Professional Documents

Culture Documents

Using DRV To Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1

Using DRV To Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1

Uploaded by

cutoCopyright:

Available Formats

You might also like

- Understanding The GIS InterlocksDocument28 pagesUnderstanding The GIS InterlocksFeodor Radilov100% (6)

- 120G Motor Grader PDFDocument766 pages120G Motor Grader PDFpapyrus100% (15)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Eaton Motor Control Basic Wiring PDFDocument14 pagesEaton Motor Control Basic Wiring PDFServasfloresNo ratings yet

- Shimadzu MC100L30 MC125L 30Document37 pagesShimadzu MC100L30 MC125L 30anon_524582163100% (1)

- Subaru Forester Manuals 2017 Forester Owner's ManualDocument634 pagesSubaru Forester Manuals 2017 Forester Owner's ManualZeckNo ratings yet

- Main Engine MAN B&W K 80 MC-CDocument868 pagesMain Engine MAN B&W K 80 MC-CAbsar Mamun94% (18)

- GET-7203 - Art of Protective RelayingDocument19 pagesGET-7203 - Art of Protective RelayingArnab BanerjeeNo ratings yet

- GET-7201 - Art of Protective RelayingDocument16 pagesGET-7201 - Art of Protective RelayingArnab Banerjee100% (1)

- SD70ACe IGBT Safety ManualDocument18 pagesSD70ACe IGBT Safety ManualAlberto Alejandro Sanchez100% (1)

- Pc8200 Super Galaxie 2000Document55 pagesPc8200 Super Galaxie 2000netbridge0% (1)

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- Final Circuit and Load Estimation British StandardDocument28 pagesFinal Circuit and Load Estimation British Standardhaidarkukum5686100% (4)

- Stepper Motor PDFDocument9 pagesStepper Motor PDFΓιώργος ΔήμαςNo ratings yet

- Brother PE180D Sewing Machine Service ManualDocument44 pagesBrother PE180D Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Manual Book Soft Starter Renle JJR8000Document70 pagesManual Book Soft Starter Renle JJR8000Herie HeriadieNo ratings yet

- Scalar V-F Control of 3-Phase Induction Motors - 2803xDocument25 pagesScalar V-F Control of 3-Phase Induction Motors - 2803xRaghu KodiNo ratings yet

- Motor ControlsDocument40 pagesMotor ControlsArlone ManaladNo ratings yet

- Mighty Mariner Instalacijski ManualDocument59 pagesMighty Mariner Instalacijski ManualDragan LugonićNo ratings yet

- Basics of Motor Control CentersDocument72 pagesBasics of Motor Control CentersRaihanKhan100% (2)

- Manual MH800 Series Electro Hydraulic ServoDocument169 pagesManual MH800 Series Electro Hydraulic Servotuan voNo ratings yet

- Application With SCALE™-2 and SCALE™-2+ Gate Driver CoresDocument32 pagesApplication With SCALE™-2 and SCALE™-2+ Gate Driver Coresbharath prabhuNo ratings yet

- MCC 1Document13 pagesMCC 1www.otomasyonegitimi.comNo ratings yet

- Slvae 59 ADocument19 pagesSlvae 59 Aประยุทธ์ อังคารชาNo ratings yet

- FX Series Positioning Beginner S Manual English ControllerDocument116 pagesFX Series Positioning Beginner S Manual English ControllerdunkhanNo ratings yet

- AB Starter DiagramDocument39 pagesAB Starter Diagramrajinipre-1100% (1)

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- 7000 Um150e en P Dec03Document456 pages7000 Um150e en P Dec03Cristian VegaNo ratings yet

- LinuxCNC IntegratorDocument17 pagesLinuxCNC IntegratorrodrigodelacalperezNo ratings yet

- VLT5000 6000 8000 LonWorks FTP MG60N202Document42 pagesVLT5000 6000 8000 LonWorks FTP MG60N202t32101949No ratings yet

- Integrator Information V2.8.2-131-Gf324cd6e2, 2022-05-28Document17 pagesIntegrator Information V2.8.2-131-Gf324cd6e2, 2022-05-28Juan Carlos LesmasNo ratings yet

- Easygen-3000 Series: ManualDocument712 pagesEasygen-3000 Series: ManualSebaSTIÁN SalazarNo ratings yet

- GD - 1SP0635 Manual Power IntegrationsDocument27 pagesGD - 1SP0635 Manual Power IntegrationsRizkiWiraPratamaNo ratings yet

- Brother Super Ace+e Sewing Machine Service ManualDocument56 pagesBrother Super Ace+e Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Integrator Information V2.8.0-98-Gae2e6bd, 2020-11-01 PDFDocument17 pagesIntegrator Information V2.8.0-98-Gae2e6bd, 2020-11-01 PDFluisNo ratings yet

- MP Hyd Power Unit 9000 0008-10-98 (Ram)Document74 pagesMP Hyd Power Unit 9000 0008-10-98 (Ram)Joao RiveraNo ratings yet

- Motor Control CenterDocument81 pagesMotor Control CenterMohamed Mohamed100% (2)

- EDC User S Manual V2 0Document142 pagesEDC User S Manual V2 0Ivan Sanabria SaavedraNo ratings yet

- ProNet User S Manual V2 11Document195 pagesProNet User S Manual V2 11Darwin DuqueNo ratings yet

- Brother PC8200 Super Galaxie 2000 Sewing Machine Service ManualDocument55 pagesBrother PC8200 Super Galaxie 2000 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- S3 Series Elevator InvertersDocument198 pagesS3 Series Elevator Inverterscông nguyễn thànhNo ratings yet

- PLC and Hmi For Conveyor Monitoring and Fault DetectionDocument5 pagesPLC and Hmi For Conveyor Monitoring and Fault DetectionIJAR JOURNALNo ratings yet

- Brushless DC MotorsDocument21 pagesBrushless DC MotorsKiran KumarNo ratings yet

- Motor Starter Components and StandardsDocument20 pagesMotor Starter Components and StandardsJellyn BaseNo ratings yet

- Variable Speed DrivesDocument41 pagesVariable Speed DrivesJuan AraqueNo ratings yet

- Snoa543a Low NoiseDocument9 pagesSnoa543a Low Noisesteviej85No ratings yet

- GE Auto Reclosing Transmission and Distribution Breakers GER-2540A PDFDocument36 pagesGE Auto Reclosing Transmission and Distribution Breakers GER-2540A PDFBalan PalaniappanNo ratings yet

- Sinumerik 810 820 GA3 Interface - Part - 2 - Connection - ConditionsDocument128 pagesSinumerik 810 820 GA3 Interface - Part - 2 - Connection - ConditionsSam eagle goodNo ratings yet

- GE Distribution System Feeder Overcurrent ProtectionDocument24 pagesGE Distribution System Feeder Overcurrent ProtectionAerwin BautistaNo ratings yet

- LEBQ8107-00 Automatic Transfer Switch PDFDocument84 pagesLEBQ8107-00 Automatic Transfer Switch PDFpowermanagerNo ratings yet

- Minor Project ReportDocument29 pagesMinor Project ReportHiteshNo ratings yet

- Convection Microwave Oven Service and Repair ManualDocument51 pagesConvection Microwave Oven Service and Repair Manuallina jobstreetNo ratings yet

- EN ACS880 R1 R11 EMC Filter Disconn J ScreenDocument40 pagesEN ACS880 R1 R11 EMC Filter Disconn J ScreenRomildo FernandesNo ratings yet

- Astat Plus: GE Power ControlsDocument35 pagesAstat Plus: GE Power ControlsRafael CastilloNo ratings yet

- MCC 1Document14 pagesMCC 1Arif SugestyanNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Ttl/Hcmos Crystal Oscillator: MCO-1510A / MCO-1510B (FULL SIZE)Document1 pageTtl/Hcmos Crystal Oscillator: MCO-1510A / MCO-1510B (FULL SIZE)cutoNo ratings yet

- VN5T016AH-E: Single Channel High-Side Driver With Analog Current Sense For 24 V Automotive ApplicationsDocument31 pagesVN5T016AH-E: Single Channel High-Side Driver With Analog Current Sense For 24 V Automotive ApplicationscutoNo ratings yet

- Workshop4: User GuideDocument52 pagesWorkshop4: User GuidecutoNo ratings yet

- (Kalmar: DCE80-45E7 10 61Document12 pages(Kalmar: DCE80-45E7 10 61cutoNo ratings yet

- Tidrh 63Document2 pagesTidrh 63cutoNo ratings yet

- PLC Arduino Ethernet 58 I/Os Analog/Digital PlusDocument54 pagesPLC Arduino Ethernet 58 I/Os Analog/Digital PluscutoNo ratings yet

- GP4000 MM01 Eng PDFDocument249 pagesGP4000 MM01 Eng PDFcutoNo ratings yet

- TF Jo'l: ( AlmarDocument20 pagesTF Jo'l: ( Almarcuto100% (1)

- DCE80-45E7 10: Reservdelar - Spare PartsDocument16 pagesDCE80-45E7 10: Reservdelar - Spare PartscutoNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument3 pagesPart Number: Status: Overview: Description:: DocumentscutoNo ratings yet

- FX Series Computer Link DriverDocument60 pagesFX Series Computer Link DrivercutoNo ratings yet

- Dimensions: (MM) Recommended Land Pattern: (MM) : Properties Value Unit Pin To Pin (Middle)Document8 pagesDimensions: (MM) Recommended Land Pattern: (MM) : Properties Value Unit Pin To Pin (Middle)cutoNo ratings yet

- Dm00119042 PWM Resolution Enhancement Through A Dithering Technique For Stm32 Advancedconfiguration Generalpurpose and Lite Timers StmicroelectronicsDocument22 pagesDm00119042 PWM Resolution Enhancement Through A Dithering Technique For Stm32 Advancedconfiguration Generalpurpose and Lite Timers StmicroelectronicscutoNo ratings yet

- Proficonn PB102Document3 pagesProficonn PB102cutoNo ratings yet

- 2.7V 4-Channel/8-Channel 12-Bit A/D Converters With SPI Serial InterfaceDocument41 pages2.7V 4-Channel/8-Channel 12-Bit A/D Converters With SPI Serial InterfacecutoNo ratings yet

- Common Mode Choke: 1812canbusDocument3 pagesCommon Mode Choke: 1812canbuscutoNo ratings yet

- General MODBUS TCP Master DriverDocument28 pagesGeneral MODBUS TCP Master DrivercutoNo ratings yet

- F C C F F F F H: Electro-Hydraulic Servo Valve Driver Servo AmplifierDocument2 pagesF C C F F F F H: Electro-Hydraulic Servo Valve Driver Servo AmplifiercutoNo ratings yet

- Proportional Pressure Relief Valve, Pilot Operated: List of Contents FeaturesDocument12 pagesProportional Pressure Relief Valve, Pilot Operated: List of Contents FeaturescutoNo ratings yet

- Series (40W) : Motor Dimension Characteristic CurveDocument2 pagesSeries (40W) : Motor Dimension Characteristic CurvecutoNo ratings yet

- 04 - RS4 Series Geared MotorDocument1 page04 - RS4 Series Geared MotorcutoNo ratings yet

- Tisp4Xxxm3Bj Overvoltage Protector SeriesDocument14 pagesTisp4Xxxm3Bj Overvoltage Protector SeriescutoNo ratings yet

- TEAM 1.2: Nguyễn Thái Dương Nguyễn Minh Hiếu Hoàng Văn Hưng Nguyễn Trọng Quang HuyDocument25 pagesTEAM 1.2: Nguyễn Thái Dương Nguyễn Minh Hiếu Hoàng Văn Hưng Nguyễn Trọng Quang HuyNguyễn Trọng Quang HuyNo ratings yet

- High Speed Machining Center: Long Chang Machinery Co., LTDDocument12 pagesHigh Speed Machining Center: Long Chang Machinery Co., LTDJaime Cortés Cortés GálvezNo ratings yet

- 32200101Document4 pages32200101bnolasco0% (1)

- 11 - ChassisDocument68 pages11 - ChassispedrojrandradeNo ratings yet

- Audio System: E4 (A), E5 (B), E6 (C), E53 (D)Document4 pagesAudio System: E4 (A), E5 (B), E6 (C), E53 (D)dadang lukmanulhakimNo ratings yet

- Prysmian FP200 Gold Fire Performance & Resistant Cables PDFDocument2 pagesPrysmian FP200 Gold Fire Performance & Resistant Cables PDFAlyaa EmadNo ratings yet

- Parts Catalog - Option Detail: Option Group Graphic Film Card DateDocument2 pagesParts Catalog - Option Detail: Option Group Graphic Film Card DateKarthickNo ratings yet

- Fisa Tehnica Centrala de Incendiu Adresabila Cu 2 Bucle FireClass FC506 500 Adrese 256 Zone PSTNDocument6 pagesFisa Tehnica Centrala de Incendiu Adresabila Cu 2 Bucle FireClass FC506 500 Adrese 256 Zone PSTNIONUT.SNAKENo ratings yet

- Polar CS100: ™ User ManualDocument60 pagesPolar CS100: ™ User Manualأم أنسNo ratings yet

- Pioneer+Sc Lx72,+Sc Lx82Document236 pagesPioneer+Sc Lx72,+Sc Lx82Raimundo de LimaNo ratings yet

- The KnowledgeDocument13 pagesThe KnowledgeJordi RibóNo ratings yet

- Sony DSC-V3 Level 2 Service Manual (P. N. - 987676232)Document59 pagesSony DSC-V3 Level 2 Service Manual (P. N. - 987676232)tm5u2r0% (1)

- SQ 100 ADocument2 pagesSQ 100 AzhobeysNo ratings yet

- Empty BOQ For Pricing MEPDocument26 pagesEmpty BOQ For Pricing MEPabdullah sahibNo ratings yet

- Experiment 3 ACA PDFDocument11 pagesExperiment 3 ACA PDFaakash dabasNo ratings yet

- BPXN Lock Mandrel Brio Tech Catalog Revised 1.01 S 63Document1 pageBPXN Lock Mandrel Brio Tech Catalog Revised 1.01 S 63Franklin de Jesus NavarroNo ratings yet

- ZanussiDocument16 pagesZanussiferiferiNo ratings yet

- Ds x61 en Relay Technical InformationDocument34 pagesDs x61 en Relay Technical InformationNesarkiran BagadeNo ratings yet

- Igbt Spice ModelingDocument43 pagesIgbt Spice ModelingBrian WillardNo ratings yet

- LP3871/LP3874 0.8A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesDocument18 pagesLP3871/LP3874 0.8A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesPaulo Henrique ValérioNo ratings yet

- JOINT FUJI Product Catalog For SUZUKIDocument15 pagesJOINT FUJI Product Catalog For SUZUKIapple bananaNo ratings yet

- Mechanical PDFDocument8 pagesMechanical PDFBAVITH KAMMANA MEETHALNo ratings yet

- Altistart 48 CatalogueDocument51 pagesAltistart 48 CataloguerubysultanaNo ratings yet

- Parts List ThermoKing SGCO3000 GensetDocument95 pagesParts List ThermoKing SGCO3000 GensetJennyJudithRuizSanchez100% (1)

- Tda 7432Document11 pagesTda 7432greemaxNo ratings yet

- Kenmore 385.19153 Sewing Machine Instruction ManualDocument211 pagesKenmore 385.19153 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

Using DRV To Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1

Using DRV To Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1

Uploaded by

cutoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Using DRV To Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1

Using DRV To Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1

Uploaded by

cutoCopyright:

Available Formats

Application Report

SLVAE59 – Frebruary 2019

Using DRV to Drive Solenoids - DRV8876/DRV8702-

Q1/DRV8343-Q1

David Vaseliou

ABSTRACT

This application report provides various methods on how to drive solenoids and relays using TI integrated

motor driver ICs. This report will discuss solenoid fundamentals, basic configurations, and different driving

methods.

Contents

1 Introduction ................................................................................................................... 2

2 Driving Typologies .......................................................................................................... 2

3 Driving Multiple Solenoids ................................................................................................. 5

4 Efficient Solenoid Driving using DRV ..................................................................................... 8

5 Fast Discharging Circuits .................................................................................................. 11

6 Conclusion .................................................................................................................. 12

List of Figures

1 Cross-Sectional View of a Pull-Type Linear Solenoid .................................................................. 2

2 A Power MOSFET Transistor and a Freewheeling Diode Used to Drive a Solenoid ............................... 3

3 Sneak Path When VBAT is Disconnected from the Board ............................................................ 3

4 Configurations for Basic Low-side, High-side, and Push-Pull Drivers ................................................ 4

5 H-Bridge Configuration Utilized to Drive a Solenoid Valve ............................................................. 4

6 Independent PWM High-Side and Low-Side Drivers ................................................................... 5

7 Solenoid Drive Configuration ............................................................................................... 6

8 Application Schematic for DRV8702-Q1 to Drive Two Solenoids .................................................... 7

9 Application Schematic for DRV8876 to Drive Two Solenoids ......................................................... 8

10 Solenoid Voltage and Current Outputs Using PWM ................................................................... 9

11 Block Diagram for DRV8343S ........................................................................................... 10

12 Zener Diode Fast Discharging Circuit .................................................................................. 11

13 H-Bridge Fast Decay ...................................................................................................... 12

List of Tables

1 ............................................................................

Trade-offs of Different Driver Configurations 4

2 Truth Table for Independent MOESFET Mode .......................................................................... 5

3 Independent Half-Bridge Mode Truth Table .............................................................................. 6

4 Independent Half Bridge Mode Truth Table .............................................................................. 6

5 Independent Half-Bridge Control Mode .................................................................................. 8

SLVAE59 – Frebruary 2019 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 1

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Introduction www.ti.com

Trademarks

All trademarks are the property of their respective owners.

1 Introduction

A solenoid is a coil that produces a linear or rotational movement in a mechanical system by applying a

current through the coil. Electromechanical solenoids consist of a copper inductive coil wound around a

steel or iron armature sometimes called a “plunger”. The magnetic field of the energized coil pulls on the

armature, and the armature transfers a mechanical force to an external mechanism. Similar to solenoids,

electromagnetic relays are electrically operated switches typically used to connect or disconnect an

electrical circuit. Typical applications of solenoids include home appliances, printers, HVAC, irrigation

systems, engine and transmission control, and much more.

Solenoids and relays can be driven using either an H-Bridge or half-bridge motor driver IC. These ICs can

be used to implement the most common configurations and driving methods to operate solenoids. These

ICs can also be used to drive multiple solenoids simultaneously and independently.

1.1 Types of Solenoids

There are two main types of solenoids, the pull-type linear solenoid and the rotatory solenoid. The pull-

type linear solenoid is used in applications where an “in and out” movement is needed. This type of

solenoid can be found in applications such as electronic door locks, valves, and robotics. Figure 1 shows

a cross-sectional view of a pull-type linear solenoid.

The second main type is the rotary solenoid. These solenoids produce a rotational motion on a

mechanism. Rotary solenoids can be used in applications where a small rotational movement is needed.

Some application examples of rotary solenoids include camera shutters, document movement machines,

and sorting systems.

FRAME

COIL

PLUNGER

SPRING

X X X X X X X X X X X X

COIL

X X X X X X X X X X X X

MAGNETIC FORCE SPRING FORCE

Figure 1. Cross-Sectional View of a Pull-Type Linear Solenoid

2 Driving Typologies

The fundamentals of driving a solenoid or relay starts with configuring one or more MOSFETs to switch on

and off a driving current. While this can be very simple, other circuitry is needed to drive a solenoid

efficiently. There are three basic driver configurations, low-side, high-side, and push-pull, each with their

trade-offs. Choosing which configuration depends on the system requirements such as switching speed

and necessary fault protection.

2 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 SLVAE59 – Frebruary 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Driving Typologies

2.1 Low-Side and High-Side Configuration

The typical low-side or high-side solenoid driver uses a single MOSFET with enough current handling

capability to drive a load, and a freewheeling diode which is forward biased when the MOSFET is

disabled. When the MOSFET is enabled, it conducts all the current needed to energize the solenoid.

When the MOSFET is disabled, the current flowing through the solenoid must be allowed to continue

flowing or decay to zero. To do this, the freewheeling diode is forward biased taking this current to avoid

damaging the power MOSFET. Figure 2 shows a low-side driver with the two possible states a solenoid

will experience as it is energized. While the low-side and high-side drivers operate similarly, high-side

drivers are more complex. This is because the high-side NMOS typically needs additional circuitry, such

as a charge pump or bootstrap, to drive its gate voltage.

VM VM

Figure 2. A Power MOSFET Transistor and a Freewheeling Diode Used to Drive a Solenoid

2.2 Push-Pull Driver Configuration

The push-pull driver type uses two MOSFET transistors in a half-bridge configuration to control the current

through the solenoid. This driver type uses one MOSFET to forward drive the solenoid and another to

recirculate current. This configuration is suited for high-speed operations (100kHz or higher), and allows

for both high-side and low-side driving. Another advantage of using a push-pull driver configuration is that

it protects both short to VBAT and short to GND scenarios.

Using a push-pull driver does add complexity due to having both high-side and low-side drivers. Along

with the added complexities, a push-pull driver also allows for sneak paths. Sneak paths are unintended

electrical current paths with the circuit and external components. This is an issue if a body diode is parallel

to the load and particularly noticeable for multiple board systems where connectors can be disconnected

when the load is still connected to the power supply. An example of a sneak path is shown in Figure 3.

The basic configurations can be seen in Figure 4 along with their trade-offs in Table 1.

Sneak Path

VBAT High-side

System Board Load High-side

+ - turns on! Load

DRV8844

Load

LDO

Battery Load

Low-side

GND

Load

System Board is

powered though

sneak path

Figure 3. Sneak Path When VBAT is Disconnected from the Board

SLVAE59 – Frebruary 2019 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 3

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Driving Typologies www.ti.com

Low-side driver High-side driver Push-Pull driver

VM VM VM

GND

GND

GND

Figure 4. Configurations for Basic Low-side, High-side, and Push-Pull Drivers

Table 1. Trade-offs of Different Driver Configurations

Low-Side driver High-side driver Push-Pull driver

+ Easy to drive - More Complex drivers - Contains HS+LS driver

- HS load only - LS load only + HS or LS loads

- No Short to GND Protection + Protects short to GND + Protects short to GND

+ Protects short to VBAT - No short to VBAT protection + Protects short to VBAT

- Slower speed operation - Slower speed operation + High speed operation

+ Sneak path prevented + Sneak path prevented - Sneak path

2.3 H-Bridge Driver

Each solenoid driving typology can be implemented with an integrated H-Bridge motor driver IC. An H-

Bridge is two half-bridges joined together by a load. This is mainly used in applications where the voltage

or current polarity applied to the load needs to be switched such as a latching relay. An H-Bridge also

allows the capability to recirculate current slower using the opposing MOSFET. Figure 5 shows how an H-

Bridge can be utilized to drive a conventional solenoid valve.

VM VM VM VM

2 2

1 3

SH1 SH2 SH1 SH2 SH1 SH2 SH1 SH2

1 Forward drive

2 High-side recirculation (brake)

3 Reverse drive

Figure 5. H-Bridge Configuration Utilized to Drive a Solenoid Valve

4 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 SLVAE59 – Frebruary 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Driving Multiple Solenoids

3 Driving Multiple Solenoids

Many motor driver ICs have the advantage of driving multiple solenoids with their multiple outputs.

Devices such as the DRV8343-Q1, DRV8702-Q1, and DRV8876 all are able to drive two or more

solenoids with a single device. For example, the DRV8343-Q1 can be configured to drive up to six

solenoids individually, three high-side and three low-side. Using these motor driver ICs can simplify the

design and decrease the board size needed to accomplish this task.

3.1 DRV8343-Q1

The Independent FET mode and Independent Half-Bridge mode on the DRV8343-Q1 are easy solutions

for driving multiple solenoids or relays with a single device. In Independent MOSFET Drive mode, the

INHx and INLx pins control the outputs, GHx and GLx, respectively. This control mode lets the DRV8343-

Q1 drive separate high-side and low-side loads with each half-bridge. In this mode, turning on both the

high-side and low-side MOSFETs at the same time in a given half-bridge gate driver is possible. In this

mode, the integrated dead time is bypassed. Table 3 shows the truth table for DRV8343-Q1 in

independent PWM mode.

Table 2. Truth Table for Independent MOESFET Mode

INLx INHx GLx GHx

0 0 L L

0 1 L H

1 0 H L

1 1 H H

Figure 6 shows how the DRV8343-Q1 device can be used to connect a high-side load and a low-side load

at the same time with one half-bridge and drive the loads independently. In this mode, the VDS monitors

are active for both the MOSFETs to protect from an overcurrent condition. This can be done for each of

the 3 phases for a total of 6 different solenoids.

+

VDS

±

VM

VDRAIN

VCP

GHx Load

INHx HS

SHx

VGLS DLx

INLx

GLx

LS

Load

Gate Driver SLx/SPx

+

VDS

±

Figure 6. Independent PWM High-Side and Low-Side Drivers

Figure 7 shows how the DRV8343-Q1 device can be used to connect a solenoid load where both the

high-side and low-side MOSFETs can be turned on at the same time to drive the load without causing

shoot-through. TI recommends having the external diodes for current recirculation. If a half-bridge is not

used, the gate pins (GHx and GLx) can stay unconnected and the sense pins (SHx and DLx) can be tied

directly or through a resistor to GND.

SLVAE59 – Frebruary 2019 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 5

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Driving Multiple Solenoids www.ti.com

VDRAIN VDRAIN VDRAIN

HS_VSD + HS_VSD + HS_VSD +

± GHx ± GHx ± GHx

SHx SHx SHx

PH_A PH_B PH_C

DLx DLx DLx

GLx GLx GLx

LS_VSD + LS_VSD + LS_VSD +

± ± ±

SLx SLx SLx

Figure 7. Solenoid Drive Configuration

In the Independent Half-Bridge mode the DRV8343-Q1 can control up to 3 different solenoids in a Push-

Pull configuration. In this mode the DRV8343-Q1 will automatically insert dead time when switching and

handle the protections for over current protection (OCP), short to battery, and short to GND faults. In

Independent Half-Bridge PWM mode, the INHx pin controls each half-bridge independently and supports

two output states: low or high. The corresponding INHx and INLx signals control the output state as listed

in Table 3. The INLx pin is used to change the half-bridge to high impedance. If the high-impedance (Hi-Z)

state is not required, tie all INLx pins logic high.

Table 3. Independent Half-Bridge Mode Truth Table

INLx INHx GLx GHx

0 x L L

1 0 H L

1 1 L H

Combinations of Half-Bridge and Independent MOSFET drive modes are available where two of the

phases will be in Independent Half-Bridge mode and the last phase in Independent MOSFET mode. This

allows a total of 4 solenoids to be driven at the same time individually, 2 in push-pull configuration, 1 in

high-side configuration, and 1 in low-side configuration. In these modes, the 2 phases in independent Half-

Bridge mode control the independent fault handling and dead time enforcement is done by the device. The

dead time insertion by the device is bypassed for the phase in Independent MOSFET mode.

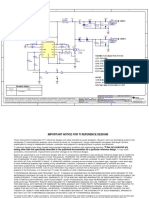

3.2 DRV8702-Q1

The DRV8702-Q1 is a small single H-Bridge gate driver that uses four external N-channel MOSFETs that

can control up to two solenoids or relays independently. Figure 8 shows how to configure the DRV8702-

Q1 in the Independent Half Bridge mode. Table 4 shows the control table for DRV8702-Q1 in Independent

Half Bridge mode. In this mode the device does not perform PWM current regulation or current chopping.

Table 4. Independent Half Bridge Mode Truth Table

nSleep IN1/PH IN2/EN GH1 GL1 SH1 GH2 GL2 SH2

0 x x x x Hi-Z x x Hi-Z

1 x 0 x x x 0 1 L

1 x 1 x x x 1 0 H

1 0 x 0 1 L x x x

6 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 SLVAE59 – Frebruary 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Driving Multiple Solenoids

Table 4. Independent Half Bridge Mode Truth Table (continued)

nSleep IN1/PH IN2/EN GH1 GL1 SH1 GH2 GL2 SH2

1 1 x 1 0 H x x x

VM

+

0.1 µF Bulk VM

0.1 µF 1 µF

+

Bulk

Solenoid

32

31

30

29

28

27

26

25

NC

CPL

CPH

VCP

VM

VDRAIN

GH2

SH2

1 24

GND GL2

2 23

IN1/PH SL2

3 22

IN2/EN SN

4 21

GND SP

GND

5 (PAD) 20

IDRIVE GL1

Solenoid

200 kŸ 6 19

VDS SH1

0Ÿ 7 18

GND GH1

8 17

nFAULT

nSLEEP GND

MODE

DVDD

AVDD

VREF

GND

GND

VM

SO

+

9

10

11

12

13

14

15

16

VM Bulk

R1 R2

10 kŸ

1 µF 1 µF

Copyright © 2017, Texas Instruments Incorporated

Figure 8. Application Schematic for DRV8702-Q1 to Drive Two Solenoids

3.3 DRV8876

For lower current applications the DRV8876 is an integrated H-Bridge driver that can also be configured to

drive two solenoids in Independent Half Bridge mode. The MOSFETs are built into the DRV8876 to

simplify the design and decrease board space. Figure 9 shows the application schematic configured to

drive two solenoids in Independent Half-Bridge mode. Table 5 shows the control modes in Independent

Half-Bridge mode.

SLVAE59 – Frebruary 2019 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 7

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Efficient Solenoid Driving using DRV www.ti.com

VCC

Controller 1 16

PWM EN/IN1 DRV887x PMODE X

2 15

PWM PH/IN2 GND

VCC 3 14 0.022 …F

I/O nSLEEP CPL

10 k

4 13

I/O nFAULT CPH

Thermal

VCC 5 12 0.1 …F

Pad

ADC VREF VCP VM

6 11

IPROPI VM

RIPROPI 7 10 0.1 …F CBulk

IMODE OUT2

8 9

OUT1 PGND

VM VM

Solenoid Solenoid

Figure 9. Application Schematic for DRV8876 to Drive Two Solenoids

Table 5. Independent Half-Bridge Control Mode

nSleep INx OUTx Description

0 X Hi-Z Sleep, (H-Bridge, Hi-Z)

1 0 L OUTx Low-side On

1 1 H OUTx High-side On

4 Efficient Solenoid Driving using DRV

To drive solenoids efficiently and reliably more than just MOSFETs are required. Using motor driver ICs

can optimize power efficiency without adding complex circuitry to the design. In most applications the full

driving current is only needed initially to pull in the plunger. After the initial pull-in current can be regulated

at a lower level to hold the solenoid in place. This allows for lower power consumption due to the lower

current and less heat generated in the coil. If the drive current is not reduced, large and unnecessary

power consumption will generate as well as large amounts of heat in the solenoid. With the increase in

temperature the solenoid initial resistance will also increase. When applying a constant voltage, the

increase in initial start up resistance will reduce the current in the solenoid, which reduces the magnetic

force. This may cause the solenoid to de-actuate or for a relay to open its contacts if the current

decreases too much.

4.1 Current Regulation using PWM

Just as pulse width modulation (PWM) is used to drive motors, it also can be used to drive solenoids.

PWM can be used to regulate the current of a solenoid to different levels at different times by varying the

duty cycle. This allows the user drive a longer duty cycle to pull in the solenoid and then a shorter duty

cycle to hold it in place, optimizing the power consumption.Figure 10 shows the current and voltage

driving outputs for the PWM implementation. Most DRV motor driver ICs, including DRV8343-Q1,

DRV8876, and DRV8702-Q1, can use this method to regulate current.

8 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 SLVAE59 – Frebruary 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Efficient Solenoid Driving using DRV

Figure 10. Solenoid Voltage and Current Outputs Using PWM

4.2 Increase Efficiency with Integrated Current Regulation or Integrated Current Sense

Amplifiers

To even further the efficiency and reliability of a solenoid driver circuit, current-sense feedback for the

current control can be implemented. Current-sense feedback provides two main advantages. One

advantage is efficiency and reliability over temperature. As the solenoid or relay coil heats up from I2R

losses or is warmed by its environment, the coil resistance increases. With the current-sense feedback,

the current can be monitored and adjusted to produce a constant force even with the changes in

resistance. The second advantage is that it allows operation regardless of supply voltage. At times a relay

or solenoid will have good performance, but may not be rated for the available voltage rails in the system.

Solenoids have these voltage ratings because they can be destroyed by too much current going through

the coil which happens when driving at higher voltages. This issue is eliminated when using current-sense

feedback by controlling the current going through the solenoid regardless of the supply voltage. This

allows a single solenoid driver design to be reused on multiple products.

There are two methods for providing current feedback to a microcontroller, one through an integrated

current shunt amplifer using an external sense resistor and the other through a current mirror where a

proportional current is fed to the microcontroller without the need for an external sense resistor, saving

cost and board space. Typically, in gate drivers you will find integrated current shunt amplifiers like in

DRV8343-Q1 which has three current shunt amplifiers as shown in Figure 11 . On the other hand,

integrated MOSFET motor drivers like the DRV8876 have a current mirror architecture which provides a

proportional current to the microcontroller through the IPROPI pin.

SLVAE59 – Frebruary 2019 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 9

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Efficient Solenoid Driving using DRV www.ti.com

DRV8343-Q1

VDRAIN VM

VCP

ENABLE

Digital GHx

Core HS

INHx Control SHx

Inputs

DLx

Smart Gate VGLS

INLx

Drive

VCC GLx

LS

Protection

VREF

0.1 …F SLx

Gate Driver

SOx SPx

Output

Offset AV RSEN

Bias SNx

CAL

Figure 11. Block Diagram for DRV8343S

Another feature in some motor drivers that can be used to control the amount of current through the

solenoids is integrated current regulation. TI Motor Drivers such as DRV8702-Q1, DRV8702D-Q1, and

DRV8876 have this feature. The DRV8702-Q1's integrated current regulation can be used when put in a

H-Bridge configuration. If only a half-bridge is needed, the DRV8702D-Q1 can be used. On the DRV8702-

Q1 and DRV8702D-Q1, the maximum current through the motor winding is regulated by a fixed off-time

PWM current regulation or current chopping. When the current hits the current chopping threshold, the

bridge enters a brake (low-side slow decay) mode until the toff time expires. The PWM chopping current is

set by a comparator that compares the voltage across a current-sense resistor connected to the SP pin,

multiplied by a factor of AV, with a reference voltage from the VREF pin. The factor AV is the shunt-

amplifier gain, which is 19.8 V/V for the DRV8702-Q1 device or configurable to 10, 19.8, 39.4, or 78 V/V

for the DRV8703-Q1 device. Use Equation 1 to calculate the chopping current ICHOP.

(1)

Integrated current regulation on the DRV8876 can be set using the VREF and IPROPI pins. The

integrated current regulation can either be set to use a fixed off-time or cycle-by-cycle PWM current

chopping scheme. Equation 2 can be used to size the appropriate IPROPI resistor to achieve the desire

ITRIP level. In the fixed off-time mode, the H-bridge enters a brake, low-side slow decay (both low-side

MOSFETs ON) for tOFF duration after IOUT exceeds ITRIP. After tOFF the outputs are re-enabled according to

the control inputs unless IOUT is still greater than ITRIP. If IOUT is still greater than ITRIP, the H-bridge will enter

another period of brake/lowside slow decay for tOFF. In cycle-by-cycle mode, the H-bridge enters a brake,

low-side slow decay (both low-side MOSFETs ON) after IOUT exceeds ITRIP until the next control input edge

on the EN/IN1 or PH/IN2 pins.

(2)

Since there is only 1 IPROPI pin on the device the current sensing on the IPROPI pin is the summation of

the currents through the two low-side internal MOSFETs.

10 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 SLVAE59 – Frebruary 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

www.ti.com Fast Discharging Circuits

5 Fast Discharging Circuits

Some applications require very fast turn on/off rates of a solenoid. Due to the nature of solenoids, current

flow cannot change instantaneously. Recirculating the current in either a freewheeling diode or opposing

MOSFET is sometimes not enough to decay the current fast enough and will cause a delay in the plunger

releasing. To do this, a fast discharging circuit is added into the application. The basic idea is to construct

a circuit that that can provide a large opposing voltage that can quickly decay the recirculation current to

zero. The higher opposing voltage, the faster the current decay. These fast discharging circuits can be

made using a Zener or TVS (Transient-voltage-suppression) diode, a varistor (Voltage Dependent

Resistor), or an H-Bridge configuration.

5.1 Zener or TVS diode

When using a Zener diode to discharge the solenoid current, the opposing voltage will be equal to

Equation 3.

(3)

If the internal resistance of the solenoid is ignored the decay time can be estimated by Equation 4.

(4)

Figure 12 shows an example of using a Zener diode for fast discharging.

VM

Driving Path

Recirculation Path

Figure 12. Zener Diode Fast Discharging Circuit

5.2 H Bridge with Fast Decay OFF Time

Using an H-Bridge can also be used as an effective fast discharge circuit. As shown in Figure 13 fast

decay can be used by turning off the MOSFETs and allowing current to flow through the body diodes. This

will result in a opposing voltage equal to the VM plus the forward voltage of the two body diodes. If

frequency response and better thermal performance is desired an H-Bridge configuration can be used.

SLVAE59 – Frebruary 2019 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 11

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

Conclusion www.ti.com

VM VM

1

SH1 SH2 SH1 SH2

1 Forward drive

2 Fast Decay

Figure 13. H-Bridge Fast Decay

6 Conclusion

Motor driver ICs can be an effective, efficient, and reliable solution to drive solenoids. With all the

integrated features, using drivers such as DRV8343-Q1, DRV8702-Q1, and DRV8876, can be used to

drive multiple solenoids with a single device, achieve greater efficiency using PWM, and increase reliability

using current sense feedback.

12 Using DRV to Drive Solenoids - DRV8876/DRV8702-Q1/DRV8343-Q1 SLVAE59 – Frebruary 2019

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2019, Texas Instruments Incorporated

You might also like

- Understanding The GIS InterlocksDocument28 pagesUnderstanding The GIS InterlocksFeodor Radilov100% (6)

- 120G Motor Grader PDFDocument766 pages120G Motor Grader PDFpapyrus100% (15)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Eaton Motor Control Basic Wiring PDFDocument14 pagesEaton Motor Control Basic Wiring PDFServasfloresNo ratings yet

- Shimadzu MC100L30 MC125L 30Document37 pagesShimadzu MC100L30 MC125L 30anon_524582163100% (1)

- Subaru Forester Manuals 2017 Forester Owner's ManualDocument634 pagesSubaru Forester Manuals 2017 Forester Owner's ManualZeckNo ratings yet

- Main Engine MAN B&W K 80 MC-CDocument868 pagesMain Engine MAN B&W K 80 MC-CAbsar Mamun94% (18)

- GET-7203 - Art of Protective RelayingDocument19 pagesGET-7203 - Art of Protective RelayingArnab BanerjeeNo ratings yet

- GET-7201 - Art of Protective RelayingDocument16 pagesGET-7201 - Art of Protective RelayingArnab Banerjee100% (1)

- SD70ACe IGBT Safety ManualDocument18 pagesSD70ACe IGBT Safety ManualAlberto Alejandro Sanchez100% (1)

- Pc8200 Super Galaxie 2000Document55 pagesPc8200 Super Galaxie 2000netbridge0% (1)

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- Final Circuit and Load Estimation British StandardDocument28 pagesFinal Circuit and Load Estimation British Standardhaidarkukum5686100% (4)

- Stepper Motor PDFDocument9 pagesStepper Motor PDFΓιώργος ΔήμαςNo ratings yet

- Brother PE180D Sewing Machine Service ManualDocument44 pagesBrother PE180D Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Manual Book Soft Starter Renle JJR8000Document70 pagesManual Book Soft Starter Renle JJR8000Herie HeriadieNo ratings yet

- Scalar V-F Control of 3-Phase Induction Motors - 2803xDocument25 pagesScalar V-F Control of 3-Phase Induction Motors - 2803xRaghu KodiNo ratings yet

- Motor ControlsDocument40 pagesMotor ControlsArlone ManaladNo ratings yet

- Mighty Mariner Instalacijski ManualDocument59 pagesMighty Mariner Instalacijski ManualDragan LugonićNo ratings yet

- Basics of Motor Control CentersDocument72 pagesBasics of Motor Control CentersRaihanKhan100% (2)

- Manual MH800 Series Electro Hydraulic ServoDocument169 pagesManual MH800 Series Electro Hydraulic Servotuan voNo ratings yet

- Application With SCALE™-2 and SCALE™-2+ Gate Driver CoresDocument32 pagesApplication With SCALE™-2 and SCALE™-2+ Gate Driver Coresbharath prabhuNo ratings yet

- MCC 1Document13 pagesMCC 1www.otomasyonegitimi.comNo ratings yet

- Slvae 59 ADocument19 pagesSlvae 59 Aประยุทธ์ อังคารชาNo ratings yet

- FX Series Positioning Beginner S Manual English ControllerDocument116 pagesFX Series Positioning Beginner S Manual English ControllerdunkhanNo ratings yet

- AB Starter DiagramDocument39 pagesAB Starter Diagramrajinipre-1100% (1)

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- 7000 Um150e en P Dec03Document456 pages7000 Um150e en P Dec03Cristian VegaNo ratings yet

- LinuxCNC IntegratorDocument17 pagesLinuxCNC IntegratorrodrigodelacalperezNo ratings yet

- VLT5000 6000 8000 LonWorks FTP MG60N202Document42 pagesVLT5000 6000 8000 LonWorks FTP MG60N202t32101949No ratings yet

- Integrator Information V2.8.2-131-Gf324cd6e2, 2022-05-28Document17 pagesIntegrator Information V2.8.2-131-Gf324cd6e2, 2022-05-28Juan Carlos LesmasNo ratings yet

- Easygen-3000 Series: ManualDocument712 pagesEasygen-3000 Series: ManualSebaSTIÁN SalazarNo ratings yet

- GD - 1SP0635 Manual Power IntegrationsDocument27 pagesGD - 1SP0635 Manual Power IntegrationsRizkiWiraPratamaNo ratings yet

- Brother Super Ace+e Sewing Machine Service ManualDocument56 pagesBrother Super Ace+e Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Integrator Information V2.8.0-98-Gae2e6bd, 2020-11-01 PDFDocument17 pagesIntegrator Information V2.8.0-98-Gae2e6bd, 2020-11-01 PDFluisNo ratings yet

- MP Hyd Power Unit 9000 0008-10-98 (Ram)Document74 pagesMP Hyd Power Unit 9000 0008-10-98 (Ram)Joao RiveraNo ratings yet

- Motor Control CenterDocument81 pagesMotor Control CenterMohamed Mohamed100% (2)

- EDC User S Manual V2 0Document142 pagesEDC User S Manual V2 0Ivan Sanabria SaavedraNo ratings yet

- ProNet User S Manual V2 11Document195 pagesProNet User S Manual V2 11Darwin DuqueNo ratings yet

- Brother PC8200 Super Galaxie 2000 Sewing Machine Service ManualDocument55 pagesBrother PC8200 Super Galaxie 2000 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- S3 Series Elevator InvertersDocument198 pagesS3 Series Elevator Inverterscông nguyễn thànhNo ratings yet

- PLC and Hmi For Conveyor Monitoring and Fault DetectionDocument5 pagesPLC and Hmi For Conveyor Monitoring and Fault DetectionIJAR JOURNALNo ratings yet

- Brushless DC MotorsDocument21 pagesBrushless DC MotorsKiran KumarNo ratings yet

- Motor Starter Components and StandardsDocument20 pagesMotor Starter Components and StandardsJellyn BaseNo ratings yet

- Variable Speed DrivesDocument41 pagesVariable Speed DrivesJuan AraqueNo ratings yet

- Snoa543a Low NoiseDocument9 pagesSnoa543a Low Noisesteviej85No ratings yet

- GE Auto Reclosing Transmission and Distribution Breakers GER-2540A PDFDocument36 pagesGE Auto Reclosing Transmission and Distribution Breakers GER-2540A PDFBalan PalaniappanNo ratings yet

- Sinumerik 810 820 GA3 Interface - Part - 2 - Connection - ConditionsDocument128 pagesSinumerik 810 820 GA3 Interface - Part - 2 - Connection - ConditionsSam eagle goodNo ratings yet

- GE Distribution System Feeder Overcurrent ProtectionDocument24 pagesGE Distribution System Feeder Overcurrent ProtectionAerwin BautistaNo ratings yet

- LEBQ8107-00 Automatic Transfer Switch PDFDocument84 pagesLEBQ8107-00 Automatic Transfer Switch PDFpowermanagerNo ratings yet

- Minor Project ReportDocument29 pagesMinor Project ReportHiteshNo ratings yet

- Convection Microwave Oven Service and Repair ManualDocument51 pagesConvection Microwave Oven Service and Repair Manuallina jobstreetNo ratings yet

- EN ACS880 R1 R11 EMC Filter Disconn J ScreenDocument40 pagesEN ACS880 R1 R11 EMC Filter Disconn J ScreenRomildo FernandesNo ratings yet

- Astat Plus: GE Power ControlsDocument35 pagesAstat Plus: GE Power ControlsRafael CastilloNo ratings yet

- MCC 1Document14 pagesMCC 1Arif SugestyanNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Ttl/Hcmos Crystal Oscillator: MCO-1510A / MCO-1510B (FULL SIZE)Document1 pageTtl/Hcmos Crystal Oscillator: MCO-1510A / MCO-1510B (FULL SIZE)cutoNo ratings yet

- VN5T016AH-E: Single Channel High-Side Driver With Analog Current Sense For 24 V Automotive ApplicationsDocument31 pagesVN5T016AH-E: Single Channel High-Side Driver With Analog Current Sense For 24 V Automotive ApplicationscutoNo ratings yet

- Workshop4: User GuideDocument52 pagesWorkshop4: User GuidecutoNo ratings yet

- (Kalmar: DCE80-45E7 10 61Document12 pages(Kalmar: DCE80-45E7 10 61cutoNo ratings yet

- Tidrh 63Document2 pagesTidrh 63cutoNo ratings yet

- PLC Arduino Ethernet 58 I/Os Analog/Digital PlusDocument54 pagesPLC Arduino Ethernet 58 I/Os Analog/Digital PluscutoNo ratings yet

- GP4000 MM01 Eng PDFDocument249 pagesGP4000 MM01 Eng PDFcutoNo ratings yet

- TF Jo'l: ( AlmarDocument20 pagesTF Jo'l: ( Almarcuto100% (1)

- DCE80-45E7 10: Reservdelar - Spare PartsDocument16 pagesDCE80-45E7 10: Reservdelar - Spare PartscutoNo ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument3 pagesPart Number: Status: Overview: Description:: DocumentscutoNo ratings yet

- FX Series Computer Link DriverDocument60 pagesFX Series Computer Link DrivercutoNo ratings yet

- Dimensions: (MM) Recommended Land Pattern: (MM) : Properties Value Unit Pin To Pin (Middle)Document8 pagesDimensions: (MM) Recommended Land Pattern: (MM) : Properties Value Unit Pin To Pin (Middle)cutoNo ratings yet

- Dm00119042 PWM Resolution Enhancement Through A Dithering Technique For Stm32 Advancedconfiguration Generalpurpose and Lite Timers StmicroelectronicsDocument22 pagesDm00119042 PWM Resolution Enhancement Through A Dithering Technique For Stm32 Advancedconfiguration Generalpurpose and Lite Timers StmicroelectronicscutoNo ratings yet

- Proficonn PB102Document3 pagesProficonn PB102cutoNo ratings yet

- 2.7V 4-Channel/8-Channel 12-Bit A/D Converters With SPI Serial InterfaceDocument41 pages2.7V 4-Channel/8-Channel 12-Bit A/D Converters With SPI Serial InterfacecutoNo ratings yet

- Common Mode Choke: 1812canbusDocument3 pagesCommon Mode Choke: 1812canbuscutoNo ratings yet

- General MODBUS TCP Master DriverDocument28 pagesGeneral MODBUS TCP Master DrivercutoNo ratings yet

- F C C F F F F H: Electro-Hydraulic Servo Valve Driver Servo AmplifierDocument2 pagesF C C F F F F H: Electro-Hydraulic Servo Valve Driver Servo AmplifiercutoNo ratings yet

- Proportional Pressure Relief Valve, Pilot Operated: List of Contents FeaturesDocument12 pagesProportional Pressure Relief Valve, Pilot Operated: List of Contents FeaturescutoNo ratings yet

- Series (40W) : Motor Dimension Characteristic CurveDocument2 pagesSeries (40W) : Motor Dimension Characteristic CurvecutoNo ratings yet

- 04 - RS4 Series Geared MotorDocument1 page04 - RS4 Series Geared MotorcutoNo ratings yet

- Tisp4Xxxm3Bj Overvoltage Protector SeriesDocument14 pagesTisp4Xxxm3Bj Overvoltage Protector SeriescutoNo ratings yet

- TEAM 1.2: Nguyễn Thái Dương Nguyễn Minh Hiếu Hoàng Văn Hưng Nguyễn Trọng Quang HuyDocument25 pagesTEAM 1.2: Nguyễn Thái Dương Nguyễn Minh Hiếu Hoàng Văn Hưng Nguyễn Trọng Quang HuyNguyễn Trọng Quang HuyNo ratings yet

- High Speed Machining Center: Long Chang Machinery Co., LTDDocument12 pagesHigh Speed Machining Center: Long Chang Machinery Co., LTDJaime Cortés Cortés GálvezNo ratings yet

- 32200101Document4 pages32200101bnolasco0% (1)

- 11 - ChassisDocument68 pages11 - ChassispedrojrandradeNo ratings yet

- Audio System: E4 (A), E5 (B), E6 (C), E53 (D)Document4 pagesAudio System: E4 (A), E5 (B), E6 (C), E53 (D)dadang lukmanulhakimNo ratings yet

- Prysmian FP200 Gold Fire Performance & Resistant Cables PDFDocument2 pagesPrysmian FP200 Gold Fire Performance & Resistant Cables PDFAlyaa EmadNo ratings yet

- Parts Catalog - Option Detail: Option Group Graphic Film Card DateDocument2 pagesParts Catalog - Option Detail: Option Group Graphic Film Card DateKarthickNo ratings yet

- Fisa Tehnica Centrala de Incendiu Adresabila Cu 2 Bucle FireClass FC506 500 Adrese 256 Zone PSTNDocument6 pagesFisa Tehnica Centrala de Incendiu Adresabila Cu 2 Bucle FireClass FC506 500 Adrese 256 Zone PSTNIONUT.SNAKENo ratings yet

- Polar CS100: ™ User ManualDocument60 pagesPolar CS100: ™ User Manualأم أنسNo ratings yet

- Pioneer+Sc Lx72,+Sc Lx82Document236 pagesPioneer+Sc Lx72,+Sc Lx82Raimundo de LimaNo ratings yet

- The KnowledgeDocument13 pagesThe KnowledgeJordi RibóNo ratings yet

- Sony DSC-V3 Level 2 Service Manual (P. N. - 987676232)Document59 pagesSony DSC-V3 Level 2 Service Manual (P. N. - 987676232)tm5u2r0% (1)

- SQ 100 ADocument2 pagesSQ 100 AzhobeysNo ratings yet

- Empty BOQ For Pricing MEPDocument26 pagesEmpty BOQ For Pricing MEPabdullah sahibNo ratings yet

- Experiment 3 ACA PDFDocument11 pagesExperiment 3 ACA PDFaakash dabasNo ratings yet

- BPXN Lock Mandrel Brio Tech Catalog Revised 1.01 S 63Document1 pageBPXN Lock Mandrel Brio Tech Catalog Revised 1.01 S 63Franklin de Jesus NavarroNo ratings yet

- ZanussiDocument16 pagesZanussiferiferiNo ratings yet

- Ds x61 en Relay Technical InformationDocument34 pagesDs x61 en Relay Technical InformationNesarkiran BagadeNo ratings yet

- Igbt Spice ModelingDocument43 pagesIgbt Spice ModelingBrian WillardNo ratings yet

- LP3871/LP3874 0.8A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesDocument18 pagesLP3871/LP3874 0.8A Fast Ultra Low Dropout Linear Regulators: General Description FeaturesPaulo Henrique ValérioNo ratings yet

- JOINT FUJI Product Catalog For SUZUKIDocument15 pagesJOINT FUJI Product Catalog For SUZUKIapple bananaNo ratings yet

- Mechanical PDFDocument8 pagesMechanical PDFBAVITH KAMMANA MEETHALNo ratings yet

- Altistart 48 CatalogueDocument51 pagesAltistart 48 CataloguerubysultanaNo ratings yet

- Parts List ThermoKing SGCO3000 GensetDocument95 pagesParts List ThermoKing SGCO3000 GensetJennyJudithRuizSanchez100% (1)

- Tda 7432Document11 pagesTda 7432greemaxNo ratings yet

- Kenmore 385.19153 Sewing Machine Instruction ManualDocument211 pagesKenmore 385.19153 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet