č AbabiiNo ratings yet

- Gears NBH FinalDocument75 pagesGears NBH FinalSaikat Bhowmick100% (1)

- Journey To The Bound StatesDocument96 pagesJourney To The Bound StatesCrainlyNo ratings yet

- Cambering Steel BeamsDocument2 pagesCambering Steel BeamsFernando PizarroNo ratings yet

- Scissor LiftDocument27 pagesScissor LiftKalai100% (1)

- Gundle Insulation Brochure PDFDocument8 pagesGundle Insulation Brochure PDFnadji habibiNo ratings yet

- Microstructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringDocument5 pagesMicrostructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringLeidy Silvana Chacón VelascoNo ratings yet

- Training Calander IRWRI 2019-20 (Rev.)Document2 pagesTraining Calander IRWRI 2019-20 (Rev.)Akash kumarNo ratings yet

- Appendix B - 13920 Changes 24.1.2018 PDFDocument1 pageAppendix B - 13920 Changes 24.1.2018 PDFChetanNo ratings yet

- Air Vent Valve VENN Air Vent ValvesDocument4 pagesAir Vent Valve VENN Air Vent ValvesFredie LabradorNo ratings yet

- NanodevicesDocument20 pagesNanodevicesHemanth Achamveedu75% (8)