Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

58 viewsControlled Expansion Alloys

Controlled Expansion Alloys

Uploaded by

leaksolveCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Lab 12Document4 pagesLab 12over allNo ratings yet

- Bamboo PilesDocument6 pagesBamboo PilesKenny YeeNo ratings yet

- Invar Nickel Iron AlloyDocument3 pagesInvar Nickel Iron AlloyAbul Kashem Sfq UllahNo ratings yet

- Nickel Alloys in Today'S Electronics Industry: C.R. Isleib N 10029Document10 pagesNickel Alloys in Today'S Electronics Industry: C.R. Isleib N 10029dpkeskesiadisNo ratings yet

- Giunzione e ManutenzioneDocument29 pagesGiunzione e Manutenzionerenhat parulian sitorusNo ratings yet

- Key Aluminum Nitride PropertiesDocument10 pagesKey Aluminum Nitride PropertiesMuhammad TanweerNo ratings yet

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Mechanical and Thermal Behaviour of Cordierite-Zirconia CompositesDocument13 pagesMechanical and Thermal Behaviour of Cordierite-Zirconia CompositesĐức MạnhNo ratings yet

- Ceramics IntroductionDocument35 pagesCeramics IntroductionSaptarshi SenguptaNo ratings yet

- Electronic Ceramics and CermetsDocument32 pagesElectronic Ceramics and Cermetsmarvel794No ratings yet

- Application of Refractory Metals and AlloysDocument36 pagesApplication of Refractory Metals and Alloysbugoff700No ratings yet

- AKANDE Heritage ProjectDocument28 pagesAKANDE Heritage ProjectAkande HeritageNo ratings yet

- Kojundi Krni SamardiDocument20 pagesKojundi Krni SamardiMehul VoraNo ratings yet

- Manpreet Et Al 2010Document12 pagesManpreet Et Al 2010manpreetNo ratings yet

- Simko SiCcorrosionDocument10 pagesSimko SiCcorrosionJarmilaMlynárikováNo ratings yet

- Arcos 625Document1 pageArcos 625bowotriantoNo ratings yet

- EM MOULDS English CatalogueDocument15 pagesEM MOULDS English CataloguekovvadkrishnaNo ratings yet

- Audio CH 552 Lesson 2 Eng. Ceram 2021Document101 pagesAudio CH 552 Lesson 2 Eng. Ceram 2021Vihanga SenanayakeNo ratings yet

- MEMS Material N Their PropertiesDocument20 pagesMEMS Material N Their PropertiesasdftyNo ratings yet

- The Study of Corrosion and Wear Resistance of CoppDocument9 pagesThe Study of Corrosion and Wear Resistance of CoppNoura Nour ElshamsNo ratings yet

- Goodfellow Looking 1112Document3 pagesGoodfellow Looking 1112arundixituNo ratings yet

- Zinc DIE CASTINGDocument10 pagesZinc DIE CASTINGFrancisco BocanegraNo ratings yet

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- Corrosion Behaviour of Ni and Nickel Aluminide Coatings Exposed in A Biomass Fired Power Plant For Two YearsDocument11 pagesCorrosion Behaviour of Ni and Nickel Aluminide Coatings Exposed in A Biomass Fired Power Plant For Two YearsmanishtubNo ratings yet

- Ijrdet 0715 03Document14 pagesIjrdet 0715 03Chrill DsilvaNo ratings yet

- IM - Proyecto Final InglesDocument33 pagesIM - Proyecto Final InglesLexi Noel Gutiérrez MéndezNo ratings yet

- Corrosion Analysis of Copper Tio2nanocomposite Coatings On Steel Usingsputtering PDFDocument6 pagesCorrosion Analysis of Copper Tio2nanocomposite Coatings On Steel Usingsputtering PDFmohamed aliNo ratings yet

- Fundamentals of Ceramics Chapter 1Document38 pagesFundamentals of Ceramics Chapter 1Tamiru MisikirNo ratings yet

- Ductile Cast Iron With High Toughness at Low TemperaturesDocument8 pagesDuctile Cast Iron With High Toughness at Low Temperatures조용재 (용자씨)No ratings yet

- DownloadfileDocument9 pagesDownloadfilefredymademydayNo ratings yet

- Natarajan2006 PDFDocument5 pagesNatarajan2006 PDFBasim Al-bhadleNo ratings yet

- 01 - Overview of Advanced CeramicsDocument18 pages01 - Overview of Advanced CeramicsJanibul Haque PritomNo ratings yet

- Electrochemical Corrosion of Silicon Carbide Ceramics in H SODocument7 pagesElectrochemical Corrosion of Silicon Carbide Ceramics in H SOGizem D.No ratings yet

- High Carbon Grades For Wire Rod Lines The Core of Danieli TechnologyDocument31 pagesHigh Carbon Grades For Wire Rod Lines The Core of Danieli TechnologyLeksono FirmansyahNo ratings yet

- 01 - Overview of Advanced CeramicsDocument19 pages01 - Overview of Advanced CeramicsMd. Rafiqul IslamNo ratings yet

- Analysis of The Interfacial Reaction Between Bulk Metallic GlassDocument8 pagesAnalysis of The Interfacial Reaction Between Bulk Metallic GlassyayangNo ratings yet

- MMP2003 1Document22 pagesMMP2003 1efc69jnNo ratings yet

- Synthesis and Study The Structure, Morphological and Optical Properties Fortio2-Al2O3-La2O3 Prepared by Chemical Bath DepositionDocument7 pagesSynthesis and Study The Structure, Morphological and Optical Properties Fortio2-Al2O3-La2O3 Prepared by Chemical Bath DepositionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- RMK Group A4 PPT MT-I (UNIT-II)Document50 pagesRMK Group A4 PPT MT-I (UNIT-II)RajmchzNo ratings yet

- Iwcc Cu-Vortrag AldDocument16 pagesIwcc Cu-Vortrag Aldhadjlarbi-h100% (1)

- Ceramics International: SciencedirectDocument7 pagesCeramics International: SciencedirectBabcsánné Kiss JuditNo ratings yet

- Aluminum Nitride Ceramic Chip: Team - Alternate FictionDocument11 pagesAluminum Nitride Ceramic Chip: Team - Alternate FictionAtul KapleNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- MMAW - Smaw FillersDocument5 pagesMMAW - Smaw FillersrkqaqcweldingNo ratings yet

- Advanced Packaging Materials For Power SemiconductorsDocument15 pagesAdvanced Packaging Materials For Power SemiconductorsBokyNo ratings yet

- Copper (Cu) Nanoparticles Properties ApplicationsDocument2 pagesCopper (Cu) Nanoparticles Properties ApplicationswprongmaneeNo ratings yet

- Savio 2013Document13 pagesSavio 2013ARSALAN AHMADNo ratings yet

- Rautomead CC PDFDocument13 pagesRautomead CC PDFDayanand SharmaNo ratings yet

- Aws WJ 201502Document141 pagesAws WJ 201502Remmy Torres VegaNo ratings yet

- 2013 CCD Material ChartsDocument18 pages2013 CCD Material ChartsRegi Octa PerdanaNo ratings yet

- Ceramic XrayDocument9 pagesCeramic XrayFandi MarcelloNo ratings yet

- Effect of The Molybdenum On The Microstructural and Mechanical Properties of Hadfield Austenitic Manganese SteelDocument8 pagesEffect of The Molybdenum On The Microstructural and Mechanical Properties of Hadfield Austenitic Manganese SteelharikaNo ratings yet

- Comparison of Electrical Properties of NiCr Thin Film Deposited On Different SubstratesDocument9 pagesComparison of Electrical Properties of NiCr Thin Film Deposited On Different SubstratesQilin XiaNo ratings yet

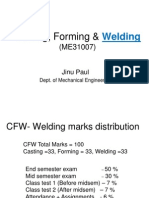

- Casting, Forming & WeldingDocument90 pagesCasting, Forming & WeldingmahdiNo ratings yet

- 19 Ijmperdapr201719Document10 pages19 Ijmperdapr201719TJPRC PublicationsNo ratings yet

- Corrosion Evaluation of Eutectic Chloride Molten Salt For N - 2020 - Journal ofDocument8 pagesCorrosion Evaluation of Eutectic Chloride Molten Salt For N - 2020 - Journal ofAmer AlmansoryNo ratings yet

- Myung Heat TreatmentDocument9 pagesMyung Heat TreatmentBabcsánné Kiss JuditNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Generator Maintenance - Common Generator Problems and How To Prevent ThemDocument3 pagesGenerator Maintenance - Common Generator Problems and How To Prevent ThemAditya Shiva AppallaNo ratings yet

- Kitz DJ E-234-03 PDFDocument16 pagesKitz DJ E-234-03 PDFYudi KurniawanNo ratings yet

- 59th Payment Blook ADocument74 pages59th Payment Blook AAbdulselam MaruNo ratings yet

- Reluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDocument2 pagesReluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDina GaranNo ratings yet

- Catalogues .EBERSPÄCHERDocument19 pagesCatalogues .EBERSPÄCHERyenNo ratings yet

- y Ry D566 y 5 L DV Ya UUDocument4 pagesy Ry D566 y 5 L DV Ya UUSACHNo ratings yet

- Digital Switching enDocument24 pagesDigital Switching enEdi LeeNo ratings yet

- Lamaran Bahasa InggrisDocument67 pagesLamaran Bahasa InggrisTafta Na E'iNo ratings yet

- RTI Brochure ProRox GRP 1000 - Int ENG (19-02-2016) PDFDocument8 pagesRTI Brochure ProRox GRP 1000 - Int ENG (19-02-2016) PDFTheophilus ThistlerNo ratings yet

- Thermodyamics R07Document9 pagesThermodyamics R07hhjjNo ratings yet

- Pulsar TesterDocument2 pagesPulsar TesterrantaroNo ratings yet

- Research and Application of Ajax TechnologyDocument18 pagesResearch and Application of Ajax TechnologySachin Ganesh ShettigarNo ratings yet

- Worksheet On StoichiometryDocument4 pagesWorksheet On Stoichiometrynics comiaNo ratings yet

- Mantle Convection Currents LabDocument3 pagesMantle Convection Currents Labapi-203269052No ratings yet

- Die Cast Chill VentsDocument6 pagesDie Cast Chill VentsSunil SharmaNo ratings yet

- PET cb-602Document1 pagePET cb-602hervian100% (1)

- Sika PDS E Intraplast ZDocument2 pagesSika PDS E Intraplast Zlwin_oo2435100% (1)

- Model1 EDDocument2 pagesModel1 EDskrtamilNo ratings yet

- Diddi Automation DiagramDocument87 pagesDiddi Automation DiagramRK PanchalNo ratings yet

- Design 1-Way One End Continuous SlabDocument9 pagesDesign 1-Way One End Continuous SlabRbcabajes ButalonNo ratings yet

- ACCC Midal Data (European Sizes)Document23 pagesACCC Midal Data (European Sizes)Kapil MishraNo ratings yet

- I Semester 15ae01 Computational Mathematics 2 2 0 3Document22 pagesI Semester 15ae01 Computational Mathematics 2 2 0 3sagarNo ratings yet

- SOP Tracked ExcavatorDocument2 pagesSOP Tracked ExcavatordaneyenzNo ratings yet

- Img 20190925 0001 PDFDocument4 pagesImg 20190925 0001 PDFChristina PerezNo ratings yet

- ASTM D 149 Standard Test Method Dielectric Breakdown VoltageDocument1 pageASTM D 149 Standard Test Method Dielectric Breakdown VoltageLaurence MalanumNo ratings yet

- Common Emitter Transistor CharacteristicsDocument6 pagesCommon Emitter Transistor CharacteristicsShiv Mangal Singh Rajawat67% (3)

- Ecology in ArchitectureDocument276 pagesEcology in ArchitectureNurholis Setiawan100% (1)

Controlled Expansion Alloys

Controlled Expansion Alloys

Uploaded by

leaksolve0 ratings0% found this document useful (0 votes)

58 views2 pagesOriginal Title

01

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

58 views2 pagesControlled Expansion Alloys

Controlled Expansion Alloys

Uploaded by

leaksolveCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Controlled Expansion Alloys Controlled Expansion Alloys

Alloy 36 (Invar®) / K93603 Alloy 42 / K94100

www.columbiametals.com

Alloy 52 (Nilo®) / N14052 Alloy K (Kovar®) / K94610

sales@columbiametals.co.uk

Controlled thermal expansion alloys are iron-nickel alloys that

exhibit an extremely low expansion rate at room temperature.

These materials are utilised in modern applications that

require metal to be joined to glass or ceramic, and areas

where the thermal expansion rates of the materials must

coincide to prevent differential expansion within the joint area.

They are used in industries such as electronics, medical

(laser and x-ray machines), aerospace engineering,

telecommunications and cryogenic components.

Iron and nickel have very similar coefficients of thermal

expansion. The addition of nickel to iron can result in the

creation of an alloy in which the coefficient is reduced by an

order of magnitude. Research in the 1920s found that an iron-

nickel alloy containing around 36% nickel exhibited virtually no thermal expansion at, or close to, room

temperature. This type of material became noted for its invariability or lack of expansion and contraction with

temperature changes. By modifying the composition of this 36% nickel alloy, metallurgists have created a

number of special materials with unique expansion characteristics to suit particular applications.

Alloy 36 (Invar®) / K93603 / ASTM F1684

Widely known under several trades names such as Invar®* and Nilo 36**, this grade is a 36% nickel-iron

alloy. It exhibits a near zero rate of thermal expansion from around –100oC up to 200oC. This is around a

tenth of the expansion rate of carbon steels. Alloy 36 also demonstrates a high retention of strength and

toughness at cryogenic temperatures, making it suitable for a variety of low temperature or low expansion

applications. The alloy is ideally suited to areas where dimensional changes due to temperature must be

minimal, such as tooling for aerospace composites, radio and electronic devices and structural members in

precision equipment such as lasers, measuring devices, thermostats and cryogenic instrumentation. Alloy 36

can also be utilised in combination with a high expansion material to crate mechanical movement with

temperature in thermomechanical controls and switchgear.

Alloy 42 / K94100 / ASTM F30

A binary nickel-iron containing around 41% nickel, this grade exhibits a low and normally consistent

coefficient of thermal expansion over the range 20-300oC. This enables its use in glass-to-metal or ceramic-

to-metal sealing applications and tooling for aerospace composites. Alloy 42 also has a coefficient of thermal

expansion matched to silicon, and ceramic materials such as alumina, beryllia and vitreous glass

compounds. It can be found as a sealing material in semiconductor packages, electronic tubes, CRT

electron guns, microelectronic components, thermostat rods, vacuum devices and electric industrial lamps.

Alloy 52 / N14052

Alloy 52 contains 52% nickel and 48% iron and is widely used in the telecommunications industry. It also

finds application in a wide variety of electronic applications, especially for glass seals.

Alloy K / K94610 / ASTM F15

Also known as Kovar®*** and Nilo K**, this alloy contains 29% nickel with a 17% cobalt addition. Its

composition is tightly controlled within narrow limits to ensure precise and universal thermal expansion and

mechanical characteristics. This helps the material provide high integrity glass-to-metal and ceramic-to-metal

seals in applications requiring reliability and resistance to thermal shock. Alloy K is often used for the

manufacture of hermetic seals with both the harder Pyrex or borosilicate glasses and alumina-type ceramic

materials. It finds extensive application in the production of transistors and diodes for lids and closures in a

variety of hybrid electronic circuit packages and also in the manufacture of microwave tubes.

PLEASE CONTACT US FOR AN IMMEDIATE QUOTATION OR TECHNICAL ADVICE

North, Scotland & International South, Midlands & Wales

Tel: 01422 343026 Tel: 01234 608888

Fax: 01422 346587 Fax: 01234 608800

halifaxsales@columbiametals.co.uk sales@columbiametals.co.uk

export@columbiametals.co.uk

Controlled Expansion Alloys Controlled Expansion Alloys

Technical Data

Coefficient of Thermal Expansion

Alloy 36 Alloy 42 Alloy 52 Alloy K

30-150°C (μm/m°C) 1.2 - 2.7

30-300°C (μm/m°C) 4.0 - 4.7

30-400°C (μm/m°C) 4.6 - 5.2

30-450°C (μm/m°C) 6.7 - 7.4 9.7 - 10.2 5.1 - 5.5

30-550°C (μm/m°C) 10.0 - 10.5

Typical Physical Properties

Alloy 36 Alloy 42 Alloy 52 Alloy K

Density (g/cm3) 8.13 8.15 8.30 8.25

Melting Point (°C) 1450 1425 1425 1450

Curie Point (°C) 230 330 510 425

Thermal conductivity (W/m°C) 10.5 12.5 13.4 17.0

Specific Heat (J/g°C) 0.51 0.50 0.50 0.50

Young’s Modulus (MPA) 140,000 145,000 165,000 139,000

Round Bar Weight and Stock Sizes

Diameter Weight Diameter Weight Diameter Weight

mm kg/ft kg/m mm kg/ft kg/m mm kg/ft kg/m

3 0.02 0.06 16 0.50 1.64 50 4.88 16.00

6 0.07 0.23 20 0.78 2.56 60 7.02 23.04

8 0.13 0.41 25 1.22 4.00 70 9.56 31.37

9.5 0.18 0.58 30 1.76 5.76 75 10.98 36.01

10 0.20 0.64 35 2.39 7.84 80 12.49 40.97

12 0.28 0.92 40 3.12 10.24 90 15.80 51.85

12.7 0.32 1.03 45 3.95 12.96 100 19.51 64.01

NB Weight data for guidance only

*Invar® is a registered trademark of Arcelor Mittal

** The Nilo® alloy family is a registered trademark of Special Metals Ltd

***Kovar® is a registered trademark of Carpenter Technology Corporation

REV3/04/18

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Lab 12Document4 pagesLab 12over allNo ratings yet

- Bamboo PilesDocument6 pagesBamboo PilesKenny YeeNo ratings yet

- Invar Nickel Iron AlloyDocument3 pagesInvar Nickel Iron AlloyAbul Kashem Sfq UllahNo ratings yet

- Nickel Alloys in Today'S Electronics Industry: C.R. Isleib N 10029Document10 pagesNickel Alloys in Today'S Electronics Industry: C.R. Isleib N 10029dpkeskesiadisNo ratings yet

- Giunzione e ManutenzioneDocument29 pagesGiunzione e Manutenzionerenhat parulian sitorusNo ratings yet

- Key Aluminum Nitride PropertiesDocument10 pagesKey Aluminum Nitride PropertiesMuhammad TanweerNo ratings yet

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Mechanical and Thermal Behaviour of Cordierite-Zirconia CompositesDocument13 pagesMechanical and Thermal Behaviour of Cordierite-Zirconia CompositesĐức MạnhNo ratings yet

- Ceramics IntroductionDocument35 pagesCeramics IntroductionSaptarshi SenguptaNo ratings yet

- Electronic Ceramics and CermetsDocument32 pagesElectronic Ceramics and Cermetsmarvel794No ratings yet

- Application of Refractory Metals and AlloysDocument36 pagesApplication of Refractory Metals and Alloysbugoff700No ratings yet

- AKANDE Heritage ProjectDocument28 pagesAKANDE Heritage ProjectAkande HeritageNo ratings yet

- Kojundi Krni SamardiDocument20 pagesKojundi Krni SamardiMehul VoraNo ratings yet

- Manpreet Et Al 2010Document12 pagesManpreet Et Al 2010manpreetNo ratings yet

- Simko SiCcorrosionDocument10 pagesSimko SiCcorrosionJarmilaMlynárikováNo ratings yet

- Arcos 625Document1 pageArcos 625bowotriantoNo ratings yet

- EM MOULDS English CatalogueDocument15 pagesEM MOULDS English CataloguekovvadkrishnaNo ratings yet

- Audio CH 552 Lesson 2 Eng. Ceram 2021Document101 pagesAudio CH 552 Lesson 2 Eng. Ceram 2021Vihanga SenanayakeNo ratings yet

- MEMS Material N Their PropertiesDocument20 pagesMEMS Material N Their PropertiesasdftyNo ratings yet

- The Study of Corrosion and Wear Resistance of CoppDocument9 pagesThe Study of Corrosion and Wear Resistance of CoppNoura Nour ElshamsNo ratings yet

- Goodfellow Looking 1112Document3 pagesGoodfellow Looking 1112arundixituNo ratings yet

- Zinc DIE CASTINGDocument10 pagesZinc DIE CASTINGFrancisco BocanegraNo ratings yet

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- Corrosion Behaviour of Ni and Nickel Aluminide Coatings Exposed in A Biomass Fired Power Plant For Two YearsDocument11 pagesCorrosion Behaviour of Ni and Nickel Aluminide Coatings Exposed in A Biomass Fired Power Plant For Two YearsmanishtubNo ratings yet

- Ijrdet 0715 03Document14 pagesIjrdet 0715 03Chrill DsilvaNo ratings yet

- IM - Proyecto Final InglesDocument33 pagesIM - Proyecto Final InglesLexi Noel Gutiérrez MéndezNo ratings yet

- Corrosion Analysis of Copper Tio2nanocomposite Coatings On Steel Usingsputtering PDFDocument6 pagesCorrosion Analysis of Copper Tio2nanocomposite Coatings On Steel Usingsputtering PDFmohamed aliNo ratings yet

- Fundamentals of Ceramics Chapter 1Document38 pagesFundamentals of Ceramics Chapter 1Tamiru MisikirNo ratings yet

- Ductile Cast Iron With High Toughness at Low TemperaturesDocument8 pagesDuctile Cast Iron With High Toughness at Low Temperatures조용재 (용자씨)No ratings yet

- DownloadfileDocument9 pagesDownloadfilefredymademydayNo ratings yet

- Natarajan2006 PDFDocument5 pagesNatarajan2006 PDFBasim Al-bhadleNo ratings yet

- 01 - Overview of Advanced CeramicsDocument18 pages01 - Overview of Advanced CeramicsJanibul Haque PritomNo ratings yet

- Electrochemical Corrosion of Silicon Carbide Ceramics in H SODocument7 pagesElectrochemical Corrosion of Silicon Carbide Ceramics in H SOGizem D.No ratings yet

- High Carbon Grades For Wire Rod Lines The Core of Danieli TechnologyDocument31 pagesHigh Carbon Grades For Wire Rod Lines The Core of Danieli TechnologyLeksono FirmansyahNo ratings yet

- 01 - Overview of Advanced CeramicsDocument19 pages01 - Overview of Advanced CeramicsMd. Rafiqul IslamNo ratings yet

- Analysis of The Interfacial Reaction Between Bulk Metallic GlassDocument8 pagesAnalysis of The Interfacial Reaction Between Bulk Metallic GlassyayangNo ratings yet

- MMP2003 1Document22 pagesMMP2003 1efc69jnNo ratings yet

- Synthesis and Study The Structure, Morphological and Optical Properties Fortio2-Al2O3-La2O3 Prepared by Chemical Bath DepositionDocument7 pagesSynthesis and Study The Structure, Morphological and Optical Properties Fortio2-Al2O3-La2O3 Prepared by Chemical Bath DepositionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- RMK Group A4 PPT MT-I (UNIT-II)Document50 pagesRMK Group A4 PPT MT-I (UNIT-II)RajmchzNo ratings yet

- Iwcc Cu-Vortrag AldDocument16 pagesIwcc Cu-Vortrag Aldhadjlarbi-h100% (1)

- Ceramics International: SciencedirectDocument7 pagesCeramics International: SciencedirectBabcsánné Kiss JuditNo ratings yet

- Aluminum Nitride Ceramic Chip: Team - Alternate FictionDocument11 pagesAluminum Nitride Ceramic Chip: Team - Alternate FictionAtul KapleNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- MMAW - Smaw FillersDocument5 pagesMMAW - Smaw FillersrkqaqcweldingNo ratings yet

- Advanced Packaging Materials For Power SemiconductorsDocument15 pagesAdvanced Packaging Materials For Power SemiconductorsBokyNo ratings yet

- Copper (Cu) Nanoparticles Properties ApplicationsDocument2 pagesCopper (Cu) Nanoparticles Properties ApplicationswprongmaneeNo ratings yet

- Savio 2013Document13 pagesSavio 2013ARSALAN AHMADNo ratings yet

- Rautomead CC PDFDocument13 pagesRautomead CC PDFDayanand SharmaNo ratings yet

- Aws WJ 201502Document141 pagesAws WJ 201502Remmy Torres VegaNo ratings yet

- 2013 CCD Material ChartsDocument18 pages2013 CCD Material ChartsRegi Octa PerdanaNo ratings yet

- Ceramic XrayDocument9 pagesCeramic XrayFandi MarcelloNo ratings yet

- Effect of The Molybdenum On The Microstructural and Mechanical Properties of Hadfield Austenitic Manganese SteelDocument8 pagesEffect of The Molybdenum On The Microstructural and Mechanical Properties of Hadfield Austenitic Manganese SteelharikaNo ratings yet

- Comparison of Electrical Properties of NiCr Thin Film Deposited On Different SubstratesDocument9 pagesComparison of Electrical Properties of NiCr Thin Film Deposited On Different SubstratesQilin XiaNo ratings yet

- Casting, Forming & WeldingDocument90 pagesCasting, Forming & WeldingmahdiNo ratings yet

- 19 Ijmperdapr201719Document10 pages19 Ijmperdapr201719TJPRC PublicationsNo ratings yet

- Corrosion Evaluation of Eutectic Chloride Molten Salt For N - 2020 - Journal ofDocument8 pagesCorrosion Evaluation of Eutectic Chloride Molten Salt For N - 2020 - Journal ofAmer AlmansoryNo ratings yet

- Myung Heat TreatmentDocument9 pagesMyung Heat TreatmentBabcsánné Kiss JuditNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Generator Maintenance - Common Generator Problems and How To Prevent ThemDocument3 pagesGenerator Maintenance - Common Generator Problems and How To Prevent ThemAditya Shiva AppallaNo ratings yet

- Kitz DJ E-234-03 PDFDocument16 pagesKitz DJ E-234-03 PDFYudi KurniawanNo ratings yet

- 59th Payment Blook ADocument74 pages59th Payment Blook AAbdulselam MaruNo ratings yet

- Reluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDocument2 pagesReluctance Motor: Ii) A Squirrel Cage Rotor Having Un Symmctrical Magnetic Construction This Is AchievedDina GaranNo ratings yet

- Catalogues .EBERSPÄCHERDocument19 pagesCatalogues .EBERSPÄCHERyenNo ratings yet

- y Ry D566 y 5 L DV Ya UUDocument4 pagesy Ry D566 y 5 L DV Ya UUSACHNo ratings yet

- Digital Switching enDocument24 pagesDigital Switching enEdi LeeNo ratings yet

- Lamaran Bahasa InggrisDocument67 pagesLamaran Bahasa InggrisTafta Na E'iNo ratings yet

- RTI Brochure ProRox GRP 1000 - Int ENG (19-02-2016) PDFDocument8 pagesRTI Brochure ProRox GRP 1000 - Int ENG (19-02-2016) PDFTheophilus ThistlerNo ratings yet

- Thermodyamics R07Document9 pagesThermodyamics R07hhjjNo ratings yet

- Pulsar TesterDocument2 pagesPulsar TesterrantaroNo ratings yet

- Research and Application of Ajax TechnologyDocument18 pagesResearch and Application of Ajax TechnologySachin Ganesh ShettigarNo ratings yet

- Worksheet On StoichiometryDocument4 pagesWorksheet On Stoichiometrynics comiaNo ratings yet

- Mantle Convection Currents LabDocument3 pagesMantle Convection Currents Labapi-203269052No ratings yet

- Die Cast Chill VentsDocument6 pagesDie Cast Chill VentsSunil SharmaNo ratings yet

- PET cb-602Document1 pagePET cb-602hervian100% (1)

- Sika PDS E Intraplast ZDocument2 pagesSika PDS E Intraplast Zlwin_oo2435100% (1)

- Model1 EDDocument2 pagesModel1 EDskrtamilNo ratings yet

- Diddi Automation DiagramDocument87 pagesDiddi Automation DiagramRK PanchalNo ratings yet

- Design 1-Way One End Continuous SlabDocument9 pagesDesign 1-Way One End Continuous SlabRbcabajes ButalonNo ratings yet

- ACCC Midal Data (European Sizes)Document23 pagesACCC Midal Data (European Sizes)Kapil MishraNo ratings yet

- I Semester 15ae01 Computational Mathematics 2 2 0 3Document22 pagesI Semester 15ae01 Computational Mathematics 2 2 0 3sagarNo ratings yet

- SOP Tracked ExcavatorDocument2 pagesSOP Tracked ExcavatordaneyenzNo ratings yet

- Img 20190925 0001 PDFDocument4 pagesImg 20190925 0001 PDFChristina PerezNo ratings yet

- ASTM D 149 Standard Test Method Dielectric Breakdown VoltageDocument1 pageASTM D 149 Standard Test Method Dielectric Breakdown VoltageLaurence MalanumNo ratings yet

- Common Emitter Transistor CharacteristicsDocument6 pagesCommon Emitter Transistor CharacteristicsShiv Mangal Singh Rajawat67% (3)

- Ecology in ArchitectureDocument276 pagesEcology in ArchitectureNurholis Setiawan100% (1)