Professional Documents

Culture Documents

Quintuple Base Case Input

Quintuple Base Case Input

Uploaded by

Prajay ManeCopyright:

Available Formats

You might also like

- Macroeconomics 6th Edition Williamson Solutions Manual DownloadDocument13 pagesMacroeconomics 6th Edition Williamson Solutions Manual DownloadDarrell Davis100% (24)

- Rancangan Pengajaran Tahunan MatematikDocument8 pagesRancangan Pengajaran Tahunan MatematikWendy Bahari100% (5)

- Kobaian - English DictionaryDocument3 pagesKobaian - English Dictionarysabbao100% (1)

- Fertial Arzew Plant2Document5 pagesFertial Arzew Plant2Azee TitouNo ratings yet

- SWT Juli 20Document24 pagesSWT Juli 20kusumaNo ratings yet

- Logsheet Boiler 10-06-2023Document696 pagesLogsheet Boiler 10-06-2023GAMING ChannelNo ratings yet

- Distillation CalculationDocument9 pagesDistillation Calculationraviralagiri020% (1)

- Principles of Refrigeration: MAE 554 Professor H. Ezzat Khalifa Syracuse UniversityDocument47 pagesPrinciples of Refrigeration: MAE 554 Professor H. Ezzat Khalifa Syracuse UniversitySamar Singhal100% (1)

- Technical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantAhmed HeikalNo ratings yet

- Cleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessDocument9 pagesCleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessArifEkoPrasetyoNo ratings yet

- Danfoss GL80ANb R134a 220 60Document4 pagesDanfoss GL80ANb R134a 220 60Edgard Tavara MaldonadoNo ratings yet

- Flash Gas/Oil Ratio, SCF/STB Bubble Point Pressure, Psi Reservoir Pressure, Psi Reservoir Temperature, of Differential Gas/Oil Ratio, SCF/STBDocument52 pagesFlash Gas/Oil Ratio, SCF/STB Bubble Point Pressure, Psi Reservoir Pressure, Psi Reservoir Temperature, of Differential Gas/Oil Ratio, SCF/STBMario HuasasquicheNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- M.Novriyanto M1B118028 - UTS SIMKOMDocument10 pagesM.Novriyanto M1B118028 - UTS SIMKOMDave N7RNo ratings yet

- Choke Valve SizingDocument8 pagesChoke Valve SizingreninbabaskiNo ratings yet

- Excel - Distillation Column Design Lab ReportDocument37 pagesExcel - Distillation Column Design Lab ReportGracylla Rose0% (1)

- Design ConditionDocument1 pageDesign ConditionPHAM THANH TUNo ratings yet

- Danfoss GD24MBc R134a 220 50Document4 pagesDanfoss GD24MBc R134a 220 50Antonio MartinNo ratings yet

- Baru - Aux Engine Performance Reports March 2022Document12 pagesBaru - Aux Engine Performance Reports March 2022Dragoș GreceanuNo ratings yet

- Autor: A MayoriDocument35 pagesAutor: A MayoriMarco Antonio Espejo PizarrosoNo ratings yet

- Overall SummaryDocument1 pageOverall SummaryTIPAZONo ratings yet

- DCM PFD CalculationDocument8 pagesDCM PFD CalculationManish GautamNo ratings yet

- Water For 3500TCDDocument3 pagesWater For 3500TCDdgmNo ratings yet

- TSFP Phase I - II Annexure - 3A1 Page 1/1: Material Balance Raw Sugar Factory - Diffuser Phase - I - 545 TCHDocument1 pageTSFP Phase I - II Annexure - 3A1 Page 1/1: Material Balance Raw Sugar Factory - Diffuser Phase - I - 545 TCHSolomon AlemuNo ratings yet

- Journal Pone 0074403 s001Document3 pagesJournal Pone 0074403 s001Sunday PaulNo ratings yet

- Data Chiller Dan Power Quality Pompa Sebelum SequencingDocument90 pagesData Chiller Dan Power Quality Pompa Sebelum Sequencingsalad garamNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- T1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segDocument1 pageT1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segTIPAZONo ratings yet

- Technical Data Sheet L22CL 220-240V 50Hz 1 R600a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet L22CL 220-240V 50Hz 1 R600a: Compressor Model Voltage RefrigerantHeru susantoNo ratings yet

- Refrigerated Gas Plant: Gas Processing With Propane Refrigeration LoopDocument12 pagesRefrigerated Gas Plant: Gas Processing With Propane Refrigeration LoopTamer LordNo ratings yet

- AQSW0512-H-T1: TECHNICAL SELECTION - AHRI 550/590 and AHRI 551/591Document4 pagesAQSW0512-H-T1: TECHNICAL SELECTION - AHRI 550/590 and AHRI 551/591ajun madana putraNo ratings yet

- Technical Data Sheet Hly90Aaa 220-240V 50Hz 1 R600A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Hly90Aaa 220-240V 50Hz 1 R600A: Compressor Model Voltage RefrigerantGeri SulanjakuNo ratings yet

- Danfoss - B25GL - R134a - 220 - 50Document4 pagesDanfoss - B25GL - R134a - 220 - 50JahazielNo ratings yet

- Marine Test (T2P02347)Document2 pagesMarine Test (T2P02347)jgmanaure3105No ratings yet

- Experiment # 4: ObjectiveDocument2 pagesExperiment # 4: ObjectiveMishi KhanNo ratings yet

- Ogpe OGPE Oil Fields: Calculation SheetDocument4 pagesOgpe OGPE Oil Fields: Calculation SheetFaber TrujilloNo ratings yet

- Multi Component DisitillationDocument90 pagesMulti Component DisitillationHatif AlamNo ratings yet

- Data Spesimen PengujianDocument8 pagesData Spesimen PengujianintanfujiNo ratings yet

- Danfoss GD36AA R134a 220 50Document4 pagesDanfoss GD36AA R134a 220 50stralis1971No ratings yet

- Room Checksums: 01F-Phong Khach&Bep Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesDocument6 pagesRoom Checksums: 01F-Phong Khach&Bep Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesSieuNhanNo ratings yet

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- Electrical and Thermal Performance: Ceramic Plate Series Thermoelectric Cooler Features ApplicationsDocument4 pagesElectrical and Thermal Performance: Ceramic Plate Series Thermoelectric Cooler Features Applicationsابكر ابو ميلادNo ratings yet

- Danfoss - GL45TG - R134a - 200 - 50 Compresor de Pizza de VerdadDocument5 pagesDanfoss - GL45TG - R134a - 200 - 50 Compresor de Pizza de VerdadEdison EspinalNo ratings yet

- Data Chiller 3 After SequencingDocument31 pagesData Chiller 3 After Sequencingsalad garamNo ratings yet

- Experiment 2 Heat of CombustionDocument7 pagesExperiment 2 Heat of Combustionain sufizaNo ratings yet

- Danfoss GL80TE R134a 115 60Document5 pagesDanfoss GL80TE R134a 115 60Luis GalvanNo ratings yet

- Performance Diesel 350 HP BarrickDocument2 pagesPerformance Diesel 350 HP BarrickEnrique RafaelNo ratings yet

- Effectiveness - NTU CurvesDocument31 pagesEffectiveness - NTU CurvesLoken Rizal0% (1)

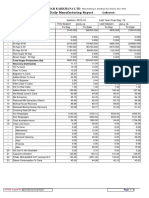

- Daily Manufacturing Report: Shreenath Mhaskoba Sakhar Karkhana LTDDocument2 pagesDaily Manufacturing Report: Shreenath Mhaskoba Sakhar Karkhana LTDSivakumar SelvarajNo ratings yet

- Thermal and Hydraulic AnalysisDocument1 pageThermal and Hydraulic AnalysisSikander MushtaqNo ratings yet

- 1 Hamaca MejoradoDocument2 pages1 Hamaca MejoradoMiguel BetancourtNo ratings yet

- Technical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage RefrigerantGrissly E. Lasso CordobaNo ratings yet

- It 1.1.4-HV 1244002 ABCDEF CV-Calc Rev4Document2 pagesIt 1.1.4-HV 1244002 ABCDEF CV-Calc Rev44122acaNo ratings yet

- Technical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage Refrigerantrafael cuellarNo ratings yet

- Danfoss HPY14RAb R600a 220 50Document4 pagesDanfoss HPY14RAb R600a 220 50zach yvesNo ratings yet

- Technical Data Sheet Gl45Aaa 220-240V 50Hz 1 R134A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Gl45Aaa 220-240V 50Hz 1 R134A: Compressor Model Voltage RefrigerantBenyoucef SmainiNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Img20181130 11105313Document1 pageImg20181130 11105313Prajay ManeNo ratings yet

- Bear H: CorporationDocument63 pagesBear H: CorporationPrajay ManeNo ratings yet

- # 66 - Welding Material 427 - ROD: Khatav Man Taluka Agro Processing Ltd. Padal Item ListDocument6 pages# 66 - Welding Material 427 - ROD: Khatav Man Taluka Agro Processing Ltd. Padal Item ListPrajay ManeNo ratings yet

- Ador Welding Air Plasma Cutting Machine, Model-Champcut 25 (C) Along With 100 A Cutting Torch (6Mtr) and 2.5 MTR Earthing Cable AssemblyDocument2 pagesAdor Welding Air Plasma Cutting Machine, Model-Champcut 25 (C) Along With 100 A Cutting Torch (6Mtr) and 2.5 MTR Earthing Cable AssemblyPrajay ManeNo ratings yet

- Ms Pipe Class & Weight ChartDocument4 pagesMs Pipe Class & Weight ChartPrajay Mane100% (1)

- Mounting: Exciter Cardan Shaft MotorDocument2 pagesMounting: Exciter Cardan Shaft MotorPrajay ManeNo ratings yet

- WR 2122Document3 pagesWR 2122Prajay ManeNo ratings yet

- 2500E AllDocument67 pages2500E AllPrajay ManeNo ratings yet

- Acpl Bush 140114134Document1 pageAcpl Bush 140114134Prajay ManeNo ratings yet

- O&M Quality Dossier 9973604123Document93 pagesO&M Quality Dossier 9973604123Prajay ManeNo ratings yet

- Fernerkundungsbasierte, Automatisierte, Multisensorale Brandflächendetektion Im Kruger National Park, SüdafrikaDocument151 pagesFernerkundungsbasierte, Automatisierte, Multisensorale Brandflächendetektion Im Kruger National Park, SüdafrikawurstomanNo ratings yet

- Oil Pressure Transmission PT2509Document3 pagesOil Pressure Transmission PT2509Trisna TeaNo ratings yet

- Delta and Estuaries PDFDocument8 pagesDelta and Estuaries PDFIwan PrabowoNo ratings yet

- Contour Lines: Representation of HeightsDocument42 pagesContour Lines: Representation of HeightsTheresa BrownNo ratings yet

- Christian History and MissionDocument50 pagesChristian History and MissionJohana Vangchhia100% (1)

- Multiprocessors Interconnection NetworksDocument32 pagesMultiprocessors Interconnection NetworksPaul CorsinaNo ratings yet

- How To Give Feedback To Students The Advanced Guide Final1Document25 pagesHow To Give Feedback To Students The Advanced Guide Final1api-313584726No ratings yet

- 1 Notes and HW On Even Odd and NeitherDocument3 pages1 Notes and HW On Even Odd and NeitherAlin LyndaNo ratings yet

- Assembly BuildingDocument1 pageAssembly BuildingHarshit RajNo ratings yet

- Adélia TrabalhoDocument9 pagesAdélia TrabalhoAmador Ambriz ZondaNo ratings yet

- Assignment Parts of SpeechDocument2 pagesAssignment Parts of SpeechFarman Ali KhaskheliNo ratings yet

- Reconsidering Mary of BethanyDocument18 pagesReconsidering Mary of BethanyGeorgeAbhayanandOicNo ratings yet

- Final PPT Siemens & NAFTADocument23 pagesFinal PPT Siemens & NAFTAJohnnybravouNo ratings yet

- Ch9 2021 2Document19 pagesCh9 2021 2muhiafrancis975No ratings yet

- Lesson 7B The PassDocument5 pagesLesson 7B The PassJessel GulfericaNo ratings yet

- How Deep Is Your LoveDocument1 pageHow Deep Is Your LoveJanina JaworskiNo ratings yet

- Assignment Solutions - 134Document6 pagesAssignment Solutions - 134Prof OliviaNo ratings yet

- Successful InterviewsDocument3 pagesSuccessful InterviewsRia SeprianiNo ratings yet

- Journal HFMDocument8 pagesJournal HFMVijayabhaskarareddy VemireddyNo ratings yet

- Pizza NightDocument16 pagesPizza NightWeldon Owen Publishing40% (5)

- SWOT Analysis Template For Technology Planning Needs AssessmentDocument12 pagesSWOT Analysis Template For Technology Planning Needs Assessmentapi-290597914No ratings yet

- CCBP Learners With Backlogs-01!12!2021Document10 pagesCCBP Learners With Backlogs-01!12!2021MohdHussainNo ratings yet

- SilencerDocument6 pagesSilencerAlem HasicNo ratings yet

- Mod 6 Soft Tissue InjuriesDocument5 pagesMod 6 Soft Tissue Injuriesrez1987100% (1)

- Slug LowDocument13 pagesSlug LowDr Mohammed AzharNo ratings yet

- Bob Fitts - Highest PlaceDocument2 pagesBob Fitts - Highest PlaceJosé Miguel Baute Rosado100% (1)

- Physics Investigatory Project Class 12Document22 pagesPhysics Investigatory Project Class 12Siddharth SinghNo ratings yet

Quintuple Base Case Input

Quintuple Base Case Input

Uploaded by

Prajay ManeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quintuple Base Case Input

Quintuple Base Case Input

Uploaded by

Prajay ManeCopyright:

Available Formats

Sugar Mill Calculations

Resource for Sugar Mill Calculations…………………………………………..

INPUTS

1 Crushing Capacity, TCD 10560 21 Steam admitted to # 1 Body > 185 MT/Hr

o

2 Working hours, Hrs 24.00 22 Pan vapour temperature. oC 65 %C

3 Mixed juice % Cane 115.00 23 SHWW %Cane 1.41 cane

o

4 Milk of lime % Cane ( V/V) 2.00 24 Condensate temp to boiler, oC 100 C

o

5 Filterate Juice % Cane 16.00 25 SHWW Temperature, oC 117.5 C

6 Filterate Juice brix 10.95 Calculated Results

7 26 Total exhaust consumption estimated 185.00 MT/Hr

8 Mixed juice brix 12.22 27 Total exhaust consumption % cane 42.05 %

9 Mixed pol 9.53 #1 #2 #3 #4 #5

10 Clear juice brix 11.75 28 Brix out assumed 16.9 30.1 37.6 46.7 60.7

11 Clear juice pol 9.16 29 Brix out estimated 16.9 30.1 37.6 46.7 60.7

12 Syrup brix required 60.00 30 Steam in, MT/Hr 185.0 158.2 37.4 27.3 16.2

13 Filtercake % Cane 2.70 31 Steam out, MT/Hr 176.0 158.9 41.0 31.7 30.2

14 Pol % Filtercake 1.80 32 Bleeds, MT/Hr 17.7 121.4 13.7 15.5 15.2

15 Melt quantity towards Refinery MT/Hr 0.00 33 Vapout to next 158.2 37.4 27.3 16.2 15.0

16 Melt brix 60.00 34 Vent, MT/Hr 1.8 1.0 0.3 0.1 0.1

17 Steam % Cane TARGET 40.00 35 E.R. ( Installed HS) 24.4 23.4 12.8 15.8 17.8

18 36 E.R. (Calc. HS) Hug. 36.5 31.0 14.6 18.0 18.2

19 37 E.R. (Calc. HS) HTC 29.6 27.1 12.3 20.8 34.0

20 38 Diff. heat in/out 0.0 0.0 0.0 0.0 0.1

Evaporator conditions Exhaust #1 #2 #3 #4 #5 Live Stem

IN OUT OUT OUT OUT OUT

Velocity m/sec 25 30 35 40 45 50 Latent heat

delta T eff 7.50 8.90 7.20 12.80 28.80 666.56

Temperature, ºC 120.2 112.7 103.8 96.6 83.8 55.0 Sen. heat

Vent qty, MT/Hr input 1.8 1 0.3 0.1 0.1 180

Vent % Vapour admitted in calendria 1.0 0.6 0.8 0.4 0.6

o

Heat loss % Total Heat Admitted in Evap. 1.5 1.5 1.5 1.5 1.5 C

Heating surface, m^2 Installed 7200 6800 3200 2000 1700 180

Number of bodies installed 2 2 2 1 1

Dessin factor 0.0010 0.001 0.0009 0.0008 0.0007

Juice level , m 0.600 0.600 0.600 0.600 0.600

Vent Heaters #1 DC=0 #2 DC=0 #3 DC=0

% In, C Out, C Tubular = 1 In, C Out, C Tubular = 1 In, C Out, C Tubular = 1

0.1 Mixed juice 0 0 1 0 0 0 0 0 1

0.1 Sulphited juice 99.7 102 1 91.4 99.7 1 76.2 89.9 1

0.1 Clear juice 101 111 0 95 101 0 0 0 1

0.1 Melt heating 60 90 1 0 0 1 0 0 1

0.1 Syrup heating 0 0 1 0 0 1 0 0 1

0.1 Filterate juice heating 0 0 0 0 0 0 0 0 0

Brix In Brix Out Brix In Brix Out Brix In Brix Out

0.1 Melt Concentrator 1 1 60 72 1 1

Max Heaters #4 DC=0 #5 DC=0 Exhaust DC=0

C Tubular = 1 Tubular = 1 Tubular = 1

72 Mixed juice 60.8 72 1 30 48.3 1 0 0 1

102 Sulphited juice 0 0 0 0 0 0 0 0 0

111 Clear juice 0 0 1 0 0 0 0 0 0

90 Melt heating 0 0 1 0 0 0 0 0 0

80 Syrup heating 57.9 80 0 0 0 0 0 0 0

75 Filterate juice heating 63.2 75 0 0 0 0 0 0 0

Brix In Brix Out Brix In Brix Out Brix In Brix Out

Melt Concentrator 1 1 1 1 1 1

Heaters Condensate DC=0 Clarifier flash DC=0 Scrubber Water DC=0

In, C Out, C In, C

Tubular = 1 Out, C Tubular = 1 In, C Out, C Tubular = 1

Quantity MT/Hr Quantity 1.47 MT/Hr Quantity 450 MT/Hr

Actual 372.1 MT/Hr Actual 3.11 1.96 Actual MT/Hr

o o o

Temp. C Temp. 100 C Temp. 55 C

o o

Actual 83.0 C Actual C

Mixed juice 48.3 60.8 1 0 0 1 0 0 1

Sulphited juice 71.2 76.2 1 89.9 91.4 0 0 0 1

Clear juice 0 0 0 0 0 0 0 0 0

Melt heating 0 0 1 0 0 1 0 0 1

Syrup heating 0 0 1 0 0 1 0 0 1

Filterate juice heating 0 0 0 0 0 0 0 0 0

Loss assumed in condensate heater 5 0 0 0 0 0 0

Sugar Mill Calculations

Resource for Sugar Mill Calculations…………………………………………..

Molasses Conditioners Molasses Brix Brix Molasses Temperature Water Loss

Direct Contact with Water Stirrer % Cane IN OUT IN OUT Temp IN % Total heat

Admitted

A Heavy 15.00 75.00 75.00 55 70 90 5

B Heavy 8.00 75.00 75.00 54 70 90 5

C Light 6.00 75.00 75.00 55 70 90 5

C1 Heavy 2.00 75.00 75.00 53 70 90 5

R1 Molasses 0.00 72.00 72.00 55 70 90 5

R2 Molasses 0.00 72.00 72.00 55 70 90 5

R3 Molasses 0.00 72.00 72.00 55 70 90 5

Massecuite % Cane

Raw House Exhaust #1 #2 #3 #4 #5 % steam Vent %

A Massecuite 0 0 35 0 0 0 0.45 1

B Massecuite 0 0 12 0 0 0 0.35 1

C Massecuite 0 0 8 0 0 0 0.45 1

C1 Massecuite 0 0 1.5 0 0 0 0.45 1

Refinery Exhaust #1 #2 #3 #4 #5 % steam Vent %

R1 Massecuite 0 0 0 0 0 0 0.30 1

R2 Massecuite 0 0 0 0 0 0 0.30 1

R3 Massecuite 0 0 0 0 0 0 0.30 1

R 4 Massecuite 0 0 0 0 0 0 0.30 1

Washing Steam % Cane Exhaust #1 Sugar Melted % Cane Ref excel

1 A Side Pans 0 0.5 B & C Sugar

2 B Side Pans 0 0.25 Scalpings Sugar

3 C Side Pans 0 0.25 Dirty / Damaged Sugar

4 Refinery Pans 0 0 Raw Sugar

You might also like

- Macroeconomics 6th Edition Williamson Solutions Manual DownloadDocument13 pagesMacroeconomics 6th Edition Williamson Solutions Manual DownloadDarrell Davis100% (24)

- Rancangan Pengajaran Tahunan MatematikDocument8 pagesRancangan Pengajaran Tahunan MatematikWendy Bahari100% (5)

- Kobaian - English DictionaryDocument3 pagesKobaian - English Dictionarysabbao100% (1)

- Fertial Arzew Plant2Document5 pagesFertial Arzew Plant2Azee TitouNo ratings yet

- SWT Juli 20Document24 pagesSWT Juli 20kusumaNo ratings yet

- Logsheet Boiler 10-06-2023Document696 pagesLogsheet Boiler 10-06-2023GAMING ChannelNo ratings yet

- Distillation CalculationDocument9 pagesDistillation Calculationraviralagiri020% (1)

- Principles of Refrigeration: MAE 554 Professor H. Ezzat Khalifa Syracuse UniversityDocument47 pagesPrinciples of Refrigeration: MAE 554 Professor H. Ezzat Khalifa Syracuse UniversitySamar Singhal100% (1)

- Technical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantAhmed HeikalNo ratings yet

- Cleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessDocument9 pagesCleaning Data Collection Sheet: Step 1: Alkaline Cleaning ProcessArifEkoPrasetyoNo ratings yet

- Danfoss GL80ANb R134a 220 60Document4 pagesDanfoss GL80ANb R134a 220 60Edgard Tavara MaldonadoNo ratings yet

- Flash Gas/Oil Ratio, SCF/STB Bubble Point Pressure, Psi Reservoir Pressure, Psi Reservoir Temperature, of Differential Gas/Oil Ratio, SCF/STBDocument52 pagesFlash Gas/Oil Ratio, SCF/STB Bubble Point Pressure, Psi Reservoir Pressure, Psi Reservoir Temperature, of Differential Gas/Oil Ratio, SCF/STBMario HuasasquicheNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- M.Novriyanto M1B118028 - UTS SIMKOMDocument10 pagesM.Novriyanto M1B118028 - UTS SIMKOMDave N7RNo ratings yet

- Choke Valve SizingDocument8 pagesChoke Valve SizingreninbabaskiNo ratings yet

- Excel - Distillation Column Design Lab ReportDocument37 pagesExcel - Distillation Column Design Lab ReportGracylla Rose0% (1)

- Design ConditionDocument1 pageDesign ConditionPHAM THANH TUNo ratings yet

- Danfoss GD24MBc R134a 220 50Document4 pagesDanfoss GD24MBc R134a 220 50Antonio MartinNo ratings yet

- Baru - Aux Engine Performance Reports March 2022Document12 pagesBaru - Aux Engine Performance Reports March 2022Dragoș GreceanuNo ratings yet

- Autor: A MayoriDocument35 pagesAutor: A MayoriMarco Antonio Espejo PizarrosoNo ratings yet

- Overall SummaryDocument1 pageOverall SummaryTIPAZONo ratings yet

- DCM PFD CalculationDocument8 pagesDCM PFD CalculationManish GautamNo ratings yet

- Water For 3500TCDDocument3 pagesWater For 3500TCDdgmNo ratings yet

- TSFP Phase I - II Annexure - 3A1 Page 1/1: Material Balance Raw Sugar Factory - Diffuser Phase - I - 545 TCHDocument1 pageTSFP Phase I - II Annexure - 3A1 Page 1/1: Material Balance Raw Sugar Factory - Diffuser Phase - I - 545 TCHSolomon AlemuNo ratings yet

- Journal Pone 0074403 s001Document3 pagesJournal Pone 0074403 s001Sunday PaulNo ratings yet

- Data Chiller Dan Power Quality Pompa Sebelum SequencingDocument90 pagesData Chiller Dan Power Quality Pompa Sebelum Sequencingsalad garamNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- T1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segDocument1 pageT1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segTIPAZONo ratings yet

- Technical Data Sheet L22CL 220-240V 50Hz 1 R600a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet L22CL 220-240V 50Hz 1 R600a: Compressor Model Voltage RefrigerantHeru susantoNo ratings yet

- Refrigerated Gas Plant: Gas Processing With Propane Refrigeration LoopDocument12 pagesRefrigerated Gas Plant: Gas Processing With Propane Refrigeration LoopTamer LordNo ratings yet

- AQSW0512-H-T1: TECHNICAL SELECTION - AHRI 550/590 and AHRI 551/591Document4 pagesAQSW0512-H-T1: TECHNICAL SELECTION - AHRI 550/590 and AHRI 551/591ajun madana putraNo ratings yet

- Technical Data Sheet Hly90Aaa 220-240V 50Hz 1 R600A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Hly90Aaa 220-240V 50Hz 1 R600A: Compressor Model Voltage RefrigerantGeri SulanjakuNo ratings yet

- Danfoss - B25GL - R134a - 220 - 50Document4 pagesDanfoss - B25GL - R134a - 220 - 50JahazielNo ratings yet

- Marine Test (T2P02347)Document2 pagesMarine Test (T2P02347)jgmanaure3105No ratings yet

- Experiment # 4: ObjectiveDocument2 pagesExperiment # 4: ObjectiveMishi KhanNo ratings yet

- Ogpe OGPE Oil Fields: Calculation SheetDocument4 pagesOgpe OGPE Oil Fields: Calculation SheetFaber TrujilloNo ratings yet

- Multi Component DisitillationDocument90 pagesMulti Component DisitillationHatif AlamNo ratings yet

- Data Spesimen PengujianDocument8 pagesData Spesimen PengujianintanfujiNo ratings yet

- Danfoss GD36AA R134a 220 50Document4 pagesDanfoss GD36AA R134a 220 50stralis1971No ratings yet

- Room Checksums: 01F-Phong Khach&Bep Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesDocument6 pagesRoom Checksums: 01F-Phong Khach&Bep Heating Coil Peak CLG Space Peak Cooling Coil Peak TemperaturesSieuNhanNo ratings yet

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- Electrical and Thermal Performance: Ceramic Plate Series Thermoelectric Cooler Features ApplicationsDocument4 pagesElectrical and Thermal Performance: Ceramic Plate Series Thermoelectric Cooler Features Applicationsابكر ابو ميلادNo ratings yet

- Danfoss - GL45TG - R134a - 200 - 50 Compresor de Pizza de VerdadDocument5 pagesDanfoss - GL45TG - R134a - 200 - 50 Compresor de Pizza de VerdadEdison EspinalNo ratings yet

- Data Chiller 3 After SequencingDocument31 pagesData Chiller 3 After Sequencingsalad garamNo ratings yet

- Experiment 2 Heat of CombustionDocument7 pagesExperiment 2 Heat of Combustionain sufizaNo ratings yet

- Danfoss GL80TE R134a 115 60Document5 pagesDanfoss GL80TE R134a 115 60Luis GalvanNo ratings yet

- Performance Diesel 350 HP BarrickDocument2 pagesPerformance Diesel 350 HP BarrickEnrique RafaelNo ratings yet

- Effectiveness - NTU CurvesDocument31 pagesEffectiveness - NTU CurvesLoken Rizal0% (1)

- Daily Manufacturing Report: Shreenath Mhaskoba Sakhar Karkhana LTDDocument2 pagesDaily Manufacturing Report: Shreenath Mhaskoba Sakhar Karkhana LTDSivakumar SelvarajNo ratings yet

- Thermal and Hydraulic AnalysisDocument1 pageThermal and Hydraulic AnalysisSikander MushtaqNo ratings yet

- 1 Hamaca MejoradoDocument2 pages1 Hamaca MejoradoMiguel BetancourtNo ratings yet

- Technical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage RefrigerantGrissly E. Lasso CordobaNo ratings yet

- It 1.1.4-HV 1244002 ABCDEF CV-Calc Rev4Document2 pagesIt 1.1.4-HV 1244002 ABCDEF CV-Calc Rev44122acaNo ratings yet

- Technical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet GP16TE 115V 60Hz 1 R134a: Compressor Model Voltage Refrigerantrafael cuellarNo ratings yet

- Danfoss HPY14RAb R600a 220 50Document4 pagesDanfoss HPY14RAb R600a 220 50zach yvesNo ratings yet

- Technical Data Sheet Gl45Aaa 220-240V 50Hz 1 R134A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Gl45Aaa 220-240V 50Hz 1 R134A: Compressor Model Voltage RefrigerantBenyoucef SmainiNo ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Img20181130 11105313Document1 pageImg20181130 11105313Prajay ManeNo ratings yet

- Bear H: CorporationDocument63 pagesBear H: CorporationPrajay ManeNo ratings yet

- # 66 - Welding Material 427 - ROD: Khatav Man Taluka Agro Processing Ltd. Padal Item ListDocument6 pages# 66 - Welding Material 427 - ROD: Khatav Man Taluka Agro Processing Ltd. Padal Item ListPrajay ManeNo ratings yet

- Ador Welding Air Plasma Cutting Machine, Model-Champcut 25 (C) Along With 100 A Cutting Torch (6Mtr) and 2.5 MTR Earthing Cable AssemblyDocument2 pagesAdor Welding Air Plasma Cutting Machine, Model-Champcut 25 (C) Along With 100 A Cutting Torch (6Mtr) and 2.5 MTR Earthing Cable AssemblyPrajay ManeNo ratings yet

- Ms Pipe Class & Weight ChartDocument4 pagesMs Pipe Class & Weight ChartPrajay Mane100% (1)

- Mounting: Exciter Cardan Shaft MotorDocument2 pagesMounting: Exciter Cardan Shaft MotorPrajay ManeNo ratings yet

- WR 2122Document3 pagesWR 2122Prajay ManeNo ratings yet

- 2500E AllDocument67 pages2500E AllPrajay ManeNo ratings yet

- Acpl Bush 140114134Document1 pageAcpl Bush 140114134Prajay ManeNo ratings yet

- O&M Quality Dossier 9973604123Document93 pagesO&M Quality Dossier 9973604123Prajay ManeNo ratings yet

- Fernerkundungsbasierte, Automatisierte, Multisensorale Brandflächendetektion Im Kruger National Park, SüdafrikaDocument151 pagesFernerkundungsbasierte, Automatisierte, Multisensorale Brandflächendetektion Im Kruger National Park, SüdafrikawurstomanNo ratings yet

- Oil Pressure Transmission PT2509Document3 pagesOil Pressure Transmission PT2509Trisna TeaNo ratings yet

- Delta and Estuaries PDFDocument8 pagesDelta and Estuaries PDFIwan PrabowoNo ratings yet

- Contour Lines: Representation of HeightsDocument42 pagesContour Lines: Representation of HeightsTheresa BrownNo ratings yet

- Christian History and MissionDocument50 pagesChristian History and MissionJohana Vangchhia100% (1)

- Multiprocessors Interconnection NetworksDocument32 pagesMultiprocessors Interconnection NetworksPaul CorsinaNo ratings yet

- How To Give Feedback To Students The Advanced Guide Final1Document25 pagesHow To Give Feedback To Students The Advanced Guide Final1api-313584726No ratings yet

- 1 Notes and HW On Even Odd and NeitherDocument3 pages1 Notes and HW On Even Odd and NeitherAlin LyndaNo ratings yet

- Assembly BuildingDocument1 pageAssembly BuildingHarshit RajNo ratings yet

- Adélia TrabalhoDocument9 pagesAdélia TrabalhoAmador Ambriz ZondaNo ratings yet

- Assignment Parts of SpeechDocument2 pagesAssignment Parts of SpeechFarman Ali KhaskheliNo ratings yet

- Reconsidering Mary of BethanyDocument18 pagesReconsidering Mary of BethanyGeorgeAbhayanandOicNo ratings yet

- Final PPT Siemens & NAFTADocument23 pagesFinal PPT Siemens & NAFTAJohnnybravouNo ratings yet

- Ch9 2021 2Document19 pagesCh9 2021 2muhiafrancis975No ratings yet

- Lesson 7B The PassDocument5 pagesLesson 7B The PassJessel GulfericaNo ratings yet

- How Deep Is Your LoveDocument1 pageHow Deep Is Your LoveJanina JaworskiNo ratings yet

- Assignment Solutions - 134Document6 pagesAssignment Solutions - 134Prof OliviaNo ratings yet

- Successful InterviewsDocument3 pagesSuccessful InterviewsRia SeprianiNo ratings yet

- Journal HFMDocument8 pagesJournal HFMVijayabhaskarareddy VemireddyNo ratings yet

- Pizza NightDocument16 pagesPizza NightWeldon Owen Publishing40% (5)

- SWOT Analysis Template For Technology Planning Needs AssessmentDocument12 pagesSWOT Analysis Template For Technology Planning Needs Assessmentapi-290597914No ratings yet

- CCBP Learners With Backlogs-01!12!2021Document10 pagesCCBP Learners With Backlogs-01!12!2021MohdHussainNo ratings yet

- SilencerDocument6 pagesSilencerAlem HasicNo ratings yet

- Mod 6 Soft Tissue InjuriesDocument5 pagesMod 6 Soft Tissue Injuriesrez1987100% (1)

- Slug LowDocument13 pagesSlug LowDr Mohammed AzharNo ratings yet

- Bob Fitts - Highest PlaceDocument2 pagesBob Fitts - Highest PlaceJosé Miguel Baute Rosado100% (1)

- Physics Investigatory Project Class 12Document22 pagesPhysics Investigatory Project Class 12Siddharth SinghNo ratings yet