Professional Documents

Culture Documents

Trinity Advanced Pro: Instruction Manual

Trinity Advanced Pro: Instruction Manual

Uploaded by

ZondaCopyright:

Available Formats

You might also like

- HARK Acuitus Service Manual Rev C PDFDocument162 pagesHARK Acuitus Service Manual Rev C PDFmarcelo ribeiroNo ratings yet

- D2356502-001 SGRE ON SG 6.0-170 Standard CT and Power Curve, Rev 0, AM-2 - Air DensityDocument6 pagesD2356502-001 SGRE ON SG 6.0-170 Standard CT and Power Curve, Rev 0, AM-2 - Air DensityMarcelo GonçalvesNo ratings yet

- CNC Machining Handbook: Building, Programming, and ImplementationFrom EverandCNC Machining Handbook: Building, Programming, and ImplementationNo ratings yet

- FANUC ARC Mate 100ib - M-6iB - Maintenance Manual - B-81545EN-01Document153 pagesFANUC ARC Mate 100ib - M-6iB - Maintenance Manual - B-81545EN-01Ariel Hernandez Jimenez100% (1)

- How To Set Up A Suspension (Time) Histogram v2Document13 pagesHow To Set Up A Suspension (Time) Histogram v2Julian Morcillo100% (2)

- Drift Indicator System ManualDocument142 pagesDrift Indicator System ManualShag ShaggyNo ratings yet

- 7-Speed DSG Transmission (0am)Document194 pages7-Speed DSG Transmission (0am)Lojan Coronel José Humberto100% (5)

- Drift Indicator System Manual - 2019Document140 pagesDrift Indicator System Manual - 2019aris4silveyraNo ratings yet

- Group 6 - BSCE 4 1Document6 pagesGroup 6 - BSCE 4 1mathewluisnavalNo ratings yet

- Zno 3 Coc 400Document7 pagesZno 3 Coc 400JUAN PABLO GUERRERO JIMENEZNo ratings yet

- Vehicle Gear RatioDocument2 pagesVehicle Gear Ratioamir sadighiNo ratings yet

- WGC 20t FrannaDocument12 pagesWGC 20t FrannaLance Zhengling YinNo ratings yet

- Instruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366Document32 pagesInstruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366APE MKTNo ratings yet

- Atlas Copco Undercarriage of 700 Series Drilling RigsDocument112 pagesAtlas Copco Undercarriage of 700 Series Drilling Rigsr.mount2004No ratings yet

- ELPLA ListAAAAAAAAAAAAAAADocument2 pagesELPLA ListAAAAAAAAAAAAAAAJosé Luis González HerreraNo ratings yet

- CHILD Fluid Connectors Product GuideDocument214 pagesCHILD Fluid Connectors Product GuideDan MoldoveanuNo ratings yet

- Key Products: Section 6-1Document13 pagesKey Products: Section 6-1awethaf9876No ratings yet

- ELPLA ListAAAAAAAAAAAAAADocument2 pagesELPLA ListAAAAAAAAAAAAAAJosé Luis González HerreraNo ratings yet

- Danuhm Bush Air Cooled Roof Top PACU-50HZ PDFDocument16 pagesDanuhm Bush Air Cooled Roof Top PACU-50HZ PDFFalak KhanNo ratings yet

- Emmc JuniDocument17 pagesEmmc JuniReki OktavianusNo ratings yet

- Limpiar MangueraDocument33 pagesLimpiar Manguerarichard castañedaNo ratings yet

- Demag AC615JDocument11 pagesDemag AC615JSBHENo ratings yet

- AOI TM-511 Drift Indicator Systems Manual - 4th Ed - Jan 07Document142 pagesAOI TM-511 Drift Indicator Systems Manual - 4th Ed - Jan 07Tri CahyadiNo ratings yet

- Iklim Template NCDCDocument331 pagesIklim Template NCDCPanca NababanNo ratings yet

- IOM - Fisher 667 Sizes 30 - 30i 76 - 76i and 87Document40 pagesIOM - Fisher 667 Sizes 30 - 30i 76 - 76i and 87AmiroucheBenlakehalNo ratings yet

- Mac 25 3 Load ChartDocument16 pagesMac 25 3 Load ChartLulut WahyudoNo ratings yet

- 103 PipenetDocument23 pages103 PipenetLucious LightNo ratings yet

- Fim Cross Country 2022 RegulationsDocument121 pagesFim Cross Country 2022 RegulationsAndrés GarciaNo ratings yet

- ELPLA ListAAAAAAAAAAAADocument2 pagesELPLA ListAAAAAAAAAAAAJosé Luis González HerreraNo ratings yet

- Residential Water Products Tech ManualDocument58 pagesResidential Water Products Tech ManualboyNo ratings yet

- Construction of Interection DiagramDocument29 pagesConstruction of Interection DiagramSuvankarNo ratings yet

- SM WW6000T CROATIAN End User 201207Document43 pagesSM WW6000T CROATIAN End User 201207Željko ĐurićNo ratings yet

- Section 8008 External Lift RamsDocument6 pagesSection 8008 External Lift Ramslungu mihaiNo ratings yet

- Handbook VVKR-A-S 202201Document38 pagesHandbook VVKR-A-S 202201mohamed roubioNo ratings yet

- Graco Technical G3 Max Pump 332305EN G 1 of 2Document40 pagesGraco Technical G3 Max Pump 332305EN G 1 of 2Diat NorNo ratings yet

- Not For Reproduction: Illustrated Parts List 126T00Document28 pagesNot For Reproduction: Illustrated Parts List 126T00John AndersonNo ratings yet

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- Design - Pinned - Column Base-PlatesDocument61 pagesDesign - Pinned - Column Base-PlatesYoshua YangNo ratings yet

- Captura de Pantalla 2023-05-17 A La(s) 9.53.36 A. M.Document206 pagesCaptura de Pantalla 2023-05-17 A La(s) 9.53.36 A. M.ericNo ratings yet

- Service Bulletin 162Document23 pagesService Bulletin 162Tatiana VásquezNo ratings yet

- Maintenance Manual PDFDocument696 pagesMaintenance Manual PDFsippolad100% (2)

- BorrarxxxDocument4 pagesBorrarxxxHeco NicNo ratings yet

- Bjve Family: Self Rotary Swivels User ManualDocument32 pagesBjve Family: Self Rotary Swivels User ManualLuiz PauloNo ratings yet

- Tower DesignDocument66 pagesTower DesignovikbasuNo ratings yet

- Crane ATF-1000XL PDFDocument8 pagesCrane ATF-1000XL PDFTrươngPhiNo ratings yet

- Spare Air Service Manual 2003Document15 pagesSpare Air Service Manual 2003Sady KanettiNo ratings yet

- Powergrip Gt3 Design Manual Us January 2014Document199 pagesPowergrip Gt3 Design Manual Us January 2014Hemraj SonarNo ratings yet

- System Operation Testing and Adjusting 3304 Vehicular EngineDocument103 pagesSystem Operation Testing and Adjusting 3304 Vehicular EngineAbdelbagi100% (2)

- System Operation Testing and Adjusting 3304 Vehicular EngineDocument103 pagesSystem Operation Testing and Adjusting 3304 Vehicular EngineAbdelbagi67% (3)

- SECTION 6004 Mechanical Rear Wheel Drive (MODELS 120 - 155)Document56 pagesSECTION 6004 Mechanical Rear Wheel Drive (MODELS 120 - 155)lungu mihaiNo ratings yet

- Mahindra Gyrovator ZLX+ Series - Feb21Document73 pagesMahindra Gyrovator ZLX+ Series - Feb21bibhaskabiNo ratings yet

- Klein Pre97 - Tech - Manual PDFDocument40 pagesKlein Pre97 - Tech - Manual PDFDwayne FitzpatrickNo ratings yet

- Throath Thickness Table For Forged Outlet Fitting: T + (T 0.7) or Min .6.4 Where, TDocument1 pageThroath Thickness Table For Forged Outlet Fitting: T + (T 0.7) or Min .6.4 Where, TK PNo ratings yet

- Output of Staad ProDocument28 pagesOutput of Staad ProramNo ratings yet

- Nexus Inter8Document37 pagesNexus Inter8Tyler ConleyNo ratings yet

- Powerboater's Guide to Electrical Systems, Second EditionFrom EverandPowerboater's Guide to Electrical Systems, Second EditionRating: 5 out of 5 stars5/5 (1)

- Provvisorio: Darra Cycles Via Roma, 135 Bis Cassolnovo (PV) 0381.928389Document5 pagesProvvisorio: Darra Cycles Via Roma, 135 Bis Cassolnovo (PV) 0381.928389ZondaNo ratings yet

- Plasma: Codice Descrizione Prezzo PubblicoDocument1 pagePlasma: Codice Descrizione Prezzo PubblicoZondaNo ratings yet

- Ridley Price List 2018Document13 pagesRidley Price List 2018ZondaNo ratings yet

- Giant Bicycles Bike 509Document1 pageGiant Bicycles Bike 509ZondaNo ratings yet

- Listino Giant 2018 Pubblico: Off Road Performance - Gravity On Road Performance - Aero RaceDocument4 pagesListino Giant 2018 Pubblico: Off Road Performance - Gravity On Road Performance - Aero RaceZondaNo ratings yet

- Specs Caratteristiche: Prezzo: 3.199Document2 pagesSpecs Caratteristiche: Prezzo: 3.199ZondaNo ratings yet

- Cube Aerum c68 2018Document1 pageCube Aerum c68 2018ZondaNo ratings yet

- Modell Empf. VK/Euro Modell Empf. VK/Euro Modell Empf. VK/EuroDocument1 pageModell Empf. VK/Euro Modell Empf. VK/Euro Modell Empf. VK/EuroZondaNo ratings yet

- SR-001MK2: Electrostatic Audio ProductsDocument1 pageSR-001MK2: Electrostatic Audio ProductsZondaNo ratings yet

- CERCDocument7 pagesCERCAnand GuptaNo ratings yet

- Results Confirmation-Control Indicators in MICDocument13 pagesResults Confirmation-Control Indicators in MICSANDEEP KKPNo ratings yet

- Capa ToolsDocument44 pagesCapa ToolsChandan ShahNo ratings yet

- Hot TappingDocument2 pagesHot TappingRochdi SahliNo ratings yet

- Liham PangnegosyoDocument28 pagesLiham PangnegosyoLeonesNo ratings yet

- Dikitanan Task1Document5 pagesDikitanan Task1Janna CrizetteNo ratings yet

- 02 Exercise Laboratory 1 TOURPLANNINGDocument8 pages02 Exercise Laboratory 1 TOURPLANNINGnicole dordeNo ratings yet

- Preservation, Its Principles and Methods PDFDocument45 pagesPreservation, Its Principles and Methods PDFRubiNo ratings yet

- Tally Exrercise 2: Date Description AmountDocument1 pageTally Exrercise 2: Date Description AmountExcel WaysNo ratings yet

- FactoryTalk Historian SE - PI Web Services vs. PI Web APIDocument5 pagesFactoryTalk Historian SE - PI Web Services vs. PI Web APIDiegoFonsecaNo ratings yet

- BlackMart APK Download Latest Version 2021.editedDocument5 pagesBlackMart APK Download Latest Version 2021.editedZia NasirNo ratings yet

- Soco Assignment 2Document4 pagesSoco Assignment 2Lara LavanyaNo ratings yet

- 5) Freshmen Sem 2 - Skills Employability (Sas)Document5 pages5) Freshmen Sem 2 - Skills Employability (Sas)Crislyn Jilou Bugas AdlawanNo ratings yet

- The Dual in LPDocument17 pagesThe Dual in LPShreeyesh MenonNo ratings yet

- Motion To Reconsider-Vacate-Modify Order, C.a.11 No.13-11585-BDocument62 pagesMotion To Reconsider-Vacate-Modify Order, C.a.11 No.13-11585-BNeil GillespieNo ratings yet

- PMP NotesDocument3 pagesPMP Notesjay2kay5793No ratings yet

- ĐỀ 1 - RCDocument30 pagesĐỀ 1 - RCLương Hữu TàiNo ratings yet

- 43 CA CPT Dec 2010 Question Paper With Answer Key 2Document6 pages43 CA CPT Dec 2010 Question Paper With Answer Key 2Vishal Gattani100% (1)

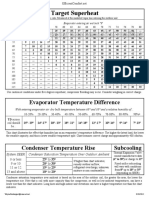

- Charging and TD Chart PlusDocument1 pageCharging and TD Chart PlusFaquruddin AliNo ratings yet

- Sample Letter of Intent To Transfer FundsDocument2 pagesSample Letter of Intent To Transfer Fundsnavid kamravaNo ratings yet

- CPD Using The Ecsa Electronic System For Entering Records: WWW - Ecsa.co - ZaDocument5 pagesCPD Using The Ecsa Electronic System For Entering Records: WWW - Ecsa.co - ZaBen MudoziNo ratings yet

- Lenoir, Frederic. - Breve Tratado de Historia de Las Religiones (2018)Document47 pagesLenoir, Frederic. - Breve Tratado de Historia de Las Religiones (2018)Kike EspinozaNo ratings yet

- Sh03 - Options Codes A 4 8 10 5 8 46 3 7 5Document73 pagesSh03 - Options Codes A 4 8 10 5 8 46 3 7 5Edward Adrian Moreno FernandezNo ratings yet

- Apt. Didik, Peluang Jasa Profesi ApotekerDocument22 pagesApt. Didik, Peluang Jasa Profesi ApotekerYudha PrasetyaNo ratings yet

- Infosys Analysis For Finlatics FMEPDocument5 pagesInfosys Analysis For Finlatics FMEPyogeshNo ratings yet

- MP C3004/C3504/C3004Ex/C3504Ex Series/Dsc1230 (D238/D239/D0Ac/D0Ad) Parts CatalogDocument228 pagesMP C3004/C3504/C3004Ex/C3504Ex Series/Dsc1230 (D238/D239/D0Ac/D0Ad) Parts CatalogBruno PLETNo ratings yet

- Rega Planet 2000 ManualDocument4 pagesRega Planet 2000 ManualjamocasNo ratings yet

- Labuenavida Business Summary 2023Document24 pagesLabuenavida Business Summary 2023UzoNo ratings yet

- Data Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeDocument10 pagesData Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeRisa RidmaNo ratings yet

Trinity Advanced Pro: Instruction Manual

Trinity Advanced Pro: Instruction Manual

Uploaded by

ZondaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trinity Advanced Pro: Instruction Manual

Trinity Advanced Pro: Instruction Manual

Uploaded by

ZondaCopyright:

Available Formats

TRINITY ADVANCED PRO

Instruction manual

ATTENTION! THIS MANUAL IS ONLY FOR PROFESSIONAL

BICYCLE MECHANICS AT AUTHORIZED GIANT DEALERS.

IT IS NOT INTENDED FOR THE CONSUMER/END-USER.

Version 9 /2015

1

Downloaded from www.Manualslib.com manuals search engine

CONTENTS

SELECTING THE CORRECT FRAME SIZE------------------------------------------------------------- 3

ARMREST STACK AND REACH RANGE ---------------------------------------------------------------- 4

FORK STEER LENGTH -------------------------------------------------------------------------------------------- 5

COCKPIT PARTS ASSEMBLY CHART -------------------------------------------------------------------- 6

STEM/BASEBAR PARTS ASSEMBLY CHART -------------------------------------------------------- 7

HANDLEBAR & STEM ASSEMBLY INSTRUCTIONS--------------------------------------------- 8

ARMREST AND EXTENSIONS ------------------------------------------------------------------------------ 10

BASEBAR HEIGHT ADJUSTMENT ----------------------------------------------------------------------------------- 10

ARMREST PAD HEIGHT ADJUSTMENT ----------------------------------------------------------------------------- 10

EXTENSION W IDTH ADJUSTMENT ---------------------------------------------------------------------------------- 11

ARMREST PAD REACH ADJUSTMENT ----------------------------------------------------------------------------- 12

ARMREST PAD W IDTH ADJUSTMENT ------------------------------------------------------------------------------ 14

ARMREST PAD ROTATION ADJUSTMENT ------------------------------------------------------------------------- 15

BRAKE ASSEMBLY ------------------------------------------------------------------------------------------------ 16

FRONT BRAKE ASSEMBLY ------------------------------------------------------------------------------------------- 16

REAR BRAKE ASSEMBLY --------------------------------------------------------------------------------------------- 17

DERAILLEUR/BRAKE CABLE HOUSING GUIDELINE & CABLE ROUTING ------ 18

DI2 DERAILLEUR PARTS LIST & CABLE ROUTING ---------------------------------------------------------------- 18

MECHANICAL PARTS LIST & CABLE ROUTING -------------------------------------------------------------------- 19

TRINITY BRAKE ROUTING -------------------------------------------------------------------------------------------- 20

AEROVAULT TOPTUBE BOX ASSEMBLY (DI2) --------------------------------------------------- 21

AEROVAULT TOPTUBE BOX ASSEMBLY (MECHANICAL)--------------------------------- 22

DI2 BATTERY SEATPOST INSTALLATION ---------------------------------------------------------- 23

AEROVAULT STEM HYDRATION ASSEMBLY CHART --------------------------------------- 24

AERO VAULT STEM HYDRATION ASSEMBLY --------------------------------------------------------------------- 25

AERO VAULT DOWN TUBE BOTTLE ASSEMBLY ----------------------------------------------- 26

Version 9 /2015

2

Downloaded from www.Manualslib.com manuals search engine

Selecting the Correct Frame Size

The Trinity Advanced Pro is available in 4 frame sizes to fit a wider range of riders.

While each individual’s unique body proportions will determine which frame size

offers the best fit, beginning with the rider’s height .inseam. saddle and height

provide a narrower range of sizing options:

※We recommend first performing the rider fit using the Right Ride System or a

comparable fitting system to find the ideal pad position, saddle height, saddle

position, etc.; then adjusting the position on the Trinity Advanced Pro accordingly.

Rider Size Inseam Saddle Height Trinity

cm inch cm inch cm inch (Frame Size)

194 76.4 91.5 36 80.5 31.7

193 76 90.7 35.7 79.8 31.4

192 75.6 89.9 35.4 79.1 31.1

191 75.2 89.1 35.1 78.4 30.9

190 74.8 88.3 34.8 77.7 30.6

189 74.4 87.4 34.4 76.9 30.3

188 74 86.4 34 76 29.9

187 73.6 85.8 33.8 75.5 29.7

186 73.2 85.1 33.5 74.9 29.5

185 72.8 84.3 33.2 74.2 29.2

184 72.4 83.5 32.9 73.5 28.9

183 72 82.6 32.5 72.7 28.6 L

182 71.7 81.6 32.1 71.8 28.3

181 71.3 80.7 31.8 71 28

180 70.9 79.7 31.4 70.1 27.6

179 70.5 79.3 31.2 69.8 27.5

178 70.1 79 31.1 69.5 27.4 M

177 69.7 78.3 30.8 68.9 27.1

176 69.3 77.5 30.5 68.2 26.9

175 68.9 76.8 30.2 67.6 26.6

174 68.5 76.1 30 67 26.4

173 68.1 75.3 29.6 66.3 26.1

172 67.7 74.5 29.3 65.6 25.8

171 67.3 73.8 29.1 64.9 25.6 S

170 66.9 72.8 28.7 64.1 25.2

169 66.5 72 28.3 63.4 25

168 66.1 71.3 28.1 62.7 24.7

167 65.7 70.8 27.9 62.3 24.5

166 65.4 70.2 27.6 61.8 24.3

165 65 69.4 27.3 61.1 24.1 XS

164 64.6 68.6 27 60.4 23.8

163 64.2 68.4 26.9 60.2 23.7

162 63.8 68.1 26.8 59.9 23.6

161 63.4 66.8 26.3 58.75 23.1

160 63 65.5 25.8 57.6 22.7

Optimal Fit Range

Overall Fit Range

Version 9 /2015

3

Downloaded from www.Manualslib.com manuals search engine

Armrest Stack and Reach Range

For many fitters, the most effective approach to determining triathlon bike fit is by

identifying the rider’s ideal armrest stack and reach measurements. The following

chart shows the armrest stack and armrest reach adjustment range attainable for

each Trinity frame size, in both the triathlon and TT conf igurations.

Tri Version UCI Version

Frame Size XS S M L

Version Tri TT Tri TT Tri TT Tri TT

Arm Pad Stack Arm Pad Reach (mm)

670

660

650 428-488

642

640

632

630 436-496

622 422-482

620

612

610

602

600 430-490

592 415-475

590

582

580

572

570 423-483

562 403-463

560

552

550

542 411-471

532

522

Trinity Advanced Pro TT

Trinity Advanced Pro Triathlon

Version 9 /2015

4

Downloaded from www.Manualslib.com manuals search engine

Fork Steer Length

Trinity/Avow Advanced Pro (TT) are high performance bikes which need

to be built with great precision, please follow the reference table for

cutting the fork steer tube to the correct length for optimal

performance.

Steer Length

(mm)

Steer

Version Model Frame Size Length

(mm)

46(XS) M 121

49(S) M 151

MY16 Trinity Advanced Pro

51.5(M) M 181

54.5(L) M 211

Triathlon

45(XXS) W 121.5

MY16 Avow Advanced Pro/ 48(XS) W 121.5

MY16 Avow Advanced Pro-FF TM 51(S) W 136.5

53(M) W 166.5

46(XS) M 91

MY16 Trinity Advance Pro TT- FF/ 49(S) M 121

UCI

MY16 Trinity Advance Pro TT- FF TM 51.5(M) M 151

54.5(L) M 181

Version 9 /2015

5

Downloaded from www.Manualslib.com manuals search engine

Cockpit Parts Assembly Chart

1 3

5

6

8

7

10

12

9

11

Specification Quantity Torque range

[1] Armrest pad 2 -

[2] Armrest Right 1 -

Left 1

[3] Armrest bolt M5X8 tapered 4 3 Nm

[4] Extension plug 2 -

[5] Extension 2 -

[6] Extension clamp Right 1 -

Left 1

[7] Tear drop spacer 10mm 8 -

20mm 4 -

[8] Handlebar 1

[9] Handlebar plug Front 2 -

Rear 2

[10] Handlebar ring 4

[11] Extension clamp bolts M5X70

(w/ Tear drop spacer H:40)

M5X60

(w/ Tear drop spacer H:30)

4 6 Nm

M5X50

(w/ Tear drop spacer H:20)

M5X40

(w/ Tear drop spacer H:10)

[12] Extension clamp bolt washer 4

Version 9 /2015

6

Downloaded from www.Manualslib.com manuals search engine

Stem/Basebar Parts Assembly Chart

4

1

3

2

6

7

8

Specification Quantity Torque range

[1] Headset compression bolts M6X30 1 6 Nm

[2] Upper stem bolts M5X15 2 6 Nm

[3] Upper stem - 1

[4] Stem bolts M5X25 2 6 Nm

M5X35 1 3 Nm

(w/o stem bottle)

M5X45 1 3 Nm

(w/ stem bottle)

[5] Handlebar bolt M4X25 1 4 Nm

[6] Lower stem - 1 -

[7] Stem spacer XS size - -

S size H:25mm*1 -

M size H:51mm*1

L size H:25mm*1

& H:51mm*1

[8] Lower stem bolts M5X10 tapered 2 3 Nm

M5X15 tapered 1 3 Nm

[9] Stem spacer bolts M5X10 tapered 3 3 Nm

Version 9 /2015

7

Downloaded from www.Manualslib.com manuals search engine

Handlebar & Stem Assembly Instructions

Warning: Please ensure you are using correct assembly parts in the correct order.

M5

Assemble extension bar

on the handlebar with M5

screws, locking torque

6Nm

M5

M5 Assemble armrest pad to

the clamp with M5

Hexagon socket

countersunk head screws,

locking torque 3Nm

M5

Handlebar alignment and

assembly handlebar

attachments

M5

Version 9 /2015

8

Downloaded from www.Manualslib.com manuals search engine

M6

Assemble upper stem to

the fork steering tube.

M5 Lock M6 screws first then

M5 screws, locking torque

6Nm

Assemble handlebar in

upper stem with M4

screws, locking

torque4Nm

Assemble stem spacer at

M4

fork with M5 Hexagon

M5 socket countersunk head

screws, locking torque

3Nm

Assemble lower stem with

M5 screws and M5

M5 Hexagon socket

countersunk head screws

M5 screws locking torque

front 3Nm, rear 6Nm,M5

Hexagon socket

countersunk head screws

M5 locking torque 3Nm

Version 9 /2015

9

Downloaded from www.Manualslib.com manuals search engine

Armrest and Extensions

Basebar Height Adjustment

By inverting the handlebar, you can choose either the low position or the

high position. The height difference between the two is 40mm.

Armrest Pad Height Adjustment

The armrest supports height can be adjusted up to 40mm with the

teardrop spacers.

Depending on the selected height, make sure you are using the correct

extension clamp screw lengths as detailed.

Version 9 /2015

10

Downloaded from www.Manualslib.com manuals search engine

Extension Width Adjustment

By positioning the extension clamps to face outside or inside, you can

choose either a wide or a narrow extension setup.

You can refine your extension setup by turning the extension’s bend

inward or outward.

Additionally, the extensions can slide in the clamps. You can adjust the

extensions both fore and aft.

Version 9 /2015

11

Downloaded from www.Manualslib.com manuals search engine

Armrest Pad Reach Adjustment

The armrests can be bolted onto the extension clamps in 4 positions and reversed to

achieve 5 different armrest fore/aft positions. With 15mm increments between

positions, Trinity offers a total of 60mm of adjustment range. The 0mm mark

represents the shortest armrest reach adjustment attainable for each given frame

size. Please refer back to the armrest stack and reach range information on page 4

for more information.

Pad locking to clamp: First and second hole

Pad locking to clamp: First and third hole

Version 9 /2015

12

Downloaded from www.Manualslib.com manuals search engine

Pad locking to clamp: Second and fourth hole

Pad locking to clamp: Third and fourth hole

Version 9 /2015

13

Downloaded from www.Manualslib.com manuals search engine

Armrest Pad Width Adjustment

The armrest pads can be bolted onto the extension clamps in 3 positions, with

additional adjustment range created by reversing the extension clamp orientation.

Version 9 /2015

14

Downloaded from www.Manualslib.com manuals search engine

Armrest Pad Rotation Adjustment

The armrest pads can be rotated on the mounting clamps, from 10-degrees inward to

8-degrees outward.

Angle Inward 8°

Angle Inward 10°

Angle Outward 8°

Version 9 /2015

15

Downloaded from www.Manualslib.com manuals search engine

Brake Assembly

Front Brake Assembly

M6

Assemble front brake at fork with M6 Assemble front brake cable by passing

screws, locking torque 6Nm. through fork, pipe and brake. Adjust to the

reasonable gap between brake pad and rim

with M5 screws, locking torque 6Nm

Assemble crown cover on the bottom of To ensure even brake pad position and

the fork, to avoid the brake cable contact action, spring tension can be adjusted using

with the tire the highlighted M4 screws.

Cut off the extra brake cable and insert Rotate the cable tension adjustment screw

to the closing line holes to fine-tune the brake pad and rim gap.

Version 9 /2015

16

Downloaded from www.Manualslib.com manuals search engine

Rear Brake Assembly

M6

M5

Assemble the rear brake cable by routing

through frame, pipe and brake. Adjust to

reasonable gap between brake pad and rim.

Assemble rear brake to the frame by M6

End of the brake cable forward with a cover

screw, locking torque 6Nm.

plate with M5 screws, locking torque 6Nm.

The end of brake cable cannot touch brake

cover to avoid affect the brake function.

To ensure even brake pad position and action, spring tension can be adjusted using the

highlighted M4 screws.

M5 M3

M3

Cut off excess brake cable, assemble Rotate the cable tension adjustment screw

brake cover with M5 screws and M3 to fine-tune the brake pad and rim gap.

Hexagon socket countersunk head screws.

To avoid affecting braking function, the end

of brake cable should not touch the brake

cover.

Version 9 /2015

17

Downloaded from www.Manualslib.com manuals search engine

DERAILLEUR/BRAKE CABLE HOUSING

GUIDELINE & CABLE ROUTING

To ensure optimal shifting and braking operation, proper cable housing

length is essential. Please see the following guideline for cable housing

length for each system and frame size

Di2 derailleur parts list & cable routing

-Cable Length (mm)

Size A B C D E

XS 350 1000 950 250 750

S 350 1000 950 250 750

M 350 1000 950 250 750

L 350 1000 950 250 750

Detail B

Detail A

Version 9 /2015

18

Downloaded from www.Manualslib.com manuals search engine

Mechanical parts list & cable routing

- Cable Length (mm)

FRONT REAR

Size

A B C D

XS 380 840 380 1410

S 380 880 380 1460

M 380 910 380 1500

L 380 930 380 1550

B

D

Version 9 /2015

19

Downloaded from www.Manualslib.com manuals search engine

Trinity Brake Routing

- Cable Length (mm)

Size FRONT REAR

XS 365 1025

S 395 1045

M 425 1075

L 455 1135

Front Brake Rear Brake

YES NO

Brake hose should be assembled into pipe Front brake cable in head tube

correctly. should not touch rear brake

cable.

Version 9 /2015

20

Downloaded from www.Manualslib.com manuals search engine

AeroVault Toptube Box Assembly (Di2)

M5 M5

The toptube box is secured with M5 screws.

Slide the Di2 control box into the allocated position in the bento box after

plugging in the Di2 wires.

By pressing down on the blue location, the cover is secured in the closed

position. Storage space is accessible from this position via the sides of the

toptube box soft cover.

Version 9 /2015

21

Downloaded from www.Manualslib.com manuals search engine

AeroVault Toptube Box Assembly

(Mechanical)

The derailleur cable/ housing can be routed through the open slot of the

toptube box

M5 M5

The toptube box is secured with M5 screws.

By pressing down on the blue location, the cover is secured in the closed position.

Storage space is accessible from this position via the sides of the toptube box soft cover.

Version 9 /2015

22

Downloaded from www.Manualslib.com manuals search engine

Di2 Battery Seatpost Installation

-Assembly

Assemble the dilator and support base After assembling, insert into seat tube

affixed to the outer wall of the battery then lock dilator with M4 screws to fix

battery inside the seatpost.

-Charging

Open the toptube box cover, remove the Open the anti-dust cover, plug in the

Di2 junction box EW90 charging cable to charge the battery

Version 9 /2015

23

Downloaded from www.Manualslib.com manuals search engine

AEROVAULT STEM HYDRATION

ASSEMBLY CHART

Part Name Specification

1 Outer cap

2 Inner cap

Fit all sizes

3 Straw

4 Straw holder

Small for XS & S

5 Bottle

Large for M & L

XS & M size

6 Spacer

S & L size

XS & S size

7 Decorate

M & L size

8 Latch

Fit all sizes

9 Cage

XS S

M XL

Version 9 /2015

24

Downloaded from www.Manualslib.com manuals search engine

Aero Vault Stem Hydration Assembly

M5

Assemble straw and cover on the bottle Assemble latch and S-type parts to the

upper stem with M5 screws, locking torque

3Nm

M3

M5

Assemble spacer with M3 screws in the Slide bottle into the spacer and fixed to

bottle bracket the latch then it can be used

Assemble bottle bracket in lower stem

or stem spacer with M5 Hexagon

socket countersunk head screws,

locking torque 3Nm

Pressing the latch and pulled forward to remove the bottle

Version 9 /2015

25

Downloaded from www.Manualslib.com manuals search engine

Aero Vault Down tube Bottle Assembly

M5

M5 Assemble cage at the

down tube with M5

Hexagon socket

countersunk head

screws.

Slide bottle into bottle

cage.

Version 9 /2015

26

Downloaded from www.Manualslib.com manuals search engine

You might also like

- HARK Acuitus Service Manual Rev C PDFDocument162 pagesHARK Acuitus Service Manual Rev C PDFmarcelo ribeiroNo ratings yet

- D2356502-001 SGRE ON SG 6.0-170 Standard CT and Power Curve, Rev 0, AM-2 - Air DensityDocument6 pagesD2356502-001 SGRE ON SG 6.0-170 Standard CT and Power Curve, Rev 0, AM-2 - Air DensityMarcelo GonçalvesNo ratings yet

- CNC Machining Handbook: Building, Programming, and ImplementationFrom EverandCNC Machining Handbook: Building, Programming, and ImplementationNo ratings yet

- FANUC ARC Mate 100ib - M-6iB - Maintenance Manual - B-81545EN-01Document153 pagesFANUC ARC Mate 100ib - M-6iB - Maintenance Manual - B-81545EN-01Ariel Hernandez Jimenez100% (1)

- How To Set Up A Suspension (Time) Histogram v2Document13 pagesHow To Set Up A Suspension (Time) Histogram v2Julian Morcillo100% (2)

- Drift Indicator System ManualDocument142 pagesDrift Indicator System ManualShag ShaggyNo ratings yet

- 7-Speed DSG Transmission (0am)Document194 pages7-Speed DSG Transmission (0am)Lojan Coronel José Humberto100% (5)

- Drift Indicator System Manual - 2019Document140 pagesDrift Indicator System Manual - 2019aris4silveyraNo ratings yet

- Group 6 - BSCE 4 1Document6 pagesGroup 6 - BSCE 4 1mathewluisnavalNo ratings yet

- Zno 3 Coc 400Document7 pagesZno 3 Coc 400JUAN PABLO GUERRERO JIMENEZNo ratings yet

- Vehicle Gear RatioDocument2 pagesVehicle Gear Ratioamir sadighiNo ratings yet

- WGC 20t FrannaDocument12 pagesWGC 20t FrannaLance Zhengling YinNo ratings yet

- Instruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366Document32 pagesInstruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366APE MKTNo ratings yet

- Atlas Copco Undercarriage of 700 Series Drilling RigsDocument112 pagesAtlas Copco Undercarriage of 700 Series Drilling Rigsr.mount2004No ratings yet

- ELPLA ListAAAAAAAAAAAAAAADocument2 pagesELPLA ListAAAAAAAAAAAAAAAJosé Luis González HerreraNo ratings yet

- CHILD Fluid Connectors Product GuideDocument214 pagesCHILD Fluid Connectors Product GuideDan MoldoveanuNo ratings yet

- Key Products: Section 6-1Document13 pagesKey Products: Section 6-1awethaf9876No ratings yet

- ELPLA ListAAAAAAAAAAAAAADocument2 pagesELPLA ListAAAAAAAAAAAAAAJosé Luis González HerreraNo ratings yet

- Danuhm Bush Air Cooled Roof Top PACU-50HZ PDFDocument16 pagesDanuhm Bush Air Cooled Roof Top PACU-50HZ PDFFalak KhanNo ratings yet

- Emmc JuniDocument17 pagesEmmc JuniReki OktavianusNo ratings yet

- Limpiar MangueraDocument33 pagesLimpiar Manguerarichard castañedaNo ratings yet

- Demag AC615JDocument11 pagesDemag AC615JSBHENo ratings yet

- AOI TM-511 Drift Indicator Systems Manual - 4th Ed - Jan 07Document142 pagesAOI TM-511 Drift Indicator Systems Manual - 4th Ed - Jan 07Tri CahyadiNo ratings yet

- Iklim Template NCDCDocument331 pagesIklim Template NCDCPanca NababanNo ratings yet

- IOM - Fisher 667 Sizes 30 - 30i 76 - 76i and 87Document40 pagesIOM - Fisher 667 Sizes 30 - 30i 76 - 76i and 87AmiroucheBenlakehalNo ratings yet

- Mac 25 3 Load ChartDocument16 pagesMac 25 3 Load ChartLulut WahyudoNo ratings yet

- 103 PipenetDocument23 pages103 PipenetLucious LightNo ratings yet

- Fim Cross Country 2022 RegulationsDocument121 pagesFim Cross Country 2022 RegulationsAndrés GarciaNo ratings yet

- ELPLA ListAAAAAAAAAAAADocument2 pagesELPLA ListAAAAAAAAAAAAJosé Luis González HerreraNo ratings yet

- Residential Water Products Tech ManualDocument58 pagesResidential Water Products Tech ManualboyNo ratings yet

- Construction of Interection DiagramDocument29 pagesConstruction of Interection DiagramSuvankarNo ratings yet

- SM WW6000T CROATIAN End User 201207Document43 pagesSM WW6000T CROATIAN End User 201207Željko ĐurićNo ratings yet

- Section 8008 External Lift RamsDocument6 pagesSection 8008 External Lift Ramslungu mihaiNo ratings yet

- Handbook VVKR-A-S 202201Document38 pagesHandbook VVKR-A-S 202201mohamed roubioNo ratings yet

- Graco Technical G3 Max Pump 332305EN G 1 of 2Document40 pagesGraco Technical G3 Max Pump 332305EN G 1 of 2Diat NorNo ratings yet

- Not For Reproduction: Illustrated Parts List 126T00Document28 pagesNot For Reproduction: Illustrated Parts List 126T00John AndersonNo ratings yet

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- Design - Pinned - Column Base-PlatesDocument61 pagesDesign - Pinned - Column Base-PlatesYoshua YangNo ratings yet

- Captura de Pantalla 2023-05-17 A La(s) 9.53.36 A. M.Document206 pagesCaptura de Pantalla 2023-05-17 A La(s) 9.53.36 A. M.ericNo ratings yet

- Service Bulletin 162Document23 pagesService Bulletin 162Tatiana VásquezNo ratings yet

- Maintenance Manual PDFDocument696 pagesMaintenance Manual PDFsippolad100% (2)

- BorrarxxxDocument4 pagesBorrarxxxHeco NicNo ratings yet

- Bjve Family: Self Rotary Swivels User ManualDocument32 pagesBjve Family: Self Rotary Swivels User ManualLuiz PauloNo ratings yet

- Tower DesignDocument66 pagesTower DesignovikbasuNo ratings yet

- Crane ATF-1000XL PDFDocument8 pagesCrane ATF-1000XL PDFTrươngPhiNo ratings yet

- Spare Air Service Manual 2003Document15 pagesSpare Air Service Manual 2003Sady KanettiNo ratings yet

- Powergrip Gt3 Design Manual Us January 2014Document199 pagesPowergrip Gt3 Design Manual Us January 2014Hemraj SonarNo ratings yet

- System Operation Testing and Adjusting 3304 Vehicular EngineDocument103 pagesSystem Operation Testing and Adjusting 3304 Vehicular EngineAbdelbagi100% (2)

- System Operation Testing and Adjusting 3304 Vehicular EngineDocument103 pagesSystem Operation Testing and Adjusting 3304 Vehicular EngineAbdelbagi67% (3)

- SECTION 6004 Mechanical Rear Wheel Drive (MODELS 120 - 155)Document56 pagesSECTION 6004 Mechanical Rear Wheel Drive (MODELS 120 - 155)lungu mihaiNo ratings yet

- Mahindra Gyrovator ZLX+ Series - Feb21Document73 pagesMahindra Gyrovator ZLX+ Series - Feb21bibhaskabiNo ratings yet

- Klein Pre97 - Tech - Manual PDFDocument40 pagesKlein Pre97 - Tech - Manual PDFDwayne FitzpatrickNo ratings yet

- Throath Thickness Table For Forged Outlet Fitting: T + (T 0.7) or Min .6.4 Where, TDocument1 pageThroath Thickness Table For Forged Outlet Fitting: T + (T 0.7) or Min .6.4 Where, TK PNo ratings yet

- Output of Staad ProDocument28 pagesOutput of Staad ProramNo ratings yet

- Nexus Inter8Document37 pagesNexus Inter8Tyler ConleyNo ratings yet

- Powerboater's Guide to Electrical Systems, Second EditionFrom EverandPowerboater's Guide to Electrical Systems, Second EditionRating: 5 out of 5 stars5/5 (1)

- Provvisorio: Darra Cycles Via Roma, 135 Bis Cassolnovo (PV) 0381.928389Document5 pagesProvvisorio: Darra Cycles Via Roma, 135 Bis Cassolnovo (PV) 0381.928389ZondaNo ratings yet

- Plasma: Codice Descrizione Prezzo PubblicoDocument1 pagePlasma: Codice Descrizione Prezzo PubblicoZondaNo ratings yet

- Ridley Price List 2018Document13 pagesRidley Price List 2018ZondaNo ratings yet

- Giant Bicycles Bike 509Document1 pageGiant Bicycles Bike 509ZondaNo ratings yet

- Listino Giant 2018 Pubblico: Off Road Performance - Gravity On Road Performance - Aero RaceDocument4 pagesListino Giant 2018 Pubblico: Off Road Performance - Gravity On Road Performance - Aero RaceZondaNo ratings yet

- Specs Caratteristiche: Prezzo: 3.199Document2 pagesSpecs Caratteristiche: Prezzo: 3.199ZondaNo ratings yet

- Cube Aerum c68 2018Document1 pageCube Aerum c68 2018ZondaNo ratings yet

- Modell Empf. VK/Euro Modell Empf. VK/Euro Modell Empf. VK/EuroDocument1 pageModell Empf. VK/Euro Modell Empf. VK/Euro Modell Empf. VK/EuroZondaNo ratings yet

- SR-001MK2: Electrostatic Audio ProductsDocument1 pageSR-001MK2: Electrostatic Audio ProductsZondaNo ratings yet

- CERCDocument7 pagesCERCAnand GuptaNo ratings yet

- Results Confirmation-Control Indicators in MICDocument13 pagesResults Confirmation-Control Indicators in MICSANDEEP KKPNo ratings yet

- Capa ToolsDocument44 pagesCapa ToolsChandan ShahNo ratings yet

- Hot TappingDocument2 pagesHot TappingRochdi SahliNo ratings yet

- Liham PangnegosyoDocument28 pagesLiham PangnegosyoLeonesNo ratings yet

- Dikitanan Task1Document5 pagesDikitanan Task1Janna CrizetteNo ratings yet

- 02 Exercise Laboratory 1 TOURPLANNINGDocument8 pages02 Exercise Laboratory 1 TOURPLANNINGnicole dordeNo ratings yet

- Preservation, Its Principles and Methods PDFDocument45 pagesPreservation, Its Principles and Methods PDFRubiNo ratings yet

- Tally Exrercise 2: Date Description AmountDocument1 pageTally Exrercise 2: Date Description AmountExcel WaysNo ratings yet

- FactoryTalk Historian SE - PI Web Services vs. PI Web APIDocument5 pagesFactoryTalk Historian SE - PI Web Services vs. PI Web APIDiegoFonsecaNo ratings yet

- BlackMart APK Download Latest Version 2021.editedDocument5 pagesBlackMart APK Download Latest Version 2021.editedZia NasirNo ratings yet

- Soco Assignment 2Document4 pagesSoco Assignment 2Lara LavanyaNo ratings yet

- 5) Freshmen Sem 2 - Skills Employability (Sas)Document5 pages5) Freshmen Sem 2 - Skills Employability (Sas)Crislyn Jilou Bugas AdlawanNo ratings yet

- The Dual in LPDocument17 pagesThe Dual in LPShreeyesh MenonNo ratings yet

- Motion To Reconsider-Vacate-Modify Order, C.a.11 No.13-11585-BDocument62 pagesMotion To Reconsider-Vacate-Modify Order, C.a.11 No.13-11585-BNeil GillespieNo ratings yet

- PMP NotesDocument3 pagesPMP Notesjay2kay5793No ratings yet

- ĐỀ 1 - RCDocument30 pagesĐỀ 1 - RCLương Hữu TàiNo ratings yet

- 43 CA CPT Dec 2010 Question Paper With Answer Key 2Document6 pages43 CA CPT Dec 2010 Question Paper With Answer Key 2Vishal Gattani100% (1)

- Charging and TD Chart PlusDocument1 pageCharging and TD Chart PlusFaquruddin AliNo ratings yet

- Sample Letter of Intent To Transfer FundsDocument2 pagesSample Letter of Intent To Transfer Fundsnavid kamravaNo ratings yet

- CPD Using The Ecsa Electronic System For Entering Records: WWW - Ecsa.co - ZaDocument5 pagesCPD Using The Ecsa Electronic System For Entering Records: WWW - Ecsa.co - ZaBen MudoziNo ratings yet

- Lenoir, Frederic. - Breve Tratado de Historia de Las Religiones (2018)Document47 pagesLenoir, Frederic. - Breve Tratado de Historia de Las Religiones (2018)Kike EspinozaNo ratings yet

- Sh03 - Options Codes A 4 8 10 5 8 46 3 7 5Document73 pagesSh03 - Options Codes A 4 8 10 5 8 46 3 7 5Edward Adrian Moreno FernandezNo ratings yet

- Apt. Didik, Peluang Jasa Profesi ApotekerDocument22 pagesApt. Didik, Peluang Jasa Profesi ApotekerYudha PrasetyaNo ratings yet

- Infosys Analysis For Finlatics FMEPDocument5 pagesInfosys Analysis For Finlatics FMEPyogeshNo ratings yet

- MP C3004/C3504/C3004Ex/C3504Ex Series/Dsc1230 (D238/D239/D0Ac/D0Ad) Parts CatalogDocument228 pagesMP C3004/C3504/C3004Ex/C3504Ex Series/Dsc1230 (D238/D239/D0Ac/D0Ad) Parts CatalogBruno PLETNo ratings yet

- Rega Planet 2000 ManualDocument4 pagesRega Planet 2000 ManualjamocasNo ratings yet

- Labuenavida Business Summary 2023Document24 pagesLabuenavida Business Summary 2023UzoNo ratings yet

- Data Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeDocument10 pagesData Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeRisa RidmaNo ratings yet