Professional Documents

Culture Documents

Cavity Wall

Cavity Wall

Uploaded by

Kavishka Perera0 ratings0% found this document useful (0 votes)

28 views1 pageThe document provides details of an external cavity wall construction, including:

- A proprietary stone tile outer skin with insulation and inner blockwork.

- A gas resistant cavity tray and partial cavity fill insulation.

- An underfloor heating system between a screed and raft foundation.

- A gas barrier and damp proof membrane below the raft and over a concrete blinding layer.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides details of an external cavity wall construction, including:

- A proprietary stone tile outer skin with insulation and inner blockwork.

- A gas resistant cavity tray and partial cavity fill insulation.

- An underfloor heating system between a screed and raft foundation.

- A gas barrier and damp proof membrane below the raft and over a concrete blinding layer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

28 views1 pageCavity Wall

Cavity Wall

Uploaded by

Kavishka PereraThe document provides details of an external cavity wall construction, including:

- A proprietary stone tile outer skin with insulation and inner blockwork.

- A gas resistant cavity tray and partial cavity fill insulation.

- An underfloor heating system between a screed and raft foundation.

- A gas barrier and damp proof membrane below the raft and over a concrete blinding layer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

E

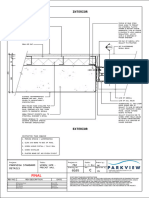

EXTERNAL CAVITY WALL WITH PROPRIETARY SS

WALL TILES @900 ctrs HORIZONTALLY (MAX) &

45 ctrs VERTICALLY (MAX)

140 INSULATING BLOCKWORK INNER SKIN

SINGLE LAYER 12.5MM GYPROC WALL BOARD ON MOTOR DABS

100 CAVITY PARTIALLY FILLED WITH 50 CELOTEX

TUFF_R CW3050Z INSULATION (OR SIMILAR APPROVED.) VISQUEEN GAS RESISTANT (GR) DPC LAPPED WITH CAVITY TRAY IN ACCORDANCE WITH

MANUFACTURERS INSTRUCTIONS

102 FACING BRICK WORK

VISQUEEN ZEDX CAVITY TRAY (OR SIMILAR APPROVED)

75MM SAN/CEMENT SCREED WITH FIBRE REINFORCEMENT

PROPRIETARY WEEPHOLES @ 1800 ctrs F.F.L.

INCORPORATING U/F HEATING PIPE WORK

0.000 (7.400 AOD)

UNDERFLOOR HEATING BUILD-UP

REINFORCED CONCRETE RAFT

FOUNDATION - REFER TO

LEAN MIX CAVITY FILL STRUCT. ENG. DETAILS

JABLITE (OR ASIMILAR APPROVED)

50mm JABLITE (OR SIMILAR APPROVED)

BELOW GROUND INSULATION

INSULATION TO SLAB EDGE

VISQUEEN GAS RESISTANT (GR) DPC TYPE 1 SUB-BASE MATERIAL TO ENGINEERS SPEC

LAPPED (MIN. 450) WITH VISQUEEN

GAS BARRIER. INSTALLED IN

ACCORDNACE WITH MANUFACTURRES

INSTRUCTIONS VISQUEEN GAS BARRIER (OR SIMILAR APPROVED)

LAID ON 50 CONCRETE BUILDING. TO BE LAID IN

ACCORDANCE WITH MANUFACTURRES INSTRUCTIONS

50MM THICK MIN. BLINDING CONCRETE

PILE PENETRATIONS SEALED WITH PRE-FORMED

TOP HAT UNITS & VISQUEEN DOUBLE SIDED

TAPE/JUBILEE CLIP IN ACCORDANCE WITH

MANUFACTURERES INSTRUCTIONS

You might also like

- GA-600-09 - Fire Resistance Design ManualDocument180 pagesGA-600-09 - Fire Resistance Design Manualjel_seagull100% (2)

- CASA 802 Norwich UniversityDocument21 pagesCASA 802 Norwich UniversityNicoleNo ratings yet

- Scope and LimitationDocument5 pagesScope and LimitationDianne Bernadeth Cos-agonNo ratings yet

- Database of Embodied Energy and Water Values For MaterialsDocument3 pagesDatabase of Embodied Energy and Water Values For MaterialsMax Yanac TelleriaNo ratings yet

- Drawing Foundation2Document1 pageDrawing Foundation2Zain Ul AbidinNo ratings yet

- Det-0105-Window Jamb - Precast Wall-CDocument1 pageDet-0105-Window Jamb - Precast Wall-Cnathan.liuNo ratings yet

- Equipment Installation Details of Fans, Room Air Conditioners & Desert CoolersDocument4 pagesEquipment Installation Details of Fans, Room Air Conditioners & Desert CoolersMahdiNo ratings yet

- Det-0102-Stepped Recessed Threshold Balcony-FDocument1 pageDet-0102-Stepped Recessed Threshold Balcony-Fnathan.liuNo ratings yet

- SPANNGLIED WR36 ENGLISCH Stand 130308Document1 pageSPANNGLIED WR36 ENGLISCH Stand 130308Jiangchang QiaoNo ratings yet

- Typical Pre-Cast MH Base With Pre-Formed Benching: TABLE 7.3 Rocker Pipe DimensionsDocument1 pageTypical Pre-Cast MH Base With Pre-Formed Benching: TABLE 7.3 Rocker Pipe DimensionsVinay RaoNo ratings yet

- Hvac Notes & AbbreviationsDocument1 pageHvac Notes & AbbreviationsShrikant SomvanshiNo ratings yet

- Isolation Unit (Poblacion) - Final-ModelDocument1 pageIsolation Unit (Poblacion) - Final-ModelEmman De los ReyesNo ratings yet

- BAND 675 North RD - Mechanical IFC - 2023-11-15Document162 pagesBAND 675 North RD - Mechanical IFC - 2023-11-15Hakar Qadir GardiNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- Materials Science and Engineering 8th Edition Callister PDFDocument6 pagesMaterials Science and Engineering 8th Edition Callister PDFJitesh RoyNo ratings yet

- Mutavhatsindi A3Document1 pageMutavhatsindi A3anzaniNo ratings yet

- Typical Shear Link Detail Sectional Elevation: A Scale: 1:30 BDocument1 pageTypical Shear Link Detail Sectional Elevation: A Scale: 1:30 BSamitha SoysaNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- Turbo Submittal At200-0.8s g5p Cargill (1) (2) - 1Document2 pagesTurbo Submittal At200-0.8s g5p Cargill (1) (2) - 1ivantellez-famNo ratings yet

- Detail Sections - SB-ModelDocument1 pageDetail Sections - SB-ModelAnbazhagan AnnaduraiNo ratings yet

- Me1 MotoDocument1 pageMe1 MotoarchtgozarNo ratings yet

- Clubhouse FDAS PlanDocument5 pagesClubhouse FDAS PlanCarlo DoragosNo ratings yet

- 573-Installation of Cellular Glass Insulation For Tank Base (Document3 pages573-Installation of Cellular Glass Insulation For Tank Base (Folarin AyodejiNo ratings yet

- Pdvsa: Engineering Design ManualDocument2 pagesPdvsa: Engineering Design ManualnlealuNo ratings yet

- Pdvsa: Engineering Design ManualDocument2 pagesPdvsa: Engineering Design ManualCarlos AlvaNo ratings yet

- Electrical Plan GMSDocument15 pagesElectrical Plan GMSJOSHUA ALZAGANo ratings yet

- General Notes:: Unit Designation Unit DesignationDocument7 pagesGeneral Notes:: Unit Designation Unit DesignationJerry MaratasNo ratings yet

- General Notes:: Material SpecificationsDocument1 pageGeneral Notes:: Material SpecificationsAbegail SatoNo ratings yet

- Standard ModelsDocument1 pageStandard ModelswalterNo ratings yet

- Installation Instructions EL-G-E500 Encore Dispenser: Shear Valve Arrangement in PlanDocument4 pagesInstallation Instructions EL-G-E500 Encore Dispenser: Shear Valve Arrangement in PlanCamilo CorreaNo ratings yet

- Det-0104-Window Jamb - Brick Veneer Wall-CDocument1 pageDet-0104-Window Jamb - Brick Veneer Wall-Cnathan.liuNo ratings yet

- Refer To Index Sheet For Notes Regarding Design Responsibility & Risk AssessmentDocument1 pageRefer To Index Sheet For Notes Regarding Design Responsibility & Risk AssessmentShane MoynihanNo ratings yet

- Water ReservoirDocument1 pageWater Reservoirrajeev kumarNo ratings yet

- Fire Suppression System: Raaw Courtyard Riffa - BahrainDocument1 pageFire Suppression System: Raaw Courtyard Riffa - BahrainemaarbrothersNo ratings yet

- 2018 1206 Fairfield County Auditor Drawings VOL 2 PDFDocument40 pages2018 1206 Fairfield County Auditor Drawings VOL 2 PDFAr Hanz Gerome SuarezNo ratings yet

- Khung Zamil-Tho Sua - 222Document17 pagesKhung Zamil-Tho Sua - 222Al-Razzaq Al-WahhabNo ratings yet

- Hvac Duct DetailDocument1 pageHvac Duct DetailZeeshan MunirNo ratings yet

- Key Plan: Reinforcement Plan Unit Substation PlanDocument1 pageKey Plan: Reinforcement Plan Unit Substation PlanAyman SaberNo ratings yet

- VIRGO - Floating-Ball ValvesDocument16 pagesVIRGO - Floating-Ball ValvesKamalNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- FOOTING IBS & RC WALL - New PRGS 11 Apr 2019-ModelDocument1 pageFOOTING IBS & RC WALL - New PRGS 11 Apr 2019-Modelazhar ahmadNo ratings yet

- Water Proofing SectionDocument1 pageWater Proofing SectionSam AzzNo ratings yet

- Spu 1253Document1 pageSpu 1253Josemir MarquesNo ratings yet

- Grounding Principle 3P-0036CDocument2 pagesGrounding Principle 3P-0036CAsif Majeed MalikNo ratings yet

- LAROS InsulatedWaffleSlabDocument1 pageLAROS InsulatedWaffleSlabTimNo ratings yet

- Securedge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Document2 pagesSecuredge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Constantin GubavuNo ratings yet

- Garage Door HeadDocument1 pageGarage Door Headmansoormasud6No ratings yet

- Khung Zamil-Tho Sua - 223Document16 pagesKhung Zamil-Tho Sua - 223Al-Razzaq Al-WahhabNo ratings yet

- Key Plan: General - Hvac - General Notes, Abbreviations, Legends - Sheet 01Document1 pageKey Plan: General - Hvac - General Notes, Abbreviations, Legends - Sheet 01usamabinladen399No ratings yet

- SBM FPSO RecordDocument32 pagesSBM FPSO RecordgpriohardonoNo ratings yet

- Rim Seal Pourer Data SheetDocument3 pagesRim Seal Pourer Data Sheetadilmomin45No ratings yet

- Flow Processing Pembuatan Propellant Komposite PolybhutadineDocument1 pageFlow Processing Pembuatan Propellant Komposite PolybhutadineKimiaNo ratings yet

- SecxionDocument1 pageSecxionDear Lakes AyoNo ratings yet

- Legend: Over All DIM Acoustical Rating RemarksDocument1 pageLegend: Over All DIM Acoustical Rating Remarkssiva ramanNo ratings yet

- Chilled Water Fan Coil Units: Supply AirDocument1 pageChilled Water Fan Coil Units: Supply AirSKYLERNo ratings yet

- RPL365 - TD - STR - PB1 - Defn - 03-VDF Flooring Detail & Compound Wall ElevationDocument1 pageRPL365 - TD - STR - PB1 - Defn - 03-VDF Flooring Detail & Compound Wall ElevationSAHANANo ratings yet

- SI 025R1 L2-L5 North Meeting Rooms Wall To Curtain Wall (Rev 1)Document9 pagesSI 025R1 L2-L5 North Meeting Rooms Wall To Curtain Wall (Rev 1)otuse557No ratings yet

- 5 Dredge 5110Document22 pages5 Dredge 5110Salomon RamirezNo ratings yet

- Hexagonal Illustrations GrayDocument5 pagesHexagonal Illustrations Graya75410No ratings yet

- Diesel Engine Pump-2850 LPM at 120M Head: Data Sheets For Fire Fighting PumpsDocument1 pageDiesel Engine Pump-2850 LPM at 120M Head: Data Sheets For Fire Fighting Pumpsravi100% (1)

- Detail Sheets (Pgs. 1-12)Document12 pagesDetail Sheets (Pgs. 1-12)Adhi DharmaNo ratings yet

- Installation Guide For Securedge 3000: #9 X 1-1/2" Ss Screw W/ WasherDocument2 pagesInstallation Guide For Securedge 3000: #9 X 1-1/2" Ss Screw W/ WasherConstantin GubavuNo ratings yet

- FIS Site Guide DryliningDocument18 pagesFIS Site Guide DryliningOliver BarNo ratings yet

- Building Code of The PhilippinesDocument43 pagesBuilding Code of The PhilippinesjeanniemanaloNo ratings yet

- Revista Global GypsumDocument44 pagesRevista Global GypsumVictor MelloNo ratings yet

- Catalog GIPPS (March 2023) - EnglishDocument16 pagesCatalog GIPPS (March 2023) - EnglishgbcomsrlNo ratings yet

- British Gypsum WB GypWall Secure With IntroductionDocument11 pagesBritish Gypsum WB GypWall Secure With IntroductionSteven AllenNo ratings yet

- Vox 1Document41 pagesVox 1Krishna KriShNo ratings yet

- BOQ MLC OfficeDocument24 pagesBOQ MLC Officeabdullah mayoufNo ratings yet

- Substantiation Is NeededDocument4 pagesSubstantiation Is NeededmarklesterNo ratings yet

- Details AliDocument1 pageDetails AliNadim SherifNo ratings yet

- ES Pro - & - CGF Pro InstallGuideDocument8 pagesES Pro - & - CGF Pro InstallGuidePușcă MartinNo ratings yet

- Sanctum Technologies LTD - Company ProfileDocument15 pagesSanctum Technologies LTD - Company ProfileKumarNo ratings yet

- 1 Skyrock Ecoblock R6 Drywall Ceiling Ref DWC TDSDocument4 pages1 Skyrock Ecoblock R6 Drywall Ceiling Ref DWC TDSSharin TpNo ratings yet

- CAS090503QAQCPlan PDFDocument20 pagesCAS090503QAQCPlan PDFvyly1723No ratings yet

- WallsDocument26 pagesWallsdeependraNo ratings yet

- Codes Standards For Architectural FinishesDocument4 pagesCodes Standards For Architectural FinishesVipin Kumar ParasharNo ratings yet

- Construction DetailsDocument56 pagesConstruction Detailsasingh400No ratings yet

- Wall Panels and Green Public Procurement Background ReportDocument48 pagesWall Panels and Green Public Procurement Background ReportDag AlpNo ratings yet

- High Risebuildingfiresmanual 141130150127 Conversion Gate01Document72 pagesHigh Risebuildingfiresmanual 141130150127 Conversion Gate01hagar18No ratings yet

- 09 - BoardDocument4 pages09 - Boardakankshas06No ratings yet

- Catalogo IIDocument612 pagesCatalogo IICapacitacion TodocatNo ratings yet

- Glass Partition Walls: What Are Glass Partitions?Document6 pagesGlass Partition Walls: What Are Glass Partitions?neeraj kumarNo ratings yet

- Anne - 2014 - Market Projections of Cellulose Nanomaterial-Enabled Products - Part 1 ApplicationsDocument8 pagesAnne - 2014 - Market Projections of Cellulose Nanomaterial-Enabled Products - Part 1 Applicationskrishnakant bholeNo ratings yet

- Durock Brand Cement Board With EdgeGuardDocument4 pagesDurock Brand Cement Board With EdgeGuardmdeenkNo ratings yet

- PDS Gyproc® X20 Plasterboard - 1615247466Document2 pagesPDS Gyproc® X20 Plasterboard - 1615247466tantanNo ratings yet

- How To Build A Sound Proof Room - 15 Steps (With Pictures)Document4 pagesHow To Build A Sound Proof Room - 15 Steps (With Pictures)Roland Cepeda100% (2)

- BASF - Prefabricated ProductsDocument4 pagesBASF - Prefabricated ProductsPamela Villanueva0% (1)