Professional Documents

Culture Documents

Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Tees

Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Tees

Uploaded by

SaidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Tees

Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Tees

Uploaded by

SaidCopyright:

Available Formats

Client

Project No / Title

Location

Document No Page Of

Line No Line No Line No

DWG No DWG No DWG No

From From From

To To To

Op Pressure (Inlet) 85.8 psia Op Pressure (Inlet) 85.8 psia Op Pressure (Inlet) 42.6 psia

Op Temp 573.0 R Op Temp 573.0 R Op Temp 564.0 R

Desity @ P,T 45.74 lb/ft3 Desity @ P,T 45.74 lb/ft3 Desity @ P,T 45.74 lb/ft3

Viscosity 1.00 cP Viscosity 1.00 cP Viscosity 1.00 cP

Molecular Weight 165.57 Molecular Weight 165.57 Molecular Weight 165.57

Liquid Flowrate 2,823.0 bbl/day Gas Flowrate 2,823.0 bbl/day Gas Flowrate 2,823.0 bbl/day

Design Factor 10 % Design Factor 10 % Design Factor 10 %

Liquid Design Flowrate 3,106.0 bbl/day Gas Design Flowrate 3,106.0 bbl/day Gas Design Flowrate 3,106.0 bbl/day

C (Emperical Constant) 122 C (Emperical Constant) 122 C (Emperical Constant) 122

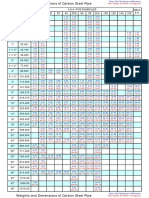

Nominal Size 2 in Nominal Size 2 in Nominal Size 2 in

Material of Constuction Commercial Steel Material of Constuction Commercial Steel Material of Constuction Commercial Steel

Sch. No 160 Sch. No 40 Sch. No 40

ID in ID in ID in

OD in OD in OD in

Actual Velocity 9.32 ft/sec Actual Velocity 9.32 ft/sec Actual Velocity 9.32 ft/sec

2 operating + 1 standby

Pressure Drop (fittings…etc) Eq Length (ft) Pressure Drop (fittings…etc) Eq Length (ft) Pressure Drop (fittings…etc) Eq Length (ft)

Elbows, Tees Elbows, Tees Elbows, Tees

Elbow 90 Short 1 4 Elbow 90 Short 0 0 Elbow 90 Short 0 0

Elbow 90 Long 6 18 Elbow 90 Long 6 18 Elbow 90 Long 6 18

Elbow 45 0 0 Elbow 45 0 0 Elbow 45 0 0

Run of Tee 0 0 Run of Tee 0 0 Run of Tee 0 0

Branch of T 1 10 Branch of T 1 10 Branch of T 1 10

Enlarger, Reducer Enlarger, Reducer Enlarger, Reducer

Enlarger (Std) d/D = 1/2 1 5 Enlarger (Std) d/D = 1/2 1 5 Enlarger (Std) d/D = 1/2 1 5

Enlarger (Sudden) d/D = 3/4 1 1 Enlarger (Sudden) d/D = 3/4 1 1 Enlarger (Sudden) d/D = 3/4 1 1

Reducer (Std) d/D = 1/2 1 1 Reducer (Std) d/D = 1/2 1 1 Reducer (Std) d/D = 1/2 1 1

Reducer (Sudden) d/D = 1/4 1 3 Reducer (Sudden) d/D = 1/4 1 3 Reducer (Sudden) d/D = 1/4 1 3

Valves Valves Valves

Plug, Gate, Ball valve 2 4 Plug, Gate, Ball valve 2 4 Plug, Gate, Ball valve 2 4

Globe valve/Ball check valve 0 0 Globe valve/Ball check valve 0 0 Globe valve/Ball check valve 0 0

Swing Check valve 0 0 Swing Check valve 0 0 Swing Check valve 0 0

Line Losses (Fittings) 46 ΔP (ft) 42 ΔP (ft) 42

Total Pressure Drop Total Pressure Drop Total Pressure Drop

Length of Pipe run 467.52 ft Length of Pipe run 467.52 ft Length of Pipe run 467.52 ft

Length Design Factor 55 % Length Design Factor 55 % Length Design Factor 55 %

Total Length Total Length Total Length

(Pipe run + Equiv. Length) 795.96 ft (Pipe run + Equiv. Length) 789.76 ft (Pipe run + Equiv. Length) 789.76 ft

Reynold Number 105,699 Reynold Number 105,699 Reynold Number 105,699

Turbulent Turbulent Turbulent

Relative Roughness 0.0000 Relative Roughness 0.0000 Relative Roughness 0.0000

Moody Friction Factor 0.0177 Moody Friction Factor 0.0177 Moody Friction Factor 0.0177

ΔP/100 ft 4.49 psi / 100 ft ΔP/100 ft 4.49 psi / 100 ft ΔP/100 ft 4.49 psi / 100 ft

Difference in Level 2.6 ft Difference in Level 2.6 ft Difference in Level 1.3 ft

0.8 psi 0.8 psi 0.4 psi

Others (strainers…etc) psi Others (strainers…etc) psi Others (strainers…etc) 3.0 psi

Outlet Pressure 50.93 psia Outlet Pressure 51.20 psia Outlet Pressure 4.62 psia

Rev. Date Description Prep'd Chk'd Appr'd

Client

Project No / Title

Location

Document No Page Of

Line No Line No Line No

DWG No DWG No DWG No

From From From

To To To

Op Pressure (Inlet) 85.8 psia Op Pressure (Inlet) 85.8 psia Op Pressure (Inlet) 42.6 psia

Op Temp 573.0 R Op Temp 573.0 R Op Temp 564.0 R

Desity @ P,T 45.74 lb/ft3 Desity @ P,T 45.74 lb/ft3 Desity @ P,T 45.74 lb/ft3

Viscosity 1.00 cP Viscosity 1.00 cP Viscosity 1.00 cP

Molecular Weight 165.57 Molecular Weight 165.57 Molecular Weight 165.57

Liquid Flowrate 2,823.0 bbl/day Gas Flowrate 2,823.0 bbl/day Gas Flowrate 2,823.0 bbl/day

Design Factor 10 % Design Factor 10 % Design Factor 10 %

Liquid Design Flowrate 3,106.0 bbl/day Gas Design Flowrate 3,106.0 bbl/day Gas Design Flowrate 3,106.0 bbl/day

C (Emperical Constant) 122 C (Emperical Constant) 122 C (Emperical Constant) 122

Nominal Size 2 in Nominal Size 2 in Nominal Size 2 in

Material of Constuction Commercial Steel Material of Constuction Commercial Steel Material of Constuction Commercial Steel

Sch. No 160 Sch. No 40 Sch. No 40

ID in ID in ID in

OD in OD in OD in

Actual Velocity 9.32 ft/sec Actual Velocity 9.32 ft/sec Actual Velocity 9.32 ft/sec

2 operating + 1 standby

Pressure Drop (fittings…etc) Eq Length (ft) Pressure Drop (fittings…etc) Eq Length (ft) Pressure Drop (fittings…etc) Eq Length (ft)

Elbows, Tees Elbows, Tees Elbows, Tees

Elbow 90 Short 1 4 Elbow 90 Short 1 4 Elbow 90 Short 1 4

Elbow 90 Long 6 18 Elbow 90 Long 6 18 Elbow 90 Long 6 18

Elbow 45 0 0 Elbow 45 0 0 Elbow 45 0 0

Run of Tee 0 0 Run of Tee 0 0 Run of Tee 0 0

Branch of T 1 10 Branch of T 1 10 Branch of T 1 10

Enlarger, Reducer Enlarger, Reducer Enlarger, Reducer

Enlarger (Std) d/D = 1/2 1 5 Enlarger (Std) d/D = 1/2 1 5 Enlarger (Std) d/D = 1/2 1 5

Enlarger (Sudden) d/D = 3/4 1 1 Enlarger (Sudden) d/D = 3/4 1 1 Enlarger (Sudden) d/D = 3/4 1 1

Reducer (Std) d/D = 1/2 1 1 Reducer (Std) d/D = 1/2 1 1 Reducer (Std) d/D = 1/2 1 1

Reducer (Sudden) d/D = 1/4 1 3 Reducer (Sudden) d/D = 1/4 1 3 Reducer (Sudden) d/D = 1/4 1 3

Valves Valves Valves

Plug, Gate, Ball valve 2 4 Plug, Gate, Ball valve 2 4 Plug, Gate, Ball valve 2 4

Globe valve/Ball check valve 0 0 Globe valve/Ball check valve 0 0 Globe valve/Ball check valve 0 0

Swing Check valve 0 0 Swing Check valve 0 0 Swing Check valve 0 0

Line Losses (Fittings) 46 ΔP (ft) 46 ΔP (ft) 46

Total Pressure Drop Total Pressure Drop Total Pressure Drop

Length of Pipe run 467.52 ft Length of Pipe run 467.52 ft Length of Pipe run 467.52 ft

Length Design Factor 10 % Length Design Factor 55 % Length Design Factor 55 %

Total Length Total Length Total Length

(Pipe run + Equiv. Length) 564.87 ft (Pipe run + Equiv. Length) 795.96 ft (Pipe run + Equiv. Length) 795.96 ft

Reynold Number 105,699 Reynold Number 105,699 Reynold Number 105,699

Turbulent Turbulent Turbulent

Relative Roughness 0.0000 Relative Roughness 0.0000 Relative Roughness 0.0000

Moody Friction Factor 0.0177 Moody Friction Factor 0.0177 Moody Friction Factor 0.0177

ΔP/100 ft 4.49 psi / 100 ft ΔP/100 ft 4.49 psi / 100 ft ΔP/100 ft 4.49 psi / 100 ft

Difference in Level 2.6 ft Difference in Level 2.6 ft Difference in Level 1.3 ft

0.8 psi 0.8 psi 0.4 psi

Others (strainers…etc) psi Others (strainers…etc) psi Others (strainers…etc) 3.0 psi

Outlet Pressure 61.30 psia Outlet Pressure 50.92 psia Outlet Pressure 4.34 psia

Rev. Date Description Prep'd Chk'd Appr'd

Client

Project No / Title

Location

Document No Page Of

Line No Line No Line No

DWG No DWG No DWG No

From From From

To To To

Op Pressure (Inlet) 85.8 psia Op Pressure (Inlet) 85.8 psia Op Pressure (Inlet) 42.6 psia

Op Temp 573.0 R Op Temp 573.0 R Op Temp 564.0 R

Desity @ P,T 45.74 lb/ft3 Desity @ P,T 45.74 lb/ft3 Desity @ P,T 45.74 lb/ft3

Viscosity 1.00 cP Viscosity 1.00 cP Viscosity 1.00 cP

Molecular Weight 165.57 Molecular Weight 165.57 Molecular Weight 165.57

Liquid Flowrate 2,823.0 bbl/day Gas Flowrate 2,823.0 bbl/day Gas Flowrate 2,823.0 bbl/day

Design Factor 10 % Design Factor 10 % Design Factor 10 %

Liquid Design Flowrate 3,106.0 bbl/day Gas Design Flowrate 3,106.0 bbl/day Gas Design Flowrate 3,106.0 bbl/day

C (Emperical Constant) 122 C (Emperical Constant) 122 C (Emperical Constant) 122

Nominal Size 2 in Nominal Size 2 in Nominal Size 2 in

Material of Constuction Commercial Steel Material of Constuction Commercial Steel Material of Constuction Commercial Steel

Sch. No 160 Sch. No 40 Sch. No 40

ID in ID in ID in

OD in OD in OD in

Actual Velocity 9.32 ft/sec Actual Velocity 9.32 ft/sec Actual Velocity 9.32 ft/sec

Pressure Drop (fittings…etc) Eq Length (ft) Pressure Drop (fittings…etc) Eq Length (ft) Pressure Drop (fittings…etc) Eq Length (ft)

Elbows, Tees Elbows, Tees Elbows, Tees

Elbow 90 Short 1 4 Elbow 90 Short 1 4 Elbow 90 Short 1 4

Elbow 90 Long 6 18 Elbow 90 Long 6 18 Elbow 90 Long 6 18

Elbow 45 0 0 Elbow 45 0 0 Elbow 45 0 0

Run of Tee 0 0 Run of Tee 0 0 Run of Tee 0 0

Branch of T 1 10 Branch of T 1 10 Branch of T 1 10

Enlarger, Reducer Enlarger, Reducer Enlarger, Reducer

Enlarger (Std) d/D = 1/2 1 5 Enlarger (Std) d/D = 1/2 1 5 Enlarger (Std) d/D = 1/2 1 5

Enlarger (Sudden) d/D = 3/4 1 1 Enlarger (Sudden) d/D = 3/4 1 1 Enlarger (Sudden) d/D = 3/4 1 1

Reducer (Std) d/D = 3/4 1 0 Reducer (Std) d/D = 3/4 1 0 Reducer (Std) d/D = 3/4 1 0

Reducer (Sudden) d/D = 1/4 1 3 Reducer (Sudden) d/D = 1/4 1 3 Reducer (Sudden) d/D = 3/4 1 3

Valves Valves Valves

Plug, Gate, Ball valve 2 4 Plug, Gate, Ball valve 2 4 Plug, Gate, Ball valve 2 4

Globe valve/Ball check valve 0 0 Globe valve/Ball check valve 0 0 Globe valve/Ball check valve 0 0

Swing Check valve 0 0 Swing Check valve 0 0 Swing Check valve 0 0

Line Losses (Fittings) 45 ΔP (ft) 45 ΔP (ft) 45

Total Pressure Drop Total Pressure Drop Total Pressure Drop

Length of Pipe run 467.52 ft Length of Pipe run 467.52 ft Length of Pipe run 467.52 ft

Length Design Factor 10 % Length Design Factor 10 % Length Design Factor 55 %

Total Length Total Length Total Length

(Pipe run + Equiv. Length) 563.77 ft (Pipe run + Equiv. Length) 563.77 ft (Pipe run + Equiv. Length) 794.41 ft

Reynold Number 105,699 Reynold Number 105,699 Reynold Number 105,699

Turbulent Turbulent Turbulent

Relative Roughness 0.0000 Relative Roughness 0.0000 Relative Roughness 0.0000

Moody Friction Factor 0.0177 Moody Friction Factor 0.0177 Moody Friction Factor 0.0177

ΔP/100 ft 4.49 psi / 100 ft ΔP/100 ft 4.49 psi / 100 ft ΔP/100 ft 4.49 psi / 100 ft

Difference in Level 2.6 ft Difference in Level 2.6 ft Difference in Level 1.3 ft

0.8 psi 0.8 psi 0.4 psi

Others (strainers…etc) psi Others (strainers…etc) psi Others (strainers…etc) 3.0 psi

Outlet Pressure 61.35 psia Outlet Pressure 61.34 psia Outlet Pressure 4.41 psia

Rev. Date Description Prep'd Chk'd Appr'd

API RP 14E (2007) Surface Roughness (Table 5-6 P.5-24 Perry)

Enlargers (Sudden) Enlargers (Std) mm ft

d/D = 1/4 d/D = 1/2 Commercial Steel 0.0457 0.00015

d/D = 1/2 d/D = 3/4 Wrought Iron 0.0457 0.00015

d/D = 3/4 Stainless Steel 0.002 0.00001

Cast Iron 0.259 0.00085

Reducer (Sudden) Reducer (Std) Galvanized Iron 0.152 0.00050

d/D = 1/4 d/D = 1/2 Asphalted Cast Iron 0.122 0.00040

d/D = 1/2 d/D = 3/4 Riveted Steel 0.914 - 9.14 0.003 - 0.03

d/D = 3/4

You might also like

- Midterm Study Guide PDFDocument51 pagesMidterm Study Guide PDFTARA PEROOMIANNo ratings yet

- Maxi ManualDocument47 pagesMaxi ManualB Gary AcostaNo ratings yet

- BEL - 6D Through Conduit GateDocument2 pagesBEL - 6D Through Conduit Gateasoka.pwNo ratings yet

- Diaphragm Pump Viscosity Correction GraphDocument2 pagesDiaphragm Pump Viscosity Correction GraphSebastian BaezNo ratings yet

- University of Aberdeen - 15 - 5) Leak Sealing Technologies For The Oil & Gas IndustryDocument4 pagesUniversity of Aberdeen - 15 - 5) Leak Sealing Technologies For The Oil & Gas IndustryAnonymous IUFzAW9wHGNo ratings yet

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocument1 pageMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiNo ratings yet

- A Double-Tail Latch-Type Voltage Sense Amplifier With 18ps Setup+Hold TimeDocument3 pagesA Double-Tail Latch-Type Voltage Sense Amplifier With 18ps Setup+Hold TimeWang TianyangNo ratings yet

- Peter Turner Drawing Duplications Vol 5 PDFDocument65 pagesPeter Turner Drawing Duplications Vol 5 PDFsteflan50% (2)

- APP Installation Detroit Diesel S2000 7SA2000 PDFDocument233 pagesAPP Installation Detroit Diesel S2000 7SA2000 PDFthanhhai31No ratings yet

- Foundation (Thumb Rules) : Concentric FootingsDocument4 pagesFoundation (Thumb Rules) : Concentric FootingsAtul Joshi90% (10)

- DeltaValve 2010 Customer VersionDocument97 pagesDeltaValve 2010 Customer VersionjoseellargoNo ratings yet

- Bandlock2 LiteratureDocument2 pagesBandlock2 LiteraturelaiminhtheNo ratings yet

- AGRU-Technical-Butt WeldingDocument4 pagesAGRU-Technical-Butt Weldingrenne_mujicaNo ratings yet

- Calculation Sheet: 2-Phase Control Valve CalculationDocument13 pagesCalculation Sheet: 2-Phase Control Valve CalculationEslamSheblNo ratings yet

- Friction and Friction Coefficients For Various MaterialsDocument7 pagesFriction and Friction Coefficients For Various MaterialsHilman NurzenNo ratings yet

- SweeperDocument8 pagesSweeperstainless31620039126No ratings yet

- Air RecieverDocument3 pagesAir Recieverjp220288No ratings yet

- BV Gate Valve DS 15111Document2 pagesBV Gate Valve DS 15111yulianus_srNo ratings yet

- User Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi TubesDocument12 pagesUser Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi Tubesxaaabbb_550464353100% (1)

- Pressure Drop For Two Phase Flow in Horizontal Pipe: Chemical Engineer's GuideDocument5 pagesPressure Drop For Two Phase Flow in Horizontal Pipe: Chemical Engineer's GuideAbhijeet SachanNo ratings yet

- Strake CalculationDocument1 pageStrake CalculationABIDEEN BAMNENo ratings yet

- Erection & Installation ProcedureDocument3 pagesErection & Installation ProcedureForos IscNo ratings yet

- 5 Foam PigsDocument13 pages5 Foam PigsLuis R MartínezNo ratings yet

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- Flanges and Bolt Dimensions ASME/ANSI B16.5 - Class 150 To 2500Document9 pagesFlanges and Bolt Dimensions ASME/ANSI B16.5 - Class 150 To 2500daveNo ratings yet

- PIpe Class and StandardDocument3 pagesPIpe Class and StandardSamim RahmanNo ratings yet

- Calculation Sheet PDFDocument32 pagesCalculation Sheet PDFHazem EmamNo ratings yet

- Expanding Gate 2016 2Document56 pagesExpanding Gate 2016 2ramyzottyNo ratings yet

- Gantrex Technical Bulletin 43Document2 pagesGantrex Technical Bulletin 43gechaves1No ratings yet

- Differential Pressure GaugeDocument2 pagesDifferential Pressure GaugeManikandan SenthilNo ratings yet

- EZR RegulatorDocument40 pagesEZR RegulatorBranko BabicNo ratings yet

- ATEC Cyclone Datasheet EnglDocument1 pageATEC Cyclone Datasheet EnglDilnesa EjiguNo ratings yet

- ASME 16.21 Nonmetalic GasketDocument21 pagesASME 16.21 Nonmetalic Gasketrc galinatoNo ratings yet

- Understanding The Importance of Bearing ClearanceDocument4 pagesUnderstanding The Importance of Bearing ClearanceHosseinNo ratings yet

- Vapour Recovery Unit Foundation Loads: Mass T T Dist F1 F2 KG LB in KG MM MM N N Blower HP RPMDocument2 pagesVapour Recovery Unit Foundation Loads: Mass T T Dist F1 F2 KG LB in KG MM MM N N Blower HP RPMHomer SilvaNo ratings yet

- 652 - Pressure Losses - Shell - DDDocument3 pages652 - Pressure Losses - Shell - DDNikhil BarshettiwarNo ratings yet

- EN ISO 11542-2 PropertiesDocument17 pagesEN ISO 11542-2 Propertieschaminda nayanajithNo ratings yet

- Bolt/hex Nut Strength MarkingsDocument3 pagesBolt/hex Nut Strength Markings322399mk7086No ratings yet

- Bomba SihiDocument24 pagesBomba SihiCristian PovedaNo ratings yet

- Stainless Steel Pressure Filters - BrochureDocument20 pagesStainless Steel Pressure Filters - Brochureviktor_gligorovNo ratings yet

- Devlon v-API OriginalDocument1 pageDevlon v-API OriginalCarlosIkedaNo ratings yet

- Calculation of Insulation Thickness For Pipes The Piping Engineering WorldDocument3 pagesCalculation of Insulation Thickness For Pipes The Piping Engineering WorldEddie FongNo ratings yet

- Rotary Valves ZRSDocument7 pagesRotary Valves ZRSkosmcNo ratings yet

- Volum Water HydrotestDocument2 pagesVolum Water HydrotestFerinoviardi100% (1)

- Data Sheet Carbon SteelsDocument17 pagesData Sheet Carbon SteelsvkmsNo ratings yet

- The Effect of Unbalance On Bearing LifeDocument8 pagesThe Effect of Unbalance On Bearing LifejaypallaNo ratings yet

- CAIRN-TSG-L-SP-0011-B2-Specification For Application of Torque For Flange JointsDocument13 pagesCAIRN-TSG-L-SP-0011-B2-Specification For Application of Torque For Flange JointsShivashankar Durga MedisettiNo ratings yet

- Class Flanges Bolt Torque LoadsDocument2 pagesClass Flanges Bolt Torque LoadsAulia RahmanNo ratings yet

- Tube Properties PDFDocument19 pagesTube Properties PDFjamoneoNo ratings yet

- Inspection Checklist Fin Fan CoolerDocument2 pagesInspection Checklist Fin Fan CoolerAnoopNo ratings yet

- Key(s) For Shaft Hub ConnectionDocument7 pagesKey(s) For Shaft Hub ConnectionEng-CalculationsNo ratings yet

- Difference Between Wrought Fittings and Forged Fittings - Google GroupsDocument1 pageDifference Between Wrought Fittings and Forged Fittings - Google Groupsim4uim4uim4uNo ratings yet

- Steam Power Plant and CoalDocument74 pagesSteam Power Plant and CoalRahul SoniNo ratings yet

- Gas Flow Calculation AGA3Document1 pageGas Flow Calculation AGA3ijaz ahmadNo ratings yet

- Crossover & Pup JointDocument2 pagesCrossover & Pup JointHassan Feki100% (1)

- Wilden Specialty CodesDocument9 pagesWilden Specialty CodesPump SpesialistNo ratings yet

- Nominal Pipe Size Chart in Inch and MMDocument2 pagesNominal Pipe Size Chart in Inch and MMMehman NasibovNo ratings yet

- Therminol vp1Document10 pagesTherminol vp1karthik1amarNo ratings yet

- Bolt Tightening Solutions BinderDocument18 pagesBolt Tightening Solutions BinderPranpath NarupantawartNo ratings yet

- Design and Analysis of Pressure Vessel Using PV Elite SoftwareDocument8 pagesDesign and Analysis of Pressure Vessel Using PV Elite SoftwareVitor OlivettiNo ratings yet

- Liquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignFrom EverandLiquid Ring Vacuum Pumps, Compressors and Systems: Conventional and Hermetic DesignNo ratings yet

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDocument4 pagesGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahNo ratings yet

- CB-8391 CBND Technical Data - Specifications PDFDocument43 pagesCB-8391 CBND Technical Data - Specifications PDFcoyuncoNo ratings yet

- 02 Stoichiometric CalculationsDocument7 pages02 Stoichiometric CalculationsAnonymous jlLBRMAr3ONo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- JV-190523-01 Choke Manifold (I-CHM-H0310-0053) IO0014444-71-1Document3 pagesJV-190523-01 Choke Manifold (I-CHM-H0310-0053) IO0014444-71-1SaidNo ratings yet

- FlexPipe Linepipe HT Product Data SheetDocument2 pagesFlexPipe Linepipe HT Product Data SheetSaidNo ratings yet

- Document 1Document1 pageDocument 1SaidNo ratings yet

- 35-8-5 Cement Diesel Powered Offshore Skid ECS BJDocument4 pages35-8-5 Cement Diesel Powered Offshore Skid ECS BJSaid100% (1)

- CV of AboubakrDocument2 pagesCV of AboubakrSaidNo ratings yet

- T N 3022 Addition and Subtraction To 20 With A Number Line Activity Sheet Ver 2Document1 pageT N 3022 Addition and Subtraction To 20 With A Number Line Activity Sheet Ver 2SaidNo ratings yet

- Copie de Logistics Management TrucksDocument34 pagesCopie de Logistics Management TrucksSaid0% (1)

- Section 15Document20 pagesSection 15SaidNo ratings yet

- CV of MD MilonDocument1 pageCV of MD MilonSaidNo ratings yet

- CV of Rakib HasanDocument3 pagesCV of Rakib HasanSaidNo ratings yet

- RB 221Document167 pagesRB 221SaidNo ratings yet

- 01 Wits1Document20 pages01 Wits1SaidNo ratings yet

- Oil Analysis File (OAN)Document70 pagesOil Analysis File (OAN)SaidNo ratings yet

- Eng105 Foelp - 08a Cementing Rev 2005 04Document51 pagesEng105 Foelp - 08a Cementing Rev 2005 04SaidNo ratings yet

- FN 76-2 Well 273.05 Casing CementingDocument5 pagesFN 76-2 Well 273.05 Casing CementingSaidNo ratings yet

- (Project Name) Project ScheduleDocument8 pages(Project Name) Project ScheduleSaidNo ratings yet

- CV Anis Gharsellaoui 2021 - 220209 - 174447Document3 pagesCV Anis Gharsellaoui 2021 - 220209 - 174447SaidNo ratings yet

- Calibration Certificate - Gas Coriolis - Unit#1Document2 pagesCalibration Certificate - Gas Coriolis - Unit#1Said100% (1)

- Water Cut Meter-1Document6 pagesWater Cut Meter-1SaidNo ratings yet

- Haitham TaskDocument6 pagesHaitham TaskSaidNo ratings yet

- Calibration Certificate Water Coriolis Unit#1Document2 pagesCalibration Certificate Water Coriolis Unit#1SaidNo ratings yet

- Calibration Certificate - Turbine - Unit#1Document2 pagesCalibration Certificate - Turbine - Unit#1SaidNo ratings yet

- Practical Well Testing: Well Test Design 4 X Half DaysDocument1 pagePractical Well Testing: Well Test Design 4 X Half DaysSaidNo ratings yet

- Surface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Document10 pagesSurface Well Testing Reporting Format and Standard GD-GL-HAL-SWT-601Said100% (1)

- Pipesim Valves Fittings Plugin CompressDocument14 pagesPipesim Valves Fittings Plugin CompressSaidNo ratings yet

- Energies: Workflow For Probabilistic Resource Estimation: Jafurah Basin Case Study (Saudi Arabia)Document24 pagesEnergies: Workflow For Probabilistic Resource Estimation: Jafurah Basin Case Study (Saudi Arabia)SaidNo ratings yet

- Ear 14Document59 pagesEar 14anon_179315406No ratings yet

- SPUTNIK360 SWITCH & PROBE - InstructionsDocument1 pageSPUTNIK360 SWITCH & PROBE - InstructionsDz Capssoula100% (1)

- FIFA Video Game - Players ClassificationDocument26 pagesFIFA Video Game - Players Classificationimmi1989No ratings yet

- Lesson Plan in English Using SRF: I. ObjectiveDocument10 pagesLesson Plan in English Using SRF: I. ObjectiveShee AntonioNo ratings yet

- A Arte Da Brevidade - Virginia WoolfDocument100 pagesA Arte Da Brevidade - Virginia WoolfAdriane LimaNo ratings yet

- BS en Iso 06272-2-2011Document14 pagesBS en Iso 06272-2-2011محمد مقلد0% (1)

- Support Supervision Analysis and Implementation of Quality of Primary Education in UgandaDocument74 pagesSupport Supervision Analysis and Implementation of Quality of Primary Education in UgandaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Syrian Pottery From Middle Kingdom Egypt: Stage, Anticipation Set A FromDocument9 pagesSyrian Pottery From Middle Kingdom Egypt: Stage, Anticipation Set A Fromsychev_dmitryNo ratings yet

- "Flexible Manufacturing System": Department of Mechanical EngineeringDocument32 pages"Flexible Manufacturing System": Department of Mechanical EngineeringGoutham ReddyNo ratings yet

- 111年下A卷題庫Document10 pages111年下A卷題庫陳奕安No ratings yet

- 0947 Power Factor CorrectionDocument4 pages0947 Power Factor CorrectionاحمدرضاNo ratings yet

- Prestressed Concrete - Lecture 1 & 2Document69 pagesPrestressed Concrete - Lecture 1 & 2Banda RajeshNo ratings yet

- Research Methods SESSIONS STUDENTS Abeeku PDFDocument287 pagesResearch Methods SESSIONS STUDENTS Abeeku PDFdomaina2008100% (3)

- M Plusteam Sterilizer - Drain Pipe Line Installation Sheet Rev.3.4Document1 pageM Plusteam Sterilizer - Drain Pipe Line Installation Sheet Rev.3.4Casamed ServiceNo ratings yet

- INSULATION COORDINATION STUDIES FOR 400 KV GIS PDFDocument6 pagesINSULATION COORDINATION STUDIES FOR 400 KV GIS PDFsorry2qazNo ratings yet

- Herramientas CSDocument2 pagesHerramientas CSCAPCOMALLSTARS POWERNo ratings yet

- 2) Spray Nozzle Specification PDFDocument41 pages2) Spray Nozzle Specification PDFkasvikrajNo ratings yet

- Fire Safe Isolation Kit: Seal Tight. Seal SafeDocument2 pagesFire Safe Isolation Kit: Seal Tight. Seal SafeAnonymous Dp4DdscGSNo ratings yet

- FastLink CAT6 (SFTP) OutdoorDocument3 pagesFastLink CAT6 (SFTP) OutdoorHaiderNo ratings yet

- Imagining Lives Through Korean DramasDocument11 pagesImagining Lives Through Korean DramasLuis FernandoNo ratings yet

- Research Paper - Emergent ChangeDocument3 pagesResearch Paper - Emergent ChangeYantieNo ratings yet

- Tin Mill Products, Black Plate, Double Reduced: Standard Specification ForDocument2 pagesTin Mill Products, Black Plate, Double Reduced: Standard Specification ForsamehNo ratings yet

- Value Proposition CanvasDocument1 pageValue Proposition CanvasCristiano AredesNo ratings yet

- Prodigalidad, Z C. - Week 2 - Day 1 - MCN DutyDocument2 pagesProdigalidad, Z C. - Week 2 - Day 1 - MCN DutyZxiayieee JeonNo ratings yet

- AC2 Specification SheetDocument4 pagesAC2 Specification SheetWiwa Hernandez DonosoNo ratings yet