Professional Documents

Culture Documents

Data Analysis Sample Problem

Data Analysis Sample Problem

Uploaded by

510617055 MayankkumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Analysis Sample Problem

Data Analysis Sample Problem

Uploaded by

510617055 MayankkumarCopyright:

Available Formats

Data Analysis

As the operations have 3 types of tools used for the process and hence they need to be analysed for

optimal usage. Moreover to figure out which process to prefer based on the number of orders.

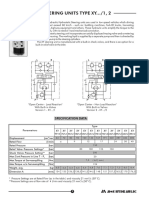

1. Selection of Manual Drill and CNC Drill:

To find the break even point of orders, selecting the most feasible drill for minimum utilization of

time

As per exhibit 2 from the case, we get that run is 0.08 and setup time is 15min for manual drill. As the

circuit contains 500 holes hence the total time is = setup time+ no of boards * Run time*no of

holes

Let the number of boards be x

= 15 + 500*0.08*x

=15 + 40x

Similarly for the CNC drill we get run =0.004 and setup time = 240 min

Total time is = setup time+ no of boards * Run time*no of holes

= 240 + 500*0.004*x

= 240 + 2x

Equating the above equations we get

15 + 40x = 240 + 2x

x = 5.92 = 6

Hence, if the number of boards is less than 6 we will use manual drill and if the number of

boards is more than 6 we will use CNC drill.

2. Selection of Punch Press and CNC Router

To find the break even point of orders

Time taken for punch press operation = 50 + z

Time taken for CNC router = 150 + 0.5z

For calculating the number of orders, equating the equations

50 + z = 150 + 0.5z

z = 200

Hence, accordingly, if the number of orders for the circuit board is ≤ 200, then use punch

press and if the number of orders for the circuit board is > 200 then use CNC Router.

(From the case exhibit)

Operation Setup Run Holes in board Run per board Order Total

Image Transfer

Drill

Manual Drill 15 0.08 500 40 x 15 + 40x

CNC Drill 240 0.004 500 2 x 240 + 2x

Fabrication

Profile

Punch Press 50 1 1 z 50 + z

150 +

CNC Router 150 0.5 0.5 z 0.5z

You might also like

- Lathe and VMC Cycle Time CalculatorDocument5 pagesLathe and VMC Cycle Time CalculatorDhanus KodiNo ratings yet

- Impeders, Carbides - Scarfing TipsDocument1 pageImpeders, Carbides - Scarfing TipsAbdurahmanNo ratings yet

- Donner CompanyDocument2 pagesDonner CompanyIslam IssaNo ratings yet

- Me PADSDocument2 pagesMe PADSJoshua Ndalo100% (1)

- NO NO Extruder 1 480 480 480 480 3 240+1 120 NO NODocument10 pagesNO NO Extruder 1 480 480 480 480 3 240+1 120 NO NOanthony saadNo ratings yet

- Flow DiagramDocument6 pagesFlow DiagramSergio Rivera StapperNo ratings yet

- Flow Diagram CalculationsDocument1 pageFlow Diagram CalculationsSergio Rivera StapperNo ratings yet

- Tops & Dress Division: "A Person Who Never Made A Mistake Never Tried Anything New."Document13 pagesTops & Dress Division: "A Person Who Never Made A Mistake Never Tried Anything New."Megha SharmaNo ratings yet

- Donner Case Operations ManagementDocument3 pagesDonner Case Operations Managementleeladon0% (1)

- Session 6: Measuring Capacity in Customized and Variety Driven ProcessesDocument30 pagesSession 6: Measuring Capacity in Customized and Variety Driven ProcessesAniket BorseNo ratings yet

- Powerbox SettingsDocument1 pagePowerbox Settingsيماني شامخNo ratings yet

- Product Catalog: Waso WasoDocument169 pagesProduct Catalog: Waso WasoNay Lin နေလင်းNo ratings yet

- Water Jet PortfoliaDocument7 pagesWater Jet PortfoliaSagar KumarNo ratings yet

- Company Profile PT Buana Merdeka JayaDocument22 pagesCompany Profile PT Buana Merdeka JayaLanCez100% (1)

- With - Load - New Equipment Data (Main File)Document8 pagesWith - Load - New Equipment Data (Main File)Munir RasheedNo ratings yet

- A9 GroupAssignment Draft OMDocument7 pagesA9 GroupAssignment Draft OMsomechnitjNo ratings yet

- Plazma Power Source Tech - Specs Sheet-V2Document1 pagePlazma Power Source Tech - Specs Sheet-V2aniketgunjalNo ratings yet

- PFA Fittings: Tube Bonding FittingDocument4 pagesPFA Fittings: Tube Bonding FittingnithinNo ratings yet

- 2023_PWS_PacketDocument9 pages2023_PWS_PacketHilal AchrafNo ratings yet

- Centauro S.P.A: Wood Working MachineryDocument2 pagesCentauro S.P.A: Wood Working MachineryMaged MagdyNo ratings yet

- Accusharp-Knife-Sharpener Related Us 2023-12-27Document3 pagesAccusharp-Knife-Sharpener Related Us 2023-12-27Raheel AbbasiNo ratings yet

- Paperless Recorder TrainingDocument9 pagesPaperless Recorder TrainingRexCrazyMindNo ratings yet

- Hoshi Company ProfileDocument35 pagesHoshi Company Profilepashamr1No ratings yet

- Profile NV Precision NewDocument26 pagesProfile NV Precision Newkiet trannguyenNo ratings yet

- B2 V3.TPDDocument11 pagesB2 V3.TPDMacp63 cpNo ratings yet

- Ukupno Vrijeme U Sekundama Ukupno Vrijeme U Sekundama 294 Zbog Nabavke CNC Skipper-A Mašine Koje Su Radile Otvore Su Zamijenjene Za Tu MašinuDocument6 pagesUkupno Vrijeme U Sekundama Ukupno Vrijeme U Sekundama 294 Zbog Nabavke CNC Skipper-A Mašine Koje Su Radile Otvore Su Zamijenjene Za Tu MašinuAdmir HericNo ratings yet

- Quotation Scheme Jstomi: Equiptech (PVT.) LTDDocument4 pagesQuotation Scheme Jstomi: Equiptech (PVT.) LTDvasiliy vasilievichNo ratings yet

- 15-2-2024 - CC-01 NGDocument1 page15-2-2024 - CC-01 NGrama.chandranNo ratings yet

- 01 P40s Alfons Haar Complete ManualDocument377 pages01 P40s Alfons Haar Complete ManualCristian RomeroNo ratings yet

- Bsil PebDocument75 pagesBsil PebSukrito Kumar MittraNo ratings yet

- Lathe and VMC Cycle Time CalculatorDocument3 pagesLathe and VMC Cycle Time Calculatorchandra shekarNo ratings yet

- BM18 Tekni̇k DökümanDocument4 pagesBM18 Tekni̇k DökümanahmetNo ratings yet

- Siddh UpdatedDocument33 pagesSiddh UpdatedVikrantNo ratings yet

- KeywordIO PricetonDocument8 pagesKeywordIO PricetonakshaytftNo ratings yet

- Zhafir Plastics MachineryDocument22 pagesZhafir Plastics MachineryERDALNo ratings yet

- New Microsoft Excel WorksheetDocument5 pagesNew Microsoft Excel WorksheetMalikFarooq AslamNo ratings yet

- Process Cost 2012Document9 pagesProcess Cost 2012phutthawongdanchai041215No ratings yet

- Catalog XY.. HKU.. HKUQ.. HKUS..Document34 pagesCatalog XY.. HKU.. HKUQ.. HKUS..KADNo ratings yet

- Group 10 - ABC Case Study Corelio PrintingDocument10 pagesGroup 10 - ABC Case Study Corelio Printingmuhammad ifwatNo ratings yet

- ADDONDocument10 pagesADDONPrakash viswanathanNo ratings yet

- ARBURG ALLROUNDER 170S TD 525600 en GBDocument6 pagesARBURG ALLROUNDER 170S TD 525600 en GBIsmail ElisNo ratings yet

- Steel Base Plate DesignDocument5 pagesSteel Base Plate DesignMichael AbandeNo ratings yet

- Data Book SERIES 3D 60Hz Bombas CentrífugasDocument47 pagesData Book SERIES 3D 60Hz Bombas Centrífugasagromecanica2024No ratings yet

- Lathe Feed CalculationDocument4 pagesLathe Feed CalculationScribdTranslationsNo ratings yet

- Submersible Stainless Steel Rewindable Motor: Quality For Your BorewellDocument6 pagesSubmersible Stainless Steel Rewindable Motor: Quality For Your BorewellSherin PaulNo ratings yet

- Wirutex Tools For Biesse Edgebanding Machines AKRON 400 JADE 300Document12 pagesWirutex Tools For Biesse Edgebanding Machines AKRON 400 JADE 300aidma05No ratings yet

- Lab CAD CNCDocument2 pagesLab CAD CNCArun AntonyNo ratings yet

- Photo Continental PricelistDocument6 pagesPhoto Continental PricelistdenymdanNo ratings yet

- Accomplishment Breakdown 5200011752Document1 pageAccomplishment Breakdown 5200011752Jeneth GalisteNo ratings yet

- Base Plate Design by PROKON.: Input DataDocument4 pagesBase Plate Design by PROKON.: Input Datasam_antony2005No ratings yet

- Number One Machining Equipment ListDocument5 pagesNumber One Machining Equipment Listlocalintheknow100% (1)

- C35 Positive Displacement FlowMeterDocument4 pagesC35 Positive Displacement FlowMetersanjay6969100% (1)

- Downtime 2021Document83 pagesDowntime 2021Borno ShahinNo ratings yet

- Capxon (Radial) 2011 HY SeriesDocument2 pagesCapxon (Radial) 2011 HY Serieshes545No ratings yet

- RH120E - Boom and Stick InfoDocument30 pagesRH120E - Boom and Stick InfoConnor TabainNo ratings yet

- Global Pulley Specification - QFDocument1 pageGlobal Pulley Specification - QFrrobles011No ratings yet

- Paramount Pistons Production Monitoring Record: Machine EfficiencyDocument4 pagesParamount Pistons Production Monitoring Record: Machine EfficiencyMechtek LabNo ratings yet

- Bom AllDocument6 pagesBom AllSwapnil CallaNo ratings yet