Professional Documents

Culture Documents

Ahu Setter Corridor

Ahu Setter Corridor

Uploaded by

CITACOM UTAMAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ahu Setter Corridor

Ahu Setter Corridor

Uploaded by

CITACOM UTAMACopyright:

Available Formats

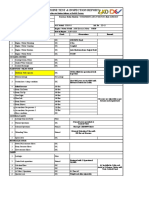

HVAC Commissioning Document – AHU

Name Hatchery Country Contact Person

PP BREEDER THAILAND Mr. Farm

AHU/Rooms Commissioned by Date: dd/mm/yyyy

AHU SETTER CORRIDOR FEBY YOGASWARA 14/10/2021

Part To check/measure N/A Data

Assembly AHU AHU modules aligned ⃞ OK ⃞

Modules connected at base frame ⃞ OK ⃞

Modules connected w. assembly corners ⃞ OK ⃞

Modules connected 'inside' with clamps ⃞ OK ⃞

Sealing strip between modules ⃞ OK ⃞

Pre-heating Electrical heating 1 ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

Electrical heating 2 ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

Electrical heating 3 ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

P/I Settings ⃞ P= I= Temperature Stability OK ⃞

Thermostat ⃞ OK ⃞

Three-way-valve ⃞ Type: ________ Glycol: _________ _________%

⃞ 0%⃞ 50⃞ 100⃞

Circulation pump ⃞ Brand: _______ ON/OFF: ⃞ Type: _______

Pre-Heating 100% open before 70/50°C heating ⃞ OK ⃞

Fresh air damper Fresh air damper ⃞ 0% ⃞ 100% ⃞

Modulating fresh/return damper ⃞ Voltage: _______ V DC

exhaust unit Separate return damper ⃞ Voltage: _______ V DC

Filter (supply) Pre-filter ⃞ OK ⃞

Filter ⃞ OK ⃞

Differential pressure meter ⃞ OK ⃞ Set at 200PA

QBM ⃞ OK ⃞ Set at 200Pa

⃞ OK ⃞ Electrical Connection between 1&3

⃞ OK ⃞ + Connection before the filter

⃞ OK ⃞ - Connection after the filter

Spare filters (hand-over to client) ⃞ OK ⃞

Filter (exhaust) Filter ⃞ OK ⃞

Differential pressure meter ⃞ OK ⃞ Set at 200PA

QBM ⃞ OK ⃞ Set at 200Pa

⃞ OK ⃞ Electrical Connection between 1&3

⃞ OK ⃞ + Connection before the filter

⃞ OK ⃞ - Connection after the filter

Spare filters (hand-over to client) ⃞ OK ⃞

Cross plate heat T room lower than set point heating --> bypass closed N/A OK ⃞

exchanger T room higher than set point cooling -0,5 --> bypass open OK ⃞

Bypass closed before heating 70/50°C OK ⃞

Rotation bypass damper Pos 1 or 2:_______ MARK!!

Siphon OK ⃞

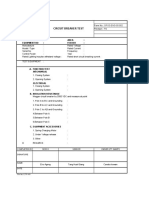

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 1

Part To check/measure N/A Data

Heating coil Temperature hot water supply ⃞ °C:_______

Three-way-valve ⃞ Type:_______ pos acc. drawing OK ⃞

0%⃞ 50⃞ 100⃞

Circulation pump ⃞ Brand: ________ ON/OFF: ⃞ Type: _______

Check water flow 3-way 100% open ⃞ _______ l/h

Direction non-return ⃞ OK ⃞

Pipe diameters to coil ⃞ mm / "_______

Frost protection sensor ⃞ Normal: _______ Alarm OK ⃞

Electrical heating Electrical heating 1 ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

Electrical heating 2 ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

Electrical heating 3 ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

P/I Settings ⃞ P= I= Temperature Stability OK ⃞

Thermostat ⃞ OK ⃞

Humidification Humidification pad ⃞ Arrow in air flow dir_____________________________

Droplet eliminator Arrow in air flow dir_____________________________

Rotation of humidity pump motor OK ⃞

Amperage of humidity pump motor Ph1: _______ A Ph2: _______ A Ph3: _______ A

Spillage valve 1/2 turn open OK ⃞

Adjustment water level OK ⃞

Adjustment water volume to pad l/min: _____________________________

Magnetic Valve humidifying OK ⃞ On/Off

Siphon OK ⃞

Cooling coil Tcold water supply ⃞ 10

°C:_______

Three-way-valve ⃞ R511

Type:_______ pos acc. drawing OK ⃞

0%⃞ 50⃞ 100⃞

Circulation pump ⃞ Brand:GRUNDFOS

________ ON/OFF: ⃞ Type: CR

_______

1-2 A-A-A-E-HQQE

Direction non-return ⃞ OK ⃞

Pipe diameters to coil 1

mm / "_______

Siphon OK ⃞

Supply ventilator ⃞ 1073

No:_________ (see no. on electric distribution plan)

(AHU) Frequency inverter ⃞ Min.:_______ Hz Max.:_______ Hz

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

(FI always on Current motor (low/normal speed) ⃞ 0.3 A

Ph1: _______ 0.3 A Ph3: _______ A

Ph2: _______

maximum output) Current motor (high/speed) ⃞ 1.8 A

Ph1: _______ 1.8 A Ph3: _______ A

Ph2: _______

Differential pressure switch QBM OK ⃞ Set at 20Pa

⃞ OK ⃞ Electrical Connection between 1&2 3&1

⃞ OK ⃞ + Connection in the ducting

⃞ OK ⃞ - Connection at the ventilator

Tension belt ⃞ OK ⃞

Spare belt ⃞ OK ⃞

Room Check Troom with value on PLC ⃞ OK ⃞ Calibration on PLC: _______°C

Temperature

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 2

Part To check/measure N/A Data

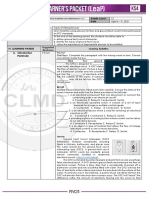

Room Switch Switch check all positions ⃞ OK ⃞ Values are changing for all positions

Measuring points Number MP on the drawing ⃞ Nr. _______

(measure at max Ducting size ⃞ Ø _______

speed)

Air Speed ⃞ _______ m/s

Air Volume ⃞ _______ m³/h

Number MP on the drawing ⃞ Nr. _______

Ducting size ⃞ Ø _______

Air Speed ⃞ _______ m/s

Air Volume ⃞ _______ m³/h

Number MP on the drawing ⃞ Nr. _______

Ducting size ⃞ Ø _______

Air Speed ⃞ _______ m/s

Air Volume ⃞ _______ m³/h

Number MP on the drawing ⃞ Nr. _______

Ducting size ⃞ Ø _______

Air Speed ⃞ _______ m/s

Air Volume ⃞ _______ m³/h

Number MP on the drawing ⃞ Nr. _______

Ducting size ⃞ Ø _______

Air Speed ⃞ _______ m/s

Air Volume ⃞ _______ m³/h

Number MP on the drawing ⃞ Nr. _______

Ducting size ⃞ Ø _______

Air Speed ⃞ _______ m/s

Air Volume ⃞ _______ m³/h

Air Damper/ Number of the Damper on the drawing ⃞ Nr. _______

Constant volume Set point handle ⃞ Approx.:_______% open Marked ⃞

damper

Set point ⃞ _______ m³/h

Number of the Damper on the drawing ⃞ Nr. _______

Set point handle ⃞ Approx.:_______% open Marked ⃞

Set point ⃞ _______ m³/h

Number of the Damper on the drawing ⃞ Nr. _______

Set point handle ⃞ Approx.:_______% open Marked ⃞

Set point ⃞ _______ m³/h

Number of the Damper on the drawing ⃞ Nr. _______

Set point handle ⃞ Approx.:_______% open Marked ⃞

Set point ⃞ _______ m³/h

Number of the Damper on the drawing ⃞ Nr. _______

Set point handle ⃞ Approx.:_______% open Marked ⃞

Set point ⃞ _______ m³/h

Number of the Damper on the drawing ⃞ Nr. _______

Set point handle ⃞ Approx.:_______% open Marked ⃞

Set point ⃞ _______ m³/h

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 3

Part To check/measure N/A Data

Exhaust ventilator Built-in the AHU ⃞ No:_______ (see no. on electric distribution plan)

Frequency inverter ⃞ Min.:_______ Hz Max.:_______ Hz

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

(FI always on Current motor (low/normal speed) ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

maximum output) Current motor (high/speed) ⃞ Ph1: _______ A Ph2: _______ A Ph3: _______ A

Differential pressure switch QBM OK ⃞ Set at 20Pa ⃞

⃞ OK ⃞ Electrical Connection between 1&2

⃞ OK ⃞ + Connection in the ducting

⃞ OK ⃞ - Connection at the ventilator

Tension belt ⃞ OK ⃞

Spare belt ⃞ OK ⃞

1075 (see no. on electric distribution plan)

Exhaust fan Exhauster SETTER CORRIDOR ⃞ No:_______

(measure at max Rotation Clockwise ⃞ Anti-clockwise ⃞

speed)

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

Current motor 1.1 A

Ph1: _______ 1.1 A Ph3: _______ A

Ph2: _______

Controlled by PPT/PPC ⃞ Node number

⃞ Nr.: ________

⃞ Power supply

⃞ Electrical cable nr. ________

Exhauster ⃞ No:_______ (see no. on electric distribution plan)

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

Current motor Ph1: _______ A Ph2: _______ A Ph3: _______ A

Controlled by PPT/PPC ⃞ Node number

⃞ Nr.: ________

⃞ Power supply

⃞ Electrical cable nr. ________

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 4

Exhauster ⃞ No:_______ (see no. on electric distribution plan)

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

Current motor Ph1: _______ A Ph2: _______ A Ph3: _______ A

Controlled by PPT/PPC ⃞ Node number

⃞ Nr.: ________

⃞ Power supply

⃞ Electrical cable nr. ________

Exhauster ⃞ No:_______ (see no. on electric distribution plan)

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

Current motor Ph1: _______ A Ph2: _______ A Ph3: _______ A

Controlled by PPT/PPC ⃞ Node number

⃞ Nr.: ________

⃞ Power supply

⃞ Electrical cable nr. ________

Exhauster ⃞ No:_______ (see no. on electric distribution plan)

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

Current motor Ph1: _______ A Ph2: _______ A Ph3: _______ A

Controlled by PPT/PPC ⃞ Node number

⃞ Nr.: ________

⃞ Power supply

⃞ Electrical cable nr. ________

Exhauster ⃞ No:_______ (see no. on electric distribution plan)

Rotation Clockwise ⃞ Anti-clockwise ⃞

Voltage ⃞ 230V ⃞

⃞ 400V ⃞

Connection ⃞ Star ⃞

⃞ Triangle ⃞

Current motor Ph1: _______ A Ph2: _______ A Ph3: _______ A

Controlled by PPT/PPC ⃞ Node number

⃞ Nr.: ________

⃞ Power supply

⃞ Electrical cable nr. ________

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 5

Part To check/measure N/A Data

Pressure PPT/PPC Node number ________

controller Type ________

Version ________

Serial number ________

Location measuring point '+' Where installed ________

Location measuring point '-' Where installed ________

Set point _______Pa

Correct and Stabilized working OK ⃞

Pressure PPT/PPC Node number ________

controller Type ________

Version ________

Serial number ________

Location measuring point '+' Where installed ________

Location measuring point '-' Where installed ________

Set point _______Pa

Correct and Stabilized working OK ⃞

Pressure PPT/PPC Node number ________

controller Type ________

Version ________

Serial number ________

Location measuring point '+' Where installed ________

Location measuring point '-' Where installed ________

Set point _______Pa

Correct and Stabilized working OK ⃞

Pressure PPT/PPC Node number ________

controller Type ________

Version ________

Serial number ________

Location measuring point '+' Where installed ________

Location measuring point '-' Where installed ________

Set point _______Pa

Correct and Stabilized working OK ⃞

Pressure PPT/PPC Node number ________

controller Type ________

Version ________

Serial number ________

Location measuring point '+' Where installed ________

Location measuring point '-' Where installed ________

Set point _______Pa

Correct and Stabilized working OK ⃞

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 6

Pressure PPT/PPC Node number ________

controller Type ________

Version ________

Serial number ________

Location measuring point '+' Where installed ________

Location measuring point '-' Where installed ________

Set point _______Pa

Correct and Stabilized working OK ⃞

Simulation Open & Close damper N/A OK ⃞

Start/Stop AHU OK ⃞

On/Off ventilators N/A OK ⃞

Electrical heating different stages N/A OK ⃞

Filter guard N/A OK ⃞

Belt guard N/A OK ⃞

Open/Close 2/3-way valves OK ⃞

On/Off heating/cooling pumps N/A OK ⃞

Frost protection simulation N/A OK ⃞

On/Off humidifying N/A OK ⃞

Open/Close dampers in the ducting N/A OK ⃞

On/Off extraction + PPT/PPC N/A OK ⃞

GENERAL REMARKS:(everything not as request by Petersime specification, to do list by customer or Petersime etc.)

You are required to send the original form back to your Global Technical Supervisor for later reference. This will allow us to

identify the correct machine and give you our best support in the shortest possible time later during the running of the

machine.

HVAC Commissioning Document – AHU

2015 12 07 HVAC Commissioning AHU.docx / 7

You might also like

- Heat Load Estimation E20 Form-SIDocument1 pageHeat Load Estimation E20 Form-SIAbg Sepul70% (10)

- MID 128, PID 106 Charge Air Pressure: MID 128: Engine Control Unit Fault CodeDocument1 pageMID 128, PID 106 Charge Air Pressure: MID 128: Engine Control Unit Fault Codeuser1No ratings yet

- Fire Pump System Test ReportDocument12 pagesFire Pump System Test Reportcoolsummer1112143100% (2)

- 800 KVA Transformer SpecificationsDocument3 pages800 KVA Transformer SpecificationsRavi Bapodra100% (1)

- Cold Start Up ChecklistDocument13 pagesCold Start Up ChecklistEr Karthikeyan V100% (1)

- Ahu Hatcher Room 3Document7 pagesAhu Hatcher Room 3CITACOM UTAMANo ratings yet

- Ahu Transfer RoomDocument7 pagesAhu Transfer RoomCITACOM UTAMANo ratings yet

- Ahu Setter TunnelDocument5 pagesAhu Setter TunnelCITACOM UTAMANo ratings yet

- JOBO CPP-3 Manual GB V1.1 26.03.13 PDFDocument11 pagesJOBO CPP-3 Manual GB V1.1 26.03.13 PDFMarian TudorNo ratings yet

- Machine Test & Inspeciton ReportDocument8 pagesMachine Test & Inspeciton Reportvenkatesh kollisettiNo ratings yet

- Boiler - Cleaver Brooks 3MW - Manual 1Document2 pagesBoiler - Cleaver Brooks 3MW - Manual 1Vignesh MahalingamNo ratings yet

- HT PFDDocument6 pagesHT PFDbaskaran.marieNo ratings yet

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- SUN Compression TesterDocument8 pagesSUN Compression TesterWongstorn DamrongmaneeNo ratings yet

- Sample: Centrifugal Fire Pump Acceptance Test FormDocument2 pagesSample: Centrifugal Fire Pump Acceptance Test FormaamedNo ratings yet

- Fire Pump Acceptance Test FormDocument2 pagesFire Pump Acceptance Test FormIvandy 99No ratings yet

- R-ME-HC-S-020 Governor System Test RecordDocument9 pagesR-ME-HC-S-020 Governor System Test Recordrotimi olalekan fataiNo ratings yet

- V4073A Installation GuideDocument2 pagesV4073A Installation GuidemohamednavaviNo ratings yet

- RC-TS-05 - Site Readyness Check List - SD SeriesDocument3 pagesRC-TS-05 - Site Readyness Check List - SD SeriesFreddy RamosNo ratings yet

- SPLIT2 Rectifier Room - Gedung - Lt.3Document9 pagesSPLIT2 Rectifier Room - Gedung - Lt.3SKYX View (UCOK GAMING)No ratings yet

- KIA Carnival 04-Emission Control SystemDocument10 pagesKIA Carnival 04-Emission Control SystemHenryHutabarat100% (1)

- SOP Maint. Service Battery With Dummy Load Test BTS 100Document2 pagesSOP Maint. Service Battery With Dummy Load Test BTS 100Agus MulyanaNo ratings yet

- Stator CW SOP - Docx-1Document12 pagesStator CW SOP - Docx-1SonratNo ratings yet

- Stator CW SOP-2Document12 pagesStator CW SOP-2SonratNo ratings yet

- Engineering Information For PDC Butterfly Valves: Valve SizingDocument9 pagesEngineering Information For PDC Butterfly Valves: Valve SizingAnonymous NwnJNONo ratings yet

- SOP-Cleanup CycleDocument5 pagesSOP-Cleanup CyclenodalpcrktpsNo ratings yet

- RDB 535 Fault Finding ChartDocument1 pageRDB 535 Fault Finding ChartFrancisco DuranNo ratings yet

- PLC 1 SetterDocument2 pagesPLC 1 SetterCITACOM UTAMANo ratings yet

- PLC 2 HatcherDocument2 pagesPLC 2 HatcherCITACOM UTAMANo ratings yet

- Form, Test TardjoenDocument30 pagesForm, Test TardjoenDangolNo ratings yet

- Importance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)Document23 pagesImportance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)rajshahieeeNo ratings yet

- Honeywell VR8105 8205 8305 Gas Control InstructionsDocument12 pagesHoneywell VR8105 8205 8305 Gas Control InstructionsAlejandro ObregonNo ratings yet

- Lap Akhir TM 160621Document6 pagesLap Akhir TM 160621imanteaNo ratings yet

- 21 SOP For Vacuum PumpDocument6 pages21 SOP For Vacuum PumpAmit Biswas100% (2)

- Fix O2 Analyzer - Nitrogen PlantDocument4 pagesFix O2 Analyzer - Nitrogen PlantefeNo ratings yet

- Coastal Cold Start Up ChecklistDocument13 pagesCoastal Cold Start Up ChecklistwonderstrikeNo ratings yet

- Diagnostic PDFDocument3 pagesDiagnostic PDFraisviranNo ratings yet

- Dust CollectorDocument1 pageDust Collectorkashifurrahaman8No ratings yet

- ATC-001 Nissan MicraDocument8 pagesATC-001 Nissan Micrajavier nieves garcíaNo ratings yet

- Commissioning Report Generator - SAMPLEDocument5 pagesCommissioning Report Generator - SAMPLEMax JohnNo ratings yet

- Field Start Up Checklist - 1Document4 pagesField Start Up Checklist - 1srdc2mjbesNo ratings yet

- 2433 ManualDocument27 pages2433 Manualladykarenna7No ratings yet

- Flare Ignition ProcedureDocument4 pagesFlare Ignition ProcedurebeyNo ratings yet

- NEOPRSP008LS001 - Rev. 00 - Pages 02 - Operation Testing Reading SheetDocument2 pagesNEOPRSP008LS001 - Rev. 00 - Pages 02 - Operation Testing Reading Sheetalialharbi021No ratings yet

- P0713Document6 pagesP0713SenaMecánicaElectrónicaNo ratings yet

- 50 MVA Trfo-2Document6 pages50 MVA Trfo-2p m yadavNo ratings yet

- SAT-S0260W - Service ManualDocument45 pagesSAT-S0260W - Service ManualTin Cậy Kỹ Thuật100% (1)

- Induction Sealing MachineDocument2 pagesInduction Sealing Machinekashifurrahaman8No ratings yet

- Gen Set Service ReportDocument1 pageGen Set Service ReportReman MarykanNo ratings yet

- Chapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsDocument16 pagesChapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsГоран ГорановNo ratings yet

- EBV Series - Energy Balancing ValveDocument4 pagesEBV Series - Energy Balancing ValveFrio EspecializadoNo ratings yet

- 01.SOP Cold Start Up.r3Document16 pages01.SOP Cold Start Up.r3K R Kumar RanjanNo ratings yet

- Material Pass BoxDocument1 pageMaterial Pass Boxkashifurrahaman8No ratings yet

- JOBO CPP-3 Manual GB V1.1 26.03.13Document11 pagesJOBO CPP-3 Manual GB V1.1 26.03.13Marian TudorNo ratings yet

- ORP Sensor TroubleshootingDocument7 pagesORP Sensor TroubleshootingRudy HerreraNo ratings yet

- Manifold Gauge Componet ListDocument2 pagesManifold Gauge Componet Listdaverb46No ratings yet

- Manual Chillers20 NewDocument14 pagesManual Chillers20 NewMinh NguyễnNo ratings yet

- Fast Track Troubleshooting: Model: WA456DR /AA BOM Models Wa456Drhdwr/Aa Wa456Drhdsu/AaDocument7 pagesFast Track Troubleshooting: Model: WA456DR /AA BOM Models Wa456Drhdwr/Aa Wa456Drhdsu/AaFaffNo ratings yet

- V. Other-Excitation Idle-Loaded Pressure Build-Up Test in The GeneratorDocument51 pagesV. Other-Excitation Idle-Loaded Pressure Build-Up Test in The GeneratorClip nhungcaunoihayNo ratings yet

- Transformer Testing and CommissioningDocument7 pagesTransformer Testing and Commissioningelia nugraha adi100% (2)

- Samsung DW ManualDocument28 pagesSamsung DW ManualtimmboNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ahu Setter TunnelDocument5 pagesAhu Setter TunnelCITACOM UTAMANo ratings yet

- Ahu Transfer RoomDocument7 pagesAhu Transfer RoomCITACOM UTAMANo ratings yet

- PLC 1 SetterDocument2 pagesPLC 1 SetterCITACOM UTAMANo ratings yet

- PLC 2 HatcherDocument2 pagesPLC 2 HatcherCITACOM UTAMANo ratings yet

- HVAC Commissioning Document - DuctingDocument1 pageHVAC Commissioning Document - DuctingCITACOM UTAMANo ratings yet

- Ahu Hatcher Room 3Document7 pagesAhu Hatcher Room 3CITACOM UTAMANo ratings yet

- EIM KS4-LeaP-Week 2-3 Q3Document4 pagesEIM KS4-LeaP-Week 2-3 Q3Jerome CasilaoNo ratings yet

- ABB BreakerDocument2 pagesABB BreakerMichael SharpeNo ratings yet

- Diamond Coring Tool DD 160Document1 pageDiamond Coring Tool DD 160AntoNo ratings yet

- CO2 SensorDocument20 pagesCO2 SensorMiraç ÖlmezNo ratings yet

- Vaporizers: Ax5: Kg/Cm2 Psig 257 Mpa 1.77Document3 pagesVaporizers: Ax5: Kg/Cm2 Psig 257 Mpa 1.77Ahmadie BianconeroNo ratings yet

- Shooting StancesDocument2 pagesShooting StancesGrenaNo ratings yet

- Instruction Manual ED 50-100ADocument25 pagesInstruction Manual ED 50-100AcrafzaclubNo ratings yet

- Diagrama Electrico AsfaltadoraDocument25 pagesDiagrama Electrico AsfaltadoraSebastian SucerquiaNo ratings yet

- Qiqihar BrochureDocument8 pagesQiqihar Brochureask101No ratings yet

- Flashcards - Topic 4.5 Dangers of Electricity - CAIE Physics IGCSEDocument19 pagesFlashcards - Topic 4.5 Dangers of Electricity - CAIE Physics IGCSEgreenNo ratings yet

- Exp. Proof, Flame and LHDDocument13 pagesExp. Proof, Flame and LHDVincent GabrielNo ratings yet

- LED Based SRI - MLRIDocument2 pagesLED Based SRI - MLRIBharat SinghNo ratings yet

- Chapter 3 Electric SystemDocument47 pagesChapter 3 Electric SystemPurnama AbhieNo ratings yet

- SMF&W 851-01-07 Manual Arc Welding 220319Document9 pagesSMF&W 851-01-07 Manual Arc Welding 220319Shahid RazaNo ratings yet

- Motor Application and Installation DataDocument64 pagesMotor Application and Installation DataBANERA Mark Joseph NegranzaNo ratings yet

- ST25 Parts CatalogDocument38 pagesST25 Parts Catalogdesechable100% (1)

- Kverneland Accord DTDocument199 pagesKverneland Accord DTАнатолійNo ratings yet

- L07-L22 Fixed Speed Rotary Screw Compressor BrochureDocument2 pagesL07-L22 Fixed Speed Rotary Screw Compressor Brochurefelix Jacinto ramirezNo ratings yet

- Conduit Design GuidelinesDocument26 pagesConduit Design GuidelinesAnirudhNo ratings yet

- Sony A3500Document195 pagesSony A3500joe jackNo ratings yet

- NS-468 Cable Tester Instruction ManualDocument4 pagesNS-468 Cable Tester Instruction Manualdanipet718341No ratings yet

- Ergonomics For Scaffold ErectionDocument2 pagesErgonomics For Scaffold ErectionTTYY08No ratings yet

- 6V6 TubeDocument2 pages6V6 TubeFrancesco GhiselliniNo ratings yet

- Manual de Actuador Belimo LMX120-3Document2 pagesManual de Actuador Belimo LMX120-3PabloriveroNo ratings yet

- Abb Sectos en Hi-ResDocument2 pagesAbb Sectos en Hi-Resdenny bactiNo ratings yet

- Gpee6.0T01Tibbgde: Technical Data SheetDocument2 pagesGpee6.0T01Tibbgde: Technical Data SheetHope SangoNo ratings yet

- Se Sco FSP en BeDocument19 pagesSe Sco FSP en Beisan.structural TjsvgalavanNo ratings yet

- FMCO-CVHB-HSE-SPE-FRM-02 - Rev-01 - Weekly Facility InspectionDocument6 pagesFMCO-CVHB-HSE-SPE-FRM-02 - Rev-01 - Weekly Facility Inspectionenjazco.rsgNo ratings yet