Professional Documents

Culture Documents

Delivery Programme: Overload Relay, 0.4-0.6A, 1N/O+1N/C Part No. ZE-0,6 Article No. 014333 Catalog No. Xtomp60Ac1

Delivery Programme: Overload Relay, 0.4-0.6A, 1N/O+1N/C Part No. ZE-0,6 Article No. 014333 Catalog No. Xtomp60Ac1

Uploaded by

mark simpsonCopyright:

Available Formats

You might also like

- CV WorksheetsDocument19 pagesCV WorksheetsBobNo ratings yet

- Delivery Programme: Step Switchflush Mounting Part No. T0-6-8271/E Article No. 015124 Catalog No. Ct06-8271-DokbqDocument6 pagesDelivery Programme: Step Switchflush Mounting Part No. T0-6-8271/E Article No. 015124 Catalog No. Ct06-8271-DokbqHoratiu CostinNo ratings yet

- Bloque de Contato MollerDocument3 pagesBloque de Contato MollerlizxcanoNo ratings yet

- 2028366isolator Moeller EatonDocument7 pages2028366isolator Moeller EatonCarlos AlbertoNo ratings yet

- Eaton 207379 P3 100 I5 SVB N en - GBDocument6 pagesEaton 207379 P3 100 I5 SVB N en - GBsamsularief03No ratings yet

- BotonDocument3 pagesBotonjuan antonio flores mendozaNo ratings yet

- Ficha Técnica Interruptor General 32 ADocument5 pagesFicha Técnica Interruptor General 32 AJosé IturvideNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- Eaton 066166 EMT6 en - GBDocument3 pagesEaton 066166 EMT6 en - GBSiva RamanNo ratings yet

- Eaton 041097 P1 25 EA SVB en - GBDocument6 pagesEaton 041097 P1 25 EA SVB en - GBAnonymous jW9BkgbQmENo ratings yet

- Chave EatonDocument6 pagesChave EatonWesly Carvalho SoeiroNo ratings yet

- Electricos MT IUSADocument5 pagesElectricos MT IUSALanh GonzáLezNo ratings yet

- Eaton 7kW 3 Pole Isolator DatasheetDocument6 pagesEaton 7kW 3 Pole Isolator DatasheetProject1 Tech7No ratings yet

- UntitledDocument3 pagesUntitledSaanounNo ratings yet

- Eaton 066168 Emt6 DBK en GBDocument4 pagesEaton 066168 Emt6 DBK en GBAriel TorresNo ratings yet

- EatonDocument6 pagesEatonkarmadewaNo ratings yet

- Emt6-Dbk (066168)Document6 pagesEmt6-Dbk (066168)hasan ziaeeNo ratings yet

- Moe F30051Document5 pagesMoe F30051Wu MonaNo ratings yet

- En 278425Document4 pagesEn 278425Haralambescu AndreiNo ratings yet

- Delivery ProgrammeDocument3 pagesDelivery ProgrammeIvanNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument6 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZJENNYNo ratings yet

- SB570 - SB5100: 5.0A Schottky Barrier RectifierDocument3 pagesSB570 - SB5100: 5.0A Schottky Barrier RectifierWalter FabianNo ratings yet

- Botonera ETONDocument7 pagesBotonera ETONwilcat1976No ratings yet

- FAK Complete Unit Emergency-Stop Part No. FAK-R/V/KC11/IY Article No. 229748Document3 pagesFAK Complete Unit Emergency-Stop Part No. FAK-R/V/KC11/IY Article No. 229748ArtesiraNo ratings yet

- Button Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5Document5 pagesButton Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5sajad ghorbaniNo ratings yet

- A5e02261863a 02 201210291111411944Document7 pagesA5e02261863a 02 201210291111411944Lucas Fuzeto VizoniNo ratings yet

- SB160 Schottky Diode 60V 1a PDFDocument3 pagesSB160 Schottky Diode 60V 1a PDFdemostenessNo ratings yet

- Eaton 271423 NZMC2 A250 en - GB PDFDocument9 pagesEaton 271423 NZMC2 A250 en - GB PDFMarin DanielNo ratings yet

- Eaton DS 207297 P1 25 - I2 - SVB - HI11 20190625Document5 pagesEaton DS 207297 P1 25 - I2 - SVB - HI11 20190625Dominik FajgaNo ratings yet

- Eaton 265763 NZMH4 AE630 en - GBDocument7 pagesEaton 265763 NZMH4 AE630 en - GBJuan LópezNo ratings yet

- NP-Series - Valve Regulated Lead Acid Battery: LayoutDocument1 pageNP-Series - Valve Regulated Lead Acid Battery: Layoutulton1237624No ratings yet

- NP2 3-12 EnglishDocument1 pageNP2 3-12 EnglishJonathan BryantNo ratings yet

- Eaton 265912 NZMN4 4 AE1000 en - GBDocument5 pagesEaton 265912 NZMN4 4 AE1000 en - GBnelson1235No ratings yet

- 5/2-Directional Valve, Series HF03-LG: Technical RemarksDocument2 pages5/2-Directional Valve, Series HF03-LG: Technical RemarksTOny OlivenciaNo ratings yet

- Eaton 092394 T5B 3 7 E en - GBDocument6 pagesEaton 092394 T5B 3 7 E en - GBJorge AmayaNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument5 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZsyahril boonieNo ratings yet

- 1N4148W, T4Document3 pages1N4148W, T4borgergo0106No ratings yet

- Ah5cn (M) HaDocument1 pageAh5cn (M) HaAgus AnwarNo ratings yet

- Botón Paro de Emergencia - 216876Document3 pagesBotón Paro de Emergencia - 216876Mónica Felula GarcíaNo ratings yet

- Yucel-Series - Valve Regulated Lead Acid Battery: LayoutDocument1 pageYucel-Series - Valve Regulated Lead Acid Battery: Layoutjp.gestsaiNo ratings yet

- Schmersal Protect Ie02 SK DatasheetDocument6 pagesSchmersal Protect Ie02 SK DatasheetDeny Tirta KusumaNo ratings yet

- Eaton 072739 PKZM0 10 en - GBDocument8 pagesEaton 072739 PKZM0 10 en - GBElizabeth RamirezNo ratings yet

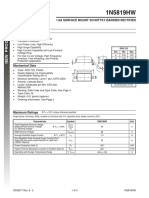

- 1N5819HW (SOD-123, 美台)Document3 pages1N5819HW (SOD-123, 美台)c8831116No ratings yet

- Safety Information: Instruction ManualDocument4 pagesSafety Information: Instruction ManualKen JunNo ratings yet

- DB-07319 Ad-00594 Azsoso 210430 eDocument2 pagesDB-07319 Ad-00594 Azsoso 210430 eŞener GüneyliNo ratings yet

- Datasheet Diode IN4002GDocument3 pagesDatasheet Diode IN4002GPoupée De SoieNo ratings yet

- Used Files HaiDocument2 pagesUsed Files Haipakyabhai143No ratings yet

- SMC Series: Surface Mount Unidirectional and Bidirectional Transient Voltage SuppressorsDocument4 pagesSMC Series: Surface Mount Unidirectional and Bidirectional Transient Voltage SuppressorsGRUPO FRIGONo ratings yet

- Circuit-Breaker, 3p, 100A Part No. NZMB1-A100 Catalog No. 259079 EL-Nummer (Norway) 4358704Document9 pagesCircuit-Breaker, 3p, 100A Part No. NZMB1-A100 Catalog No. 259079 EL-Nummer (Norway) 4358704shashirajNo ratings yet

- Contactor Ac-6b Capacitor CJ19Document2 pagesContactor Ac-6b Capacitor CJ19ChangKhenNo ratings yet

- PB Features: 1.0A Surface Mount Schottky Barrier DiodeDocument4 pagesPB Features: 1.0A Surface Mount Schottky Barrier DiodeMomo MendozaNo ratings yet

- Datasheet BES0045 267525 en PDFDocument2 pagesDatasheet BES0045 267525 en PDFGerardo Cruz EspinosaNo ratings yet

- Stavka 7. ZAMIJENITIDocument1 pageStavka 7. ZAMIJENITIjosip022No ratings yet

- SMCJ 778393Document7 pagesSMCJ 778393aprioris84No ratings yet

- BXA15 48S12 F ArtesynDocument2 pagesBXA15 48S12 F ArtesynShahji ElectronicNo ratings yet

- Power Relay K (Open - Sealed) : Automotive Relays PCB Single RelaysDocument4 pagesPower Relay K (Open - Sealed) : Automotive Relays PCB Single RelaysAngelitoSaranguitoGonzalecitoNo ratings yet

- Valvula Piezotronic Atex Serie 630 AscoDocument4 pagesValvula Piezotronic Atex Serie 630 AscoBase SistemasNo ratings yet

- SR5150 Won TopDocument4 pagesSR5150 Won TopRafael LehmkuhlNo ratings yet

- Eaton 015036 T0 5 8361 E en - GBDocument6 pagesEaton 015036 T0 5 8361 E en - GBSeoane GustavoNo ratings yet

- NPW-Series - Valve Regulated Lead Acid BatteryDocument1 pageNPW-Series - Valve Regulated Lead Acid BatteryfuffinoNo ratings yet

- Roller BlindsDocument2 pagesRoller Blindsmark simpsonNo ratings yet

- Qualcast 41cm Petrol Self Propelled Lawnmower: Assembly Manual XSZ41DDocument27 pagesQualcast 41cm Petrol Self Propelled Lawnmower: Assembly Manual XSZ41Dmark simpsonNo ratings yet

- Sherborne S Series Boilers Room Sealed Fully Modulating Pre Mix Gas Fired Boilers 500001103 eDocument48 pagesSherborne S Series Boilers Room Sealed Fully Modulating Pre Mix Gas Fired Boilers 500001103 emark simpsonNo ratings yet

- Position Qty. Description MAGNA3 65-150 F: Company Name: Created By: Phone: DateDocument3 pagesPosition Qty. Description MAGNA3 65-150 F: Company Name: Created By: Phone: Datemark simpsonNo ratings yet

- Your Ticket: Think Floyd - Through The WallDocument4 pagesYour Ticket: Think Floyd - Through The Wallmark simpsonNo ratings yet

- Instruction-Manual BFC UKDocument116 pagesInstruction-Manual BFC UKmark simpsonNo ratings yet

- ECL Comfort 310, Application A319: Operating GuideDocument121 pagesECL Comfort 310, Application A319: Operating Guidemark simpsonNo ratings yet

- 2 Simulation Study On 104 MHZ Radio Frequency Quadrupole Accelerator - ICEEE2010Document4 pages2 Simulation Study On 104 MHZ Radio Frequency Quadrupole Accelerator - ICEEE2010Mridula Mittal BansalNo ratings yet

- 2-3design of Capacitor BanksDocument25 pages2-3design of Capacitor BanksnazeerNo ratings yet

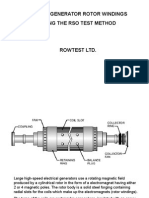

- RSO TestingDocument19 pagesRSO TestingAntonio DsfvsdcNo ratings yet

- Altistart 46 VW3G46101 Display and Adjustment enDocument37 pagesAltistart 46 VW3G46101 Display and Adjustment enValentin AgacheNo ratings yet

- Load Flow Analysis of 66 KV Substation Using ETAP SoftwareDocument4 pagesLoad Flow Analysis of 66 KV Substation Using ETAP SoftwareNasser SabrNo ratings yet

- Some Aspects of Structural Dynamics: Appendix BDocument26 pagesSome Aspects of Structural Dynamics: Appendix BEdgar Enrique Vilca RomeroNo ratings yet

- Universal Law of GravitationDocument6 pagesUniversal Law of GravitationKrish AggrawalNo ratings yet

- PS PressureDocument6 pagesPS PressuremirarpNo ratings yet

- Electrical Machines 2: Course Instructor: Sumaiya Umme Hani EmailDocument14 pagesElectrical Machines 2: Course Instructor: Sumaiya Umme Hani Emailmushfic fahimNo ratings yet

- MOV Check List Dept: Electrical: Equipment Tag No (Kks Code) Mov Name Motor Feeder NoDocument3 pagesMOV Check List Dept: Electrical: Equipment Tag No (Kks Code) Mov Name Motor Feeder NosuperthambiNo ratings yet

- Right Hand RuleDocument14 pagesRight Hand RuleTyra Christine Victorio FloresNo ratings yet

- Engi 1111 OutlineDocument3 pagesEngi 1111 OutlineDylan LawNo ratings yet

- CG Science 8 Q1Document4 pagesCG Science 8 Q1Emieleah Lorenzo Pauig100% (1)

- K5. The Angular Acceleration of The Links of The MechanismDocument15 pagesK5. The Angular Acceleration of The Links of The MechanismCeyla Danişyan-Abuzər100% (1)

- Laminar Flow: Moody's DiagramDocument1 pageLaminar Flow: Moody's DiagramDaniel GómezNo ratings yet

- Power Electronics: AC To DC Converters (Rectifiers)Document79 pagesPower Electronics: AC To DC Converters (Rectifiers)Frew FrewNo ratings yet

- Thevenin and Norton EquivalentsDocument36 pagesThevenin and Norton EquivalentsJosé Guillermo De Chomón AranguenaNo ratings yet

- An Itroduction To ElectromagnetismDocument82 pagesAn Itroduction To ElectromagnetismbastisnNo ratings yet

- Concept Strengthening Sheet (CSS-02) - RM - PhysicsDocument5 pagesConcept Strengthening Sheet (CSS-02) - RM - PhysicsNancy RaniNo ratings yet

- CL29M6P8X - XAO Electrical Parts List 12Document10 pagesCL29M6P8X - XAO Electrical Parts List 12ITOGAMYNo ratings yet

- Work, Energy and PowerDocument27 pagesWork, Energy and PowersuperultimateamazingNo ratings yet

- Laboratory Manual For Ac Electrical CircuitsDocument80 pagesLaboratory Manual For Ac Electrical CircuitsAngelo Palaming100% (1)

- Ieee 539Document50 pagesIeee 539darkjhesusNo ratings yet

- June 2012 QP - M1 EdexcelDocument13 pagesJune 2012 QP - M1 EdexcelSaiyara KhanNo ratings yet

- Performance Analysis of LLC Resonant Converter Incorporating Pi Fuzzy and Neural ControllersDocument12 pagesPerformance Analysis of LLC Resonant Converter Incorporating Pi Fuzzy and Neural ControllersDouglas SantosNo ratings yet

- Spencer MethodDocument36 pagesSpencer MethodJhofre FloresNo ratings yet

- Lesson 7: Electricity and Magnetism Learning ObjectivesDocument58 pagesLesson 7: Electricity and Magnetism Learning ObjectivesAdriel MarasiganNo ratings yet

Delivery Programme: Overload Relay, 0.4-0.6A, 1N/O+1N/C Part No. ZE-0,6 Article No. 014333 Catalog No. Xtomp60Ac1

Delivery Programme: Overload Relay, 0.4-0.6A, 1N/O+1N/C Part No. ZE-0,6 Article No. 014333 Catalog No. Xtomp60Ac1

Uploaded by

mark simpsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Delivery Programme: Overload Relay, 0.4-0.6A, 1N/O+1N/C Part No. ZE-0,6 Article No. 014333 Catalog No. Xtomp60Ac1

Delivery Programme: Overload Relay, 0.4-0.6A, 1N/O+1N/C Part No. ZE-0,6 Article No. 014333 Catalog No. Xtomp60Ac1

Uploaded by

mark simpsonCopyright:

Available Formats

Overload�relay,�0.4-0.

6A,�1N/O+1N/C

Part�no. ZE-0,6

Article�no. 014333

Catalog�No. XTOMP60AC1

Delivery�programme

Product range ZE overload relays for mini contactor relays

Phase-failure sensitivity IEC/EN 60947, VDE 0660 Part 102

Description Test/off button

Reset pushbutton manual/auto

Trip-free release

Mounting type Direct mounting

Setting�range

Overload releases Ir A 0.4 - 0.6

Contact sequence

Auxiliary�contacts

N/O = Normally open 1 N/O

N/C = Normally closed 1 N/C

For use with DILEM

DIULEM/21/MV

SDAINLEM

Short-circuit�protection

Type “1” coordination gG/gL A 20

Type “2” coordination gG/gL A 2

Notes

Overload release: tripping class 10 A

Short-circuit protection: Observe the maximum permissible fuse of the contactor with direct device mounting.

Suitable for protection of Ex e-motors

II (2) G

PTB 10 ATEX 3014

Observe manual MN03407003Z-DE/EN.

Notes

When fitted directly to the contactor a clearance of at least 5 mm is required between the overload relays.

02/13/2015 014333 - HPL-ED2014 V9.0 EN 1/6

1 Contactor

Technical�data

General

Standards IEC/EN 60947, VDE 0660, UL, CSA

Climatic proofing Damp heat, constant, to IEC 60068-2-78

Damp heat, cyclic, to IEC 60068-2-30

Ambient temperature °C

Operating range to IEC/EN 60947

PTB: -5 °C - +55 °C

Open °C - 25 - 50

Enclosed °C - 25 - 40

Temperature compensation Continuous

Weight kg 0.07

Mechanical shock resistance g 10

Sinusoidal

Shock duration 10 ms

Degree of Protection IP20

Protection against direct contact when actuated from front (EN 50274) Finger and back-of-hand proof

Main�conducting�paths

Rated impulse withstand voltage Uimp V AC 6000

Overvoltage category/pollution degree III/3

Rated insulation voltage Ui V 690

Rated operational voltage Ue V AC 690

Safe isolation to EN 61140

Between auxiliary contacts and main contacts V AC 300

Between main circuits V AC 300

Temperatur compensation residual error > 40 ºC

0.25 %/K

Current heat loss (3 conductors)

Lower value of the setting range W 2.5

Maximum setting W 6

Terminal capacities mm

2

Solid mm

2 2 x (0.75 - 2.5)

Flexible with ferrule mm

2 2 x (0.5 - 1.5)

Solid or stranded AWG 18 - 14

Terminal screw M3.5

Tightening torque Nm 1.2

Tools

Pozidriv screwdriver Size 2

Standard screwdriver mm 0.8 x 5.5

Auxiliary�and�control�circuits

Rated impulse withstand voltage Uimp V 4000

Overvoltage category/pollution degree III/3

Terminal capacities mm

2

Solid mm

2 2 x (0.75 - 2.5)

Flexible with ferrule mm

2 2 x (0.5 - 1.5)

Solid or stranded AWG 2 x (18 - 12)

02/13/2015 014333 - HPL-ED2014 V9.0 EN 2/6

Terminal screw M3.5

Tightening torque Nm 0.8 - 1.2

Tools

Pozidriv screwdriver Size 2

Standard screwdriver mm 0.8 x 5.5

Rated insulation voltage Ui V AC 500

Rated operational voltage Ue V AC 500

Safe isolation to EN 61140

between the auxiliary contacts V AC 300

Conventional thermal current Ith A 6

Rated operational current Ie A

AC-15

Make contact

120 V Ie A 1.5

220 V 230 V 240 V Ie A 1.5

380 V 400 V 415 V Ie A 0.5

500 V Ie A 0.3

Break contact

120 V Ie A 1.5

220 V 230 V 240 V Ie A 1.5

380 V 400 V 415 V Ie A 0.7

500 V Ie A 0.5

DC-13 L/R - 15 ms

24 V Ie A 0.9

60 V Ie A 0.75

110 V Ie A 0.4

220 V Ie A 0.2

Short-circuit rating without welding

max. fuse A gG/gL 4

Notes

Notes�Ambient temperature: operating range to IEC/EN 60947, PTB: -5°C to +50°C

Rated operational current: Making and breaking conditions to DC-13, L/R constant as stated

Data�for�design�verification�according�to�IEC/EN�61439

Technical data for design verification

Rated operational current for specified heat dissipation In A 0.6

Heat dissipation per pole, current-dependent Pvid W 0

Equipment heat dissipation, current-dependent Pvid W 6

Static heat dissipation, non-current-dependent Pvs W 0

Heat dissipation capacity Pdiss W 0

IEC/EN 61439 design verification

10.2 Strength of materials and parts

10.2.2 Corrosion resistance Meets the product standard's requirements.

10.2.3.1 Verification of thermal stability of enclosures Meets the product standard's requirements.

10.2.3.2 Verification of resistance of insulating materials to normal heat Meets the product standard's requirements.

10.2.3.3 Verification of resistance of insulating materials to abnormal heat Meets the product standard's requirements.

and fire due to internal electric effects

10.2.4 Resistance to ultra-violet (UV) radiation Meets the product standard's requirements.

10.2.5 Lifting Does not apply, since the entire switchgear needs to be evaluated.

10.2.6 Mechanical impact Does not apply, since the entire switchgear needs to be evaluated.

10.2.7 Inscriptions Meets the product standard's requirements.

10.3 Degree of protection of ASSEMBLIES Does not apply, since the entire switchgear needs to be evaluated.

10.4 Clearances and creepage distances Meets the product standard's requirements.

10.5 Protection against electric shock Does not apply, since the entire switchgear needs to be evaluated.

10.6 Incorporation of switching devices and components Does not apply, since the entire switchgear needs to be evaluated.

02/13/2015 014333 - HPL-ED2014 V9.0 EN 3/6

10.7 Internal electrical circuits and connections Is the panel builder's responsibility.

10.8 Connections for external conductors Is the panel builder's responsibility.

10.9 Insulation properties

10.9.2 Power-frequency electric strength Is the panel builder's responsibility.

10.9.3 Impulse withstand voltage Is the panel builder's responsibility.

10.9.4 Testing of enclosures made of insulating material Is the panel builder's responsibility.

10.10 Temperature rise The panel builder is responsible for the temperature rise calculation. Eaton will

provide heat dissipation data for the devices.

10.11 Short-circuit rating Is the panel builder's responsibility. The specifications for the switchgear must be

observed.

10.12 Electromagnetic compatibility Is the panel builder's responsibility. The specifications for the switchgear must be

observed.

10.13 Mechanical function The device meets the requirements, provided the information in the instruction

leaflet (IL) is observed.

Technical�data�ETIM�5.0

Low-voltage industrial components (EG000017) / Thermal overload relay (EC000106)

Electric engineering, automation, process control engineering / Low-voltage switch technology / Overload protection device / Thermal overload relay (ecl@ss8-27-37-15-01 [AKF075010])

Adjustable current range A 0.4 - 0.6

Mounting method Direct attachment

Connection type main current circuit Screw connection

Number of auxiliary contacts as normally closed contact 1

Number of auxiliary contacts as normally open contact 1

Number of auxiliary contacts as change-over contact 0

Release class CLASS 10

Approvals

Product Standards UL 508; CSA-C22.2 No. 14; IEC/EN 60947-4-1; IEC/EN 60947-5-1; CE marking

UL File No. E29184

UL Category Control No. NKCR

CSA File No. 12528

CSA Class No. 3211-03

North America Certification UL listed, CSA certified

Specially designed for North America No

Suitable for Branch circuits

Max. Voltage Rating 600 V AC

Degree of Protection IEC: IP20, UL/CSA Type: -

02/13/2015 014333 - HPL-ED2014 V9.0 EN 4/6

Characteristics

These tripping characteristics are mean values of the spread at 20 °C ambient temperature in a cold state. Tripping time depends on response current.

On devices at operating temperature the tripping time of the overload relay drops to approx. 25 % of the read value. Specific characteristics for each individual setting range can be found in the

manual.

02/13/2015 014333 - HPL-ED2014 V9.0 EN 5/6

Dimensions

Additional�product�information�(links)

IL03407007Z�(AWA2300-0883)�Overload�relay

IL03407007Z (AWA2300-0883) Overload relay ftp://ftp.moeller.net/DOCUMENTATION/AWA_INSTRUCTIONS/IL03407007Z2010_10.pdf

MN03407003Z�(AWB2300-1425)�Overload�relay�ZE,�overload�monitoring�for�EEx�e-motors

MN03407003Z (AWB2300-1425) Overload relay ftp://ftp.moeller.net/DOCUMENTATION/AWB_MANUALS/MN03407003Z_DE_EN.pdf

ZE, overload monitoring for EEx e-motors -

Deutsch / English

02/13/2015 Eaton Industries GmbH 6/6

http://www.eaton.eu

© 12/2014 by Eaton Industries GmbH

014333 - HPL-ED2014 V9.0 EN

You might also like

- CV WorksheetsDocument19 pagesCV WorksheetsBobNo ratings yet

- Delivery Programme: Step Switchflush Mounting Part No. T0-6-8271/E Article No. 015124 Catalog No. Ct06-8271-DokbqDocument6 pagesDelivery Programme: Step Switchflush Mounting Part No. T0-6-8271/E Article No. 015124 Catalog No. Ct06-8271-DokbqHoratiu CostinNo ratings yet

- Bloque de Contato MollerDocument3 pagesBloque de Contato MollerlizxcanoNo ratings yet

- 2028366isolator Moeller EatonDocument7 pages2028366isolator Moeller EatonCarlos AlbertoNo ratings yet

- Eaton 207379 P3 100 I5 SVB N en - GBDocument6 pagesEaton 207379 P3 100 I5 SVB N en - GBsamsularief03No ratings yet

- BotonDocument3 pagesBotonjuan antonio flores mendozaNo ratings yet

- Ficha Técnica Interruptor General 32 ADocument5 pagesFicha Técnica Interruptor General 32 AJosé IturvideNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- Eaton 066166 EMT6 en - GBDocument3 pagesEaton 066166 EMT6 en - GBSiva RamanNo ratings yet

- Eaton 041097 P1 25 EA SVB en - GBDocument6 pagesEaton 041097 P1 25 EA SVB en - GBAnonymous jW9BkgbQmENo ratings yet

- Chave EatonDocument6 pagesChave EatonWesly Carvalho SoeiroNo ratings yet

- Electricos MT IUSADocument5 pagesElectricos MT IUSALanh GonzáLezNo ratings yet

- Eaton 7kW 3 Pole Isolator DatasheetDocument6 pagesEaton 7kW 3 Pole Isolator DatasheetProject1 Tech7No ratings yet

- UntitledDocument3 pagesUntitledSaanounNo ratings yet

- Eaton 066168 Emt6 DBK en GBDocument4 pagesEaton 066168 Emt6 DBK en GBAriel TorresNo ratings yet

- EatonDocument6 pagesEatonkarmadewaNo ratings yet

- Emt6-Dbk (066168)Document6 pagesEmt6-Dbk (066168)hasan ziaeeNo ratings yet

- Moe F30051Document5 pagesMoe F30051Wu MonaNo ratings yet

- En 278425Document4 pagesEn 278425Haralambescu AndreiNo ratings yet

- Delivery ProgrammeDocument3 pagesDelivery ProgrammeIvanNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument6 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZJENNYNo ratings yet

- SB570 - SB5100: 5.0A Schottky Barrier RectifierDocument3 pagesSB570 - SB5100: 5.0A Schottky Barrier RectifierWalter FabianNo ratings yet

- Botonera ETONDocument7 pagesBotonera ETONwilcat1976No ratings yet

- FAK Complete Unit Emergency-Stop Part No. FAK-R/V/KC11/IY Article No. 229748Document3 pagesFAK Complete Unit Emergency-Stop Part No. FAK-R/V/KC11/IY Article No. 229748ArtesiraNo ratings yet

- Button Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5Document5 pagesButton Plate: 11/05/2020 Eaton 216509 ED2020 V74.0 EN 1 / 5sajad ghorbaniNo ratings yet

- A5e02261863a 02 201210291111411944Document7 pagesA5e02261863a 02 201210291111411944Lucas Fuzeto VizoniNo ratings yet

- SB160 Schottky Diode 60V 1a PDFDocument3 pagesSB160 Schottky Diode 60V 1a PDFdemostenessNo ratings yet

- Eaton 271423 NZMC2 A250 en - GB PDFDocument9 pagesEaton 271423 NZMC2 A250 en - GB PDFMarin DanielNo ratings yet

- Eaton DS 207297 P1 25 - I2 - SVB - HI11 20190625Document5 pagesEaton DS 207297 P1 25 - I2 - SVB - HI11 20190625Dominik FajgaNo ratings yet

- Eaton 265763 NZMH4 AE630 en - GBDocument7 pagesEaton 265763 NZMH4 AE630 en - GBJuan LópezNo ratings yet

- NP-Series - Valve Regulated Lead Acid Battery: LayoutDocument1 pageNP-Series - Valve Regulated Lead Acid Battery: Layoutulton1237624No ratings yet

- NP2 3-12 EnglishDocument1 pageNP2 3-12 EnglishJonathan BryantNo ratings yet

- Eaton 265912 NZMN4 4 AE1000 en - GBDocument5 pagesEaton 265912 NZMN4 4 AE1000 en - GBnelson1235No ratings yet

- 5/2-Directional Valve, Series HF03-LG: Technical RemarksDocument2 pages5/2-Directional Valve, Series HF03-LG: Technical RemarksTOny OlivenciaNo ratings yet

- Eaton 092394 T5B 3 7 E en - GBDocument6 pagesEaton 092394 T5B 3 7 E en - GBJorge AmayaNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument5 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZsyahril boonieNo ratings yet

- 1N4148W, T4Document3 pages1N4148W, T4borgergo0106No ratings yet

- Ah5cn (M) HaDocument1 pageAh5cn (M) HaAgus AnwarNo ratings yet

- Botón Paro de Emergencia - 216876Document3 pagesBotón Paro de Emergencia - 216876Mónica Felula GarcíaNo ratings yet

- Yucel-Series - Valve Regulated Lead Acid Battery: LayoutDocument1 pageYucel-Series - Valve Regulated Lead Acid Battery: Layoutjp.gestsaiNo ratings yet

- Schmersal Protect Ie02 SK DatasheetDocument6 pagesSchmersal Protect Ie02 SK DatasheetDeny Tirta KusumaNo ratings yet

- Eaton 072739 PKZM0 10 en - GBDocument8 pagesEaton 072739 PKZM0 10 en - GBElizabeth RamirezNo ratings yet

- 1N5819HW (SOD-123, 美台)Document3 pages1N5819HW (SOD-123, 美台)c8831116No ratings yet

- Safety Information: Instruction ManualDocument4 pagesSafety Information: Instruction ManualKen JunNo ratings yet

- DB-07319 Ad-00594 Azsoso 210430 eDocument2 pagesDB-07319 Ad-00594 Azsoso 210430 eŞener GüneyliNo ratings yet

- Datasheet Diode IN4002GDocument3 pagesDatasheet Diode IN4002GPoupée De SoieNo ratings yet

- Used Files HaiDocument2 pagesUsed Files Haipakyabhai143No ratings yet

- SMC Series: Surface Mount Unidirectional and Bidirectional Transient Voltage SuppressorsDocument4 pagesSMC Series: Surface Mount Unidirectional and Bidirectional Transient Voltage SuppressorsGRUPO FRIGONo ratings yet

- Circuit-Breaker, 3p, 100A Part No. NZMB1-A100 Catalog No. 259079 EL-Nummer (Norway) 4358704Document9 pagesCircuit-Breaker, 3p, 100A Part No. NZMB1-A100 Catalog No. 259079 EL-Nummer (Norway) 4358704shashirajNo ratings yet

- Contactor Ac-6b Capacitor CJ19Document2 pagesContactor Ac-6b Capacitor CJ19ChangKhenNo ratings yet

- PB Features: 1.0A Surface Mount Schottky Barrier DiodeDocument4 pagesPB Features: 1.0A Surface Mount Schottky Barrier DiodeMomo MendozaNo ratings yet

- Datasheet BES0045 267525 en PDFDocument2 pagesDatasheet BES0045 267525 en PDFGerardo Cruz EspinosaNo ratings yet

- Stavka 7. ZAMIJENITIDocument1 pageStavka 7. ZAMIJENITIjosip022No ratings yet

- SMCJ 778393Document7 pagesSMCJ 778393aprioris84No ratings yet

- BXA15 48S12 F ArtesynDocument2 pagesBXA15 48S12 F ArtesynShahji ElectronicNo ratings yet

- Power Relay K (Open - Sealed) : Automotive Relays PCB Single RelaysDocument4 pagesPower Relay K (Open - Sealed) : Automotive Relays PCB Single RelaysAngelitoSaranguitoGonzalecitoNo ratings yet

- Valvula Piezotronic Atex Serie 630 AscoDocument4 pagesValvula Piezotronic Atex Serie 630 AscoBase SistemasNo ratings yet

- SR5150 Won TopDocument4 pagesSR5150 Won TopRafael LehmkuhlNo ratings yet

- Eaton 015036 T0 5 8361 E en - GBDocument6 pagesEaton 015036 T0 5 8361 E en - GBSeoane GustavoNo ratings yet

- NPW-Series - Valve Regulated Lead Acid BatteryDocument1 pageNPW-Series - Valve Regulated Lead Acid BatteryfuffinoNo ratings yet

- Roller BlindsDocument2 pagesRoller Blindsmark simpsonNo ratings yet

- Qualcast 41cm Petrol Self Propelled Lawnmower: Assembly Manual XSZ41DDocument27 pagesQualcast 41cm Petrol Self Propelled Lawnmower: Assembly Manual XSZ41Dmark simpsonNo ratings yet

- Sherborne S Series Boilers Room Sealed Fully Modulating Pre Mix Gas Fired Boilers 500001103 eDocument48 pagesSherborne S Series Boilers Room Sealed Fully Modulating Pre Mix Gas Fired Boilers 500001103 emark simpsonNo ratings yet

- Position Qty. Description MAGNA3 65-150 F: Company Name: Created By: Phone: DateDocument3 pagesPosition Qty. Description MAGNA3 65-150 F: Company Name: Created By: Phone: Datemark simpsonNo ratings yet

- Your Ticket: Think Floyd - Through The WallDocument4 pagesYour Ticket: Think Floyd - Through The Wallmark simpsonNo ratings yet

- Instruction-Manual BFC UKDocument116 pagesInstruction-Manual BFC UKmark simpsonNo ratings yet

- ECL Comfort 310, Application A319: Operating GuideDocument121 pagesECL Comfort 310, Application A319: Operating Guidemark simpsonNo ratings yet

- 2 Simulation Study On 104 MHZ Radio Frequency Quadrupole Accelerator - ICEEE2010Document4 pages2 Simulation Study On 104 MHZ Radio Frequency Quadrupole Accelerator - ICEEE2010Mridula Mittal BansalNo ratings yet

- 2-3design of Capacitor BanksDocument25 pages2-3design of Capacitor BanksnazeerNo ratings yet

- RSO TestingDocument19 pagesRSO TestingAntonio DsfvsdcNo ratings yet

- Altistart 46 VW3G46101 Display and Adjustment enDocument37 pagesAltistart 46 VW3G46101 Display and Adjustment enValentin AgacheNo ratings yet

- Load Flow Analysis of 66 KV Substation Using ETAP SoftwareDocument4 pagesLoad Flow Analysis of 66 KV Substation Using ETAP SoftwareNasser SabrNo ratings yet

- Some Aspects of Structural Dynamics: Appendix BDocument26 pagesSome Aspects of Structural Dynamics: Appendix BEdgar Enrique Vilca RomeroNo ratings yet

- Universal Law of GravitationDocument6 pagesUniversal Law of GravitationKrish AggrawalNo ratings yet

- PS PressureDocument6 pagesPS PressuremirarpNo ratings yet

- Electrical Machines 2: Course Instructor: Sumaiya Umme Hani EmailDocument14 pagesElectrical Machines 2: Course Instructor: Sumaiya Umme Hani Emailmushfic fahimNo ratings yet

- MOV Check List Dept: Electrical: Equipment Tag No (Kks Code) Mov Name Motor Feeder NoDocument3 pagesMOV Check List Dept: Electrical: Equipment Tag No (Kks Code) Mov Name Motor Feeder NosuperthambiNo ratings yet

- Right Hand RuleDocument14 pagesRight Hand RuleTyra Christine Victorio FloresNo ratings yet

- Engi 1111 OutlineDocument3 pagesEngi 1111 OutlineDylan LawNo ratings yet

- CG Science 8 Q1Document4 pagesCG Science 8 Q1Emieleah Lorenzo Pauig100% (1)

- K5. The Angular Acceleration of The Links of The MechanismDocument15 pagesK5. The Angular Acceleration of The Links of The MechanismCeyla Danişyan-Abuzər100% (1)

- Laminar Flow: Moody's DiagramDocument1 pageLaminar Flow: Moody's DiagramDaniel GómezNo ratings yet

- Power Electronics: AC To DC Converters (Rectifiers)Document79 pagesPower Electronics: AC To DC Converters (Rectifiers)Frew FrewNo ratings yet

- Thevenin and Norton EquivalentsDocument36 pagesThevenin and Norton EquivalentsJosé Guillermo De Chomón AranguenaNo ratings yet

- An Itroduction To ElectromagnetismDocument82 pagesAn Itroduction To ElectromagnetismbastisnNo ratings yet

- Concept Strengthening Sheet (CSS-02) - RM - PhysicsDocument5 pagesConcept Strengthening Sheet (CSS-02) - RM - PhysicsNancy RaniNo ratings yet

- CL29M6P8X - XAO Electrical Parts List 12Document10 pagesCL29M6P8X - XAO Electrical Parts List 12ITOGAMYNo ratings yet

- Work, Energy and PowerDocument27 pagesWork, Energy and PowersuperultimateamazingNo ratings yet

- Laboratory Manual For Ac Electrical CircuitsDocument80 pagesLaboratory Manual For Ac Electrical CircuitsAngelo Palaming100% (1)

- Ieee 539Document50 pagesIeee 539darkjhesusNo ratings yet

- June 2012 QP - M1 EdexcelDocument13 pagesJune 2012 QP - M1 EdexcelSaiyara KhanNo ratings yet

- Performance Analysis of LLC Resonant Converter Incorporating Pi Fuzzy and Neural ControllersDocument12 pagesPerformance Analysis of LLC Resonant Converter Incorporating Pi Fuzzy and Neural ControllersDouglas SantosNo ratings yet

- Spencer MethodDocument36 pagesSpencer MethodJhofre FloresNo ratings yet

- Lesson 7: Electricity and Magnetism Learning ObjectivesDocument58 pagesLesson 7: Electricity and Magnetism Learning ObjectivesAdriel MarasiganNo ratings yet